Machining method and tool for elastic check rings

A technology for retaining rings and processing methods, which is applied in the fields of tool manufacturing, wire processing, metal processing, etc., can solve the problems of difficult processing of retaining rings, etc., and achieve the effects of improving processing efficiency and processing quality, and controlling deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

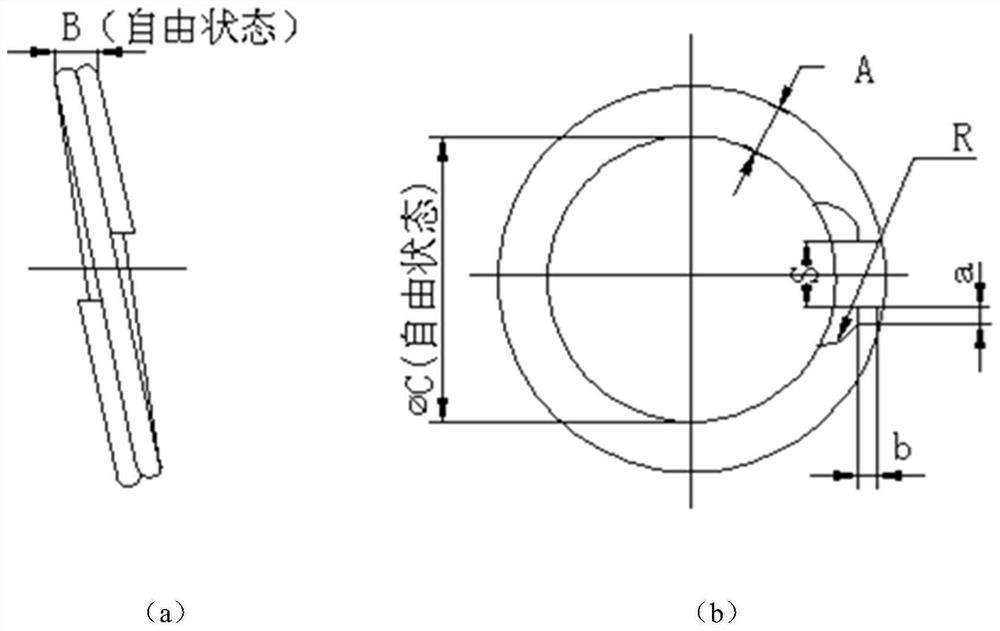

[0049] see figure 1 In (a) and (b), the processing method of the retaining ring of the present invention is used to process the outer retaining ring, the raw material of the outer retaining ring is 75Mn flat steel wire, the standard is WS9-S203 flat wire-96, and the state is annealed.

[0050] The illustrated outlines refer to two circlip parts of different sizes, the specific dimensions are shown in Table 1 respectively.

[0051] Table 1 Outer retaining ring retaining ring number and corresponding size

[0052]

[0053] For the above-mentioned circlip, the processing method of the present invention comprises the following steps:

[0054] 1. Winding

[0055] The CNC-620 automatic spring winding machine is used to wind the spring according to the dimensions shown in Table 1. When programming, first set the starting points of all X, Y, and Z axes as 0, and program while manually winding. After the test piece meets the requirements, start the program to start automatic wind...

Embodiment 2

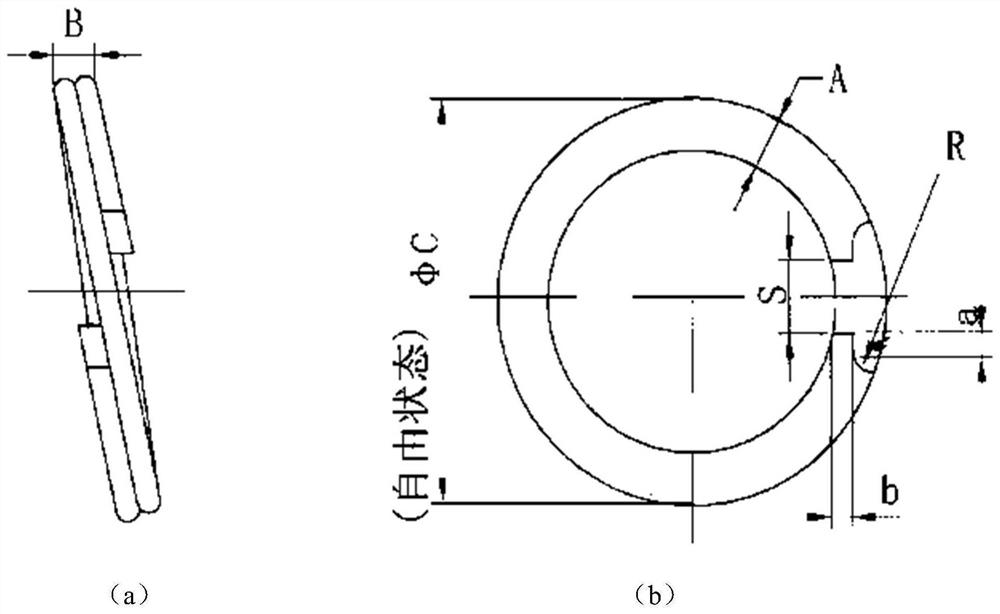

[0076] see figure 2 In (a) and (b), adopt the processing method of the circlip of the present invention to process the inner retaining ring, the inner retaining ring raw material is 75Mn flat steel wire, the standard is WS9-S203 flat wire-96, and the state is annealing.

[0077] The ring numbers and specific size requirements corresponding to the inner ring shown in the figure are shown in Table 2.

[0078] Table 2 Numbers and corresponding dimensions of inner retaining rings

[0079]

[0080] For the above-mentioned circlip, the processing method of the present invention comprises the following steps:

[0081] 1. Winding

[0082] Adopt CNC-620 automatic spring winding machine, and carry out spring winding according to the dimensions shown in Table 2. Note that when programming, first set the starting points of all X, Y, and Z axes as 0, and program while manually winding, and start the program after the test piece meets the requirements. During winding, spot check the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com