Zinc-nickel alloy and preparation method thereof

A zinc-nickel alloy and nickel alloy technology, applied in the field of zinc-nickel alloy and its preparation, can solve the problems of general coating adhesion, insufficient nickel content in zinc-nickel alloy, reducing the production capacity of galvanizing plant, etc. The effect of forming quality, reducing production cost and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

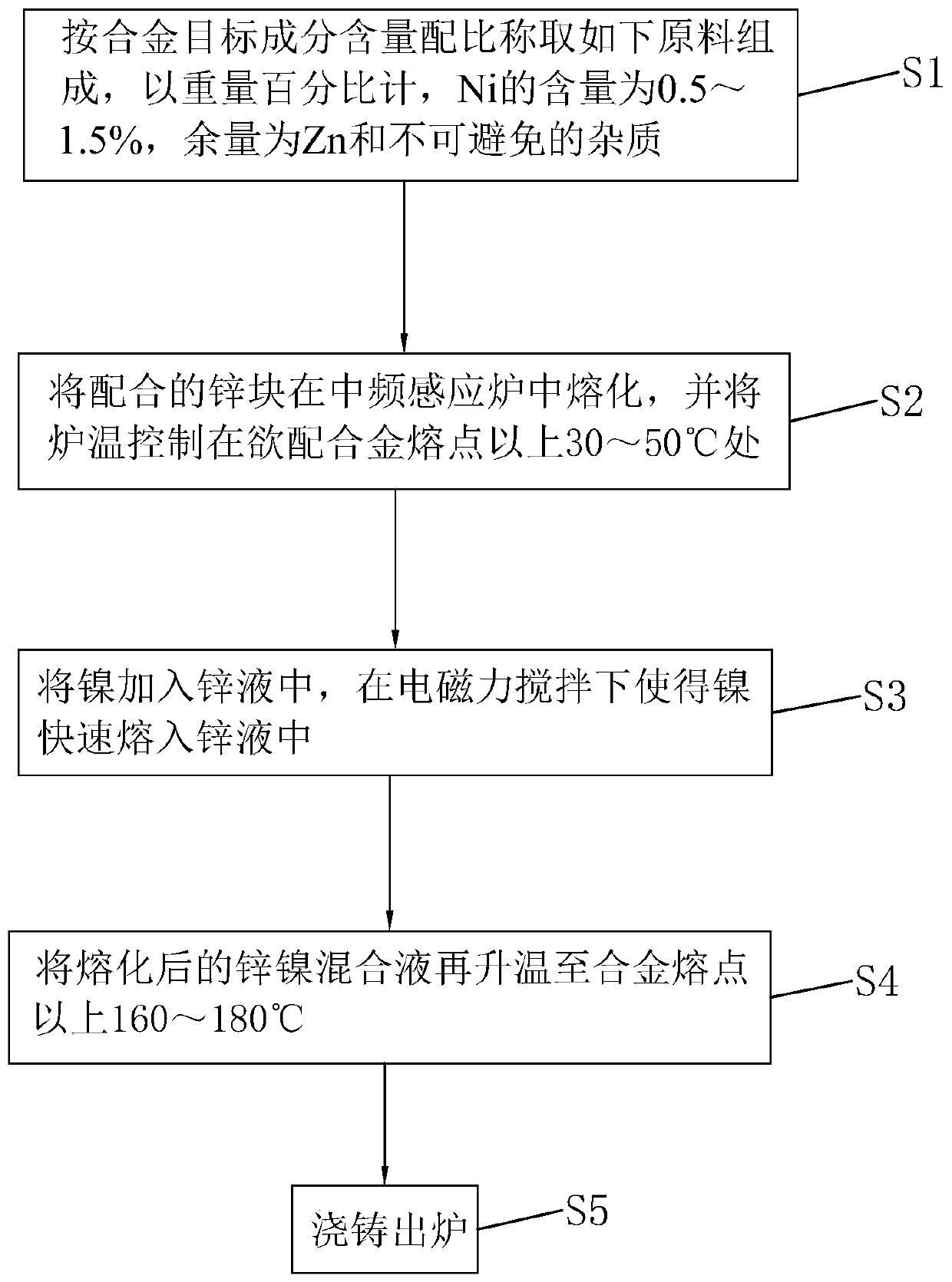

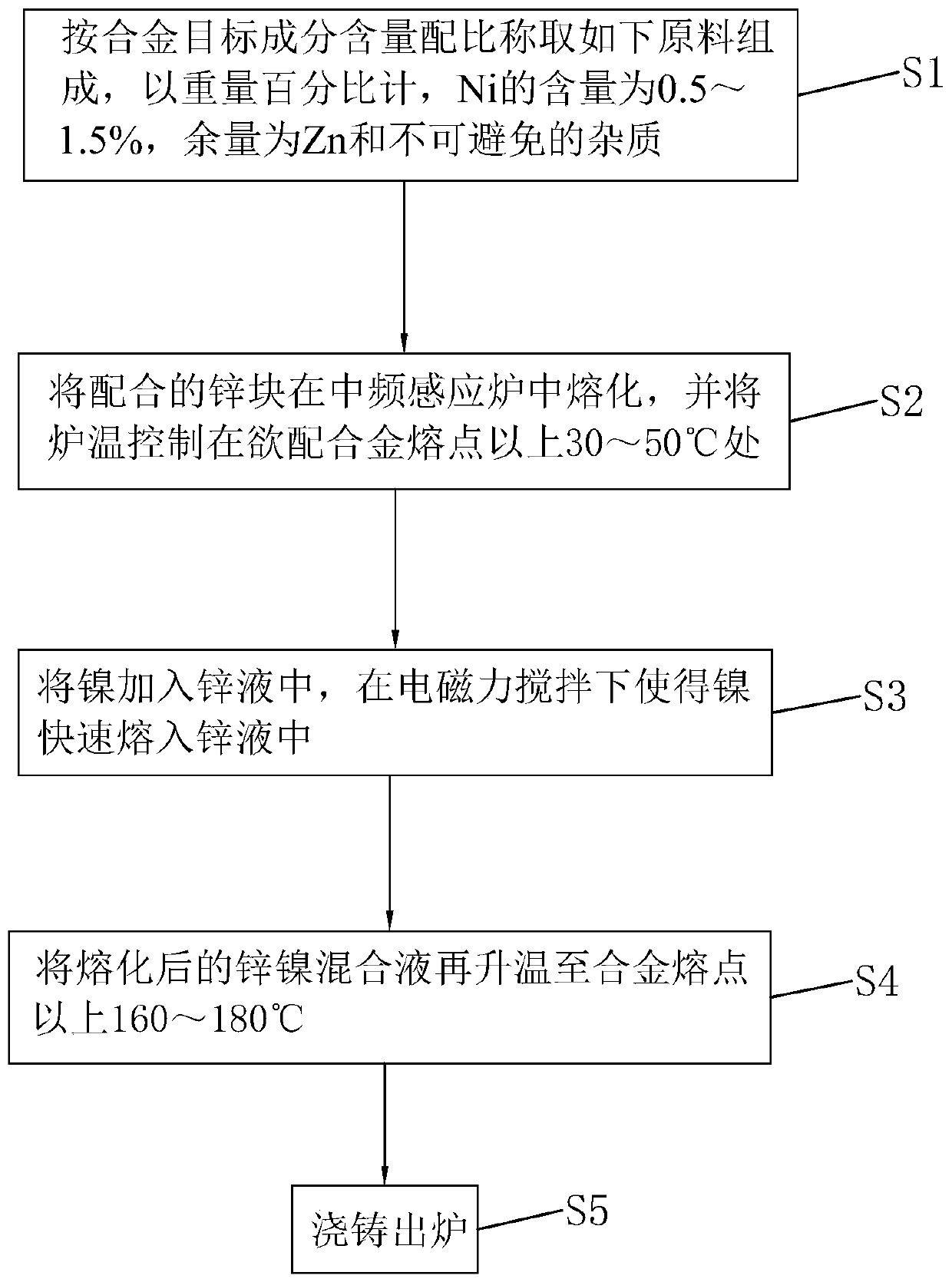

[0024] Embodiment 1: A zinc-nickel alloy, comprising components and their corresponding mass percentages: Ni 0.5%, the balance being Zn and unavoidable impurities. Specifically, see the attached figure 1 , the zinc-nickel alloy is prepared by the following steps:

[0025] S1. The following raw material composition is weighed according to the target composition ratio of the alloy. The content of Ni is 0.5% by weight percentage, and the balance is Zn and unavoidable impurities. Among them, the raw material of Zn is zinc ingot No. 0, and the raw material of Ni is sponge nickel or metal powder with a purity exceeding 99.99%. When Ni uses metal powder with a purity exceeding 99.99% as a raw material, the particle size of the Ni powder can be 20 μm. When nickel sponge is used as the raw material of Ni, nickel sponge is a nickel-based porous sponge-like structure with a large specific surface area, which can achieve low temperature, fast speed, and does not require molten salt prot...

Embodiment 2

[0031] Embodiment 2: A zinc-nickel alloy, including components and their corresponding mass percentages: Ni 1%, the balance being Zn and unavoidable impurities. Specifically, see the attached figure 1 , the zinc-nickel alloy is prepared by the following steps:

