Patents

Literature

33results about How to "Meet anti-rust requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

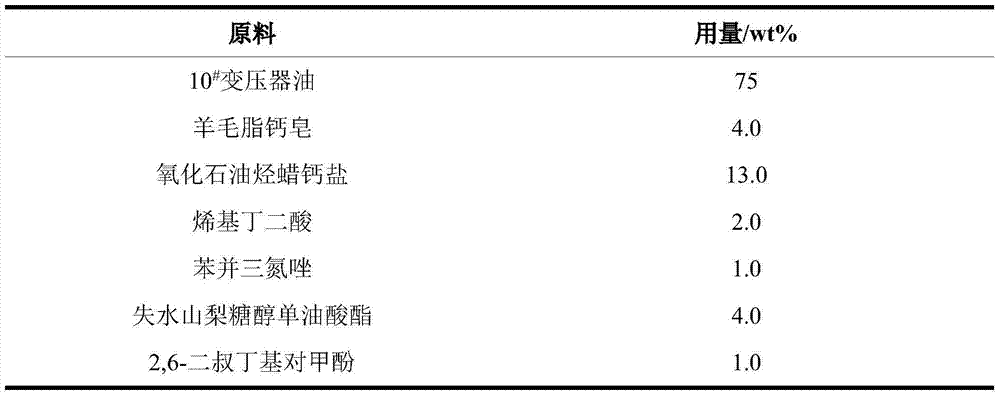

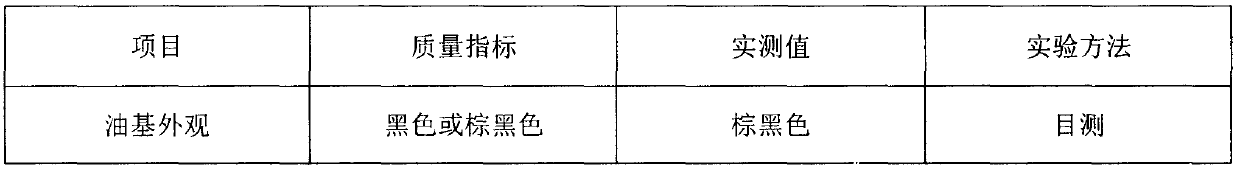

Environment-friendly electrostatic spraying antirust oil and preparation method thereof

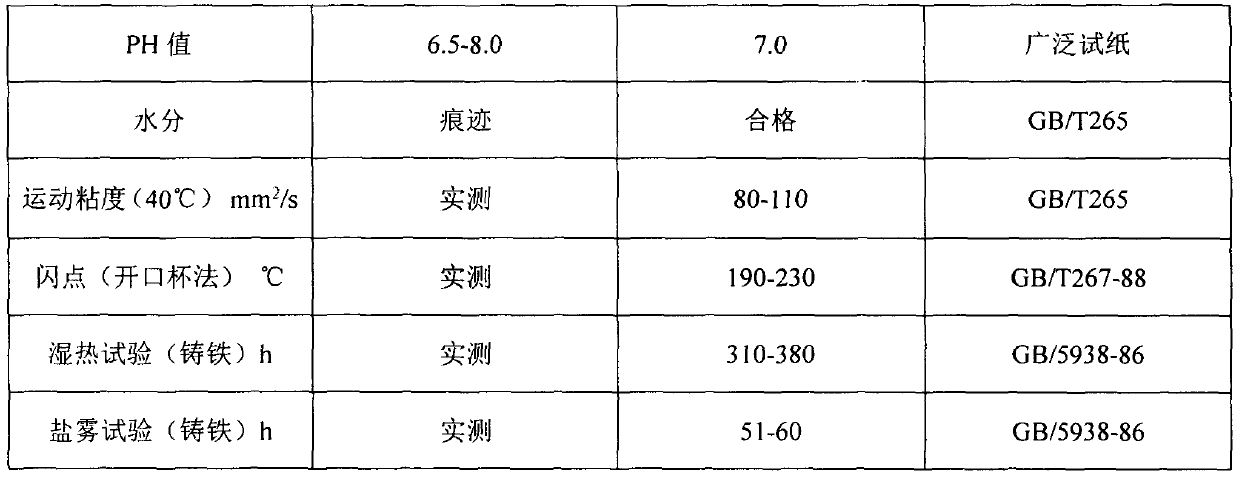

The invention discloses an environment-friendly electrostatic spraying antirust oil which is prepared from the following raw materials in percentage by mass: 70.0-90.0% of base oil, 5.0-25.0% of rust inhibitor, 1.0-5.0% of surfactant and 0.5-5.0% of antioxidant. The preparation method of the environment-friendly electrostatic spraying antirust oil comprises the following steps: mixing the measured base oil, rust inhibitor, surfactant and antioxidant, heating, and stirring uniformly to obtain the environment-friendly electrostatic spraying antirust oil. The antirust oil has the advantages of higher breakdown voltage, high safety, high atomization tendency of the oil product and low viscosity, and is convenient for cleaning; and the antirust oil can satisfy the requirement for antirust properties and conform to the requirement for environmental protection.

