Patents

Literature

35results about How to "Reduce paper breaks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

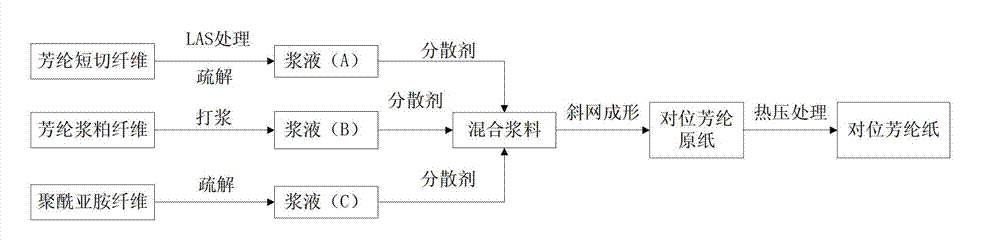

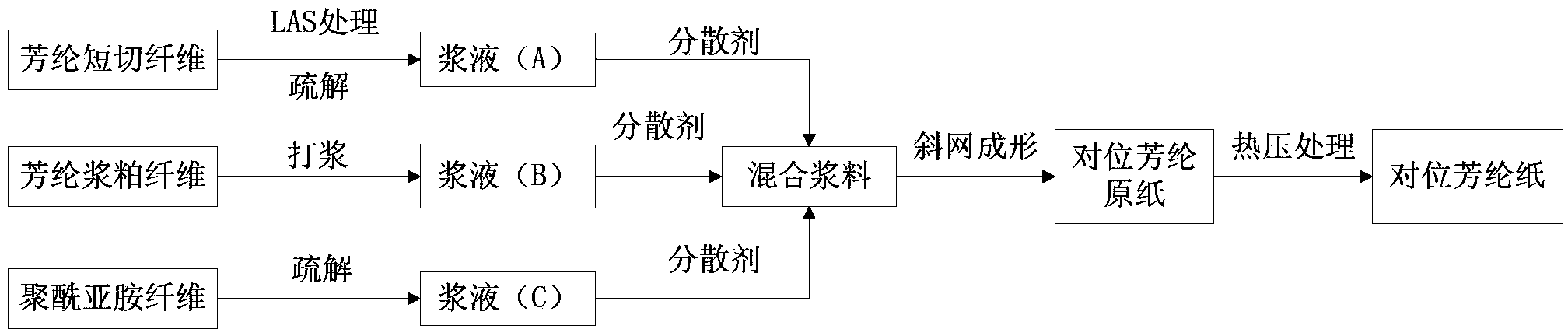

Para-position aramid fiber paper used for cellular material and preparation method thereof

ActiveCN102899959AReduce water repellencyImprove dispersion compatibilityPulp beating methodsPaper/cardboardPolyesterPapermaking

The invention discloses a para-position aramid fiber paper used for a cellular material and a preparation method thereof. The preparation process comprises the following steps: adding polyimide fibers, defibering and dispersing; papermaking together with para-position aramid fiber, wherein the papermaking proportion in parts by weight is as follows: 20-50% of para-position aramid short cut fiber, 35-60% of para-position aramid pulp fiber and 5-30% of polyimide fiber; and squeezing, drying and carrying out hot press moulding.. According to the preparation method, tear strength, temperature resistance and fire resistance of the para-position aramid fiber paper can be obviously improved, paper breaking during papermaking is reduced, operating speed of a paper machine and production efficiency are improved, and negative effects on properties of a paper sheet as a cohesive fiber such as a polyester fiber is introduced can be avoided.

Owner:SHAANXI UNIV OF SCI & TECH

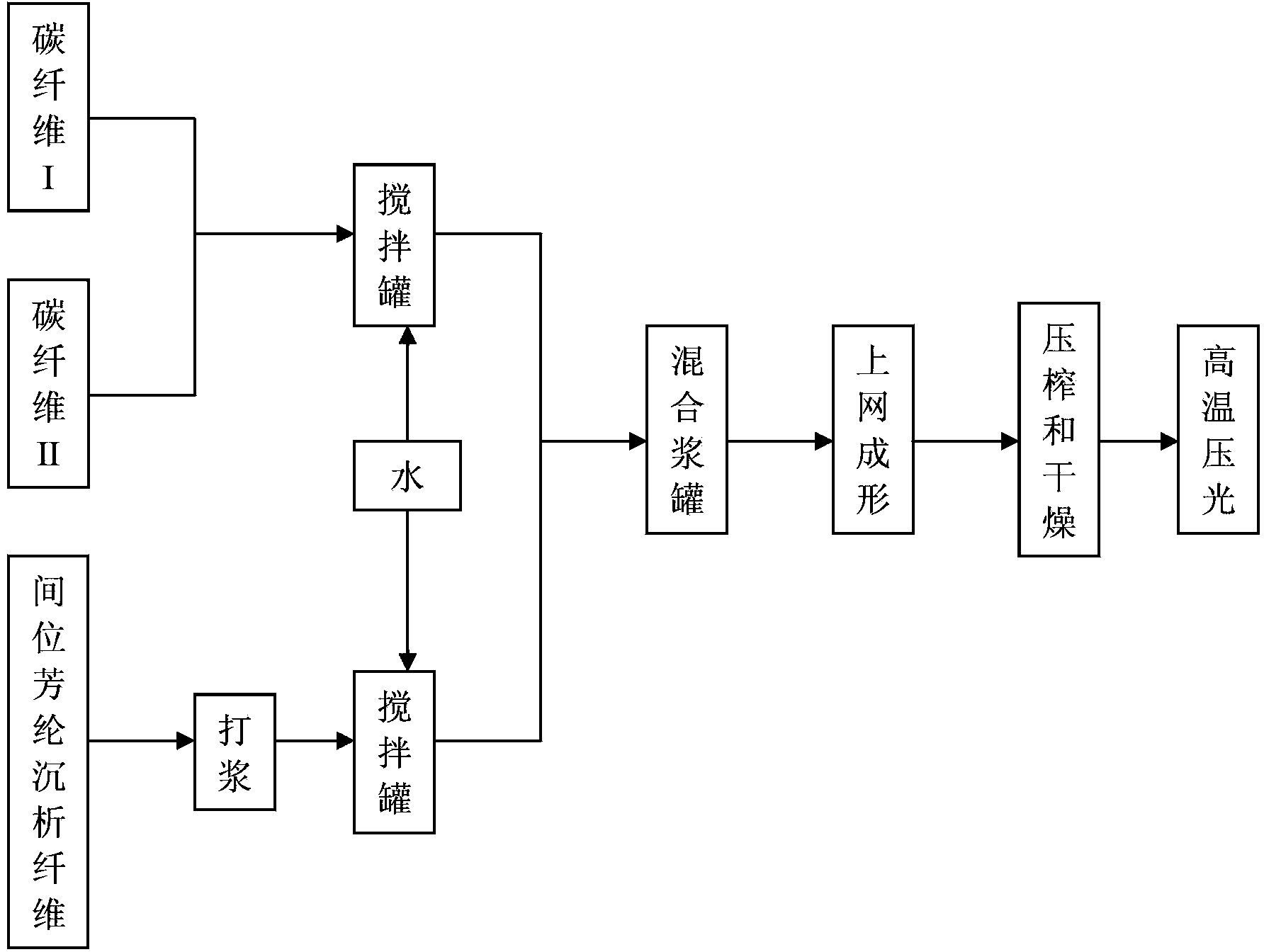

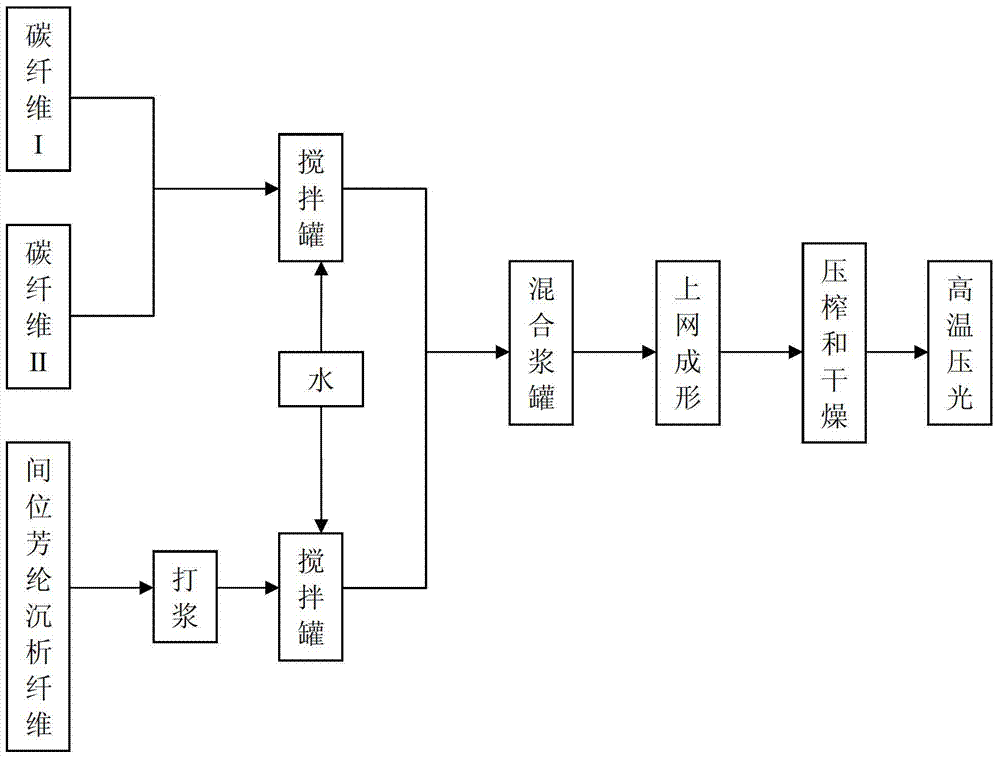

Electrothermal high-temperature-resistant carbon fiber paper and preparation method thereof

ActiveCN103451989AHigh mechanical strengthEasy to operateSynthetic cellulose/non-cellulose material pulp/paperFiberPapermaking

The invention discloses pulp of electrothermal high-temperature-resistant carbon fiber paper. Fiber in the pulp comprises the following components in percentage by weight: 40-70% of carbon fiber I, 5-30% of carbon fiber II and 5-30% of meta-aromatic acrylic fibrid, wherein the length of the carbon fiber I is 1-5mm, and the fiber number is 1.5D; the length of the carbon fiber II is 8-10mm, and the fiber number is 1.5D; the pulp beating degree of the meta-aromatic acrylic fibrid is 40-80 degree SR. The invention further discloses a preparation method of the pulp, meta-aromatic acrylic fibrid / carbon fiber composite electrothermal high temperature-resistant carbon fiber paper prepared by using the pulp and a preparation method thereof. According to the method disclosed by the invention, the mechanical strength and the operability of the composite paper are significantly improved, paper breaking during papermaking is reduced, the production efficiency is improved, the temperature resistance level and the flame retardance of the composite carbon fiber paper are simultaneously upgraded, and the safety performance is improved.

Owner:YANTAI METASTAR SPECIAL PAPER

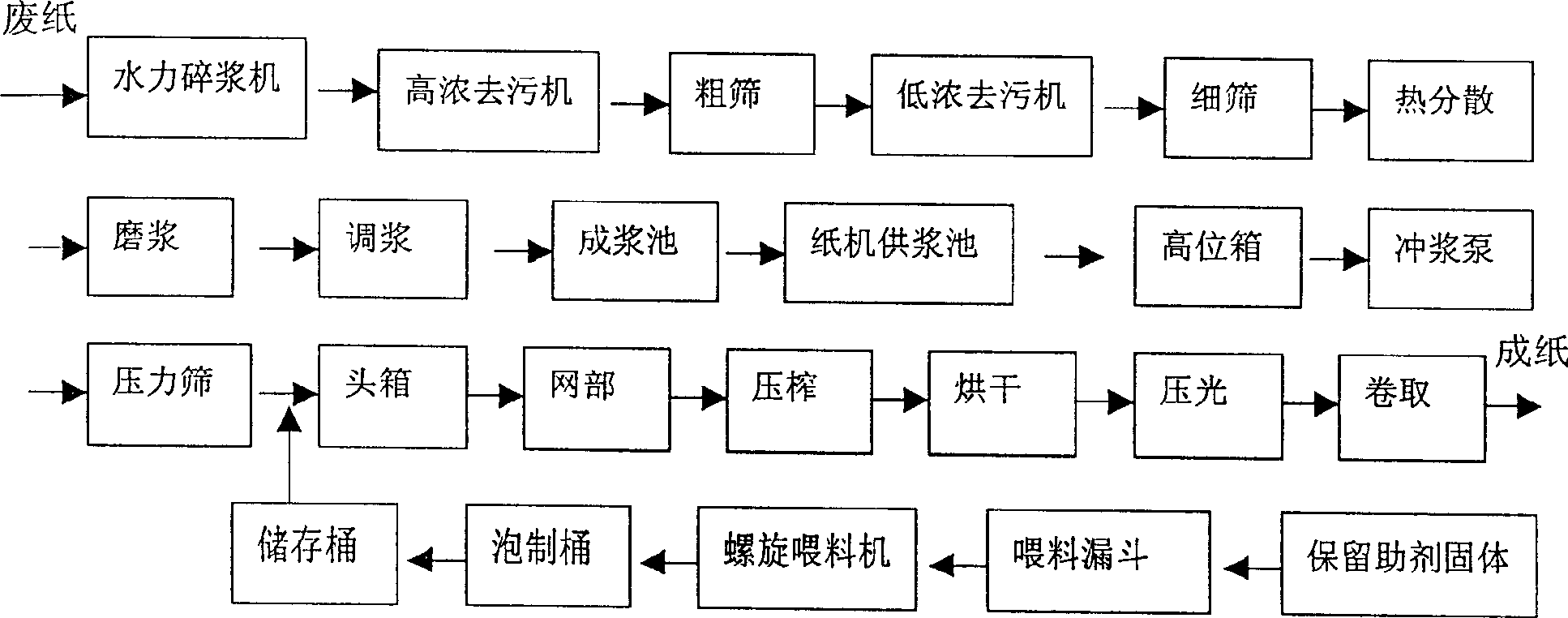

Method for preparing kraft cardboard paper

InactiveCN1431364AHigh retention rateSave raw materialsPaper-making machinesRetention agents additionCardboardFiber

A technology for making kraft paper includes breaking the used paper, hydrolyzing, removing dirt, screening, thermal dispersing, grinding, mixing, adding retaining aid, shaping, squeezing baking, press finishing and winding. Its advantages are high utilization rate of fibre material, high uniformity, high speed and output, and less sewage drainage.

Owner:平湖荣成环保科技有限公司

Process for producing low-basis-weight waxed base paper

The invention a process for producing low-basis-weight waxed base paper. The process for producing the low-basis-weight waxed base paper comprises the following steps of: (1) disintegrating and mixing bleached sulfate needlebush chemical pulp and bleached sulfate broadleaf wood chemical pulp, adding a bulking agent into the mixture, and performing defibrination to prepare a pulp material; (2) preparing internal pulp starch, a filler, an internal sizing agent and a wet strengthening agent into an auxiliary material respectively; (3) adding the auxiliary materials prepared in the step (2) into the pulp material of the step (1) respectively to form waxed base paper pulp, and adding water to confect the base paper pulp into a net pulp; and (4) performing net forming on the net pulp of the step (3) by using a Haber net paper machine, squeezing, drying, performing calender finishing, and then rolling to prepare the waxed base paper. By the process for producing the low-basis-weight waxed base paper, the structures of the conventional domestic straw pulp and wood pulp are changed; the tensile strength and the whiteness of the base paper are improved; the cost is reduced; the gram weight is reduced; and broken paper in the waxing process of the waxed base paper is reduced.