[0032] S1. The following raw material composition is weighed according to the alloy target composition ratio. The content of Ni is 1% by weight percentage, and the balance is Zn and unavoidable impurities. Among them, the raw material of Zn is zinc ingot No. 0, and the raw material of Ni is sponge nickel or metal powder with a purity exceeding 99.99%. When Ni uses metal powder with a purity exceeding 99.99% as a raw material, the particle size of the Ni powder can be 20 μm. When nickel sponge is used as the raw material of Ni, nickel sponge is a nickel-based porous sponge-like structure with a large specific surface area, which can achieve low temperature, fast speed, and does not require molten salt protection.

[...

Embodiment 3

[0038] Embodiment 3: A zinc-nickel alloy, including components and their corresponding mass percentages: Ni 1.5%, the balance being Zn and unavoidable impurities. Specifically, see the attached figure 1 , the zinc-nickel alloy is prepared by the following steps:

[0039] S1. The following raw material composition is weighed according to the target composition ratio of the alloy. The content of Ni is 1.5% by weight percentage, and the balance is Zn and unavoidable impurities. Among them, the raw material of Zn is zinc ingot No. 0, and the raw material of Ni is sponge nickel or metal powder with a purity exceeding 99.99%. When Ni uses metal powder with a purity exceeding 99.99% as a raw material, the particle size of the Ni powder can be 20 μm. When nickel sponge is used as the raw material of Ni, nickel sponge is a nickel-based porous sponge-like structure with a large specific surface area, which can achieve low temperature, fast speed, and does not require molten salt prote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com