Runner system for production of ultrathin light guide plate

A technology of light guide plate and flow channel, applied in the field of flow channel system, can solve the problems of inability to guarantee the optical dot replication rate, low pressure of molten plastic fluid, unable to fill the cavity, etc., so as to improve the quality of ultra-thin plates, improve fluidity, The effect of reducing pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

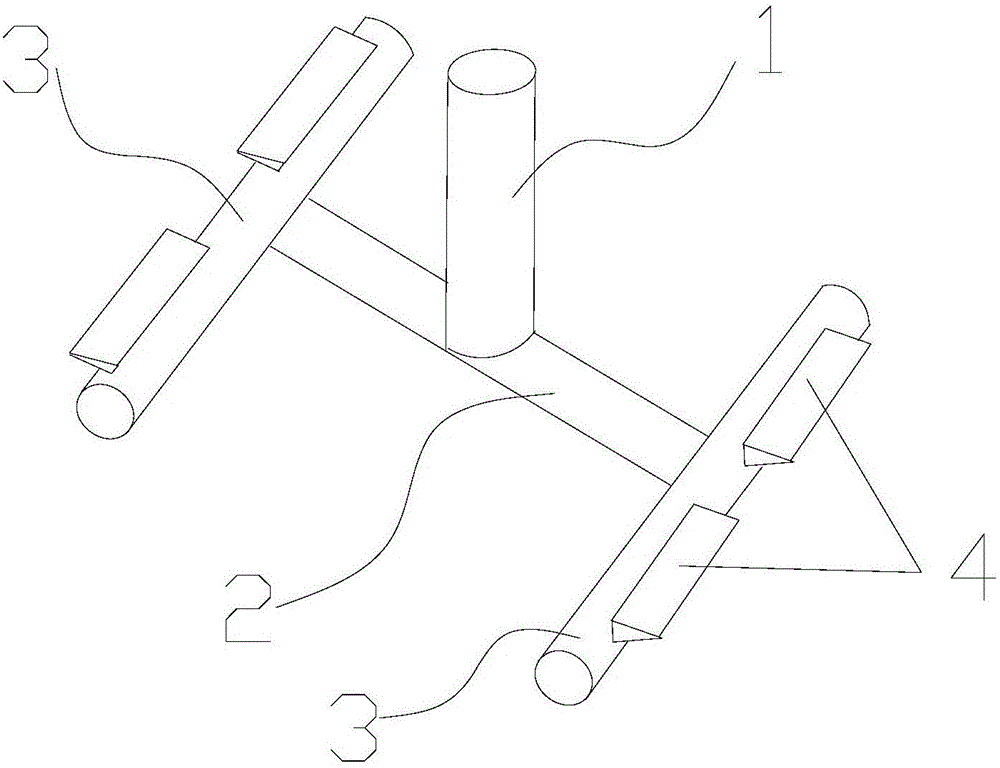

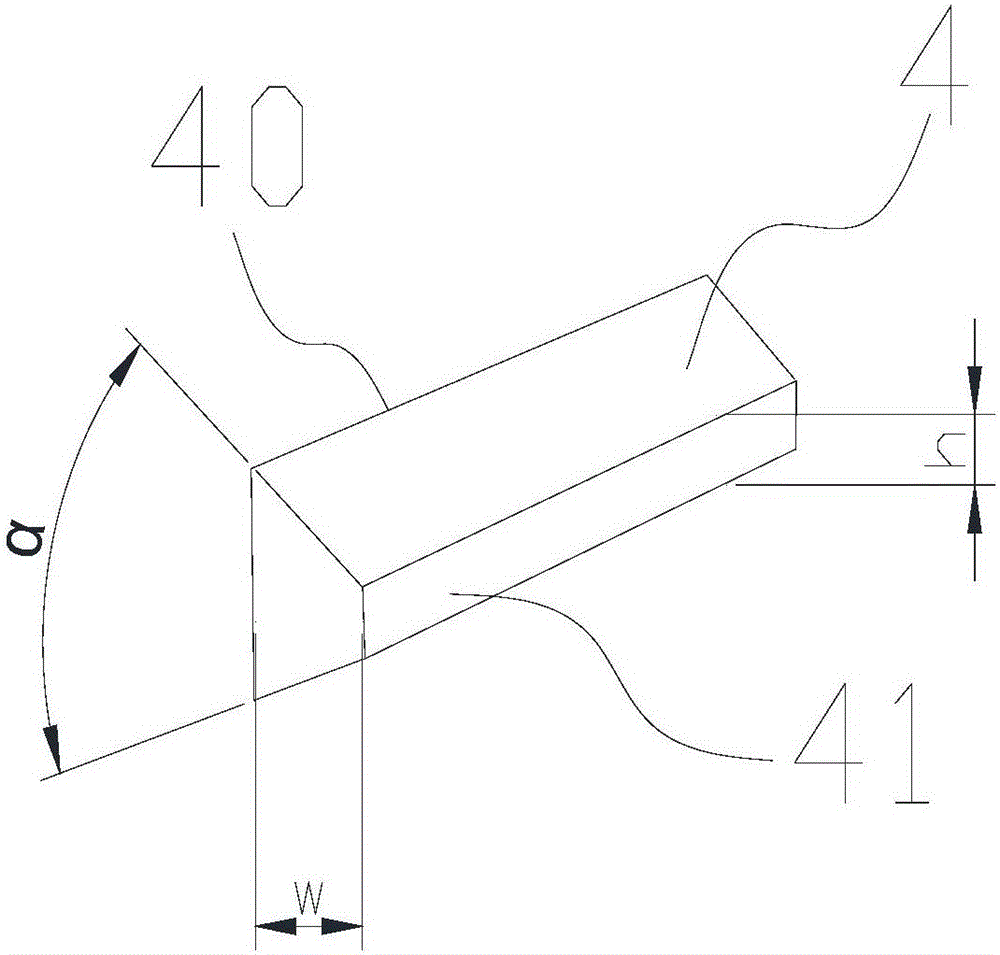

[0024] see figure 1 , a runner system for ultra-thin light guide plate production, the runner system includes a main channel 1, a runner and a gate, the main channel communicates with the runner, the runner communicates with the gate, and the gate The gate is a "wedge" gate 4, the "wedge" gate includes a feed end 40 and a discharge end 41, the height of the feed end is greater than the height of the discharge end, and the angle α of the "wedge" gate is 60°, the width w of the "wedge" gate is 0.15mm, and the height h of the discharge end of the "wedge" gate is 0.1mm;