Owner:广州中机实业有限公司 +1

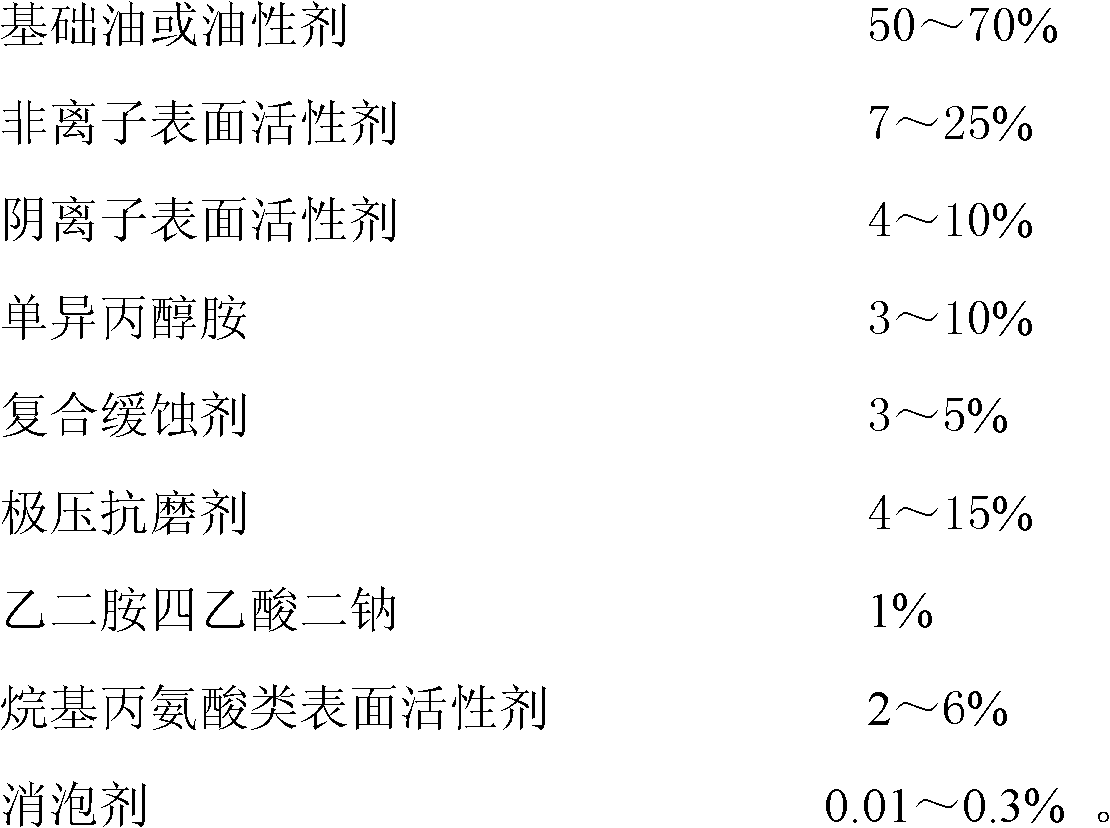

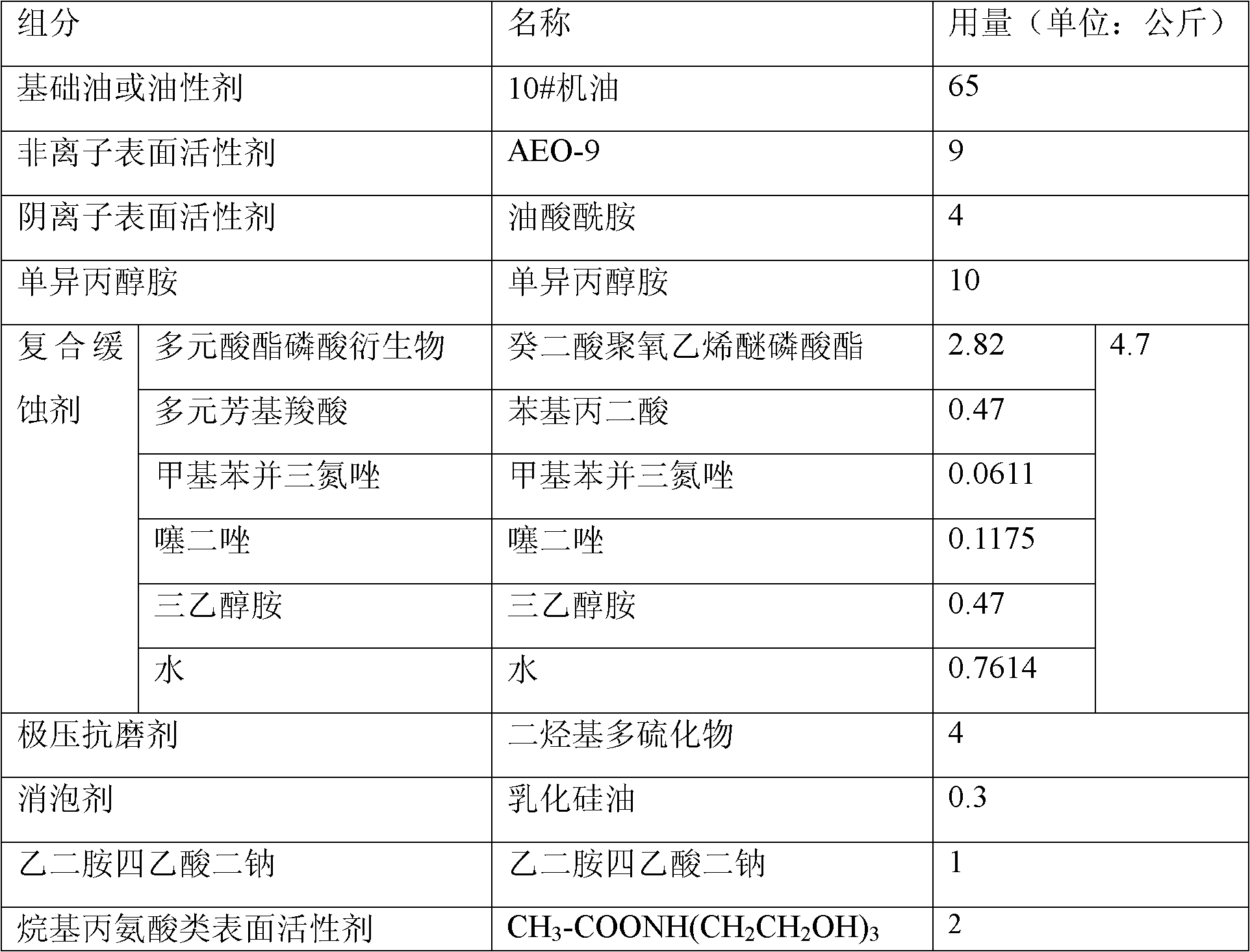

Self-bacteriostasis general emulsion cutting fluid and preparing method thereof

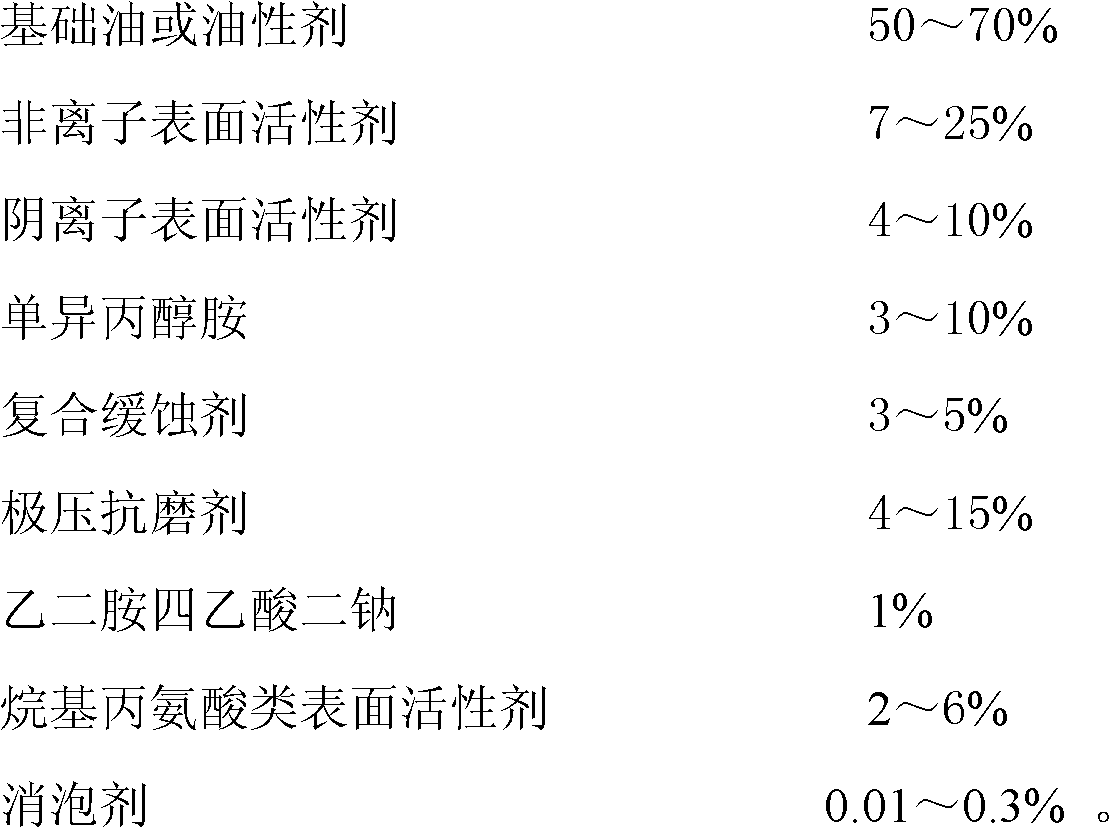

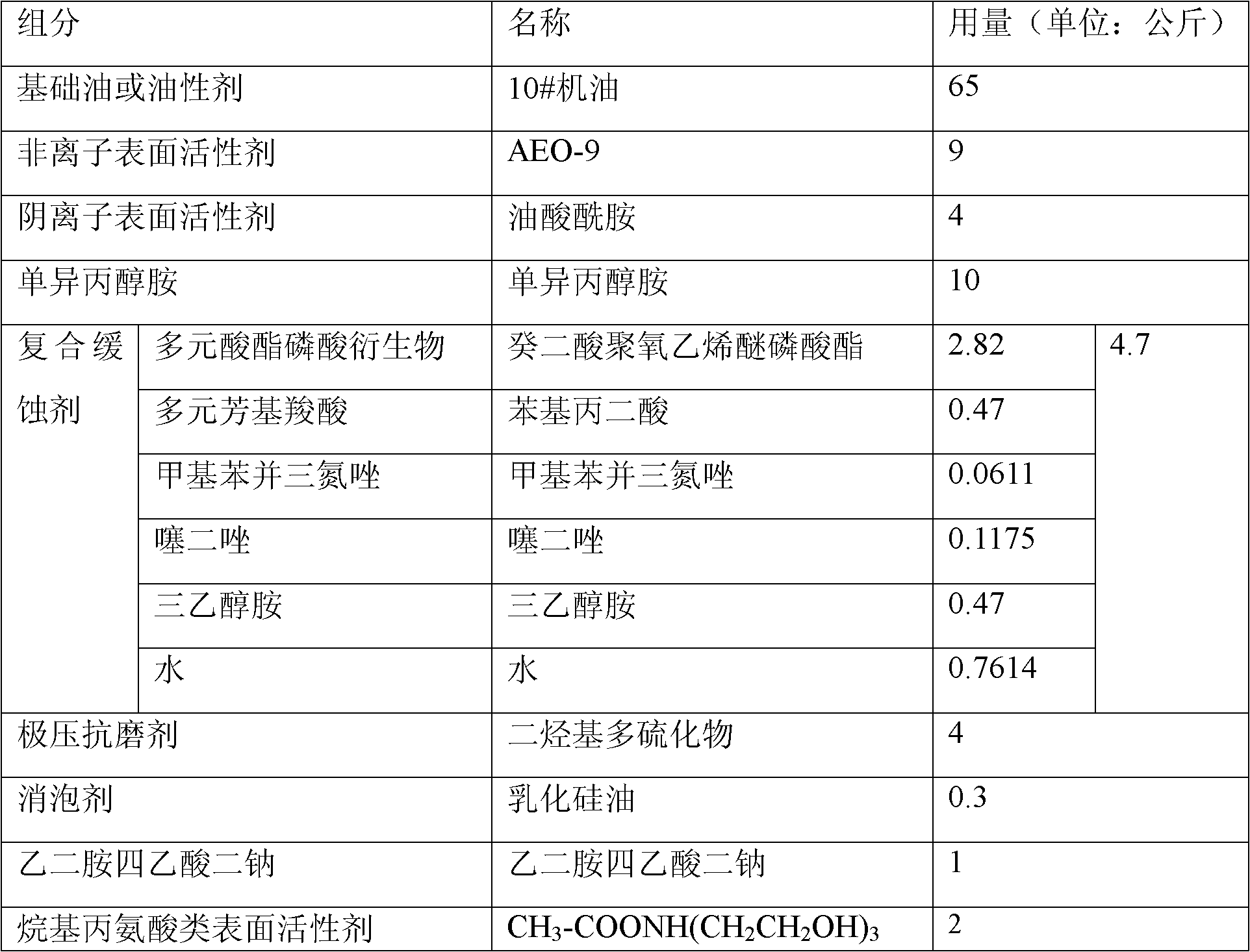

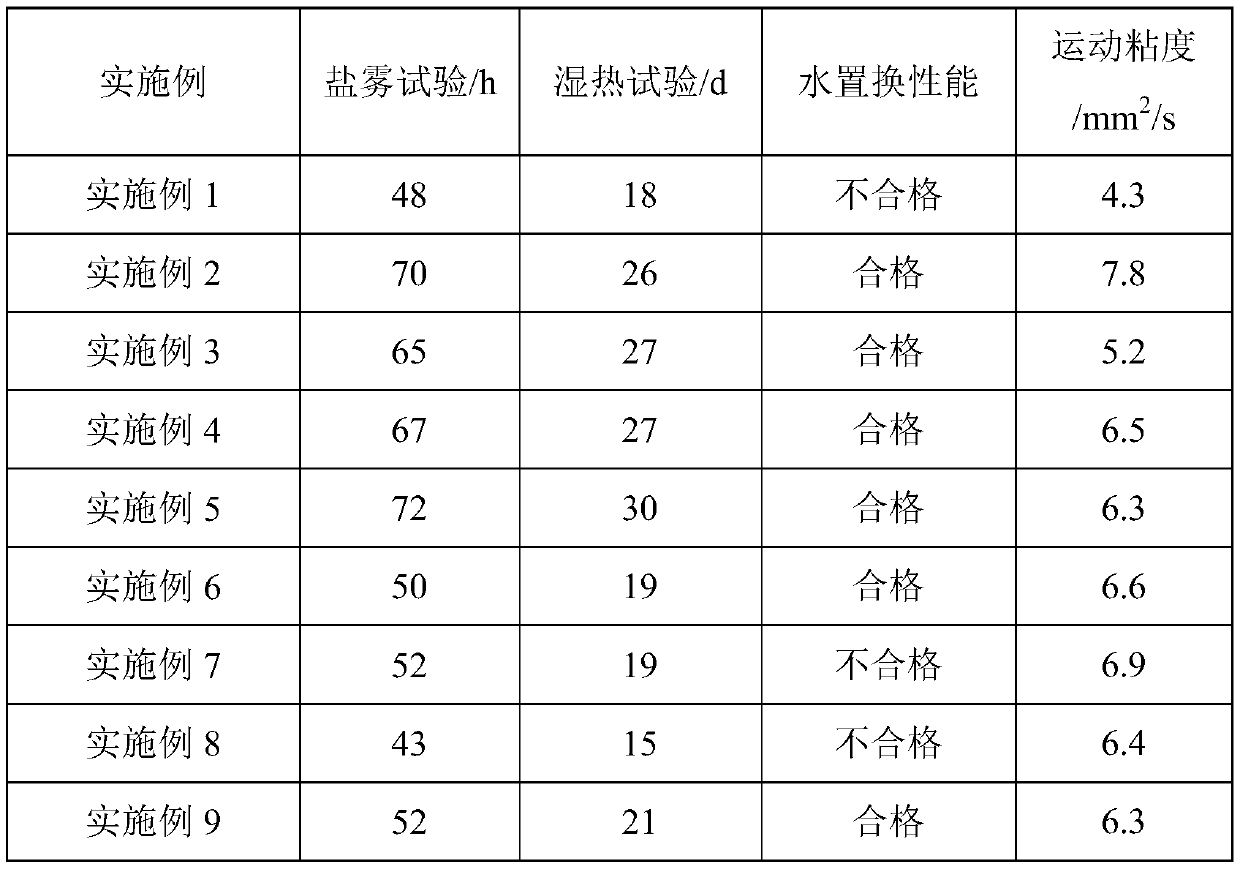

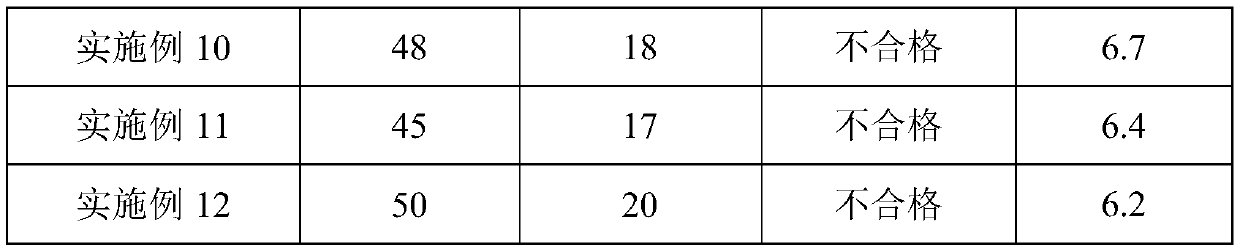

The invention relates to a self-bacteriostasis general emulsion cutting fluid and a preparing method thereof. The components of the emulsion cutting fluid includes, by weight, 50-70 parts of base oils, 7-25 parts of non-ionic surface active agents, 4-10 parts of anion surface active agents, 3-10 parts of monoisopropanolamines, 3-5 parts of compound corrosion inhibitors, 4-15 parts of extreme pressure antiwear agents, 0.01-0.3 parts of defoaming agents, 1 part of ethylene diamine tetraacetic acid, and 2-6 parts of alkyl alanine surface active agents. According to the self-bacteriostasis general emulsion cutting fluid, an organic triethylhexanoin process is adopted, cutting fluids produced has strong cooling characteristics, lubricity and rust protection, and is easy to wash, defects of heavy loading water-soluble cutting fluids in rust protection and odor aspects in use are avoided, simultaneously, bacteriacides are replaced by the alkyl alanine surface active agents, therefore strong bacteriostatic capacity for bacteria, fungi and molds can be achieved without adding special bacteriacides into products, service life of products is prolonged, and cost of products is reduced.

