Steel supporting plate cleaning machine for partition plate production

The technology of a partition board and a cleaning machine is applied in the direction of cleaning methods using tools, cleaning methods and utensils, chemical instruments and methods, etc., which can solve problems such as cleaning defects of formed steel pallets, and achieve the effect of improving cleaning quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

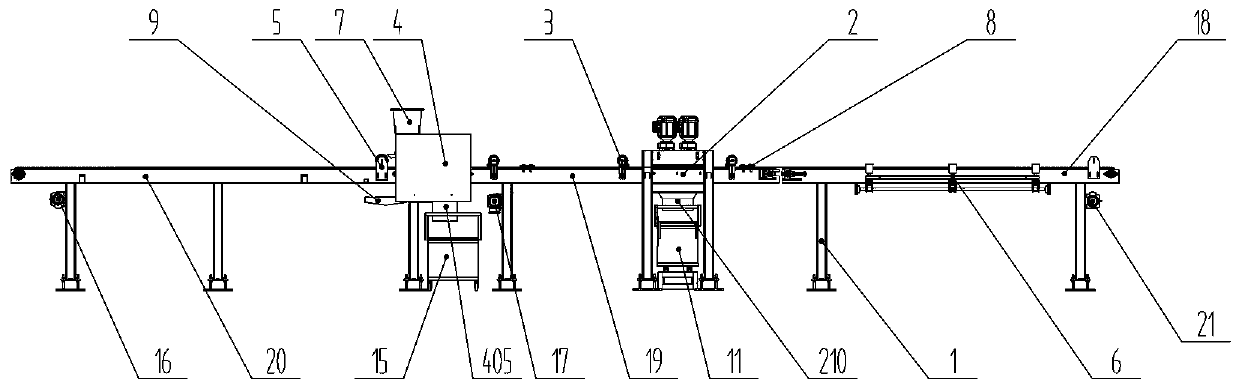

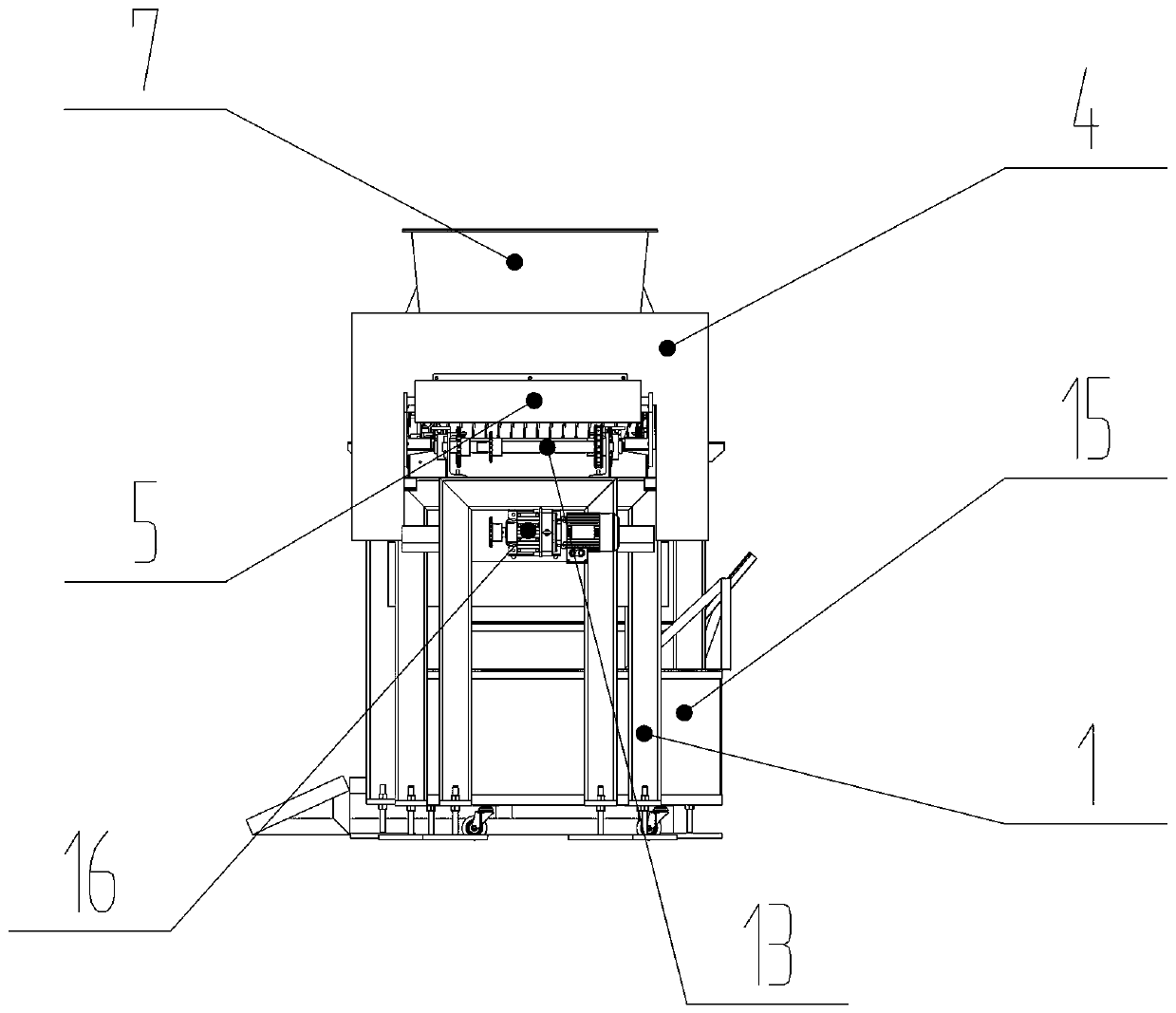

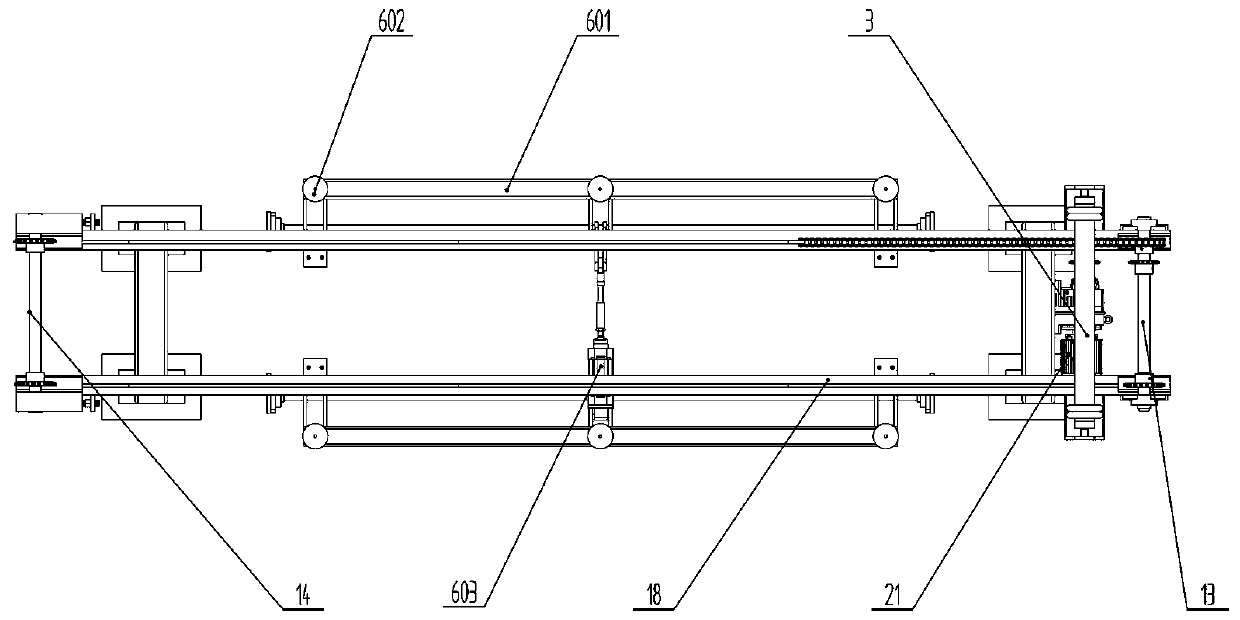

[0038] Such as Figure 1-12 As shown, a steel pallet cleaning machine for partition wall production includes a frame 1, a chain conveyor is installed on the frame 1 along the steel pallet conveying direction, and milling mills are arranged on the chain conveyor along the steel pallet conveying direction. Plate mechanism 2, cleaning mechanism; the chain conveyor adopts chain conveyor one 18, chain conveyor two 19, and chain conveyor three 20 connected by segmental assembly, and chain conveyor one 18, chain conveyor two 19, The conveying plane of the chain conveyor No.3 20 is at the same level to ensure the stability of the formed steel pallet during the conveying process. Both ends of the chain conveyor No.1 18, the chain conveyor No.2 19 and the chain conveyor No.3 20 are equipped with driving chains Wheel shaft 13 and driven sprocket shaft 14, the driving sprocket shaft 13 on the chain conveyor one is connected with chain drive motor one 21 by chain, and the driving sprocket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com