Owner:WELBON SPECIAL MATERIALS CO LTD

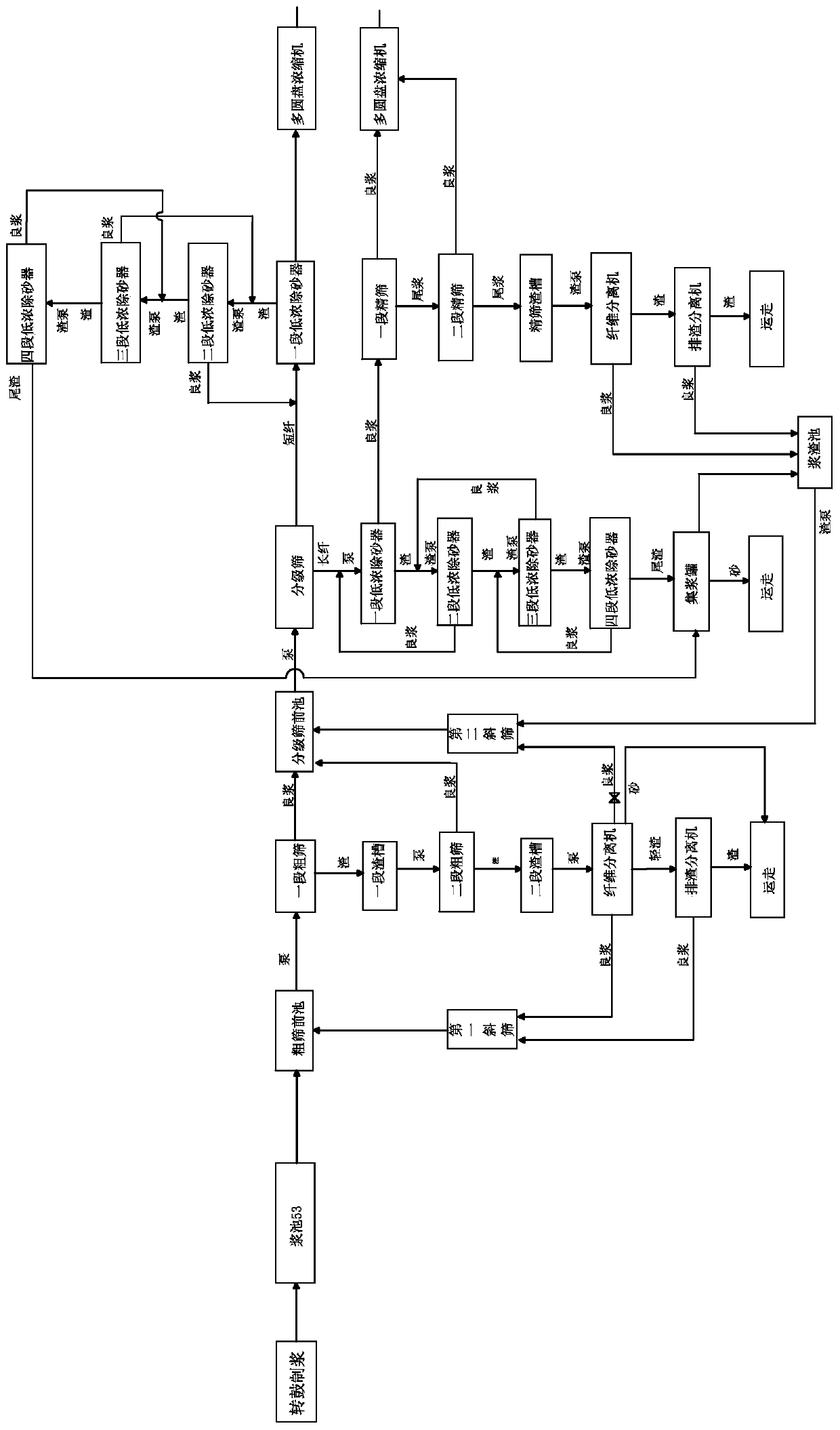

Production method of regenerated ultralow-gram-weight high-strength corrugated base paper

InactiveCN111118956APut an end to importsSolve cut offSpecial paperDryer sectionPaper sheetPapermaking

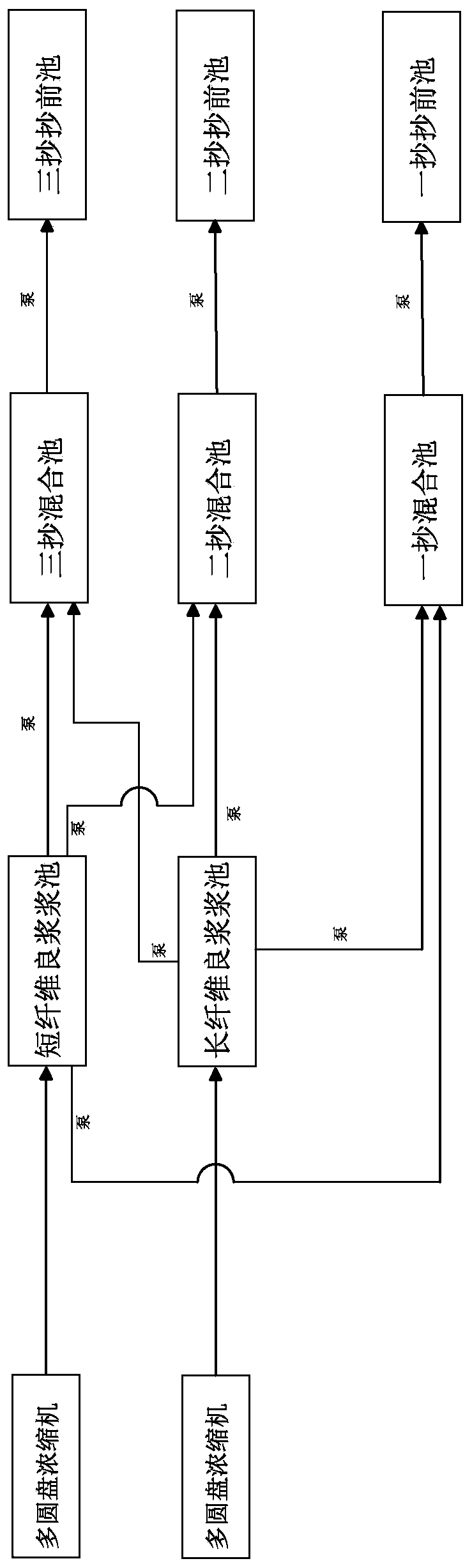

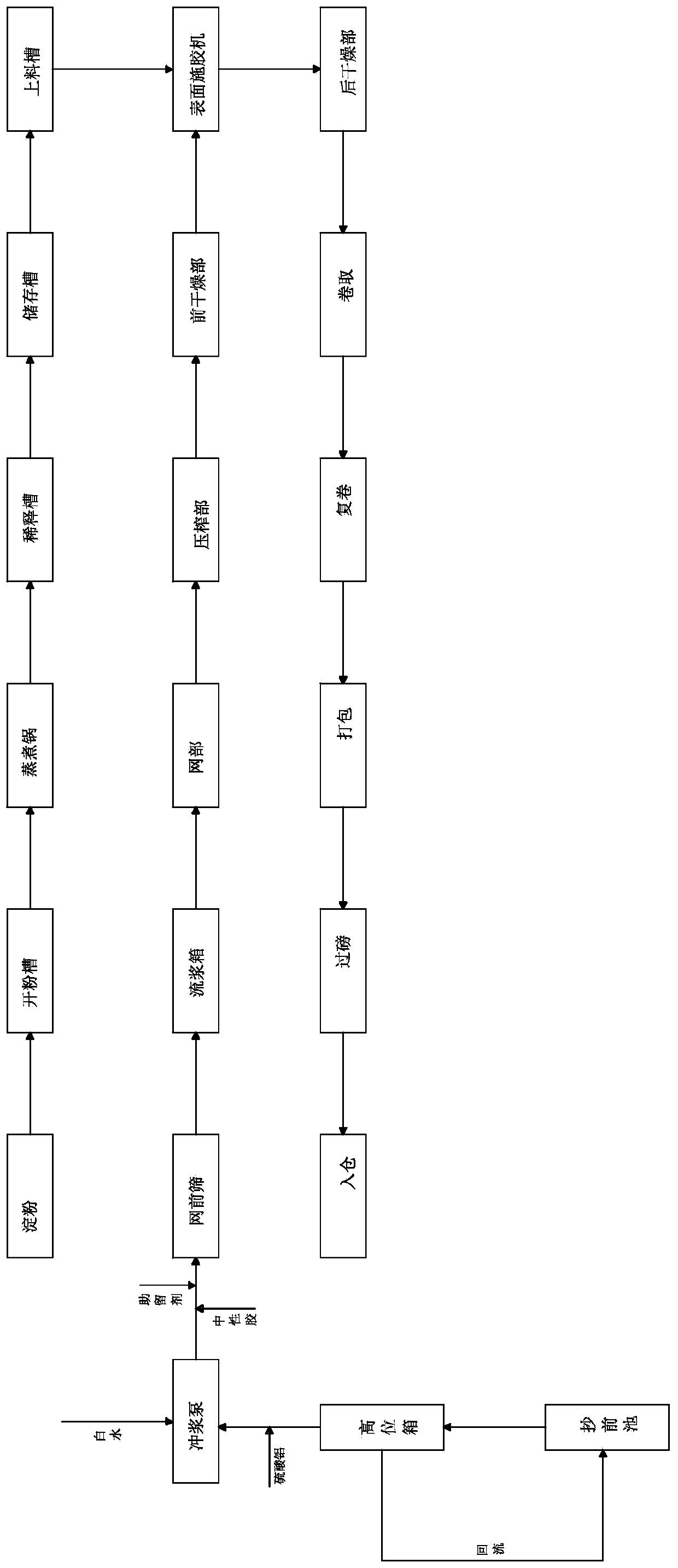

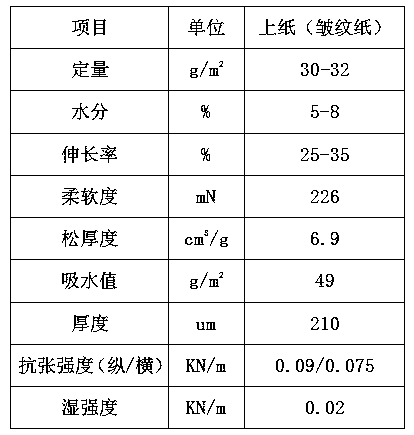

The invention provides a production method of regenerated ultralow-gram-weight high-strength corrugated base paper, which can ensure the physical strength of the base paper and reduce the impurity treatment load. The method comprises the steps of drum pulping, coarse screening, classifying screening, short fiber purifying treatment, long fiber purifying treatment, long fiber fine screening, shortfiber concentration, long fiber concentration, pulp preparation and paper machine papermaking. Domestic OCC waste paper raw materials are made into pulp through a drum pulping device, the pulp is screened by a pressure screen, the pulp subjected to the coarse screen is subjected to classification screening to divide fibers into long fibers and short fibers, short fiber good pulp and long fiber good pulp are proportionately mixed, the mixed pulp is sent to a papermaking forebay, the pulp is thickened, diluted, dispersed by a before-net, molded by a forming screen, dehydrated at the screen partto obtain wet paper sheets, the wet paper sheets are subjected to steam drying at a front drying part and then enter a film transfer surface sizing machine for surface sizing, and the paper sheets subjected to surface sizing enter a rear drying part for drying.

Owner:中山联合鸿兴造纸有限公司

Novel dyeing kraft bottom coating white board paper production method

ActiveCN106436458AImprove running stabilityLess holesPaper/cardboardPulp material addition processesWhiteboardDeinking

The present invention provides a novel dyeing kraft bottom coating white board paper production method, wherein online dyeing is performed on the 100% specific deinking base pulp mainly through three dyes such as a yellow dye, a black dye and a red dye. According to the present invention, the previous waste kraftpaper having the poor operating rate is adopted as the base pulp to replace the dyeing base pulp of the 100% specific deinking base pulp, such that the broken holes on the raw paper due to the pre-drying during the operating of the paper machine can be reduced, the paper breaking number can be reduced, the operating rate of the paper machine can be substantially improved, the A grade rate of the finished product can be improved, and the cost of per ton of the paper can be further reduced; and in the case of the same physical strength indicators, the back surface has characteristics of delicate appearance, dot reducing and good visual effects, and is favored by customers.

Owner:NINE DRAGONS PAPER IND TIANJIN

Production method of sizing mica paper

ActiveCN103132369AImprove surface adhesionReduce tensionSpecial paperPaper/cardboardViscosityImpurity

The invention provides a production method of sizing mica paper. Firstly, mica raw materials are crushed to mica raw pulp through a pulping machine, the mica raw pulp is conveyed to a papermaking pulp tank, and the papermaking pulp tank is filled with water through a container, bone glue with viscosity between 8 DEG C and 12 DEG C is added to the water, the volume of the added bone glue is 15% to 20% of the water mass, the water is heated by steam with the temperature between 70 DEG C and 90 DEG C so as to enable the bone glue to be dissolved in the water, insoluble impurities are filtered and bone glue solution is made, the bone glue solution and antifoaming agents are added to the papermaking pulp tank containing the mica raw pulp, the volume of the added bone glue solution is 4%. to 6%. of the total mass of the mica raw pulp in the papermaking pulp tank, the volume of the antifoaming agents is 0.005% to 0.015% of the total mass of the mica raw pulp in the papermaking pulp tank, the mica raw pulp, the bone glue solution and the antifoaming agents are mixed evenly, and eventually the mica paper is made in a papermaking molding mode through a mica paper machine, the mica paper is dried and the standard mica paper is produced. According to the production method of the sizing mica paper, adhesive force on the surface of lodicule in the production method of the mica paper can be improved, tensile force of the mica paper in the process of production is increased and the purpose of winding the paper easily is achieved.

Owner:PINGJIANG COUNTY CHUANG YI MICA PROD

Manufacturing method for gel-doped clinker-powder mica paper

The invention discloses a manufacturing method for gel-doped clinker-powder mica paper. The gel-doped clinker-powder mica paper is manufactured from the following raw materials in parts by weight: 120-140 parts of mica, 3-4 parts of gelatine, 5-6 parts of polyvinyl alcohol, 2-3 parts of polyvinylpyrrolidone, 1-2 parts of borax, 2-3 parts of aluminium hydroxide, 1-2 parts of boric acid, 1-2 parts of sodium persulfate, 1-2 parts of grape seed oil, 3-4 parts of acrylic emulsion, and an appropriate amount of water. According to the manufacturing method disclosed by the invention, the surface adhesive force of newly-generated slurry sheets in a production process for the mica paper can be remarkably improved via the gelatine, the polyvinyl alcohol 5 and the polyvinylpyrrolidone, and the tensile force during production for the mica paper can be increased, so as to reduce paper breakage during papermaking; the mica paper manufactured by the manufacturing method disclosed by the invention is good in electric strength and tensile strength.

Owner:ANHUI JIANGWEI PRECISION IND

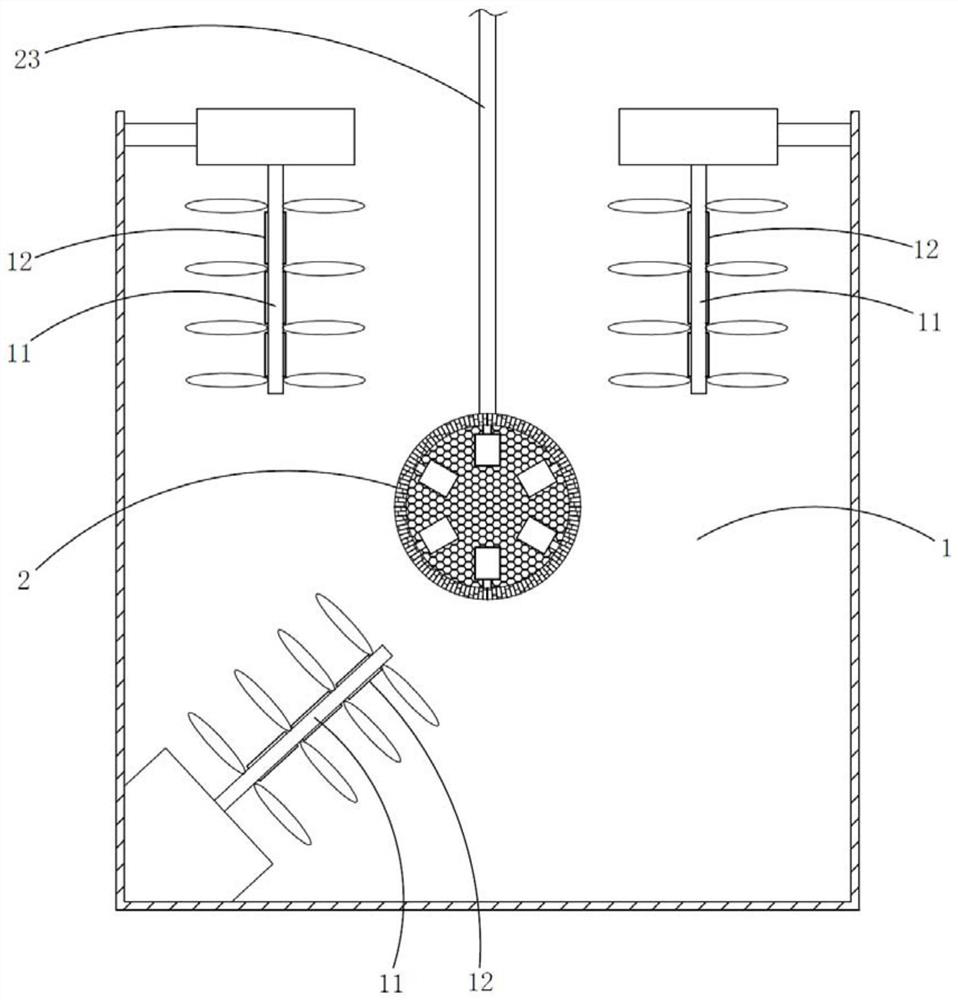

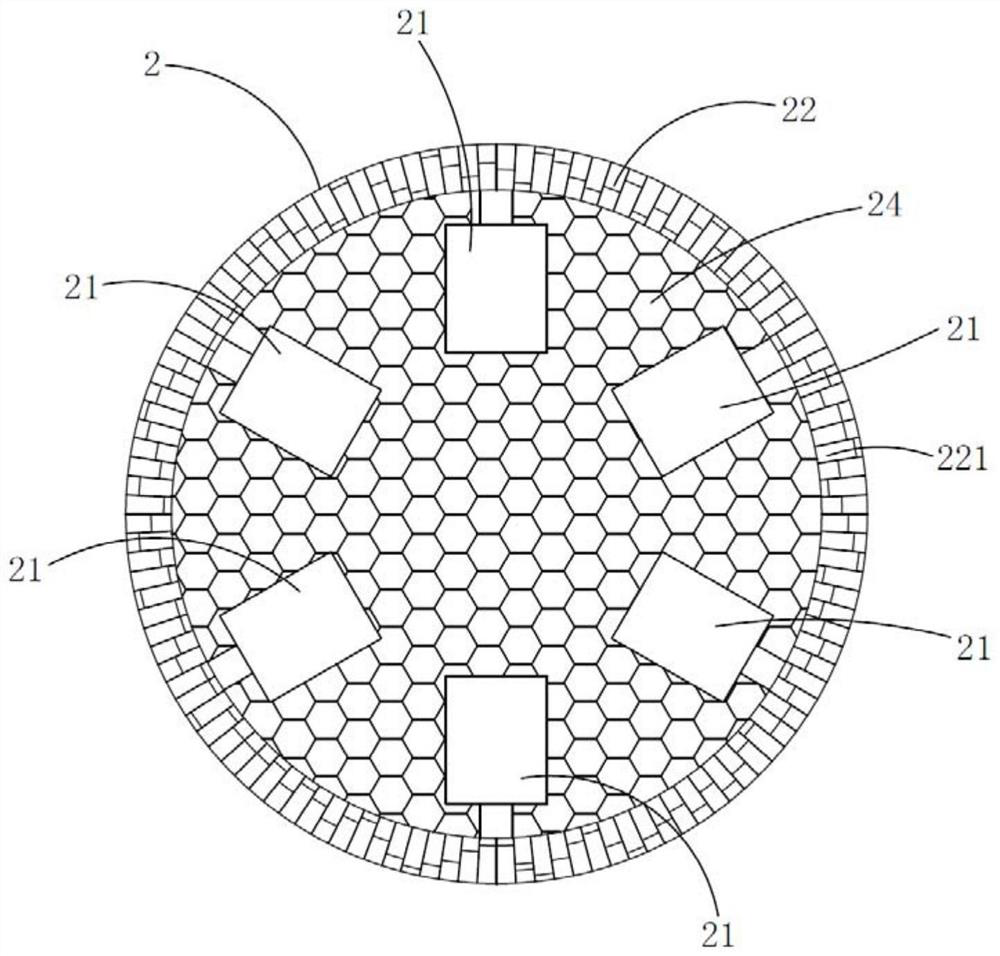

Papermaking and composite processing technology for composite liquid absorbing material and equipment thereof