Owner:泰伦特生物工程股份有限公司

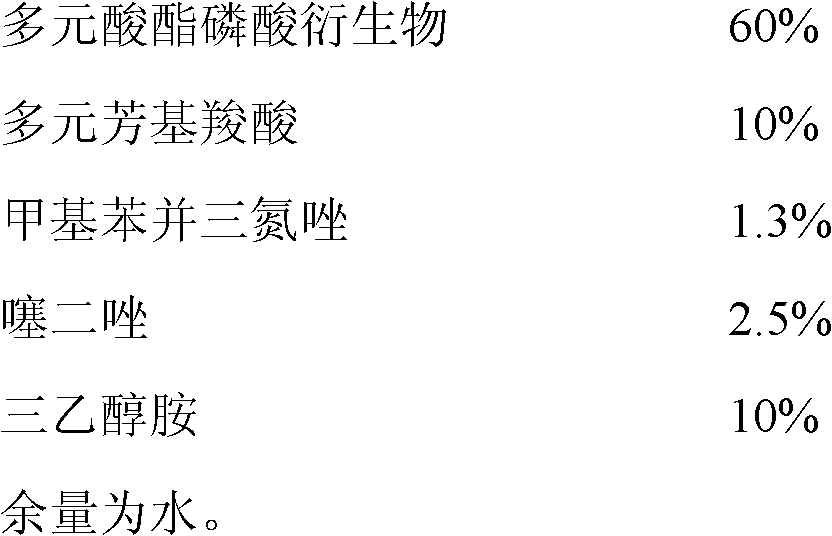

Cleaning antirust agent and preparation method thereof

InactiveCN101113524AThe mechanism of action is simple and scientificInhibit bacterial growthDisinfectantOrganic acid

The invention relates to a cleaning and rust inhibiting agent and a preparation method thereof, pertaining to chemical cleaning agent field, and the cleaning and rust inhibiting agent consists of the components: 1 to 2 percent of ethylenediamine tetraacetic acid solution, 3 to 4 percent of triethanolamine solution, 0.5 to 1 percent of eynanolamine solution, 5 to 10 percent of compound borate ester solution, 5 to 10 percent of polyacrylic acid solution, 1 to 3 percent of triazine disinfectant solution, and the other is water to be added into 100 percent. The cleaning and rust inhibiting agent is prepared through a scientific processing technology by using organic acid, surfactant and disinfectant as main materials, without needing to be rinsed after cleaning, and the surfaces of cleaned parts have no white spot and are as shiny as new ones, thus reaching the rust inhibiting requirements of a workshop. The product is weak alkaline, and has advantages of wide sources, easy acquiring, small using quantity and strong cleaning ability to such processing oil as rust inhibiting oil, emulsified oil, cutting fluid, oleostearine, transformer oil, etc., which is particularly applied to the cleaning and rust inhibiting for steel and aluminum materials.

Owner:华阳新兴科技(天津)集团有限公司

Cleaning and antirust agent for secondary processing of casting parts and preparation method thereof

The invention discloses a cleaning and antirust agent for secondary processing of casting parts and a preparation method thereof, and the cleaning and antirust agent has simple cleaning process, high operation efficiency, standard cleaning quality and capability to meet the antirust requirements of preparing process. The agent consists of the following raw materials by weight: 2-5% of potassium hydroxide, 3-6% of sodium hydroxide, 15-20% of sodium carbonate, 10-20% of sodium metasilicate pentahydrate, 10-20% of sodium tripolyphosphate, 10-20% of sodium nitrite, 1-1.5% of osmotic agent, 2-6% of nonionic block polyether surfactant, 2-6% of special surfactant for dewaxing fluid, and 4-6% of antifoaming agent. According to the preparation method of the agent, the above raw materials are gradually added into a mixer in order. The adding of each material is associated with 10-15min of stirring, and when the raw materials are all added, at least 30min are needed to stir the materials continuously.

Owner:DALIAN JIESHI CLEANING PRODS +1

Multifunctional barium-free anti-rusting oil and preparation process thereof

InactiveCN103602492AConcentration is easy to monitor and adjustGuaranteed anti-rust performanceLubricant compositionSulfonateCresol

The invention discloses multifunctional barium-free anti-rusting oil. The multifunctional barium-free anti-rusting oil comprises the following components in percentage by weight: 8%-10% of petroleum calcium sulfonate, 4%-6% of petroleum sodium sulfonate, 2%-5% of S-80, 0.1%-0.5% of T501 / 2, 6 di-tert-butyl p-cresol, 0.3%-0.5% of T706 benzotriazole, 10%-20% of 32# base oil, and 60%-70% of a refined petroleum solvent. The preparation process of the multifunctional barium-free anti-rusting oil comprises the following steps of: adding the refined base oil, the petroleum calcium sulfonate, the S-80 and the petroleum sodium sulfonate into a reaction kettle; heating to 90 DEG C-95 DEG C, cooling to 70 DEG C-80 DEG C after dissolving uniformly, adding the T706 benzotriazole and the T501 / 2, 6 di-tert-butyl p-cresol for uniformly dissolving, preserving the heat for stirring for over half an hour; and finally, filtering and filling into a barrel after diluting by using the refined petroleum solvent. Compared with the prior art, the multifunctional barium-free anti-rusting oil disclosed by the invention has the advantages that anti-rusting requirements of various metals can be satisfied at the same time, an oil film is thin, easy to clean, and the multifunctional barium-free anti-rusting oil is compatible with automobile lubricating oil, can be used for oil assembling, and is barium-free and environment-friendly.

Owner:SHANGHAI THRIVING SPECIAL OIL SCI & TECH

Special grinding fluid for ductile regime lapping of optical glass and preparation method of special grinding fluid

InactiveCN102977987AIncrease the critical depth of cut valueReduce hardnessLubricant compositionHexamethylenetetraminePotassium

The invention discloses a preparation method of a special grinding fluid for ductile regime lapping of optical glass. The preparation method comprises the steps of: at room temperature, adding sodium carbonate in water, stirring; heating, sequentially adding potassium tetraborate, benzotriazole, hexamethylenetetramine and sodium molybdate under the condition of continuously stirring; heating, sequentially adding triethanolamine and polyethylene glycol; and cooling the liquid to room temperature under the condition of stirring, and continuously stirring for 5-30min to obtain the special grinding fluid for ductile regime lapping of optical glass. The grinding fluid prepared by adopting the preparation method has better functions of cooling, lubricating, rust preventing and cleaning, the surface of the optical glass is chemically modified through the components in the grinding fluid, a microcosmic network structure of the optical glass is broken, the physical form of the material surface is changed, the bond energy of a bond is weakened, the hardness of the surface of the optical glass is reduced, the critical grinding depth value of crispness-ductility transformation of the optical glass is increased, and the difficulty in realizing the ductile regime lapping of the optical glass industrially is lowered.

Owner:TIANJIN UNIV

Environmentally-friendly antirust oil for iron-based powder metallurgy parts and preparation method of antirust oil

ActiveCN110437917AImprove rust resistanceStrong anti-salt spray performanceLubricant compositionEnvironmental resistanceMetalworking

The invention belongs to the technical field of metal processing, and more particularly relates to environmentally-friendly antirust oil for iron-based powder metallurgy parts and a preparation methodof the antirust oil. The environmentally-friendly antirust oil for the iron-based powder metallurgy parts comprises the following components, in parts by weight: 60-90 parts of base oil, 3-20 parts of a barium-free sulfonate, 0.1-20 parts of a rust inhibitor, 0.5-10 parts of an auxiliary agent and 0.1-1 part of an antioxidant. According to the environmentally-friendly antirust oil for the iron-based powder metallurgy parts provided by the invention, the base oil, the barium-free sulfonate, the rust inhibitor, the auxiliary agent and the antioxidant are adopted for compounding to provide highantirust performance, different from a traditional antirust method of powder metallurgy which needs high-temperature cooking, the product provided by the invention is immersed at room temperature andcan be quickly penetrated into metal gaps to discharge moisture in pores and the metal surface out, after draining is performed, an oil film is thin and non-sticky, has good salt spray resistance andmeets the antirust requirements for sea export of products, and the product does not contain heavy metals such as barium and is safe and environmentally friendly.

Owner:GUANGZHOU LANDNOK CHEM TECH

Method for preparing metal cutting fluid with high extreme pressure resistance

InactiveCN102703197AStrong resistance to extreme pressureImprove rust resistanceLubricant compositionCarboxylic acidOleic Acid Triglyceride

The invention discloses a method for preparing a metal cutting fluid with high extreme pressure resistance. The method for preparing the metal cutting fluid with high extreme pressure resistance comprises the following steps of: 1) synthesizing diethanolamine-boric acid-polycarboxylic acid complex ester, namely performing esterification reaction of diethanolamine, polycarboxylic acid and boric acid in a molar ratio of 3:1:1 at the temperature of 150 to 155 DEG C for 2 to 4 hours; 2) synthesizing diethanolamine-boric acid-maleic anhydride complex ester, namely performing esterification reaction of diethanolamine, maleic anhydride and boric acid in a molar ratio of 3:1:1 at the temperature of 150 to 155 DEG C for 2 to 4 hours; 3) raising the temperature of water to 70 to 80 DEG C, sequentially adding lead naphthenate, oleic acid, barium petroleum sulfonate, triethanolamine, borax, sodium silicate and nitrobenzoic acid under stirring, continuing to stir for 20 to 40 minutes, reducing the temperature to 50 to 60 DEG C, adding sodium molybdate and boric acid under the condition of constant stirring, stirring for 20 to 30 minutes, adding methylsilicone oil, and stirring for 10 to 20 minutes; and 4) mixing products obtained in step 1)-3), and stirring at the temperature of 50 to 60 DEG C for 60 to 90 minutes to obtain the metal cutting fluid.

Owner:TIANCHANG RUNDA METAL ANTIRUST AUX

Multifunctional alkaline cleaning agent, and preparation method and application thereof

The invention discloses a multifunctional alkaline cleaning agent. The raw material composition of the multifunctional alkaline cleaning agent comprises, by weight, 2-5 parts of potassium carbonate, 2-5 parts of sodium gluconate, 0.5-5 parts of cocoanut fatty acid diethanolamide, 2-5 parts of sodium dodecylbenzene sulfonate, 5-10 parts of monoethanolamine borate, 5-10 parts of dipropylene glycol methyl ether, 5-10 parts of penetrants, 0.5-5 parts of solubilizers, and 10-20 parts of HEDP-4Na, and water is used for complementing to 100 parts. A steel product treated through the cleaning agent has the high surface cleanliness, no oil dirt residue, and no scrap iron, rust deposit and dust particle residue are achieved, the steel product after being cleaned can still meet interprocess rust prevention, the surface brightness of the steel product can be increased, the using cycle is long, the using concentration is low, and the rust prevention period is up to 10-20 days; the safe and environmental protection effects are achieved, the multifunctional alkaline cleaning agent is harmless to a human body, raw materials are wide in sources and easy to obtain, the cost is low, and the multifunctional alkaline cleaning agent is suitable for mass production.

