Production method of regenerated ultralow-gram-weight high-strength corrugated base paper

A technology of corrugated base paper and production method, which is applied in the field of papermaking, can solve problems such as difficulties, increase processing load, hinder the process of low-quantity high-strength corrugated base paper, and achieve the effect of eliminating imported foreign garbage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

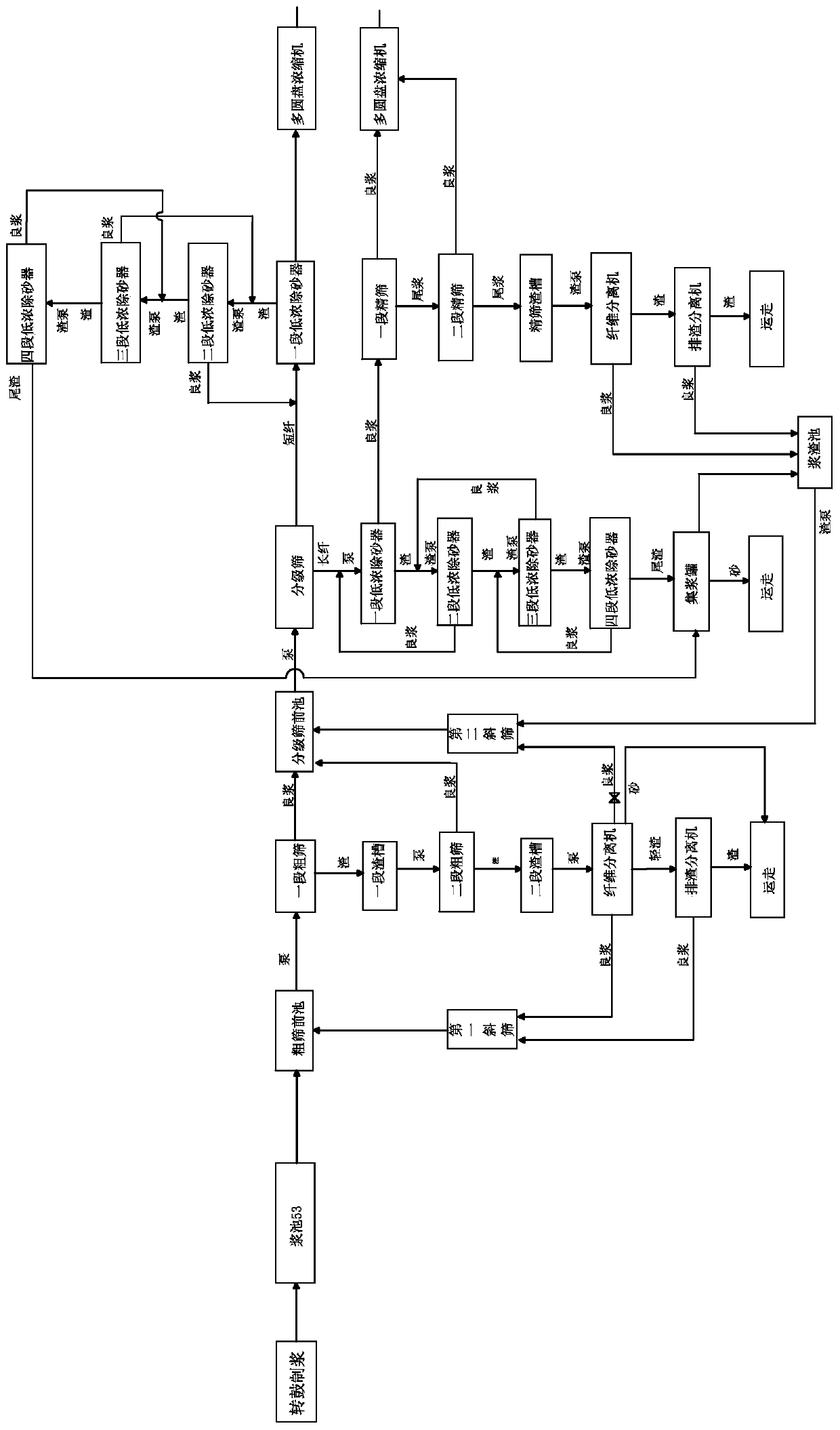

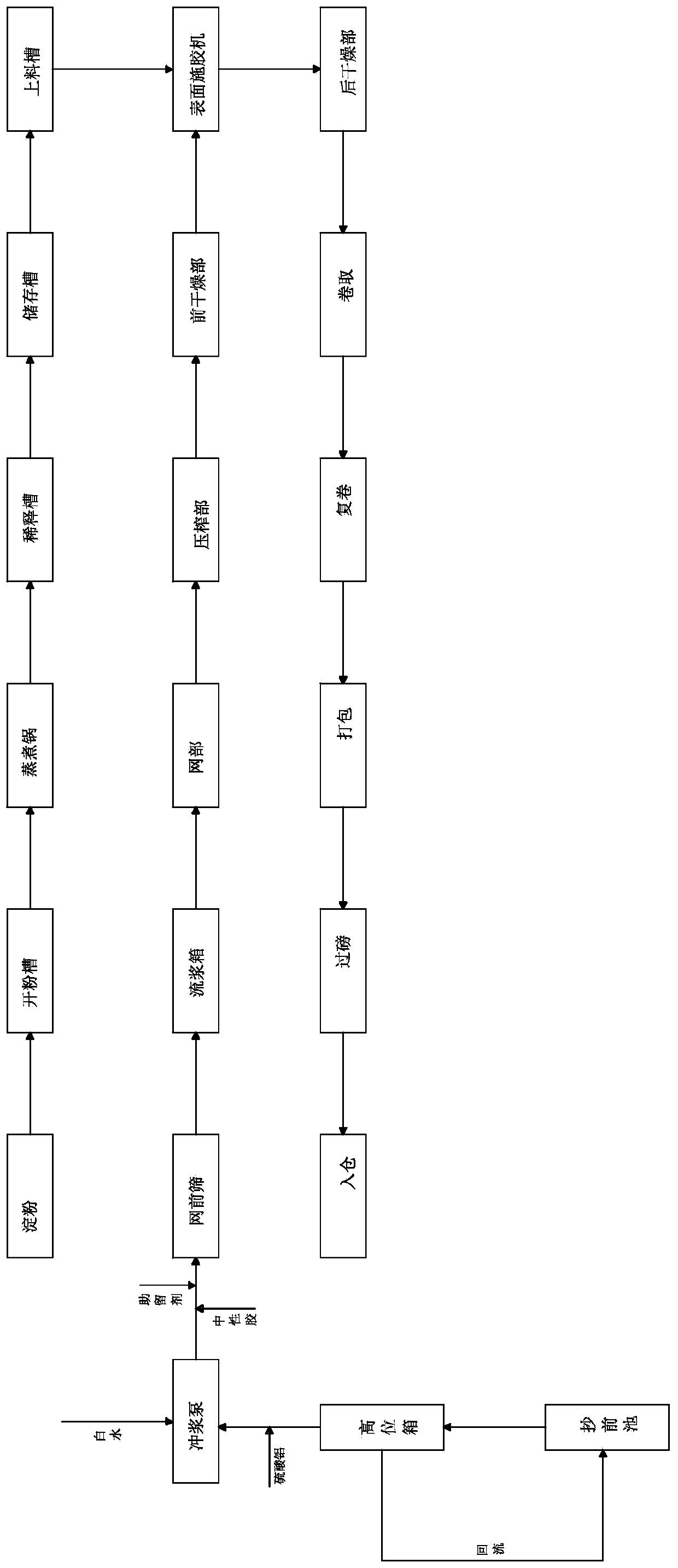

[0075] A method for producing regenerated ultra-low grammage high-strength corrugated base paper, comprising the steps of:

[0076] A: Drum pulping, the domestic OCC waste paper raw materials are made into pulp through the drum pulping device;