ActiveCN111379188AThe total amount is easy to controlEasy to operatePaper-making machinesArticle deliveryMolding machinePapermaking

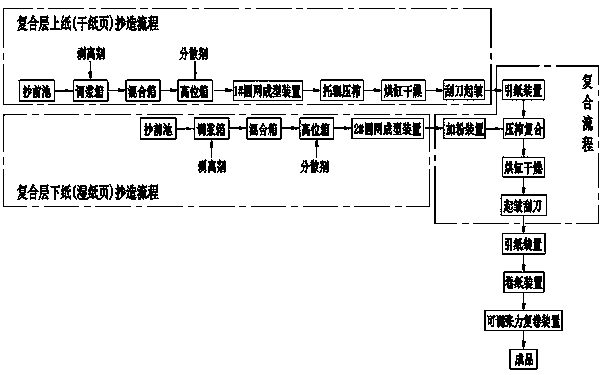

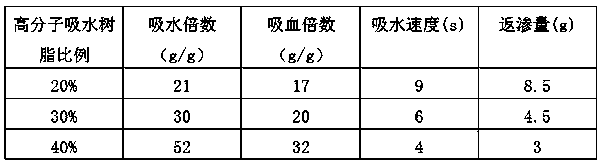

The invention discloses a papermaking and composite processing technology of a composite liquid absorbing material. The technology comprises the steps of composite layer upper paper papermaking, composite layer lower paper papermaking, compounding and rewinding processing. The invention further discloses papermaking and composite processing equipment for the composite liquid absorbing material, the papermaking and composite processing equipment comprises a first rotary screen forming mechanism, a second rotary screen forming mechanism, a drying cylinder drying mechanism, a composite drying cylinder drying mechanism and a novel adjustable tension rewinding mechanism, and the first rotary screen forming mechanism and the second rotary screen forming mechanism are symmetrically arranged and are opposite in rotating direction; a squeezing composite mechanism is installed under the composite drying cylinder drying mechanism, and a powder scattering mechanism is installed under the squeezingcomposite mechanism; the process for adding the high-molecular water-absorbent resin is simple and convenient to operate, and the total adding amount is easy to control; the water absorption speed, the water locking performance and the comfort level of the liquid absorption material are improved; the water absorption rate is increased to 50 times or above, and the diffusion and permeation width can be adjusted as required; continuous production is realized; and powder spraying process is uniform.

Owner:潍坊杰高非织材料科技有限公司

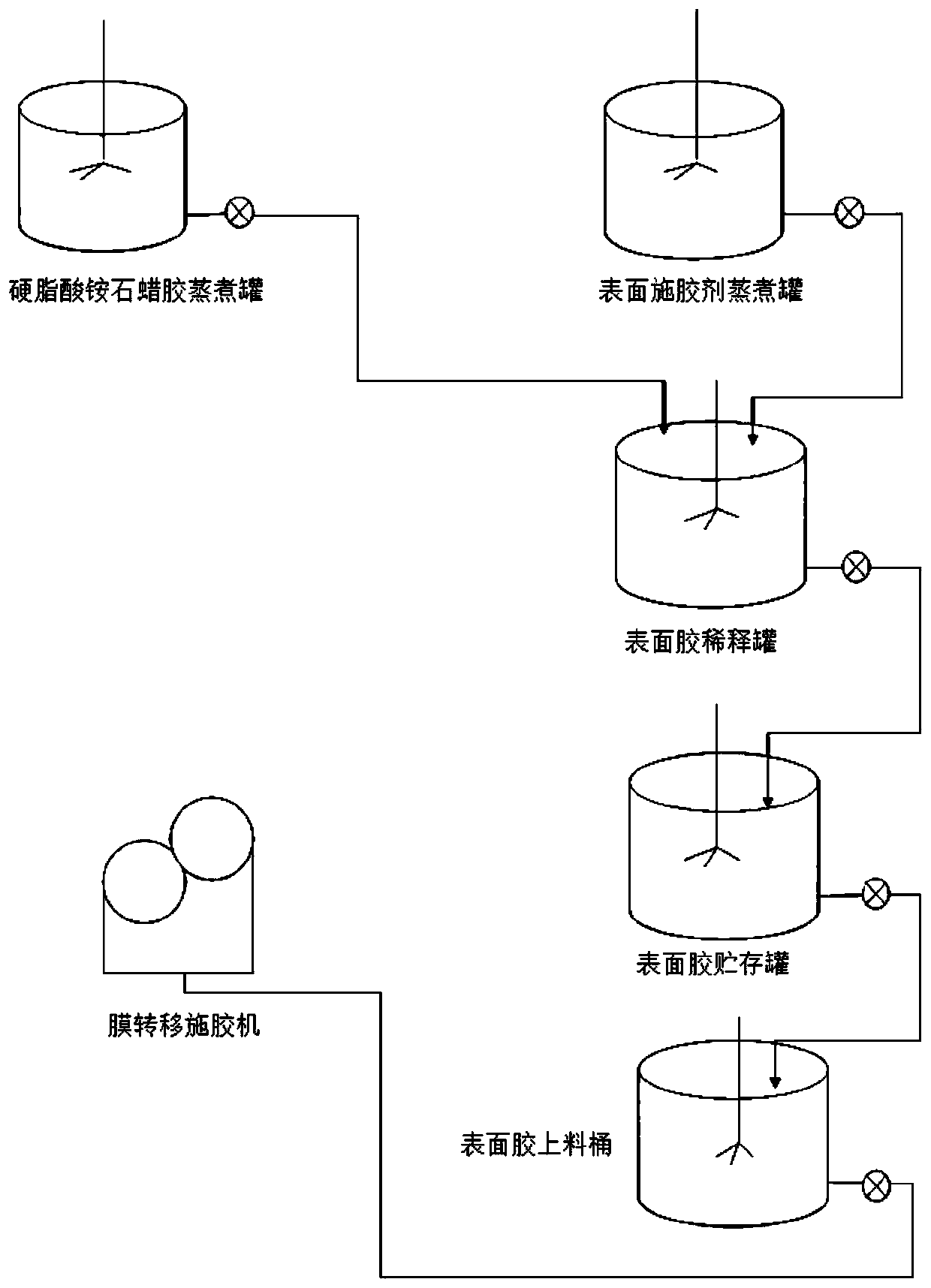

Film transfer sizing method of oil-proof paper

PendingCN111379195AImprove paper drynessIncrease productionWater-repelling agents additionPaper coatingParaffin waxPaper sheet

The invention provides a film transfer sizing method of oil-proof paper. In the technical scheme, a surface sizing agent with a brand new formula is adopted in a film transfer sizing process, and thecontrol conditions of a film transfer sizing machine are optimized and improved. Specifically, stearic acid, paraffin, ammonia water and clear water are used for preparing an ammonium stearate paraffin glue solution, the ammonium stearate paraffin glue solution is used for replacing part of an oil-proof agent, and the ammonium stearate paraffin glue solution, and cationic surface cassava starch, polyvinyl alcohol, an anionic oil-proof agent and clear water with a specific proportion are jointly prepared into the surface sizing agent. The binding force of the oil-proof agent and fibers is improved, the oil-proof grade is increased, the paper sheet appearance frosted performance is enhanced, and the use amount of the oil-proof agent is reduced, so that the cost is reduced. On the basis, thecontrol conditions of the film transfer sizing machine are improved, and the problem that the difference between the oil-proof grades of the two sides of oil-proof paper of a large cylinder machine istoo large can be solved by adjusting the models and the pressures of the metering rods of an upper beam and a lower beam.

Owner:SHANDONG RENFENG SPECIAL MATERIALS

Tissue paper storage device

The invention belongs to the technical field of paper product storage devices and discloses a tissue paper storage device. The tissue paper storage device comprises a double-layer barrel, an inner barrel body is fixed while an outer barrel body is rotatable, and a bottom plate between the two barrel bodies is provided with a limiting shaft for paper roll placement. The top of the inner barrel is provided with a paper outlet, and an unwinding block for driving a paper roll to automatically rotate for unwinding is arranged on one side of the paper outlet. A paper cutting mechanism is arranged inan inner cavity of the inner barrel and comprises a fixed part and a control part, the fixed part and the control part are fixedly connected with two spring sides of a same torsion spring respectively, the fixed part is fixed, the outer end face of the control part is provided with a shifting rod, each of the fixed part and the control part comprises a clamping block and a shear block in verticalconnection, and a cutter driven by a magnet is arranged in each shear block. The tissue paper storage device has advantages that due to high one-time paper storage capacity, frequent replacement is avoided, and labor saving is benefited; owing to a paper cutting function, cut uniformity of paper is realized, accidental tearing is avoided, application is benefited, and paper waste can be reduced;high convenience in use and convenience in popularization and application are achieved.