Owner:华阳新兴科技(天津)集团有限公司 +1

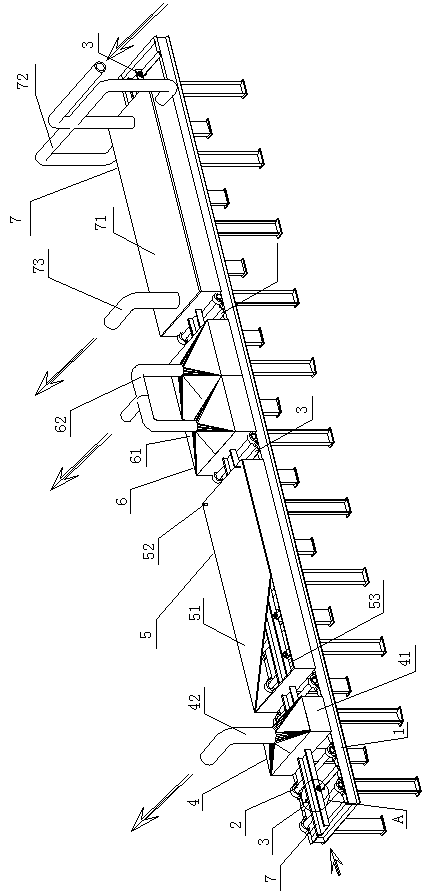

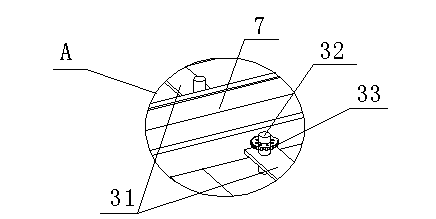

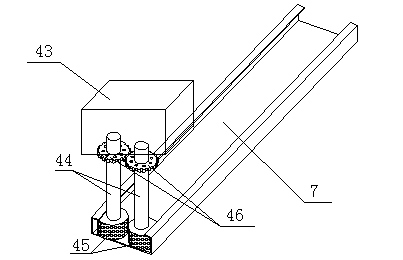

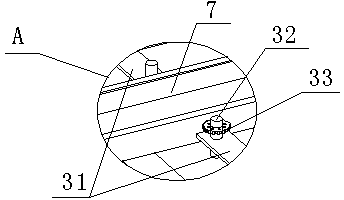

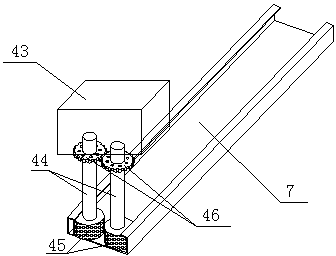

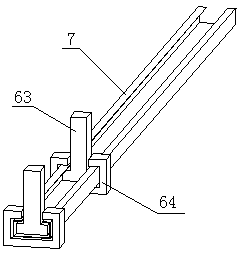

Thin-walled cold-formed steel assembly line coating equipment

ActiveCN103008177AEasy to operateQuality improvementPretreated surfacesCoatingsAssembly lineEngineering

The invention discloses thin-walled cold-formed steel assembly line coating equipment which comprises a frame, wherein the top of the frame is provided with a conveying deice; and the top end of the frame is sequentially provided with a pretreatment device, a preheating treatment device, a coating device and a drying treatment device from the input end to the output end of the conveying device. The thin-walled cold-formed steel assembly line coating equipment is simple in structure and convenient to operate and use, the thin-walled cold-formed steel is sequentially subjected to cleaning pretreatment, preheating treatment, coating treatment and drying treatment, to complete a coating process, poison gas is not exhausted in the coating process, the environmental pollution is extremely low, and the coated thin-walled cold-formed steel is high in anti-rust quality; and moreover, only the mold coating size and shape are required to be changed, and the equipment can be suitable for sections of various section bars and is wide in application range.

Owner:ANHUI WEIHONG STEEL STRUCTURE GRP

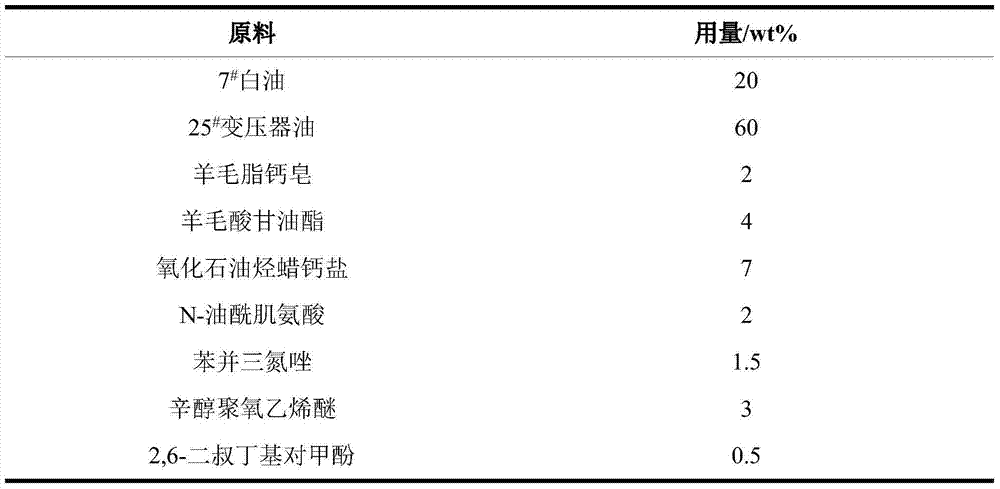

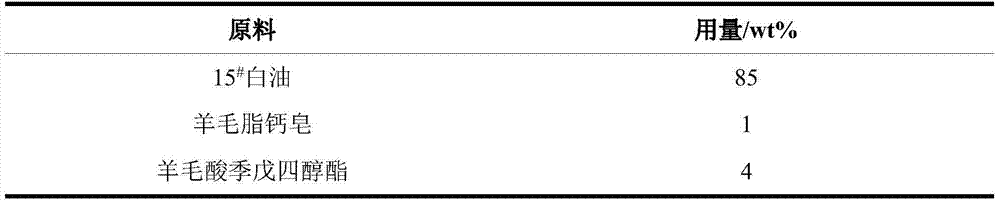

Lubricating rust-preventative oil

InactiveCN110467959AImprove rust resistanceSatisfy the anti-rust requirements of storageLubricant compositionAviationMechanical equipment

The invention relates to a lubricating rust-preventative oil product suitable to be used for rusting prevention, sealing rusting prevention, and lubricating processing of mechanical workpieces in stainless steel, cast iron, aluminium alloy, and copper alloy material processing process in the fields of automobile industry and aviation industry. The lubricating rust-preventative oil product possesses both rust prevention effect and lubricating effect, is capable of satisfying process rust prevention requirements in mechanical processing, and satisfying workpiece sealing rust prevention requirements; and lubrication machine processing technology requirements in mechanical industry workpiece manufacturing process can be satisfied; and the lubricating rust-preventative oil can be used for lubricating maintenance in mechanical equipment operation process.

Owner:广西工业职业技术学院

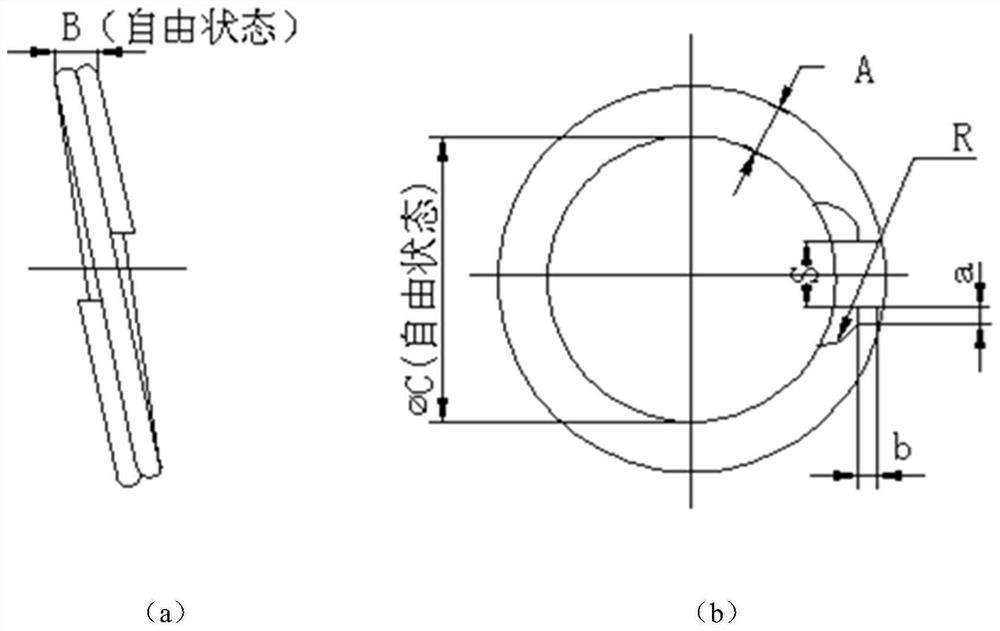

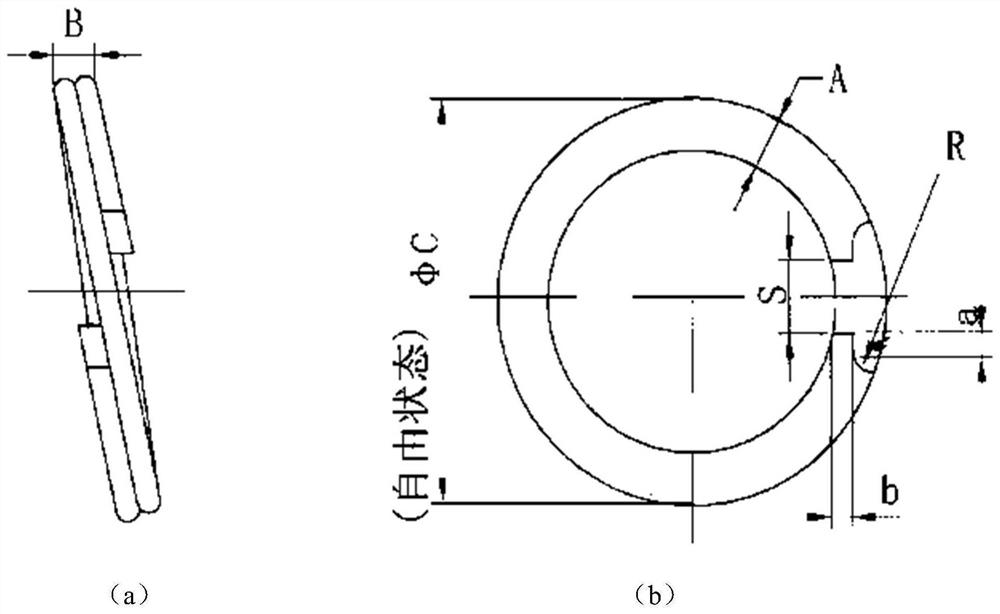

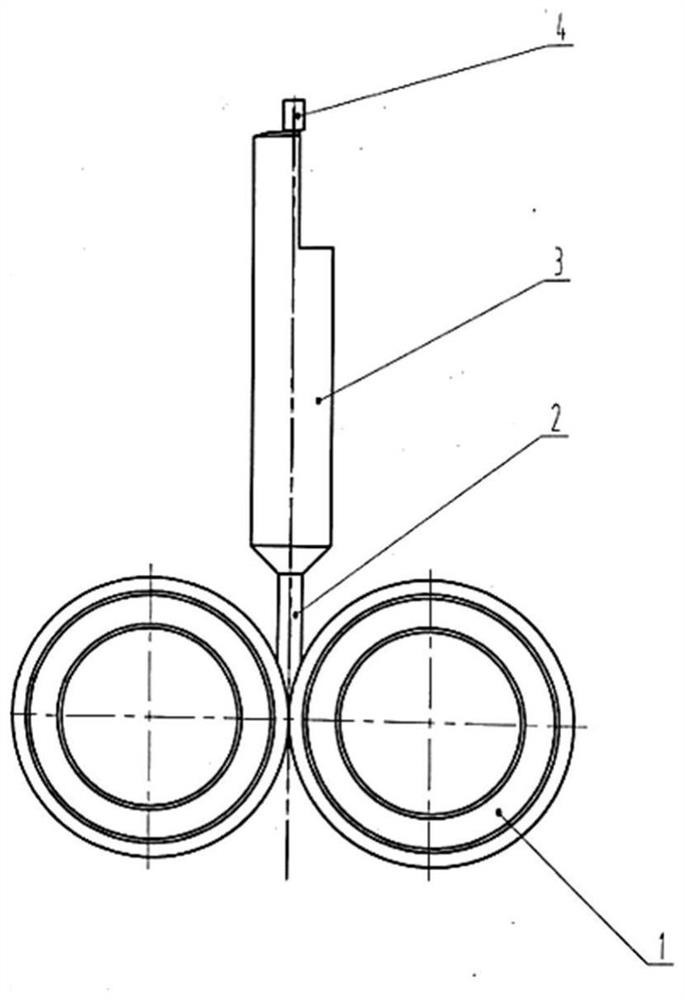

Machining method and tool for elastic check rings

ActiveCN112846004AFulfill size requirementsAchieving Tolerance RequirementsWire springsMetal working apparatusHardnessMachining