[0077] B: Coarse sieve, the slurry made into slurry through the drum device is screened by pressure sieve;

[0078] C: Grading sieve, classifying and sieving the coarsely screened pulp to divide the fibers into long fibers and short fibers;

[0079] D: short fiber purification treatment, the short fiber obtained by grading screen is purified by low-concentration desander;

[0080] E: Long fiber purification treatment, the long fiber obtained by grading screen is purified by low-concentration desander;

[0081] F: long fiber fine sieve, fine sieve for the purified long fiber;

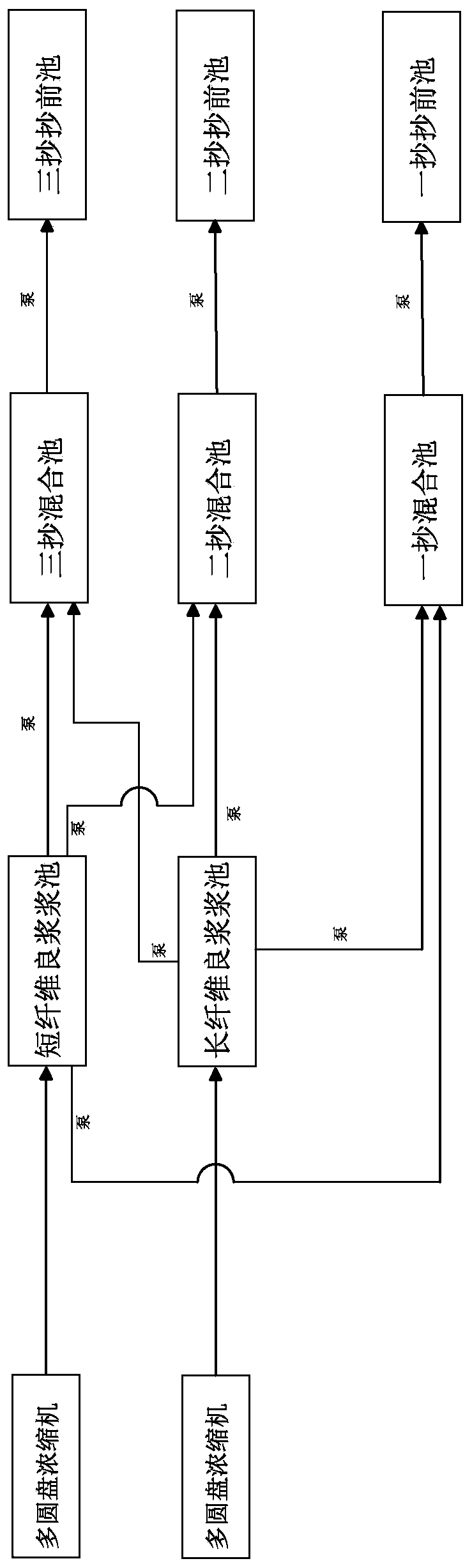

[0082] G: Concentrate short fiber, concentrate the purified short fiber good stock, and store it in the short fiber good stock tank;

[0083] H: Concentrate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com