Owner:张凤

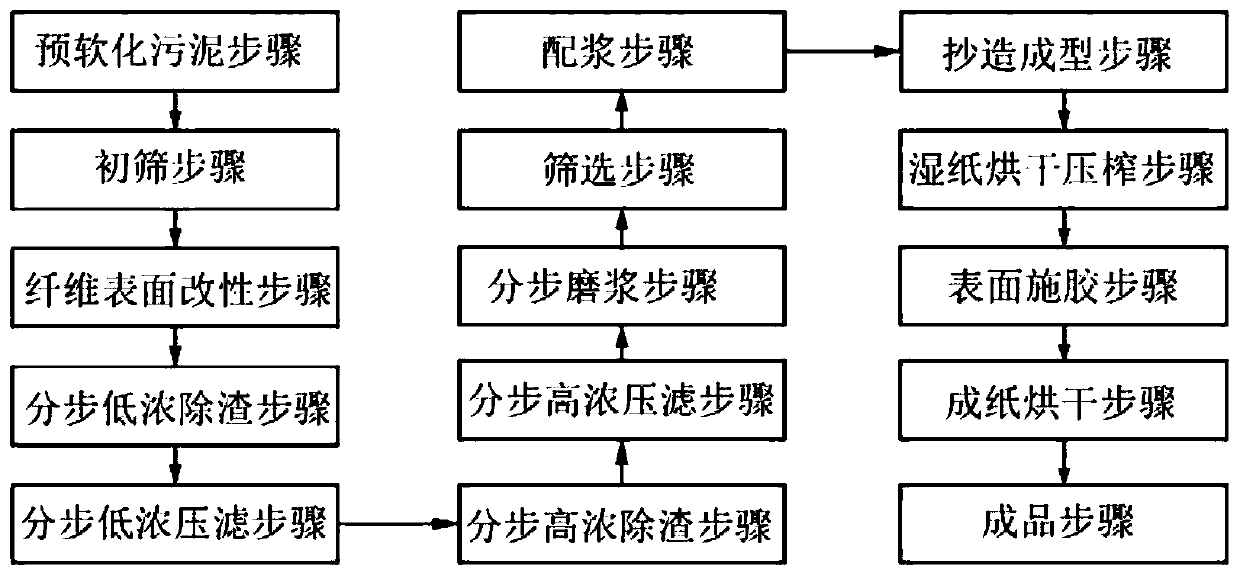

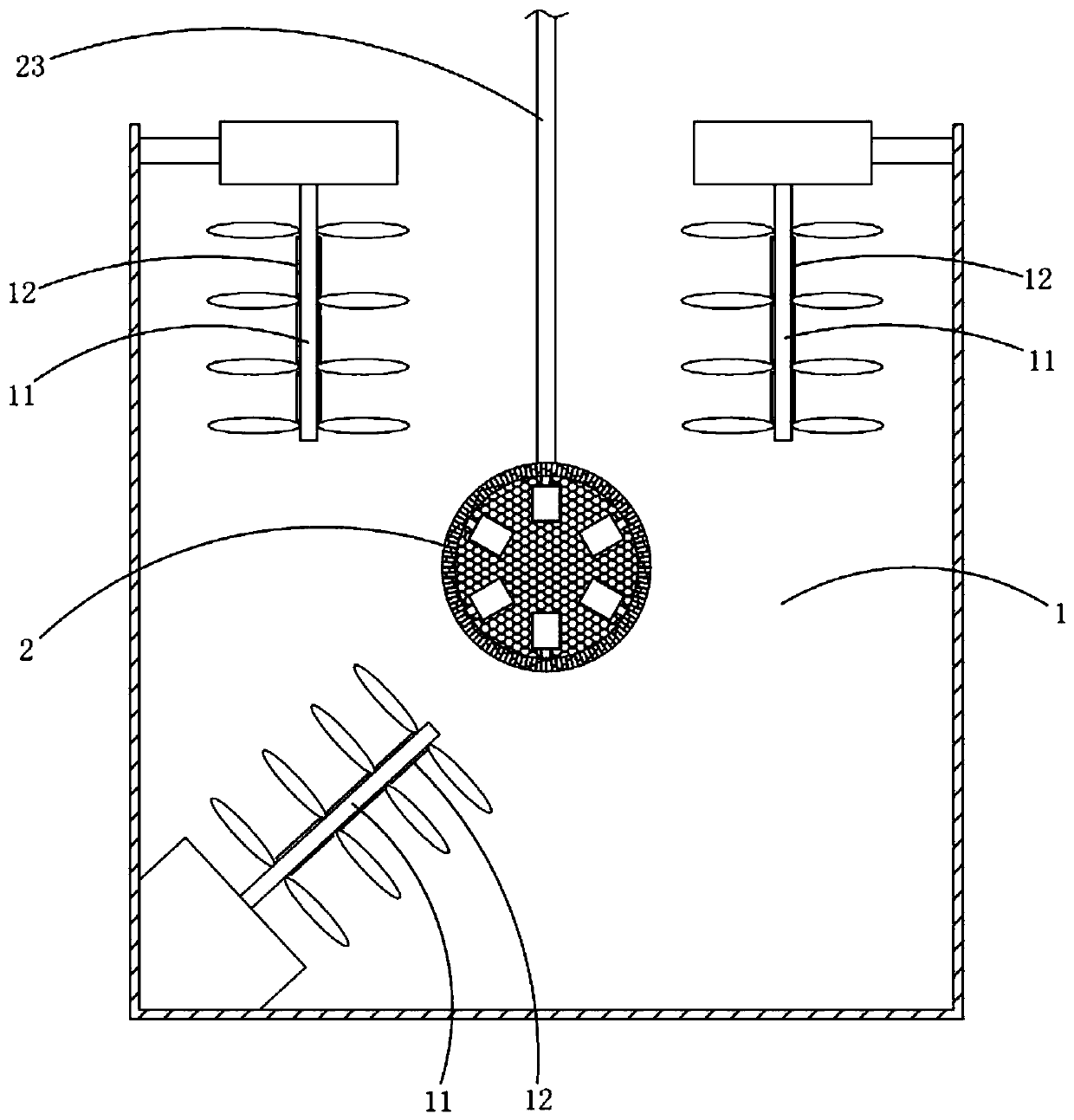

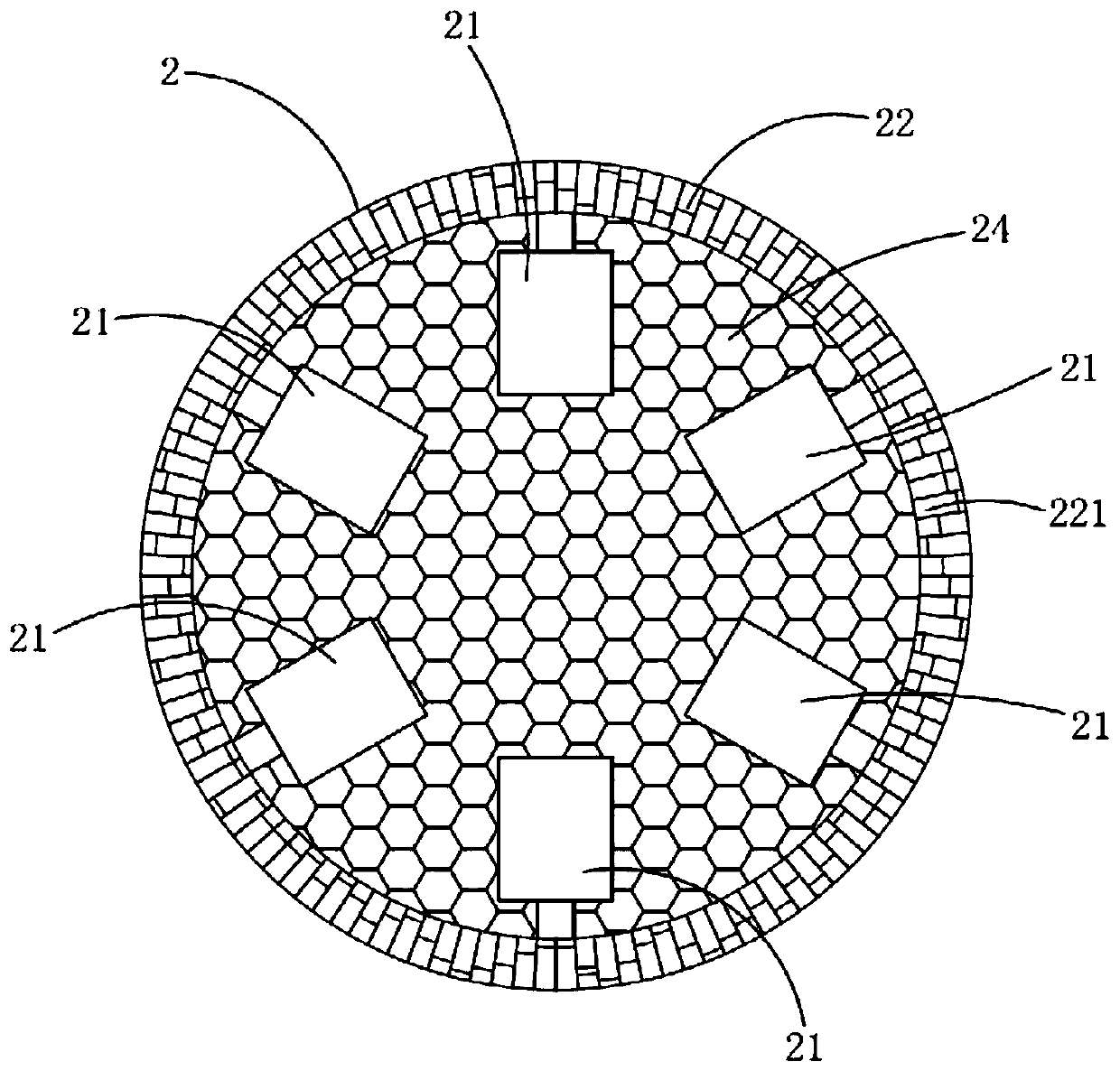

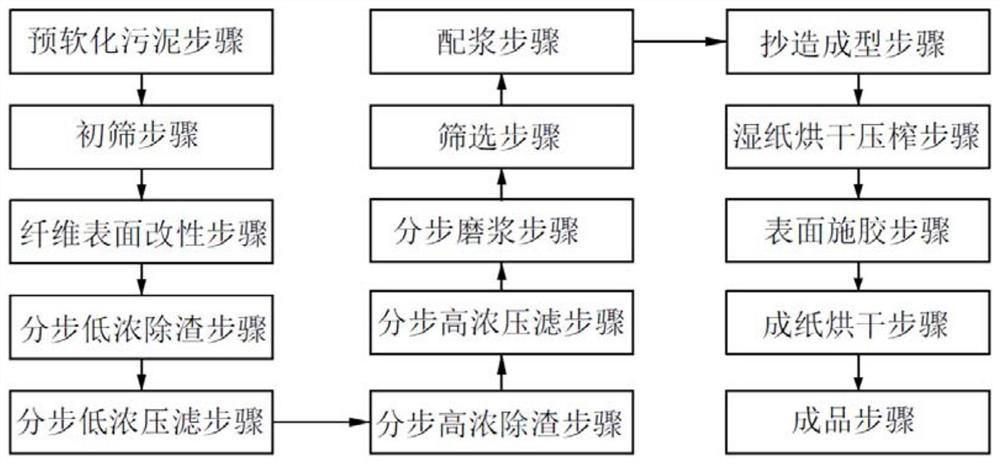

Method for reproducing antibacterial corrugated paper from high-salinity high-hardness waste paper sludge

The invention discloses a method for reproducing antibacterial corrugated paper from high-salinity high-hardness waste paper sludge. Through a technical means of combining a physical method and a chemical method, the waste paper sludge is recovered and used for producing the corrugated paper with an antibacterial function, the sticker weight of waste paper fibers subjected to surface modificationis reduced by 2%, thus the difficulty level of dehydration during paper making of a paper machine is reduced, physical indexes of water absorption, ring crush and the like of the made paper are improved, paper breaking of the paper machine is reduced, the operating rate of the paper machine is improved, and no secondary pollution is caused for the environment; and primary corrugated paper obtainedthrough sizing treatment of the method already has very stable corrugated paper characteristics, has excellent extensibility, elastoplasticity, crack resistance, anti-permeability and weather resistance, can have effects of water prevention, seepage prevention and protection, and is prevented from being affected with damp, a water-resistant grade reaches an ISO 4 grade, and breeding of bacteria in the corrugated paper can be effectively avoided.

Owner:东莞顺裕纸业有限公司

AKD (Alkyl Ketene Dimer) reinforcement accelerator for surface glue and preparation method thereof

InactiveCN106632846AHigh sizing efficiencyShorten the ripening timeWater-repelling agents additionPaper coatingCross-linkFiber

The invention belongs to the field of papermaking additives, and particularly relates to an AKD (Alkyl Ketene Dimer) reinforcement accelerator for surface glue and a preparation method thereof. The AKD reinforcement accelerator is prepared from 40 to 50 parts of dimethyl diallyl ammonium chloride, 40 to 50 parts of unsaturated organic acid, 10 parts of functional monomers, 2 to 10 parts of polyvinyl alcohol, 0.01 to 0.03 part of initiator and 300 parts of water. The AKD reinforcement accelerator disclosed by the invention can be combined with AKD, so that the lagging maturation period of gluing is shortened, distribution coverage of the AKD on the surface of fiber is promoted, a gluing function is fully expressed by the AKD, formation of a fiber cross-linked network can be promoted, and not only is the gluing effect improved, but also the strength of paper can be increased.

Owner:SHANDONG YUANGEN CHEM TECH RES & DEV CO LTD

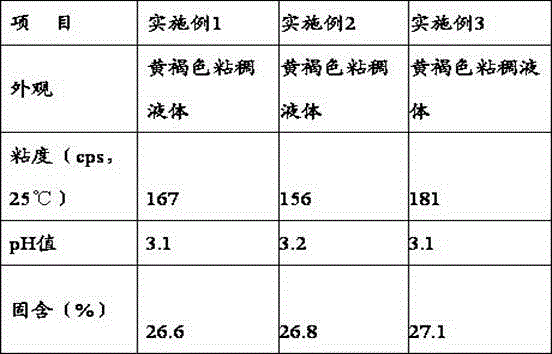

Preparation method of polymeric material for neutral paper-making

InactiveCN108951285AReduce chemical corrosionReduce downtimeWater-repelling agents additionPaper coatingPapermakingMechanical equipment

The invention relates to the field of paper-making auxiliaries, in particular to a preparation method of a polymeric material for neutral paper-making. The preparation method of the polymeric materialfor neutral paper-making is characterized in that alkyl ketene dimer is prepared, modified polyether glycol is prepared, and the modified polyether glycol is uniformly melted with diphenylmethane diisocyanate, and then an acetone solution of a catalyst is dropwise added, a chain extender is added after reaction is carried out, and then purified water is added and is stirred at high speed to prepare aqueous polyurethane neutral sizing agent emulsions. By adopting the neutral sizing agent, chemical corrosion of mechanical equipment can be greatly reduced, paper breaking phenomenon is reduced, the downtime of a paper machine is shortened, the dryness of paper sheets is improved, the papermaking speed is accelerated, and thus, the production ability of the paper sheets can be improved.