The invention discloses a machining method and a tool for elastic check rings. The machining method comprises the following steps that spring winding is conducted; the two end faces of springs are machined, the sizes of the check rings are checked, and the unsatisfied sizes are finely calibrated; the check rings are loaded into a heat treatment clamp to be quenched and tempered, and the hardness value of the material of the check rings is 82 HR15N-86 HR15N; the flatness and the end face sizes of the check rings are finely trimmed, and heat treatment deformation is corrected; burrs are polished, so that the edges of the check rings are smooth; and all the sizes of the check rings are inspected, anti-corrosion and anti-rust treatment is conducted on the surfaces of the check rings which are inspected to be qualified, and finally packaging and delivery are conducted. The invention further provides the heat treatment clamp for the elastic check rings and the size inspection tools for the elastic check rings. Aiming at precision machining of 75Mn wire elastic check rings with the large width-to-thickness ratio, the machining method meets the requirements for the size and tolerance of the check rings, deformation is controlled, and the requirement for rapid detection during mass production is met.

Owner:AECC AVIATION POWER CO LTD

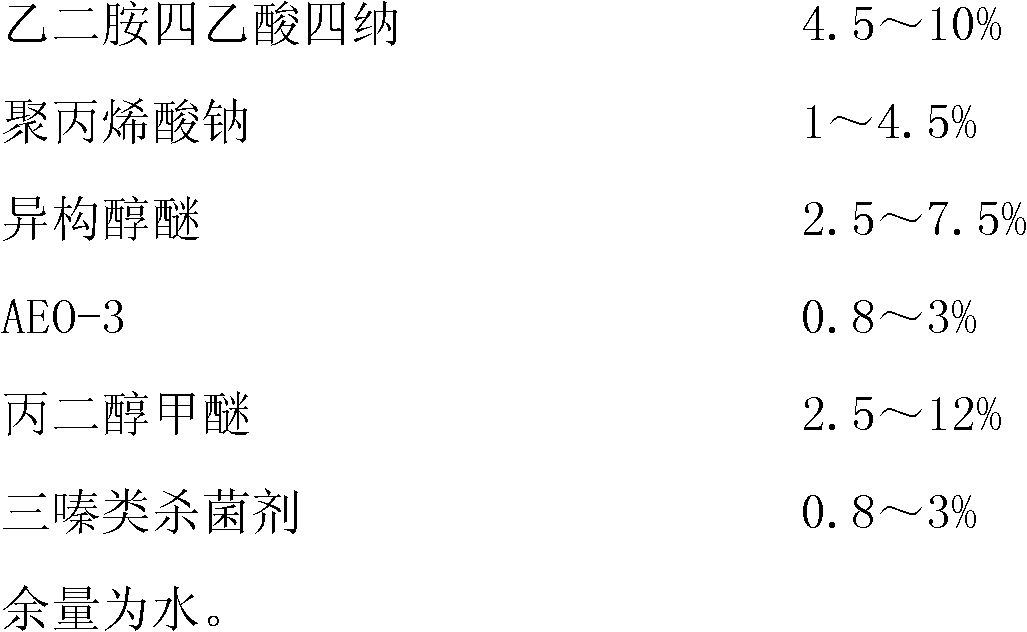

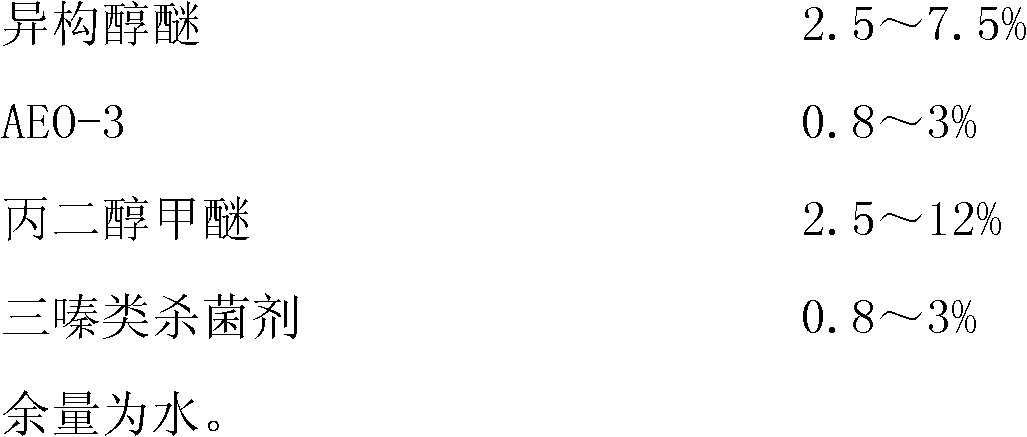

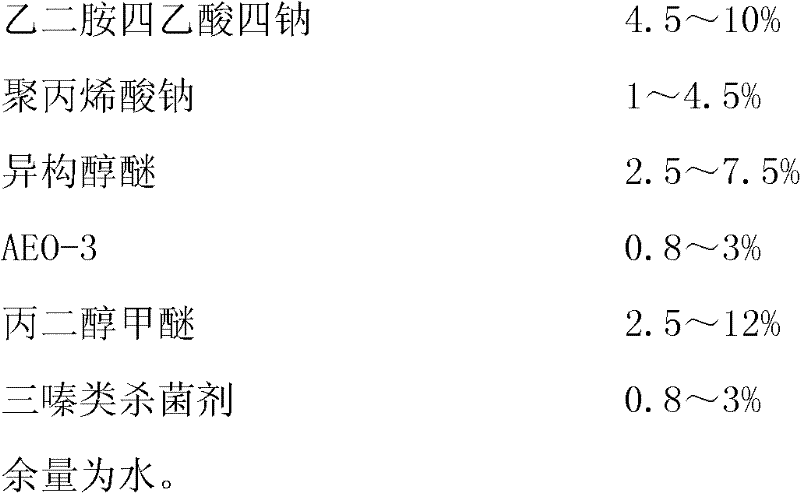

Dusting cleaning antirusting agent and preparation method thereof

The invention relates to a dusting cleaning antirusting agent and a preparation method thereof. The dusting cleaning antirusting agent comprises the following components in percentage by weight: 4.5 to 10 percent of tetrasodium ethylenediamine tetraacetate, 1 to 4.5 percent of sodium polyacrylate, 2.5 to 7.5 percent of heterogeneous alcohol ether, 0.8 to 3 percent of fatty alcohol-polyoxyethylene ether (AEO)-3, 2.5 to 12 percent of propylene glycol monomethyl ether, 0.8 to 3 percent of triazine bacteriacide and the balance of water. The dusting cleaning antirusting agent is suitable for spraying and ultrasonic cleaning; parts processed by the dusting cleaning antirusting agent are not needed to be rinsed and are high in cleanness, the surfaces of the parts do not have granule residues and white dirt residues, and the brightness of the parts can be increased; and the dusting cleaning antirusting agent has long service life and low concentration, and the antirusting period is 5 to 10 days. The dusting cleaning antirusting agent is safe, environment-friendly and low in cost, made of widely and readily available raw material, and is suitable for large-scale production.

Owner:华阳新兴科技(天津)集团有限公司

Environment-friendly anti-rust oil

The invention discloses environment-friendly anti-rust oil which comprises the following raw materials in parts by weight: 60-80 parts of base oil, 5-10 parts of petroleum sulfonate, 5-8 parts of polyvinyl alcohol, 1-8 parts of nano ceramic powder, 1-3 parts of a film forming aid, 0.5-2 parts of an antioxidant, 0.1-1.2 parts of a dispersant, 1-2.5 parts of an accelerant and 0.1-1 part of a lubricant. The anti-rust oil can meet the anti-rust requirement of various metal parts, is good in corrosion resistance, excellent in effect, long in service life, environment-friendly and healthy, and cannot cause pollution to the environment and a human body.

