Thin-walled cold-formed steel assembly line coating equipment

A technology of cold-formed thin-walled steel and coating equipment, which is applied to the device for coating liquid on the surface, coating, and pre-treatment of the surface, etc., which can solve the problem of poor operating environment for workers, difficulty in uniform coating of paint, and low coating efficiency and other problems to achieve the effect of ensuring coating uniformity, good quality and improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] See figure 1 , cold-formed thin-walled steel flowing water coating equipment, including a frame 1, the top of the frame 1 is provided with a conveying roller table 2, and a plurality of uniformly arranged The centering device 3, the top of the frame 1 is sequentially provided with a pretreatment device 4, a preheat treatment device 5, a coating device 6 and a drying treatment device 8 from the input end to the output end of the conveying roller table 2;

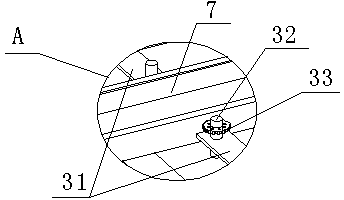

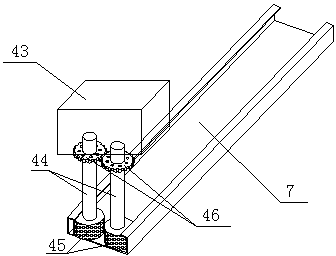

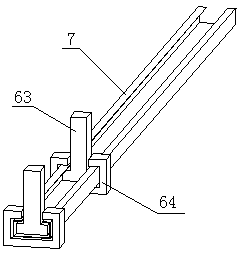

[0030] See figure 2 , the centering device 3 includes two centering fixing plates 31, the outer ends of the two centering fixing plates 31 are fixed on the frame 1, the inner ends of the two centering fixing plates 31 are opposite and the two centering fixing plates are fixed The distance between the inner ends of the plates 31 is the width of the section steel, and the inner ends of the two centering fixed plates 31 are provided with rotating rollers 31, and the rotating rollers 32 are equipped with clamping gears 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com