Owner:宁波高新区诠宝绶新材料科技有限公司

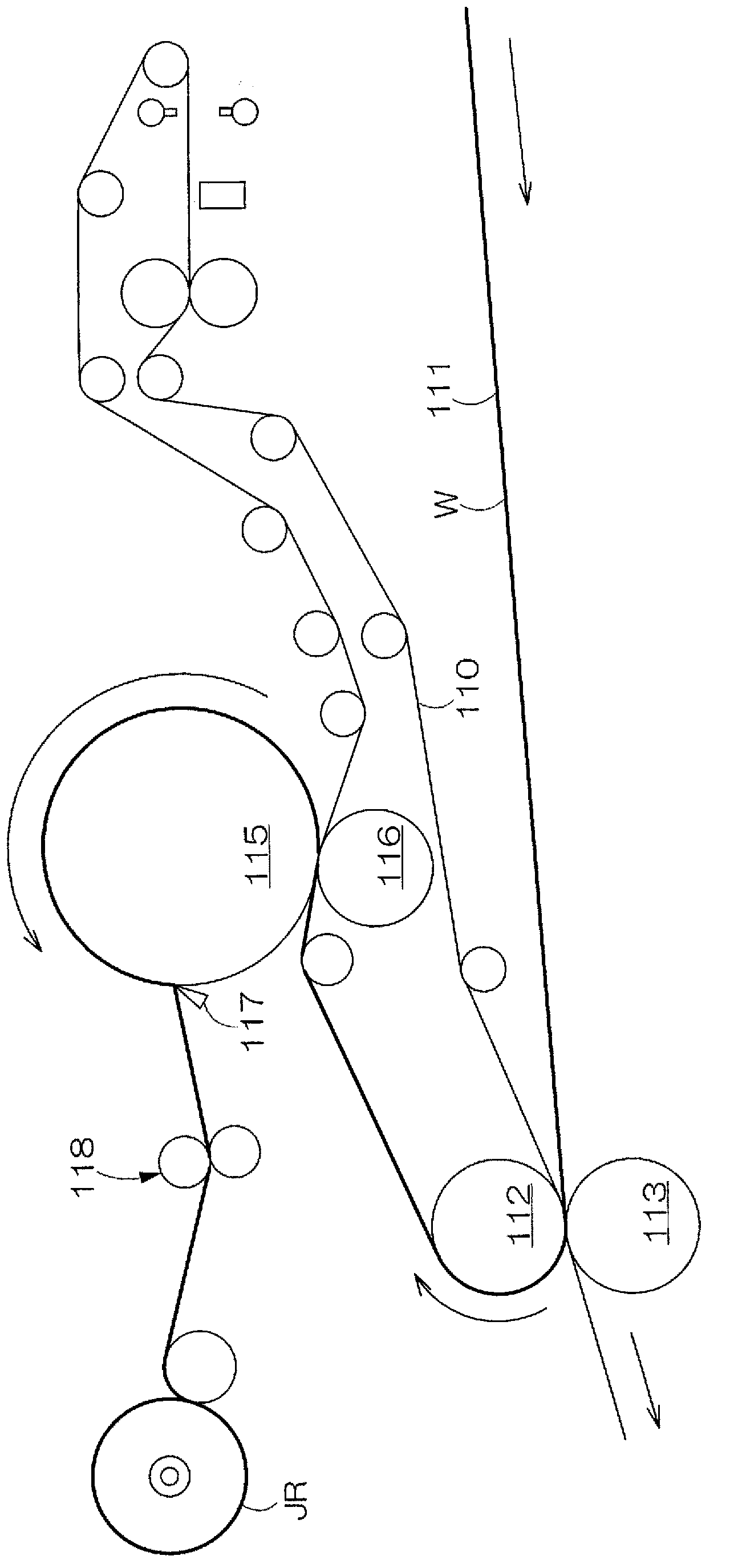

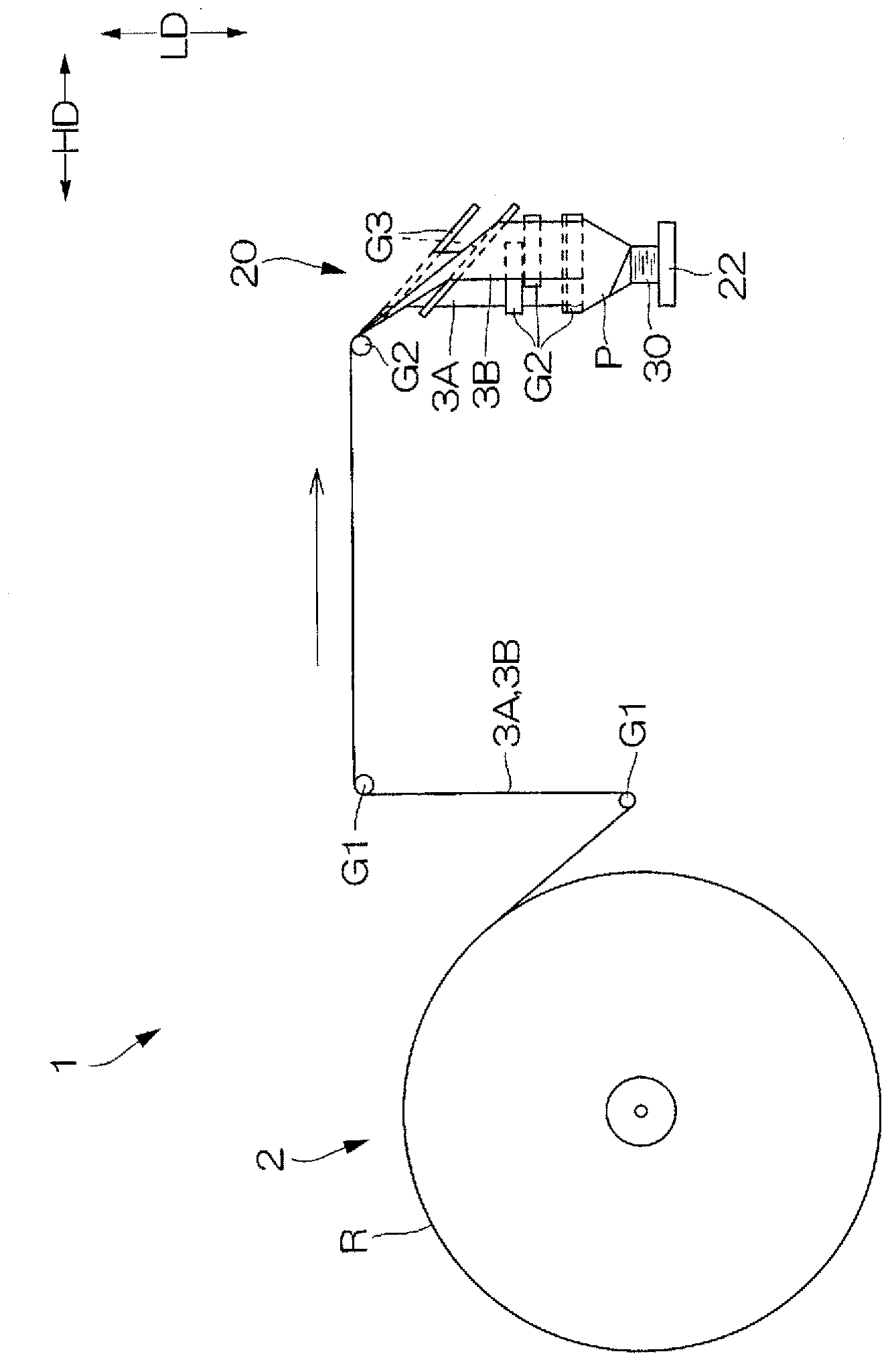

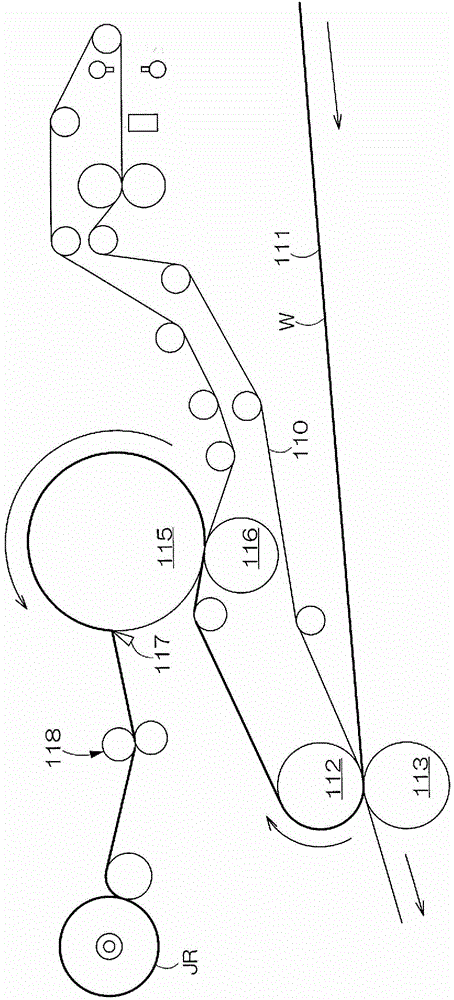

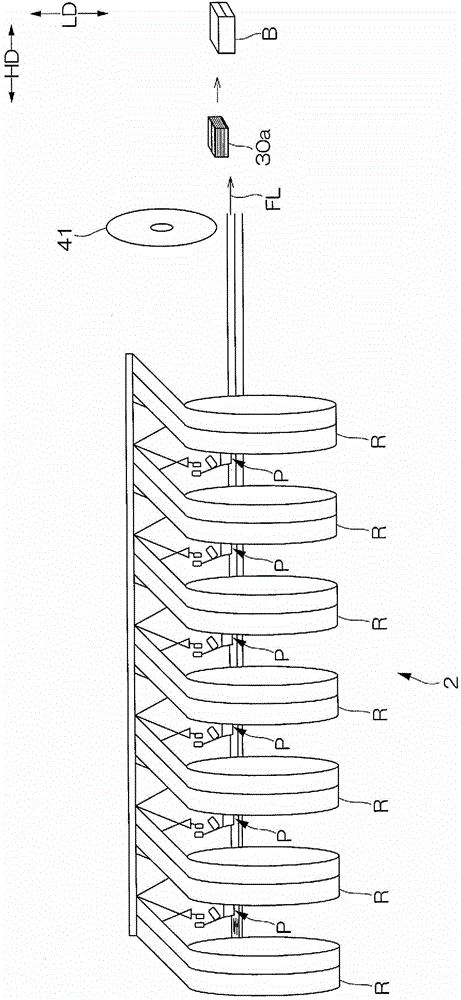

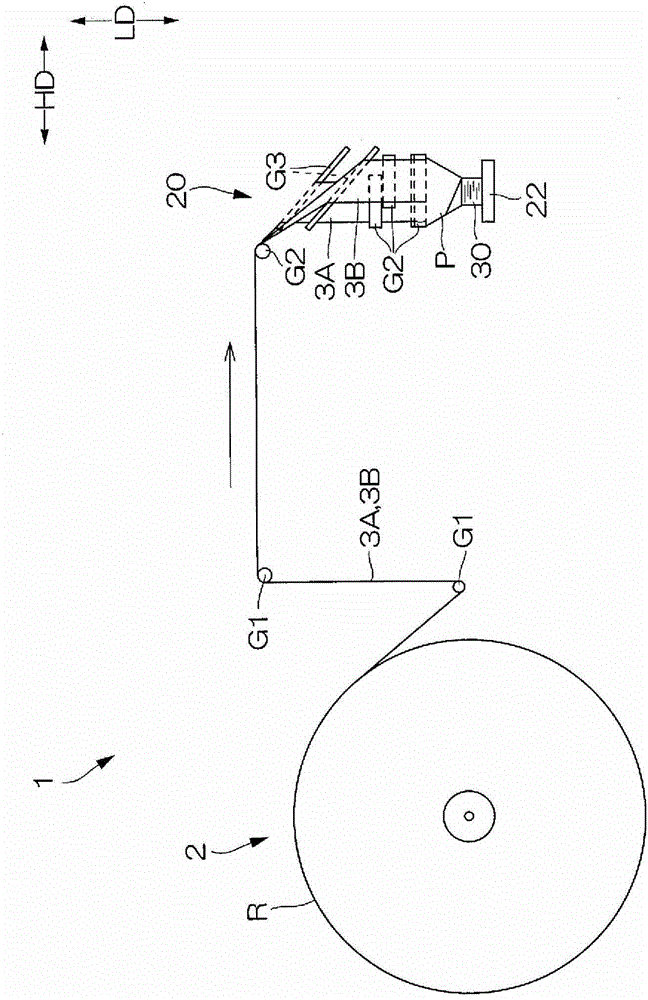

Method of manufacturing secondary whole roll for tissue paper product

ActiveCN102781298ALow costEasy to switchMechanical working/deformationPaper/cardboardChemical solutionEngineering

Disclosed is a method of manufacturing secondary whole rolls for a tissue paper product capable of preventing separation or displacement of layers of laminated continuous sheets to which chemical solution is applied. Specifically disclosed is a method of manufacturing secondary whole rolls for a tissue paper product, which comprises a laminating step (51) of forming a laminated continuous sheet (S2) by laminating primary continuous sheets (S1) fed from a plurality of primary whole rolls (JR); a contact embossing step (54) of contact embossing the laminated continuous sheet (S2) so as to prevent separation and displacement of the layers; a chemical-solution applying step (53) of applying chemical solution to the laminated continuous sheet (S2) after the contact embossing step (54); a slitting step (55) of slitting the laminated continuous sheet (S2) into sheets having a width or a several-fold width of a tissue paper product; and a coiling step (56) of forming a plurality of secondary whole rolls (R) having the width or the several-fold width of the tissue paper product by coaxially coiling the slit laminated continuous sheets (S2).

Owner:DAIO PAPER CORP

Production method of sizing mica paper

ActiveCN103132369BImprove surface adhesionReduce tensionSpecial paperPaper/cardboardViscosityImpurity

The invention provides a production method of sizing mica paper. Firstly, mica raw materials are crushed to mica raw pulp through a pulping machine, the mica raw pulp is conveyed to a papermaking pulp tank, and the papermaking pulp tank is filled with water through a container, bone glue with viscosity between 8 DEG C and 12 DEG C is added to the water, the volume of the added bone glue is 15% to 20% of the water mass, the water is heated by steam with the temperature between 70 DEG C and 90 DEG C so as to enable the bone glue to be dissolved in the water, insoluble impurities are filtered and bone glue solution is made, the bone glue solution and antifoaming agents are added to the papermaking pulp tank containing the mica raw pulp, the volume of the added bone glue solution is 4%. to 6%. of the total mass of the mica raw pulp in the papermaking pulp tank, the volume of the antifoaming agents is 0.005% to 0.015% of the total mass of the mica raw pulp in the papermaking pulp tank, the mica raw pulp, the bone glue solution and the antifoaming agents are mixed evenly, and eventually the mica paper is made in a papermaking molding mode through a mica paper machine, the mica paper is dried and the standard mica paper is produced. According to the production method of the sizing mica paper, adhesive force on the surface of lodicule in the production method of the mica paper can be improved, tensile force of the mica paper in the process of production is increased and the purpose of winding the paper easily is achieved.

Owner:PINGJIANG COUNTY CHUANG YI MICA PROD

A soaking surface sizing process

The invention discloses an immersed type surface gluing process and belongs to the technical field of gluing of paper products. The process is characterized in that the immersed type surface gluing process comprises the following steps: uniformly dispersing, cooking, lifting and spraying a gluing agent, extruding and coating glue through an upper glue roller and a lower glue roller, overflowing and returning the gluing agent, then removing impurities in the gluing agent through a vibration screen, then enabling the gluing agent to flow back to a dispersion tank again, successively circulatingrepeatedly to complete the operation of gluing paper products. The gluing process is capable of controlling the viscosity and the concentration of starch and controlling the diameter and the bucklingwidth of the upper glue roller and the lower glue roller so as to effectively reduce the occurrence of the phenomena of broken paper and improve the production efficiency of the paper; in addition, ahard rubber sleeve and a soft rubber sleeve are arranged, the phenomena of glue leakage of the upper glue roller and the lower glue roller are reduced; meanwhile, the probability of breakage of the paper is further reduced; and the production efficiency of the paper is improved.

Owner:嘉兴市荣晟包装材料有限公司

A new production method of dyed bovine bottom coated white board paper

ActiveCN106436458BImprove running stabilityLess holesPaper/cardboardPulp material addition processesWhiteboardDeinking

The present invention provides a novel dyeing kraft bottom coating white board paper production method, wherein online dyeing is performed on the 100% specific deinking base pulp mainly through three dyes such as a yellow dye, a black dye and a red dye. According to the present invention, the previous waste kraftpaper having the poor operating rate is adopted as the base pulp to replace the dyeing base pulp of the 100% specific deinking base pulp, such that the broken holes on the raw paper due to the pre-drying during the operating of the paper machine can be reduced, the paper breaking number can be reduced, the operating rate of the paper machine can be substantially improved, the A grade rate of the finished product can be improved, and the cost of per ton of the paper can be further reduced; and in the case of the same physical strength indicators, the back surface has characteristics of delicate appearance, dot reducing and good visual effects, and is favored by customers.

Owner:NINE DRAGONS PAPER IND TIANJIN

A method for remanufacturing antibacterial corrugated paper from waste paper sludge with high salinity and high hardness

ActiveCN110144745BReduces dehydrationReduce paper breaksDryer sectionPaper recyclingFiberWeather resistance

The invention discloses a method for reproducing antibacterial corrugated paper from high-salinity high-hardness waste paper sludge. Through a technical means of combining a physical method and a chemical method, the waste paper sludge is recovered and used for producing the corrugated paper with an antibacterial function, the sticker weight of waste paper fibers subjected to surface modificationis reduced by 2%, thus the difficulty level of dehydration during paper making of a paper machine is reduced, physical indexes of water absorption, ring crush and the like of the made paper are improved, paper breaking of the paper machine is reduced, the operating rate of the paper machine is improved, and no secondary pollution is caused for the environment; and primary corrugated paper obtainedthrough sizing treatment of the method already has very stable corrugated paper characteristics, has excellent extensibility, elastoplasticity, crack resistance, anti-permeability and weather resistance, can have effects of water prevention, seepage prevention and protection, and is prevented from being affected with damp, a water-resistant grade reaches an ISO 4 grade, and breeding of bacteria in the corrugated paper can be effectively avoided.

Owner:东莞顺裕纸业有限公司

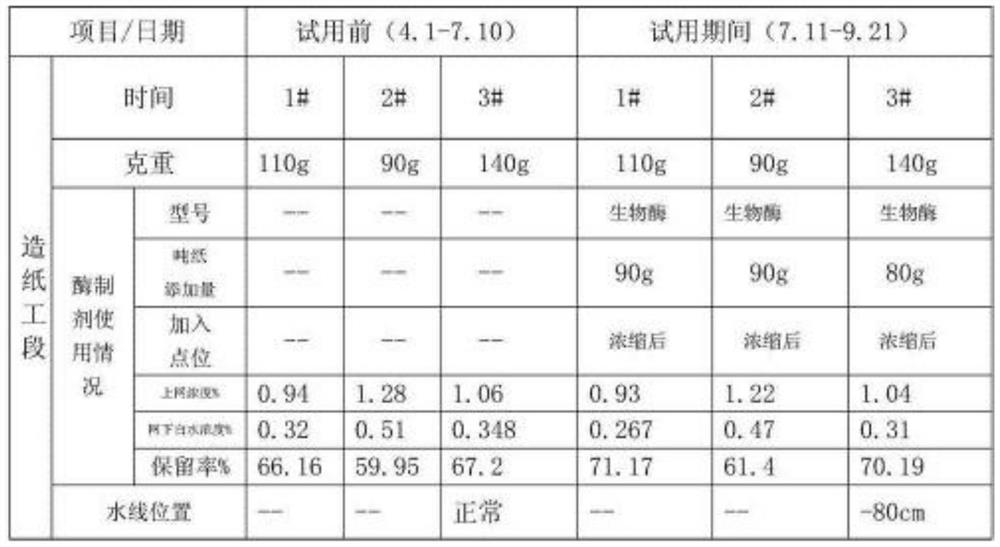

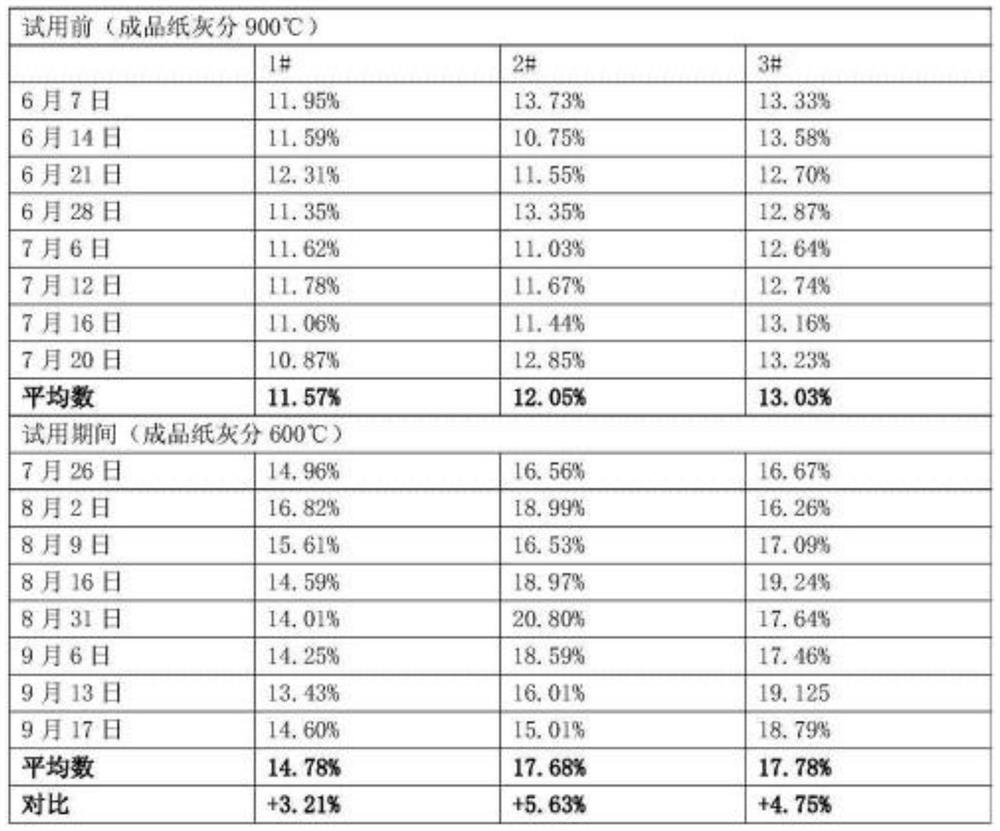

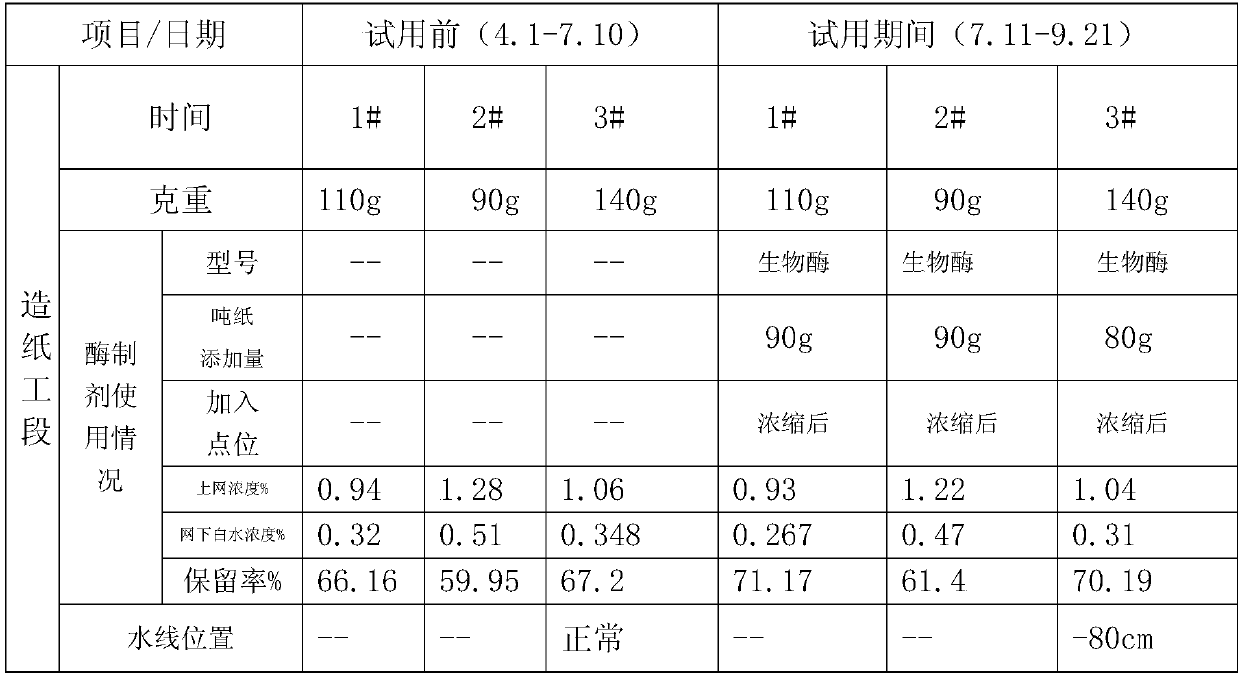

Bacillus cereus

ActiveCN107893039BReduce concentrationEasy to shapeBacteriaMicroorganism based processesBiotechnologyMicrobiology

The invention discloses a bacillus cereus (Bacillus cereus WENA703), which is preserved in the China Center for Type Culture Collection, and the preservation number is: CCTCC NO: M2017368. The enzyme-producing ability of the WENA703 strain is 50 times higher than that of the original starting strain (neutral endo-pectate lyase), and the performance is stable through more than 8 generations of passage. The strain has high enzyme-producing activity and good stability, and its action temperature (15°C-70°C) and action pH value (5.5-9.5) are relatively broad, and can maintain more than 80% of the enzyme activity.