Owner:昆山瑞昱化工有限公司

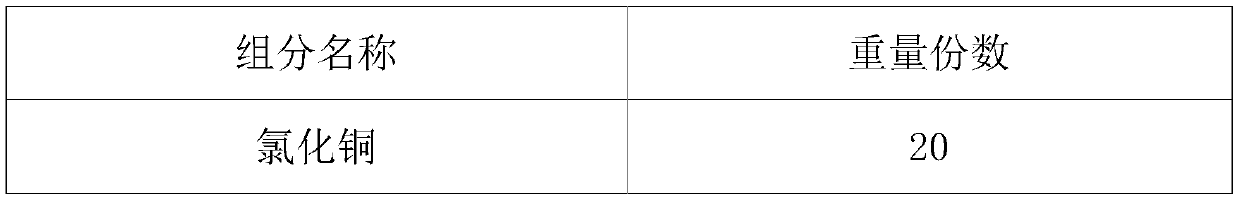

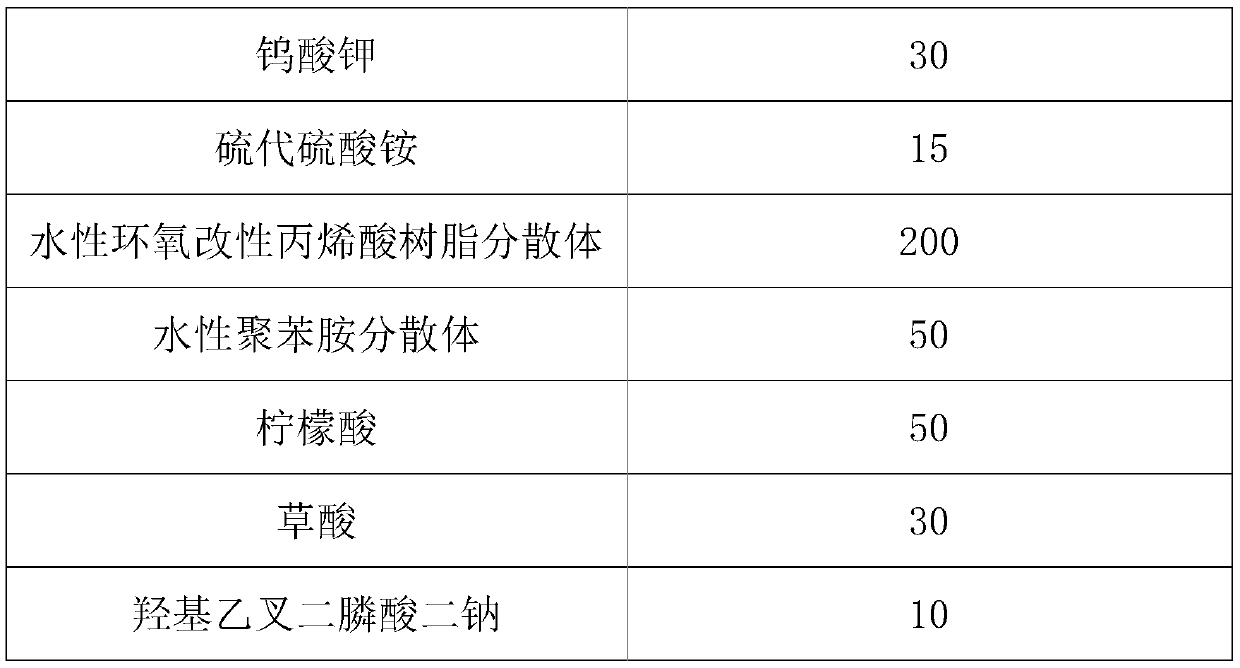

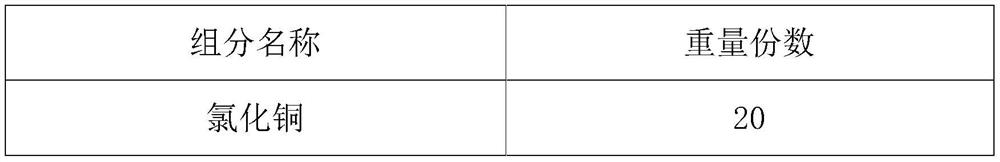

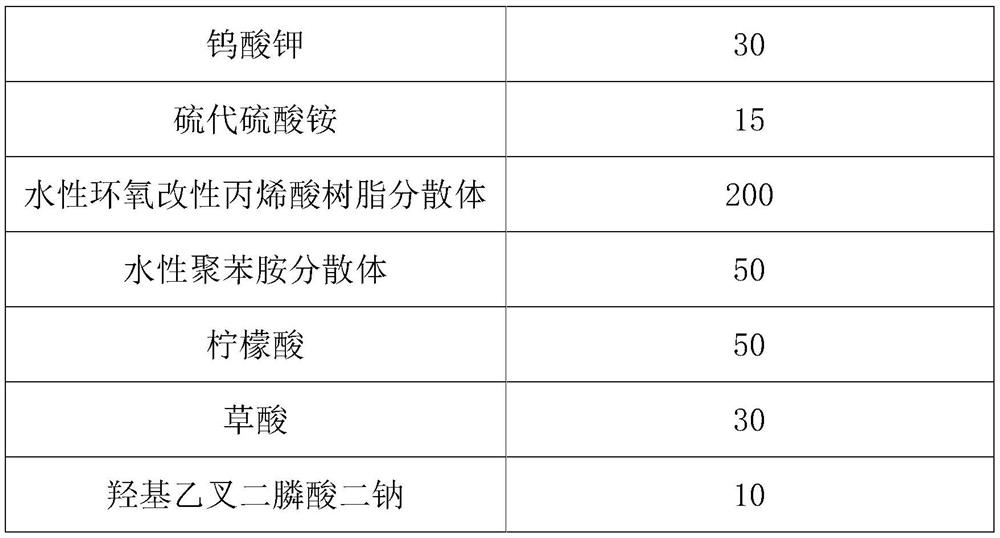

Oil-immersion-free antirust blackening agent and preparation method and application thereof

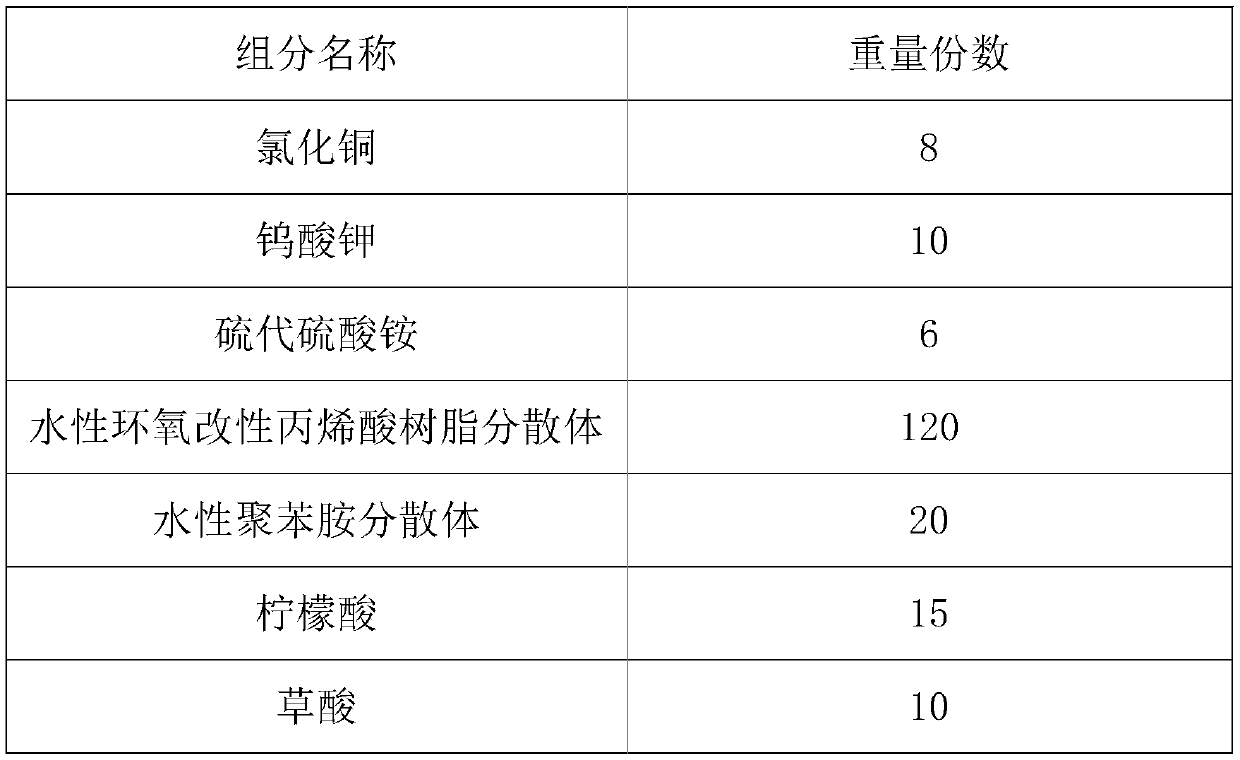

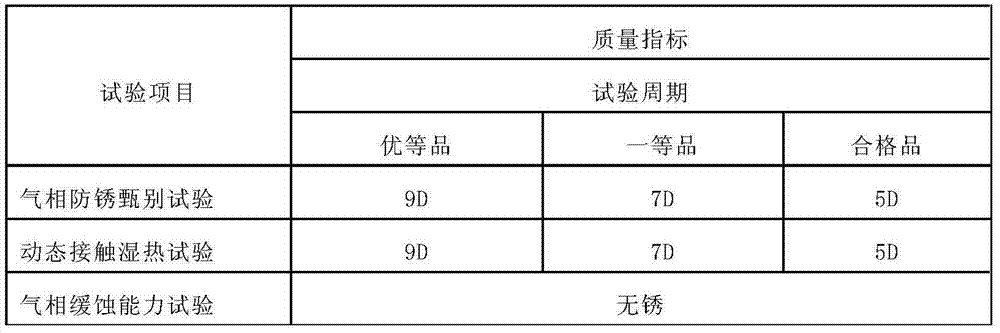

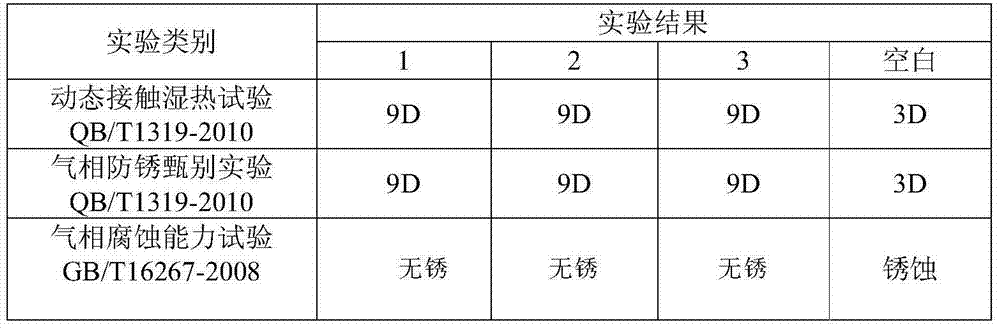

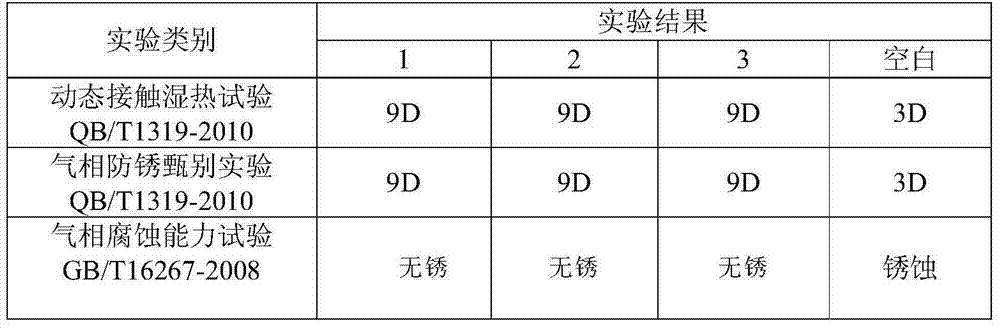

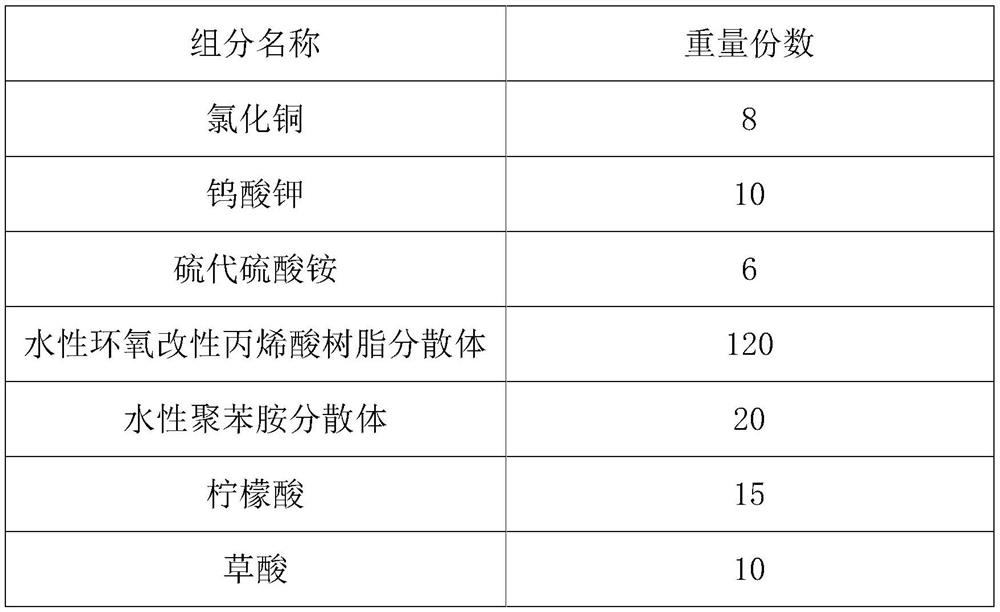

ActiveCN111087877AReduce porosityImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsOXALIC ACID DIHYDRATEEpoxy

The invention discloses an oil-immersion-free antirust blackening agent and a preparation method and application thereof, and relates to the technical field of metal surface treatment. The oil-immersion-free antirust blackening agent comprises the following components: 1-20 parts by weight of copper chloride, 2-30 parts of potassium tungstate, 1-15 parts of ammonium thiosulfate, 50-300 parts of waterborne epoxy modified acrylic resin dispersion, 5-50 parts of waterborne polyaniline dispersion, 5-50 parts of citric acid, 2-50 parts of oxalic acid, 0.5-10 parts of disodium 1-hydroxyethylidene-1,1-diphosphonate and a proper amount of deionized water. After the oil-immersion-free antirust blackening agent is used for blackening treatment, antirust performance requirements under most conditions can be met even if oil immersion treatment is not carried out.

