Environment-friendly composite volatile corrosion inhibitor for galvanized steel sheet and preparation method thereof

A vapor-phase corrosion inhibitor, technology of galvanized steel sheet, applied in flexible covering, packaging, wrapping paper, etc., can solve the problems of limited corrosion inhibition effect of galvanized steel sheet, environmental and human harm, large dosage, etc., to achieve corrosion inhibition Good effect, cost-effective, low toxicity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

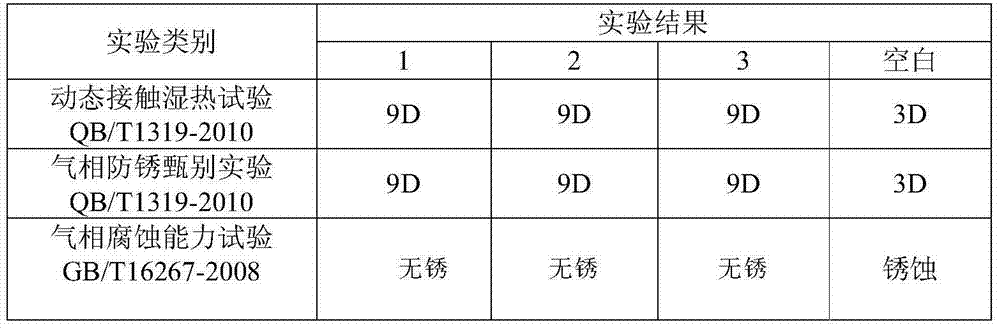

Embodiment 1

[0031] The preparation method of the compound vapor phase corrosion inhibitor for environment-friendly galvanized steel sheets is as follows: weigh 17.5 parts of sodium benzoate, 33.65 parts of water-soluble benzotriazole, 26.85 parts of sodium tungstate, 15.5 parts of cinnamic acid, 6.5 parts of triethanolamine, Deionized water was used to prepare solutions respectively, and the mass concentrations of the active component solutions were 25.93%, 25.18%, 34.94%, 23.66%, and 11.5%, respectively. After standing to clarify, the solutions were mixed. It is obtained by adjusting the pH value of the mixed solution to 8.3-8.8 with saturated ammonia water.

[0032] Quantitative 80g / m 2 The plain weave single-folding base paper is dipped in the environment-friendly galvanized steel sheet prepared in this example for 10 seconds, and then placed in a constant temperature oven with a set temperature of 55°C for 15 minutes and then taken out to obtain an environment-friendly coating. Anti...

Embodiment 2

[0037] The preparation method of the compound vapor phase corrosion inhibitor for environment-friendly galvanized steel sheets is as follows: weigh 20.13 parts of sodium benzoate, 30.77 parts of water-soluble benzotriazole, 24.05 parts of sodium tungstate, 18.1 parts of cinnamic acid, 6.95 parts of triethanolamine, Prepare solutions with deionized water respectively, and the mass concentration of each active component solution is 26.5%, 24.35%, 27.0%, 22.85%, and 15.55%, respectively. After standing for clarification, the solutions are mixed. Adjust the pH value of the mixture to 8.3-8.8 with saturated sodium carbonate solution.

[0038] Quantitative 80g / m 2The plain weave single-folding base paper was dipped in the environment-friendly galvanized steel composite gas-phase corrosion inhibitor prepared in this example for 20 seconds, and then placed in a constant temperature oven with a set temperature of 100°C for 25 minutes and then taken out to obtain an environment-friendly...

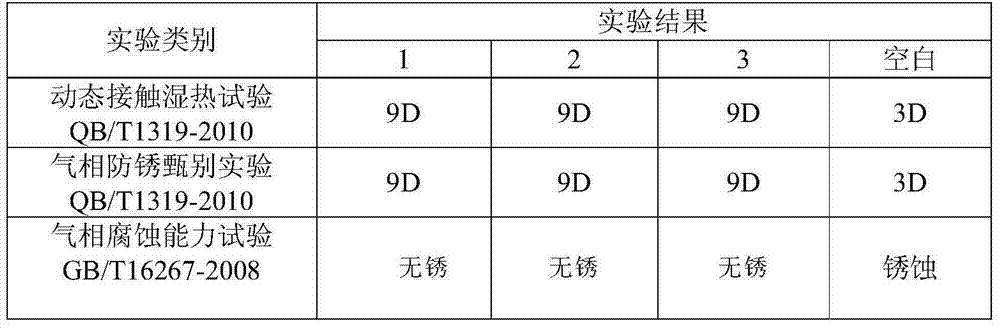

Embodiment 3

[0043] The preparation method of the compound vapor phase corrosion inhibitor for environment-friendly galvanized steel sheets is as follows: weigh 25.15 parts of sodium benzoate, 23.75 parts of water-soluble benzotriazole, 18.84 parts of sodium tungstate, 24.21 parts of cinnamic acid, 8.05 parts of triethanolamine, Prepare solutions with deionized water respectively, and the mass concentration of each active component solution is 27.5%, 24.75%, 30.45%, 23.05%, and 20.43%, respectively. After standing for clarification, the solutions are mixed. It is obtained by adjusting the pH value of the mixture to 8.3-8.8 with saturated sodium bicarbonate solution.

[0044] Quantitative 100g / m 2 The plain-weave single-coated base paper is dipped in the environment-friendly galvanized steel composite gas-phase corrosion inhibitor prepared in this example for 15 seconds, and then placed in a constant temperature oven with a set temperature of 80°C for 20 minutes and then taken out to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com