Owner:嘉兴温华环保科技有限公司

Salt-reducing adsorbent used for papermaking production and preparation method and application thereof

InactiveCN110586044AStrong adsorptionEfficient use ofOther chemical processesWaste water treatment from plant processingCelluloseSorbent

The invention belongs to the field of papermaking technology and functional materials, and discloses a preparation and application of a salt-reducing adsorbent used for papermaking production. The preparation method of the salt-reducing adsorbent comprises the following steps: sulfonating cellulose and sulfonating reagent to generate sulfonated cellulose A; reacting dicyandiamide, acrylamide, hydrochloric acid and formaldehyde to obtain graft polymer B; mixing sulfonated cellulose A, grafted polymer B and initiator and reacting to obtain salt-reducing adsorbent. According to the invention, active groups such as sulfonic acid group, amino group and the like are introduced into cellulose through two graft modifications, and atoms such as N, S, O and the like in these groups can provide lonepair electrons in the adsorption process and further form complexes with metal ions, so that metal ions in the solution are adsorbed. At the same time, cellulose is also rich in hydroxyl groups, and lone pair electrons on each group can cooperate to adsorb free metal ions more stably. In addition, the branched chain can make better use of space and better wrap and adsorb metal ions.

Owner:广东二十四克垃环保科技有限公司

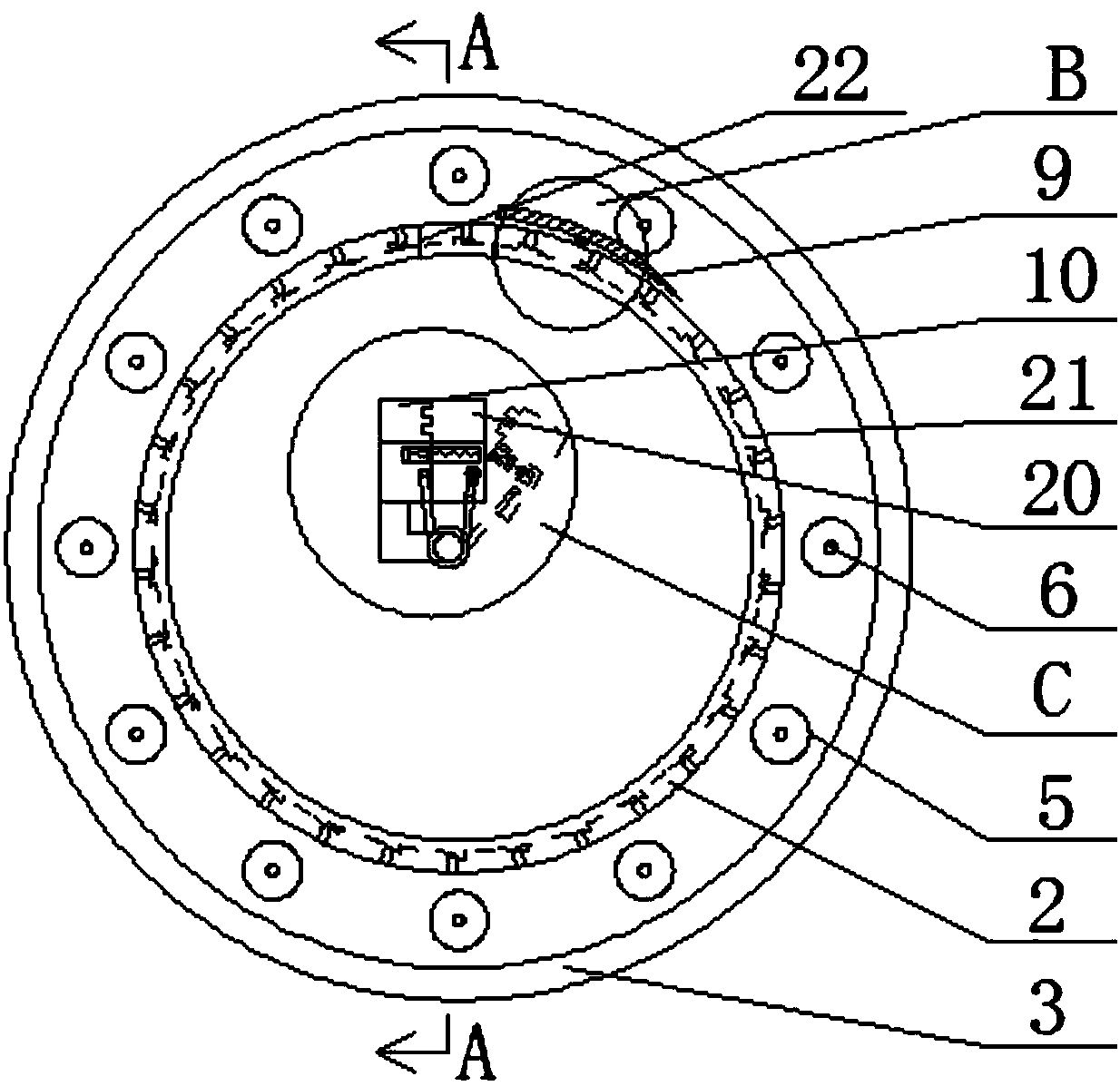

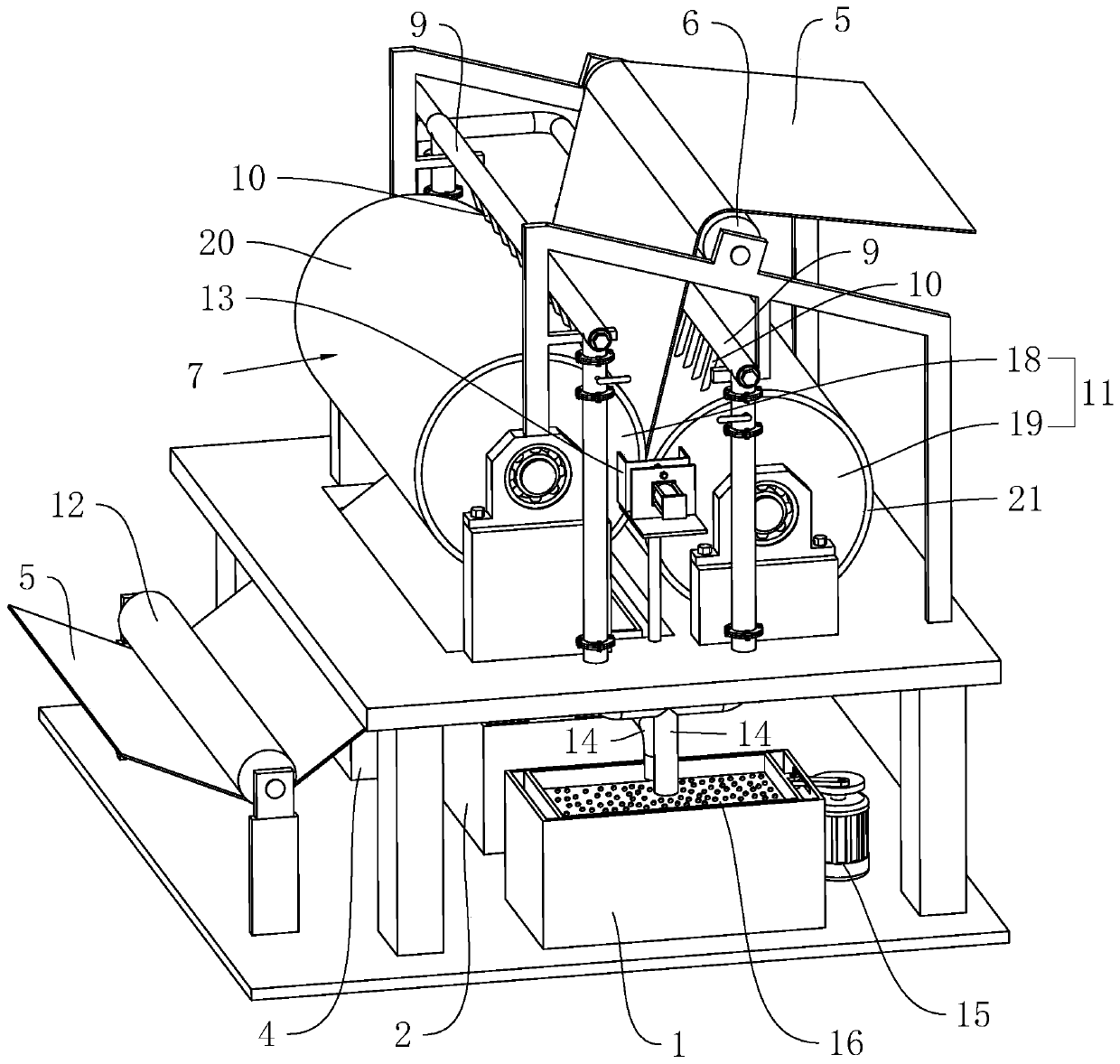

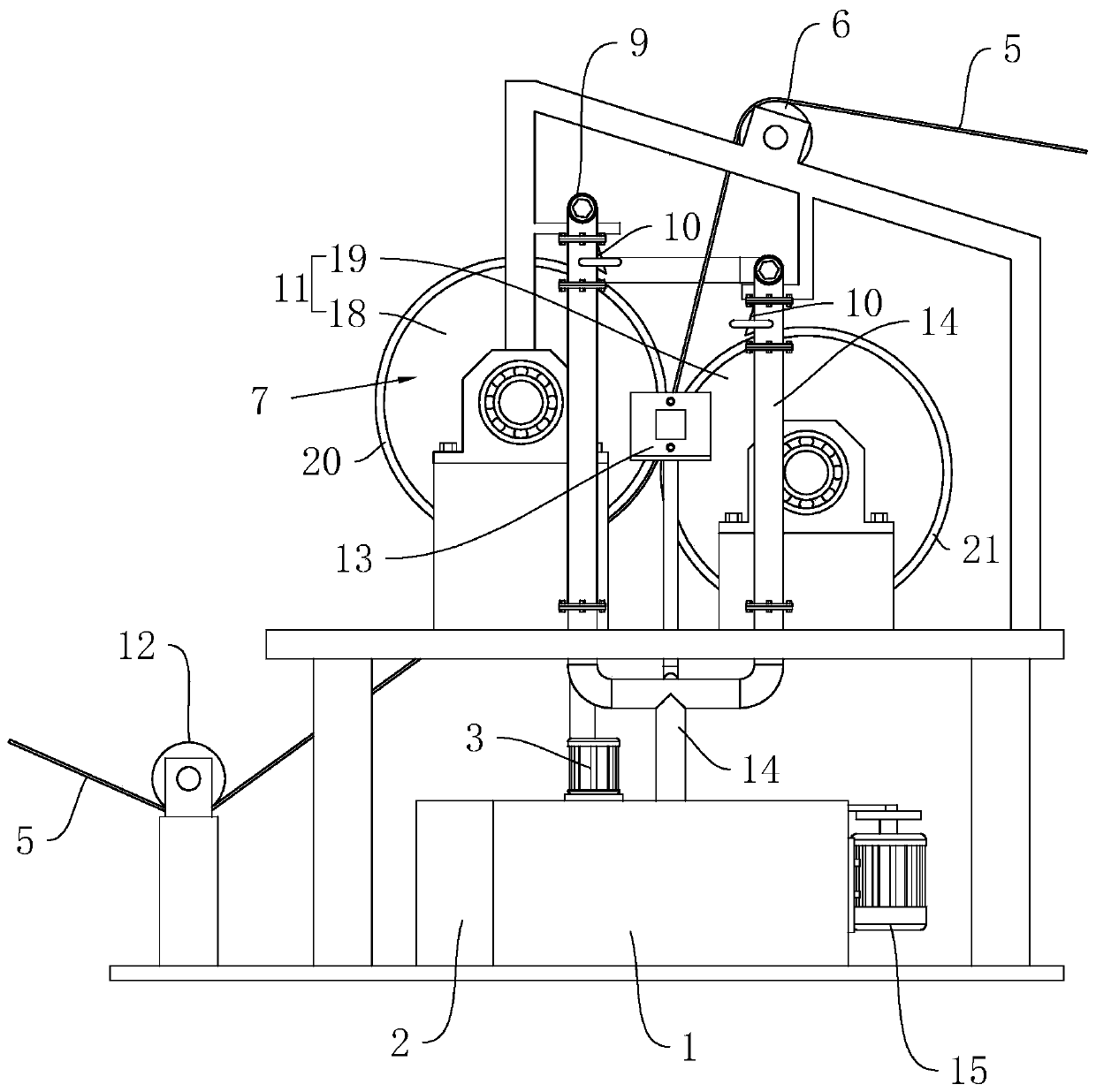

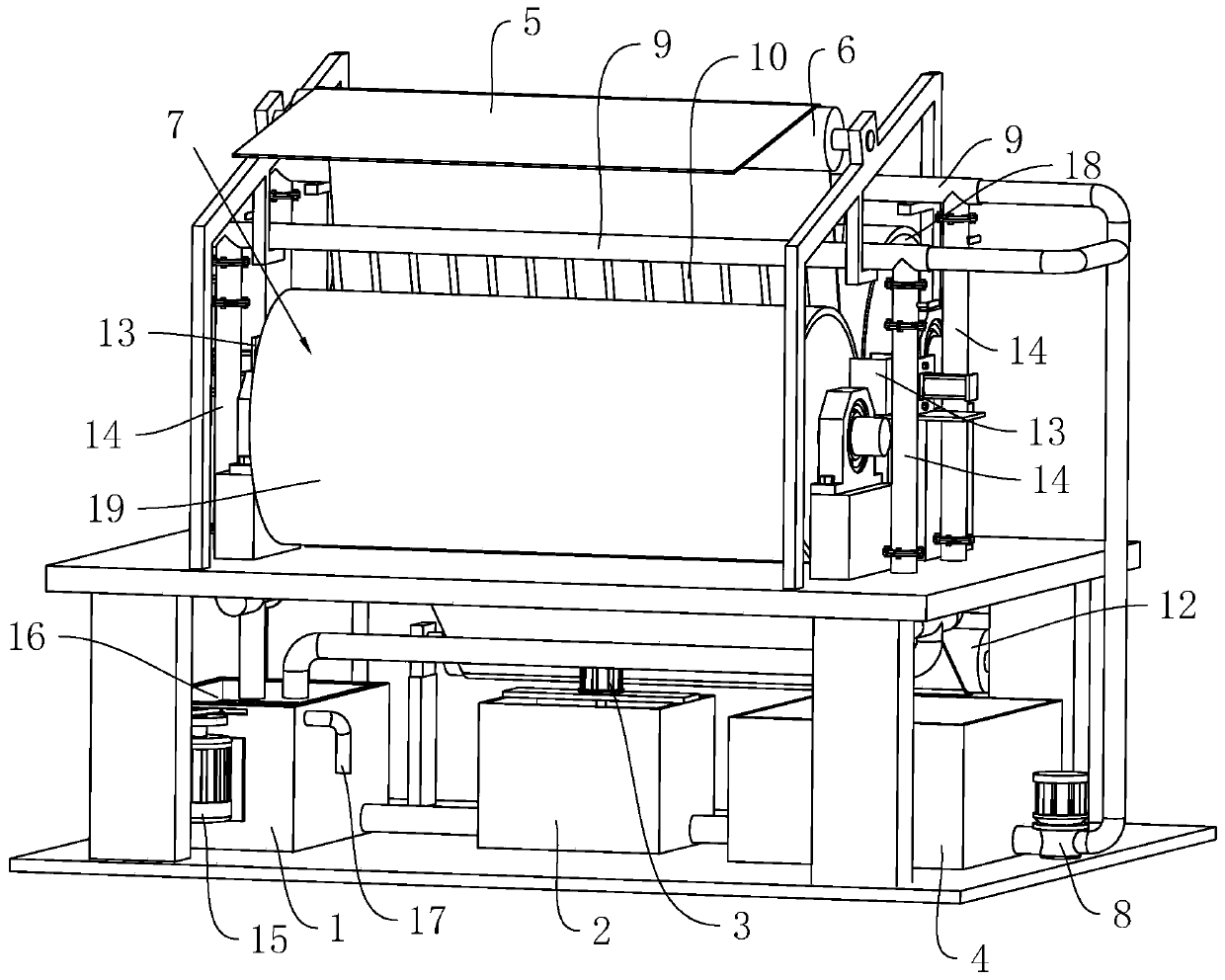

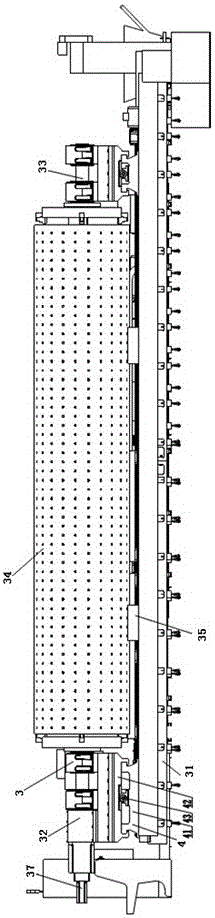

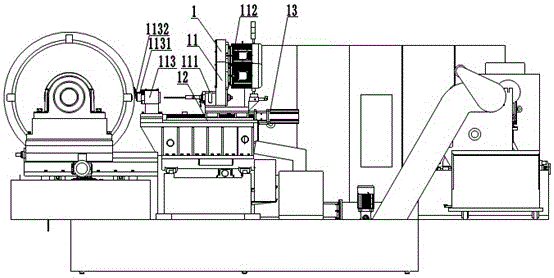

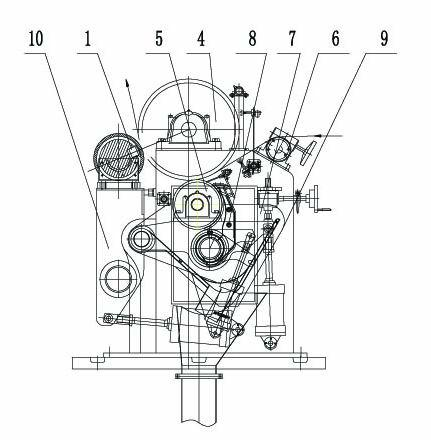

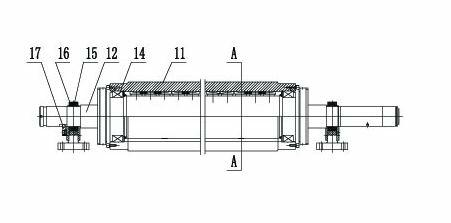

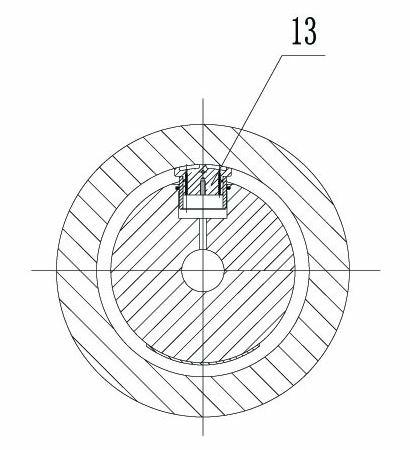

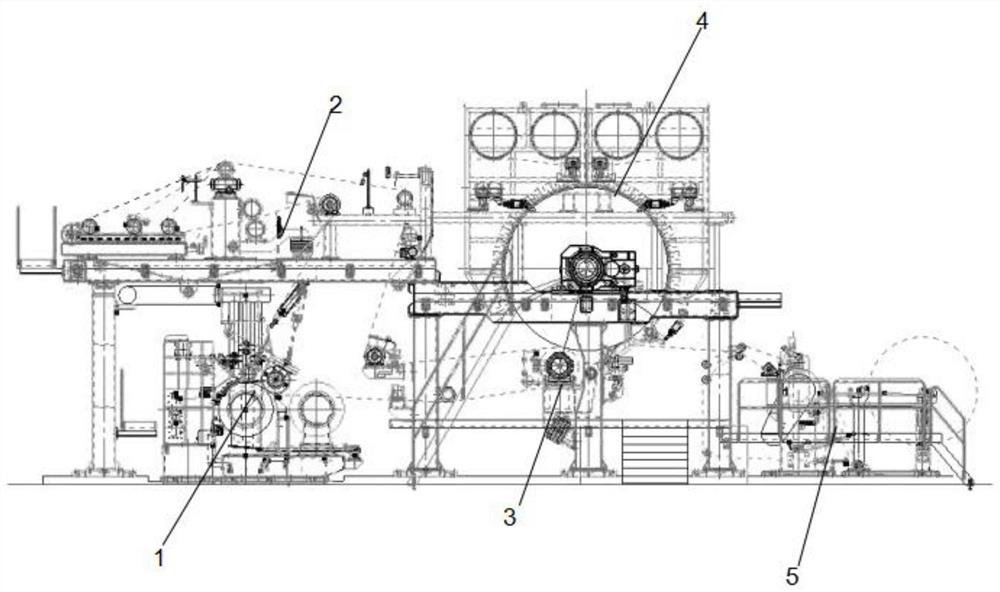

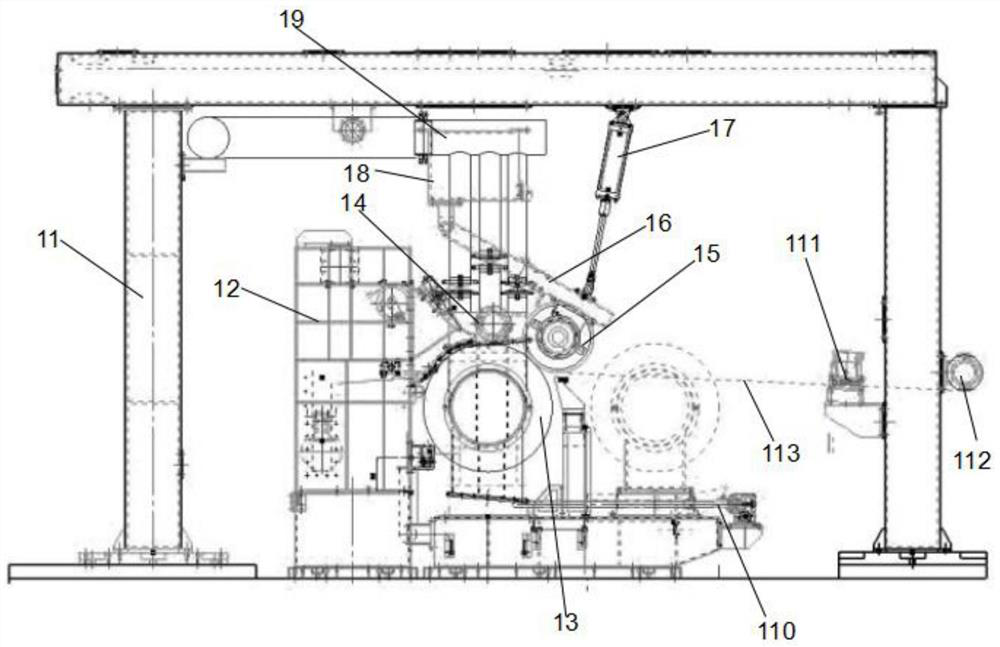