Owner:HUNAN JINHUA SCI & TECH GRP

Environment-friendly composite volatile corrosion inhibitor for galvanized steel sheet and preparation method thereof

InactiveCN104762623AMeet anti-rust requirementsActs as a stabilizerFlexible coversWrappersVolatile corrosion inhibitorSodium tungstate dihydrate

The invention relates to an environment-friendly composite volatile corrosion inhibitor for a galvanized steel sheet and a preparation method thereof. The composite volatile corrosion inhibitor comprises the following active components by mass: 17.5 to 30.15% of sodium benzoate, 15.75 to 33.65% of water-soluble benzotriazol, 15.84 to 26.85% of sodium tungstate, 15.5 to 29.26% of cinnamic acid and 6.5 to 9% of triethanolamine. The preparation method comprises the following steps: 1) weighing the active components; and 2) separately preparing a solution of each active component through addition of water, mixing the solutions of all the active components after standing and clarification so as to obtain a mixed solution, and adjusting the pH value of the mixed solution to 8.3 to 8.8 by using buffering alkali lye. According to the invention, the environment-friendly composite volatile corrosion inhibitor is prepared by using the simple method and exerts a good antirust effect when applied on the surface of antirust raw paper.

Owner:武汉江南铁依环保产业发展有限公司

Dusting cleaning antirusting agent and preparation method thereof

The invention relates to a dusting cleaning antirusting agent and a preparation method thereof. The dusting cleaning antirusting agent comprises the following components in percentage by weight: 4.5 to 10 percent of tetrasodium ethylenediamine tetraacetate, 1 to 4.5 percent of sodium polyacrylate, 2.5 to 7.5 percent of heterogeneous alcohol ether, 0.8 to 3 percent of fatty alcohol-polyoxyethyleneether (AEO)-3, 2.5 to 12 percent of propylene glycol monomethyl ether, 0.8 to 3 percent of triazine bacteriacide and the balance of water. The dusting cleaning antirusting agent is suitable for spraying and ultrasonic cleaning; parts processed by the dusting cleaning antirusting agent are not needed to be rinsed and are high in cleanness, the surfaces of the parts do not have granule residues andwhite dirt residues, and the brightness of the parts can be increased; and the dusting cleaning antirusting agent has long service life and low concentration, and the antirusting period is 5 to 10 days. The dusting cleaning antirusting agent is safe, environment-friendly and low in cost, made of widely and readily available raw material, and is suitable for large-scale production.

Owner:华阳新兴科技(天津)集团有限公司

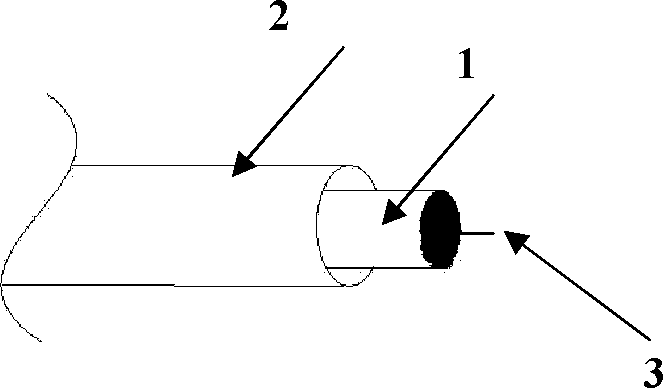

Application of a kind of vapor phase antirust paper

ActiveCN103043319BMeets rust protection requirementsEasy to insertShock-sensitive articlesGas phaseEngineering

Owner:上海一诺金属防护材料有限公司

Thin-walled cold-formed steel assembly line coating equipment

ActiveCN103008177BEasy to operateQuality improvementPretreated surfacesCoatingsEngineeringAssembly line

The invention discloses thin-walled cold-formed steel assembly line coating equipment which comprises a frame, wherein the top of the frame is provided with a conveying deice; and the top end of the frame is sequentially provided with a pretreatment device, a preheating treatment device, a coating device and a drying treatment device from the input end to the output end of the conveying device. The thin-walled cold-formed steel assembly line coating equipment is simple in structure and convenient to operate and use, the thin-walled cold-formed steel is sequentially subjected to cleaning pretreatment, preheating treatment, coating treatment and drying treatment, to complete a coating process, poison gas is not exhausted in the coating process, the environmental pollution is extremely low, and the coated thin-walled cold-formed steel is high in anti-rust quality; and moreover, only the mold coating size and shape are required to be changed, and the equipment can be suitable for sections of various section bars and is wide in application range.

Owner:ANHUI WEIHONG STEEL STRUCTURE GRP

Preparation method of industrial machine tool cleaning agent

InactiveCN111139151AQuick removalEasy to cleanOrganic non-surface-active detergent compositionsInorganic non-surface-active detergent compositionsCleansing AgentsTert butyl

The invention provides a preparation method of an industrial machine tool cleaning agent. The cleaning agent is prepared from 3-10% of a sodium salt, 10-20% of ethylene glycol tert-butyl ether, 20-30%of concentrated sulfuric acid, 10-20% of ethylene glycol and the balance of water. According to the invention, after the cleaning agent is used for cleaning, the antirust time of a workpiece is long,is 5-7 days and greatly exceeds the storage time between common procedures, so that the antirust requirement between the procedures is completely met; the cleaning agent and the method for cleaning the workpieces are suitable for cleaning the workpieces in the fields of automobile parts, engineering machinery, agricultural machinery and the like, and particularly have obvious advantages when theworkpieces are iron castings or cold-rolled sheet workpieces.

Owner:陕西速源节能科技有限公司

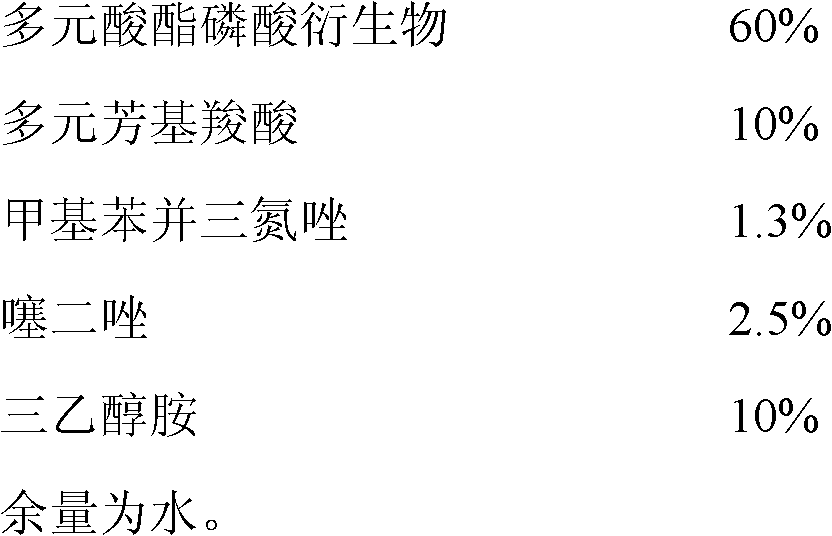

Water-based antirust agent for filter and preparation thereof

The invention relates to a water base rust preventive for a filter, which comprises 50 to 60 weight parts of hydroxyalkyl starch, 40 to 50 weight parts of acetic ester starch, 80 to 100 weight parts of aqueous fluorocarbon emulsion, 300 to 350 weight parts of water, 55 to 75 weight parts of polyfluortetraethylene emulsion, 8 to 10 weight parts of micron or nanometer zinc powder, 40 to 50 weight parts of isopropanol and 20 to 30 weight parts of acetone, wherein the hydroxyalkyl starch is ethoxyl starch or hydroxypropyl starch; the aqueous fluorocarbon emulsion is multipolymer of fluorothene and an oxhydryl vinyl ether, the weight percentage concentration of fluorin is from 8 percent to 11.5 percent, and a main chain comprises fluorin atoms. A preparation method comprises traditional methods of mixing, heating stirring and ultrasonic dispersion. The rust preventive has the advantages of good antirust effect, high temperature resistance, favorable adhesive attraction to polyester powder coatings, and the like and can satisfy the antirust requirements of a metal outer casing and a treaded cover plate of the filter. The preparation method is technically simple and uses less equipment.

Owner:NANTONG HUAXING OIL EQUIP

Method for preparing metal cutting fluid with high extreme pressure resistance

InactiveCN102703197BStrong resistance to extreme pressureImprove rust resistanceLubricant compositionCarboxylic acidOleic Acid Triglyceride

The invention discloses a method for preparing a metal cutting fluid with high extreme pressure resistance. The method for preparing the metal cutting fluid with high extreme pressure resistance comprises the following steps of: 1) synthesizing diethanolamine-boric acid-polycarboxylic acid complex ester, namely performing esterification reaction of diethanolamine, polycarboxylic acid and boric acid in a molar ratio of 3:1:1 at the temperature of 150 to 155 DEG C for 2 to 4 hours; 2) synthesizing diethanolamine-boric acid-maleic anhydride complex ester, namely performing esterification reaction of diethanolamine, maleic anhydride and boric acid in a molar ratio of 3:1:1 at the temperature of 150 to 155 DEG C for 2 to 4 hours; 3) raising the temperature of water to 70 to 80 DEG C, sequentially adding lead naphthenate, oleic acid, barium petroleum sulfonate, triethanolamine, borax, sodium silicate and nitrobenzoic acid under stirring, continuing to stir for 20 to 40 minutes, reducing the temperature to 50 to 60 DEG C, adding sodium molybdate and boric acid under the condition of constant stirring, stirring for 20 to 30 minutes, adding methylsilicone oil, and stirring for 10 to 20 minutes; and 4) mixing products obtained in step 1)-3), and stirring at the temperature of 50 to 60 DEG C for 60 to 90 minutes to obtain the metal cutting fluid.

Owner:TIANCHANG RUNDA METAL ANTIRUST AUX

Oil-free antirust and blackening agent and its preparation method and application

ActiveCN111087877BReduce porosityImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsOXALIC ACID DIHYDRATEEpoxy

The oil-free anti-rust and blackening agent and its preparation method and application relate to the technical field of metal surface treatment, wherein the above-mentioned oil-free anti-rust and blackening agent comprises the following components: 1-20 parts by weight of copper chloride, tungsten Potassium acid 2-30 parts by weight, ammonium thiosulfate 1-15 parts by weight, water-based epoxy modified acrylic resin dispersion 50-300 parts by weight, water-based polyaniline dispersion 5-50 parts by weight, citric acid 5-50 parts by weight 2-50 parts by weight of oxalic acid, 0.5-10 parts by weight of disodium hydroxyethylidene diphosphonate and appropriate amount of deionized water. After using the oil-free antirust blackening agent for blackening treatment, it can meet the antirust performance requirements in most cases even without oil immersion treatment.

Owner:HUNAN JINHUA SCI & TECH GRP

Construction reserved steel bar antirust coating and construction method

InactiveCN112538286AMeet anti-rust requirementsGuaranteed gripAnti-corrosive paintsSpecial surfacesAcrylate esterRebar

The invention discloses a construction reserved steel bar antirust coating and a construction method. The formula of the construction reserved steel bar antirust coating polyacrylate cement-based antirust coating comprises the following components in parts by weight: 80-120 parts of cement, 20-30 parts of polyacrylate emulsion, 0.5-0.9 part of naphthalene water reducer, 0.05-0.2 part of defoamingagent and 25-50 parts of water. The construction reserved steel bar antirust coating is easy to brush and construct on site, the polyacrylate cement-based antirust coating can cover the surface of a reserved steel bar, a coating layer on the surface of the steel bar does not crack for a long time, and the reserved steel bar is protected against rust spots in the outdoor natural environment for oneyear; and the bond stress between the concrete and the steel bar coated with the antirust coating is not reduced.

