Method for regenerating mica paper through reinforcement of aramid precipitated fiber

A kind of aramid fiber, mica paper technology, applied in synthetic cellulose/non-cellulose material pulp/paper, fiber raw material processing, papermaking, etc., can solve the problem of lack of natural mica sheet material strength, difficult to improve speed, and production efficiency Low and other problems, to achieve the effect of improving insulation strength and dielectric properties, upgrading grades, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

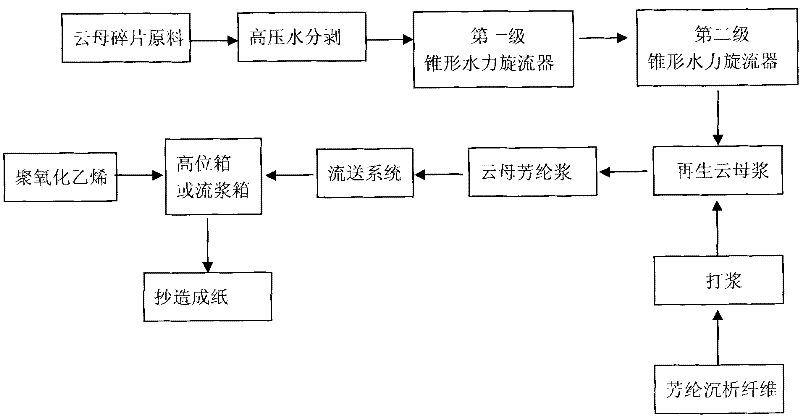

[0017] The production process of the present invention is as shown in the figure, and the specific process is as follows:

[0018] The mica fragments are crushed by high-pressure hydraulic force, and the pressure of the high-pressure water flow from the nozzle is about 2MPa, the choice is φ250, and the cone angle is 20°. The conical hydrocyclone further removes scales, stones, and sand through hydraulic classification. Thick flakes and sand particles larger than 0.3mm are discharged from the slag outlet, while thinner and finer pulp with a size of 0.3mm flows out from the good pulp outlet and enters the second-stage conical hydrocyclone for classification and selection, becoming Slurry suitable for papermaking. Then select a suitable grading sieve for further classification according to the mica paper requirements, select mica pulp of suitable size and distribution, add 2%-20% aramid fibrids (mass ratio relative to mica fragments), mix evenly, After a certain beating treatme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com