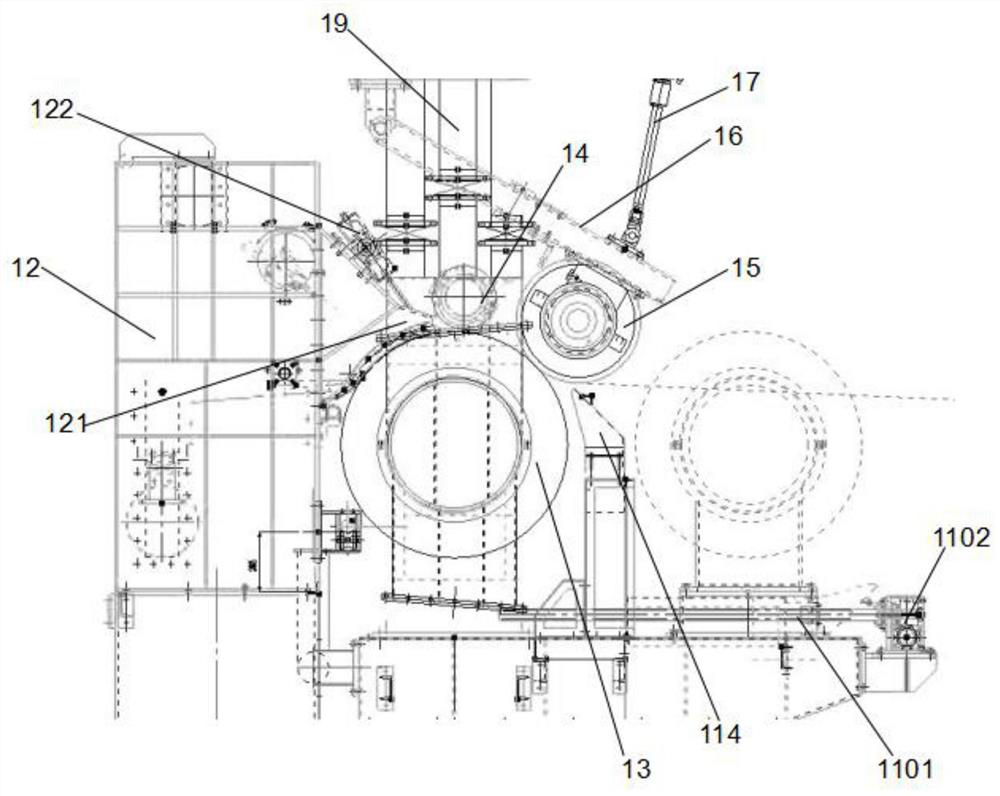

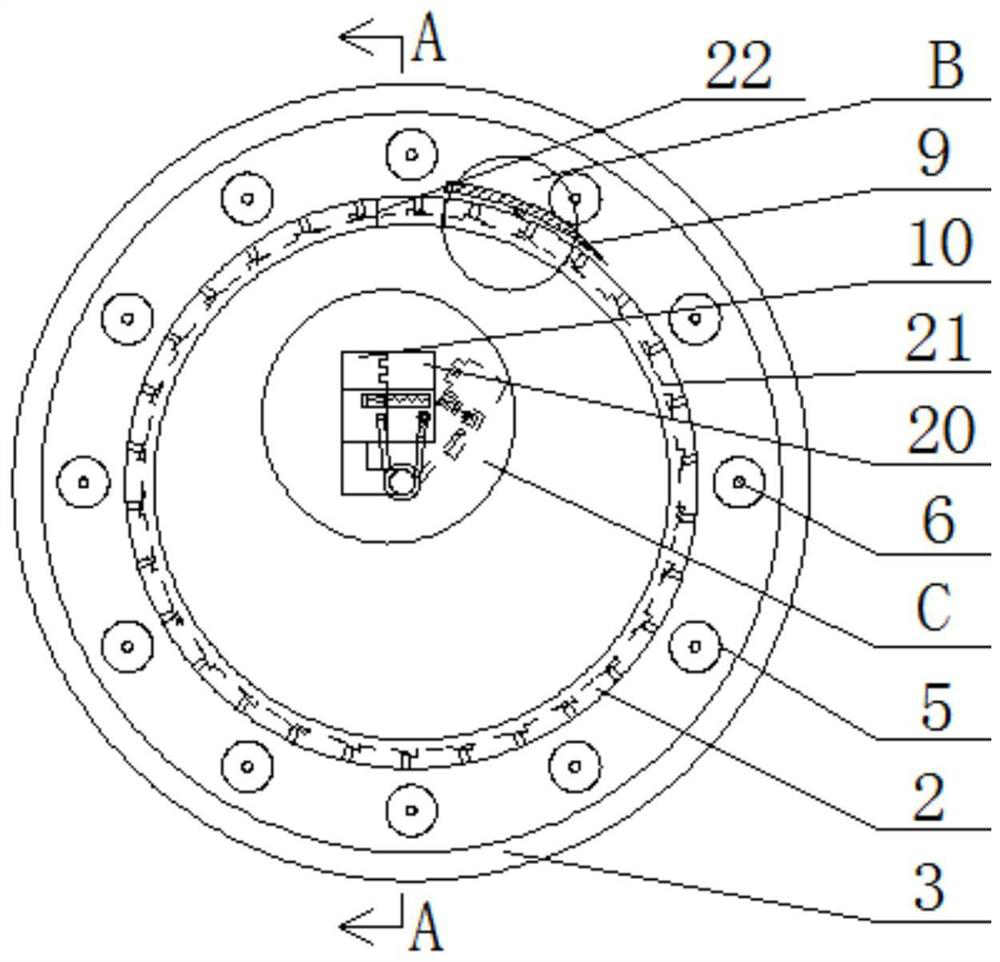

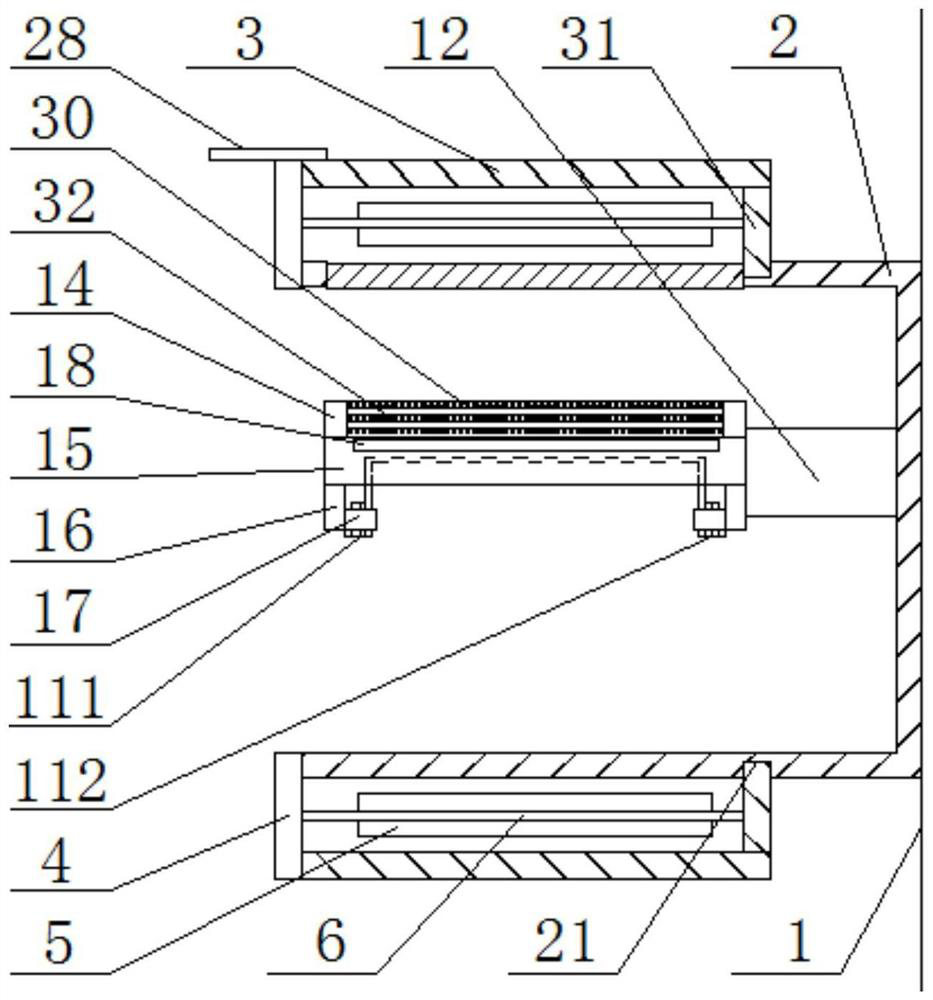

A CNC deep hole drilling machine tool for processing group holes on the outer circle of rollers

ActiveCN103978247BEasy to operateImprove performanceBoring/drilling machinesSurface finishNumerical control

The invention relates to a numerical-control deep hole drill machine tool for processing group holes in an outer circle of a roller. The numerical-control deep hole drill machine tool is characterized by comprising a hole drilling movement mechanism, a transverse shifting movement mechanism, a work-piece dividing movement mechanism and an oil supply filtering mechanism; the hole drilling movement mechanism comprises five groups of drilling units and five groups of numerical-control sliding tables; the transverse shifting movement mechanism comprises a tool body, a lead screw transmission assembly, a large carriage and a servo motor, wherein the tool body is mounted on the ground; the lead screw transmission assembly driven by the servo motor is mounted on the tool body and connected with the large carriage; the work-piece dividing movement mechanism comprises a workbench, a driving rotating device, a driven rotating device, a work-piece, a carrier roller, a transverse shifting assembly and another servo motor; the oil supply filtering mechanism consists of a high-pressure oil supply device and a filtering device. With the adoption of the numerical-control deep hole drill machine tool, the processing efficiency and processing precision, in particular the degree of finish of processed holes, are improved; processed deep holes are effectively prevented from floccule hanging on a wall with the extremely high surface finish, and therefore, the portability that a hole of the roller is blocked can be greatly reduced, the use efficiency is improved, and the maintenance cost can be decreased.