Owner:上海泾东建筑发展有限公司

Alkylated rust-preventative oil for metal parts

InactiveCN104450028AGood compatibilityImprove film formationLubricant compositionPhosphateEthyl citrate

The invention discloses alkylated rust-preventative oil for metal parts. The alkylated rust-preventative oil for metal parts is composed of the following raw materials in parts by weight: 0.8-1 parts of erythritol, 70-80 parts of 400sn basic oil, 2-4 parts of oleic acid polyoxyethylene ester, 2-5 parts of paraffin, 1-2 parts of dimethylpropylmethane, 1-2 parts of benzotriazole, 1-2 parts of zinc dialkyl dithiophosphate, 0.5-2 parts of sodium nitrite, 2-4 parts of ethyl acetyl citrate, 0.4-1 part of methylisobutylketone, 0.5-1 part of dialkyl hydroquinone, 15-20 parts of rare-earth corrosion-inhibition hydraulic oil, 0.2-0.4 part of polysiloxane and 1-3 parts of glycerinum. The rare-earth rust-preventative hydraulic oil is added to the rust-preventative oil disclosed by the invention; a great synergistic effect can be acted by mixing polyepoxysuccinic acid with phosphate, and a stable corrosion-inhibition function is realized; an aluminosiloxane sol is capable of promoting the compatibility among the various materials and improving the film-forming effect of the finished product; the added rare-earth ions are capable of generating insoluble complexes with the OH<-> generated during an oxygen absorption corrosion process on the surface of a metal base material, slowing down the electrode reaction of the corrosion and acting a great slow-release effect.

Owner:HEFEI ZHENGTUO DECORATION MATERIALS CO LTD

A kind of multifunctional alkaline cleaning agent and its preparation method and application

The invention discloses a multifunctional alkaline cleaning agent. The raw material composition of the multifunctional alkaline cleaning agent comprises, by weight, 2-5 parts of potassium carbonate, 2-5 parts of sodium gluconate, 0.5-5 parts of cocoanut fatty acid diethanolamide, 2-5 parts of sodium dodecylbenzene sulfonate, 5-10 parts of monoethanolamine borate, 5-10 parts of dipropylene glycol methyl ether, 5-10 parts of penetrants, 0.5-5 parts of solubilizers, and 10-20 parts of HEDP-4Na, and water is used for complementing to 100 parts. A steel product treated through the cleaning agent has the high surface cleanliness, no oil dirt residue, and no scrap iron, rust deposit and dust particle residue are achieved, the steel product after being cleaned can still meet interprocess rust prevention, the surface brightness of the steel product can be increased, the using cycle is long, the using concentration is low, and the rust prevention period is up to 10-20 days; the safe and environmental protection effects are achieved, the multifunctional alkaline cleaning agent is harmless to a human body, raw materials are wide in sources and easy to obtain, the cost is low, and the multifunctional alkaline cleaning agent is suitable for mass production.

Owner:华阳新兴科技(天津)集团有限公司 +1

Metal cutting fluid with high extreme pressure resistance

InactiveCN102757853BStrong resistance to extreme pressureImprove cooling effectLubricant compositionCarboxylic acidOleic Acid Triglyceride

The invention discloses a metal cutting fluid with high extreme pressure resistance, which comprises the following components in part by weight: 16 to 18 parts of barium petroleum sulfonate, 10 to 12 parts of lead naphthenate, 8 to 10 parts of oleic acid, 22 to 28 parts of triethanolamine, 2 to 3 parts of boric acid, 4 to 6 parts of sodium molybdate, 0.5 to 1 part of methyl silicone oil, 3 to 5 parts of borax, 10 to 12 parts of diethanolamine boric acid polycarboxylic acid composite ester, 8 to 10 parts of diethanolamine boric acid maleic anhydride composite ester, 2 to 3 parts of sodium silicate, 3 to 5 parts of nitrobenzoic acid, and 40 to 50 parts of water. A method for synthesizing the diethanolamine boric acid polycarboxylic acid composite ester comprises the step that diethanol amine, polycarboxylic acid and boric acid are subjected to esterification reaction for 2 to 4 h at 150 to 155 DEG C at a mole ratio of 3:1:1. Another method for synthesizing the diethanolamine boric acid maleic anhydride composite ester comprises the step that diethanol amine, maleic anhydride and boric acid are subjected to esterification reaction for 2 to 4 h at 150 to 155 DEG C at a mole ratio of 3:1:1.

Owner:TIANCHANG RUNDA METAL ANTIRUST AUX

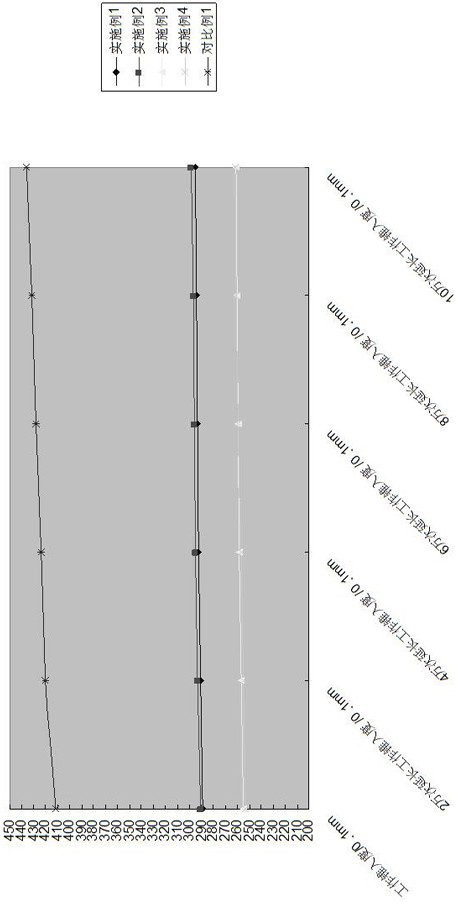

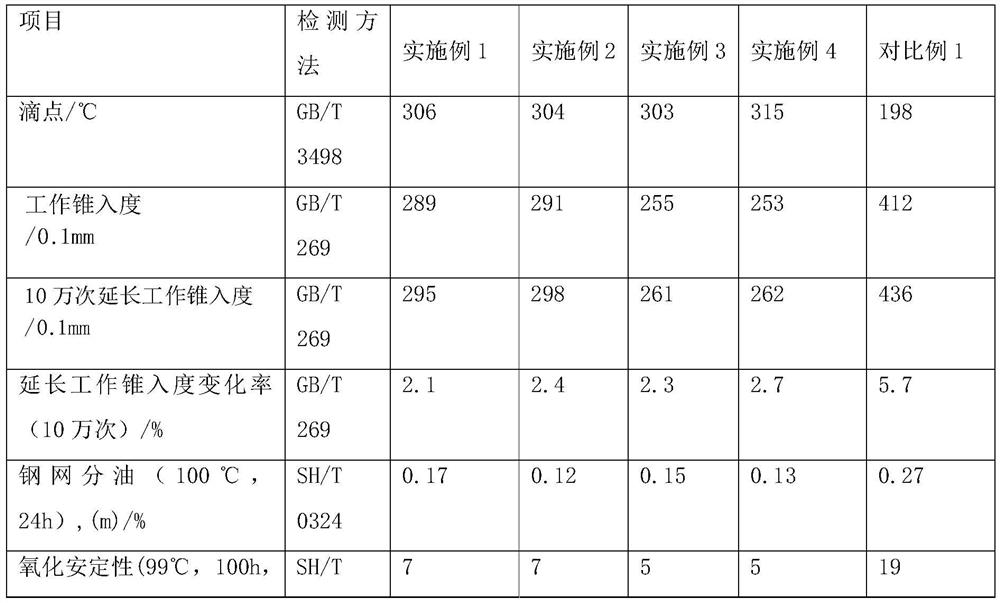

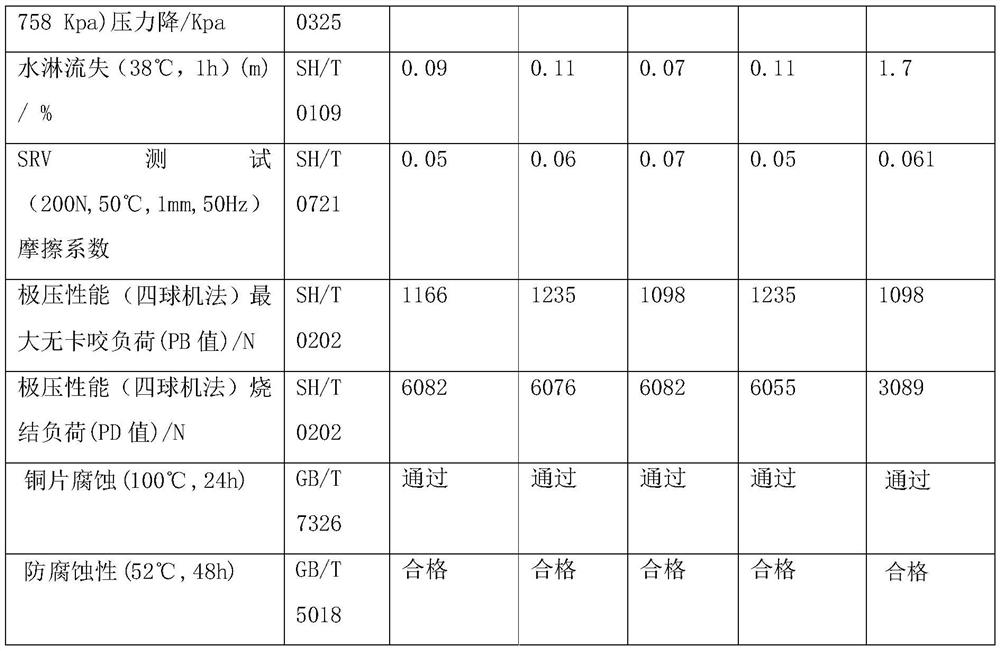

A kind of lubricating grease for industrial robot and preparation method thereof

ActiveCN111996063BReduce coefficient of frictionImprove carrying capacityLubricant compositionSulfonateProcess engineering

The invention provides a lubricating grease for industrial robots, which is composed of base oil, tetrapolyurea-complex calcium sulfonate thickener, antioxidant, solid additive, extreme pressure antiwear agent, antirust agent and antifoaming agent. The present invention also provides a preparation method of the above lubricating grease for industrial robots. The most notable feature of the present invention is that the service life is very long at high temperature; the friction coefficient is very low, the transmission efficiency of the reducer is improved, the energy consumption is reduced, and the anti-fretting wear performance is excellent; extreme pressure anti-wear, water resistance, shear resistance, rust resistance and Excellent stability. In addition, the production and preparation process of the present invention is simple, the product is environmentally friendly, and the quality is stable.

Owner:上海中孚油品集团有限公司

Self-bacteriostasis general emulsion cutting fluid and preparing method thereof

ActiveCN102559355BReasonable ratioImprove the activation effectAdditivesActive agentMonoisopropanolamine

The invention relates to a self-bacteriostasis general emulsion cutting fluid and a preparing method thereof. The components of the emulsion cutting fluid includes, by weight, 50-70 parts of base oils, 7-25 parts of non-ionic surface active agents, 4-10 parts of anion surface active agents, 3-10 parts of monoisopropanolamines, 3-5 parts of compound corrosion inhibitors, 4-15 parts of extreme pressure antiwear agents, 0.01-0.3 parts of defoaming agents, 1 part of ethylene diamine tetraacetic acid, and 2-6 parts of alkyl alanine surface active agents. According to the self-bacteriostasis general emulsion cutting fluid, an organic triethylhexanoin process is adopted, cutting fluids produced has strong cooling characteristics, lubricity and rust protection, and is easy to wash, defects of heavy loading water-soluble cutting fluids in rust protection and odor aspects in use are avoided, simultaneously, bacteriacides are replaced by the alkyl alanine surface active agents, therefore strong bacteriostatic capacity for bacteria, fungi and molds can be achieved without adding special bacteriacides into products, service life of products is prolonged, and cost of products is reduced.

Owner:泰伦特生物工程股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com