[0025] The height of the glue outlet gap is equal to the height of the feed end of the "wedge" gate.

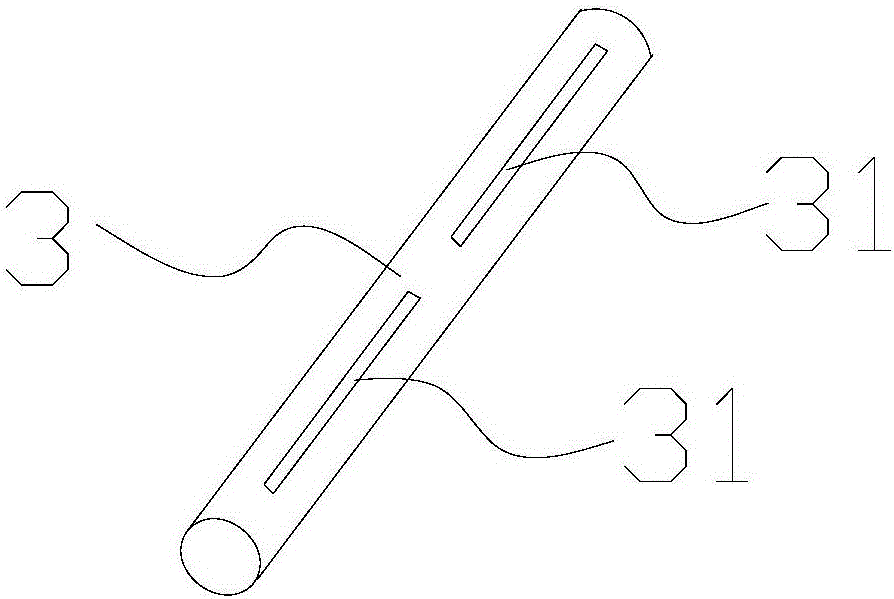

[0026] The runner is an "I"-shaped runner, and the "I"-shaped runner includes a first runner 2 in a vertical direction and two second runners 3 in a horizontal direction; the main channel It communicates with the middle part of the first flow channel, and the two ends of the first flow channel respectively com...

Embodiment 2

[0031] A flow channel system for the production of ultra-thin light guide plates, the two ends of the second flow channel and the positions between the two glue outlet gaps are provided with cold material areas, and the rest of the structure and parameters are the same as in Example 1.

Embodiment 3

[0033] A flow channel system for the production of ultra-thin light guide plates, the shape of the glue outlet gap is rectangular, and the rest of the structure and parameters are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com