Owner:SHANGHAI NINGYUAN PRECISION MACHINERY

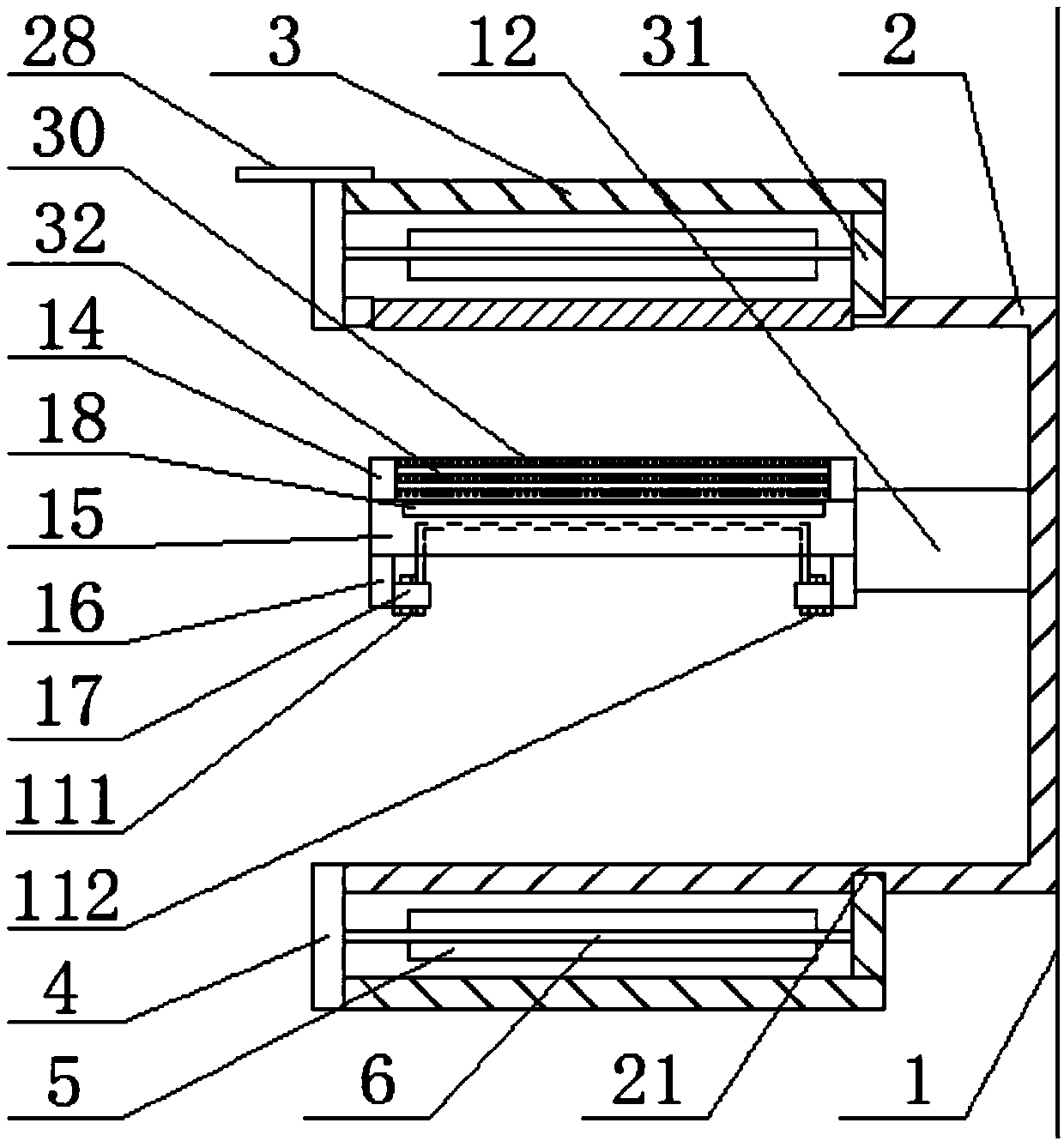

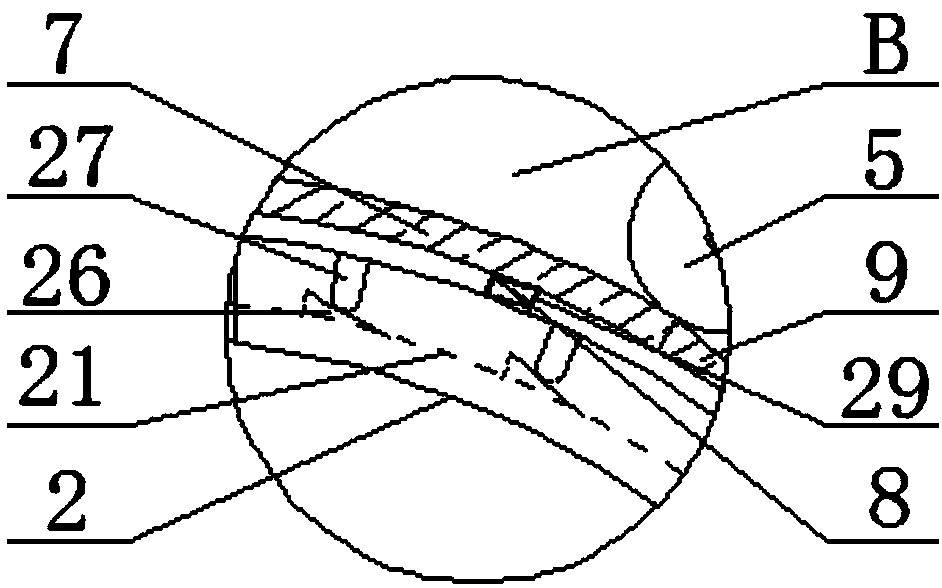

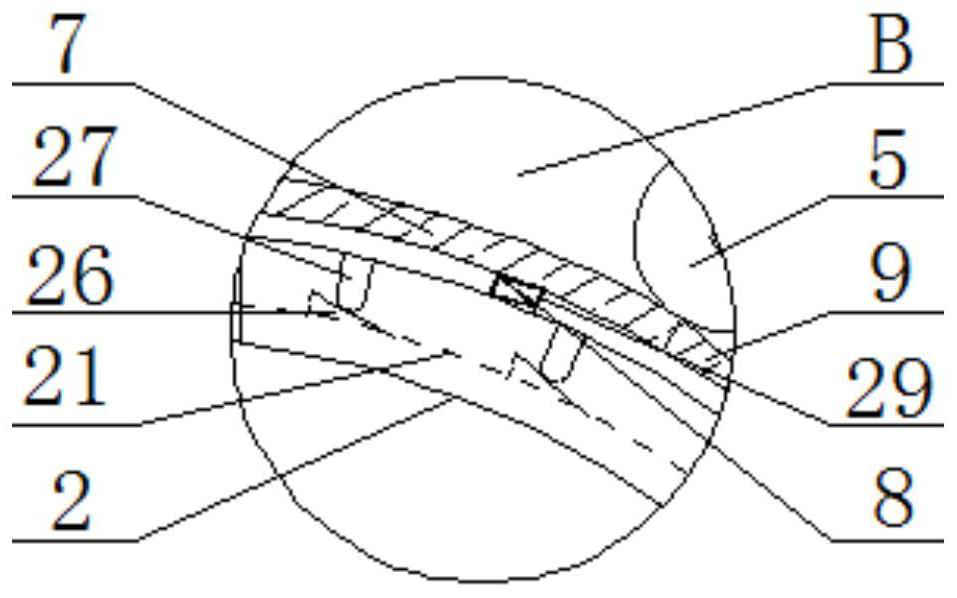

Static-pressure sectional controllable spreader

The invention relates to a static-pressure sectional controllable spreader, which belongs to the technical field of paper making machinery and comprises a static-pressure sectional controllable roll, a backup roll, a feeding roll, an arc-shaped roll, a spreading groove, a flow guide plate, a framework and the like. The backup roll is mounted on the upper portion of the framework by a bearing, the static-pressure sectional controllable roll is mounted on one side of the backup roll, the arc-shaped roll is mounted on the other side of the backup roll, the feeding roll is mounted on the lower portion of the backup roll, the static-pressure controllable roll and the feeding roll are respectively meshed with the backup roll, and the flow guide plate and the spreading groove are mounted on one side of the feeding roll. The static-pressure sectional controllable roll replaces a scraper beam or scraper bar, the static-pressure sectional controllable spreader is supplemented with a control device, precision adjustment is realized, the horizontal spreading quantity can be controlled, paper loss and paper breakage are avoided, the quality of a product is good, the static-pressure sectional controllable spreader is high in production efficiency and convenient in operation, and cost is saved. In addition, the static-pressure sectional controllable spreader solves the problems that in the prior art, paper cannot be dried easily and buckles due to uneven horizontal spreading quantity, damage to parts is severe, and production efficiency and the quality of a paper machine are seriously affected, and paper loss and paper breakage are often caused.

Owner:SHASHI LIGHT IND MACHINERY

Bacillus cereus

ActiveCN107893039AImprove enzyme production capacityImprove stabilityBacteriaMicroorganism based processesMicrobiologyBacillus cereus

The invention discloses Bacillus cereus WENA703, which is preserved in the China Center for Type Culture Collection and is assigned with the accession number of CCTCC NO: M2017368. Compared with the activity of an original strain (neutral incision pectate lyase), the enzyme production capacity of the WENA703 strain is improved by 50 times, and the passage for more than 8 generations shows that theperformance is stable. The strain is high in enzyme production activity, good in stability, and wide in action temperature (15 DEG C-70 DEG C) and action pH value (5.5-9.5), and 80% or above of the enzyme activity can be kept.

Owner:嘉兴温华环保科技有限公司

Electrothermal high-temperature-resistant carbon fiber paper and preparation method thereof

ActiveCN103451989BHigh mechanical strengthEasy to operateSynthetic cellulose/non-cellulose material pulp/paperFiberPapermaking

The invention discloses pulp of electrothermal high-temperature-resistant carbon fiber paper. Fiber in the pulp comprises the following components in percentage by weight: 40-70% of carbon fiber I, 5-30% of carbon fiber II and 5-30% of meta-aromatic acrylic fibrid, wherein the length of the carbon fiber I is 1-5mm, and the fiber number is 1.5D; the length of the carbon fiber II is 8-10mm, and the fiber number is 1.5D; the pulp beating degree of the meta-aromatic acrylic fibrid is 40-80 degree SR. The invention further discloses a preparation method of the pulp, meta-aromatic acrylic fibrid / carbon fiber composite electrothermal high temperature-resistant carbon fiber paper prepared by using the pulp and a preparation method thereof. According to the method disclosed by the invention, the mechanical strength and the operability of the composite paper are significantly improved, paper breaking during papermaking is reduced, the production efficiency is improved, the temperature resistance level and the flame retardance of the composite carbon fiber paper are simultaneously upgraded, and the safety performance is improved.

Owner:YANTAI METASTAR SPECIAL PAPER

A kind of manufacturing process of single-sided see-through sticker

ActiveCN105479919BHigh densityImprove release forceLaminationLamination apparatusHazardous substanceWork in process

The invention relates to the technical field of building decoration materials, in particular to a manufacturing process of a single-sided see-through sticker. A manufacturing process for a single-sided see-through sticker includes the following manufacturing steps: raw material preparation stage, equipment preparation stage, lamination operation, silicon coating operation, coating operation, punching operation, lamination operation and surface treatment to obtain a finished product. Due to the adoption of the above technical solution, the present invention reduces the diameter of the product in the semi-finished product, improves the utilization rate of the mold, and effectively improves the production efficiency; To ensure that the release of harmful substances in the production process has been controlled, energy saving and environmental protection.

Owner:SHANGHAI HANKER PLASTICS

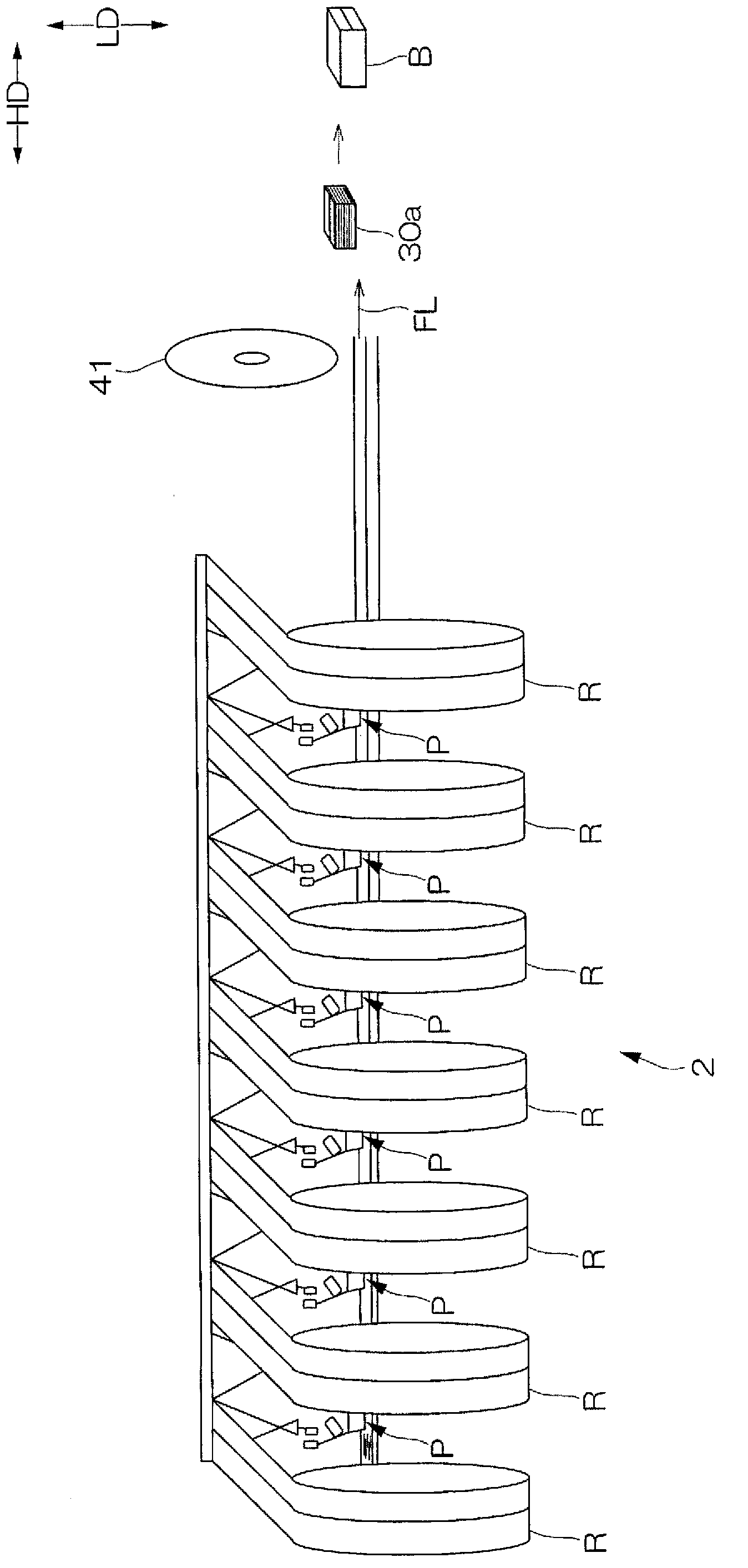

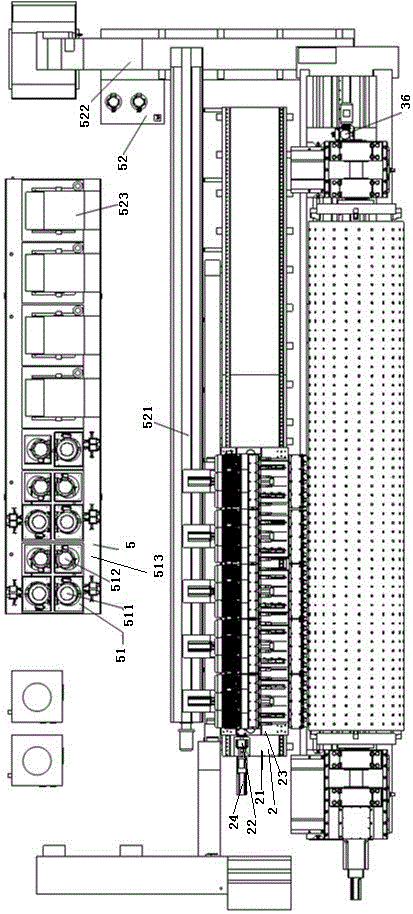

High-speed vacuum cylinder paper machine

InactiveCN111979830AWon't fallImprove molding qualityDryer sectionMachine wet endRolling paperToilet paper

The invention provides a high-speed vacuum cylinder paper machine. The high-speed vacuum cylinder paper machine comprises a vacuum cylinder forming part, a vacuum pressing part, a wet paper web transferring part, a drying part, a paper guiding part and a paper winding part, wherein the vacuum pressing part is installed on the rear side of the vacuum cylinder forming part; the wet paper web transferring part is installed between the vacuum pressing part and the vacuum cylinder forming part; the drying part is installed on the rear side of the vacuum pressing part; the paper winding part is installed on the rear side of the drying part; and the paper guiding part is installed between the paper winding part and the drying part. According to the high-speed vacuum cylinder paper machine, through the structural optimization design of the vacuum cylinder forming part, the wet paper web transferring part, the drying part and the paper guiding and winding parts, the position of a vacuum cylinder is adjustable, the paper sheet forming quality is good, a wet paper web and a dry paper web are not prone to paper breaking in a transferring process, the drying efficiency is high, and high-speed and high-quality production of toilet paper can be achieved.

Owner:肇庆万隆纸业有限公司

Para-aramid paper for honeycomb material and preparation method thereof

ActiveCN102899959BReduce water repellencyImprove dispersion compatibilityPulp beating methodsPaper/cardboardPolyesterPapermaking

Owner:SHAANXI UNIV OF SCI & TECH

Method of manufacturing secondary whole roll for tissue paper product

ActiveCN102781298BLow costEasy to switchMechanical working/deformationPaper/cardboardChemical solutionEngineering

Disclosed is a method of manufacturing secondary whole rolls for a tissue paper product capable of preventing separation or displacement of layers of laminated continuous sheets to which chemical solution is applied. Specifically disclosed is a method of manufacturing secondary whole rolls for a tissue paper product, which comprises a laminating step (51) of forming a laminated continuous sheet (S2) by laminating primary continuous sheets (S1) fed from a plurality of primary whole rolls (JR); a contact embossing step (54) of contact embossing the laminated continuous sheet (S2) so as to prevent separation and displacement of the layers; a chemical-solution applying step (53) of applying chemical solution to the laminated continuous sheet (S2) after the contact embossing step (54); a slitting step (55) of slitting the laminated continuous sheet (S2) into sheets having a width or a several-fold width of a tissue paper product; and a coiling step (56) of forming a plurality of secondary whole rolls (R) having the width or the several-fold width of the tissue paper product by coaxially coiling the slit laminated continuous sheets (S2).

Owner:DAIO PAPER CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com