Oil-free antirust and blackening agent and its preparation method and application

A technology of blackening agent and oil immersion, which is applied in the direction of anti-corrosion coating, coating, epoxy resin coating, etc., and can solve the problems of not meeting the anti-rust requirements and increasing the complexity of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] component name parts by weight Copper chloride 1 Potassium tungstate 2 ammonium thiosulfate 1 Waterborne Epoxy Modified Acrylic Resin Dispersion 80 Aqueous Polyaniline Dispersion 20 citric acid 5 oxalic acid 2 Disodium Hydroxyethylidene Diphosphonate 0.5

[0020] Among the components used above, the aqueous epoxy-modified acrylic resin dispersion can be commercially available raw materials, preferably with a solid content of 45%. The water-based polyaniline dispersion can also choose commercially available raw materials, preferably the effective content of polyaniline is 30%, and the remaining components are dispersant and water.

Embodiment 2

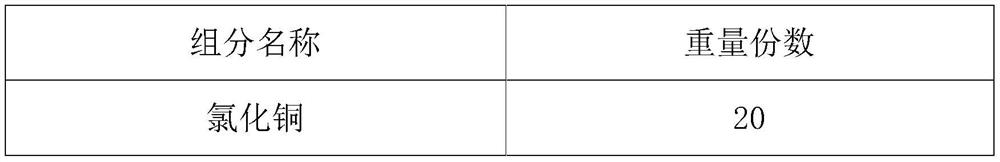

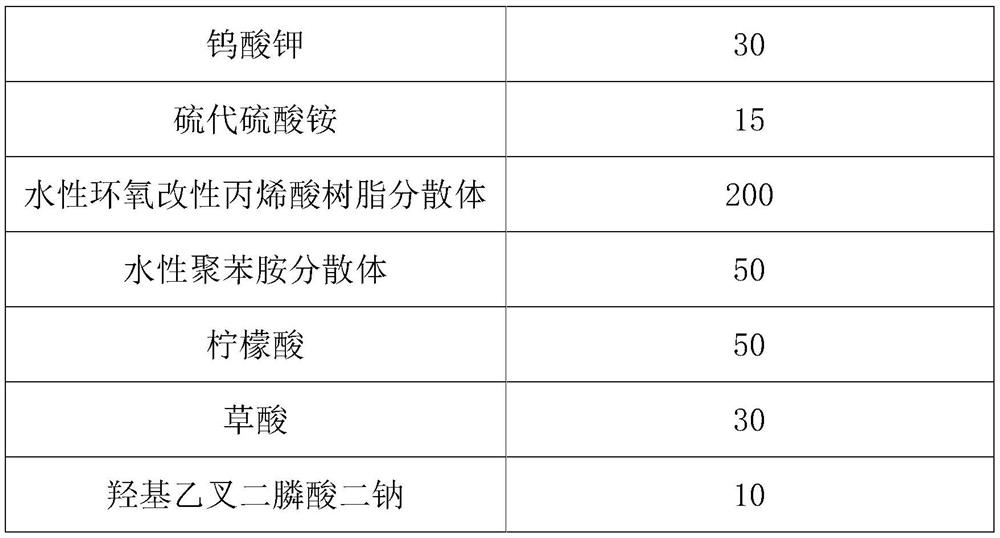

[0022] Embodiment 2 is compared with embodiment 1, only the proportioning of each component changes to some extent, and the proportioning of each component in embodiment 2 is as follows:

[0023]

[0024]

Embodiment 3

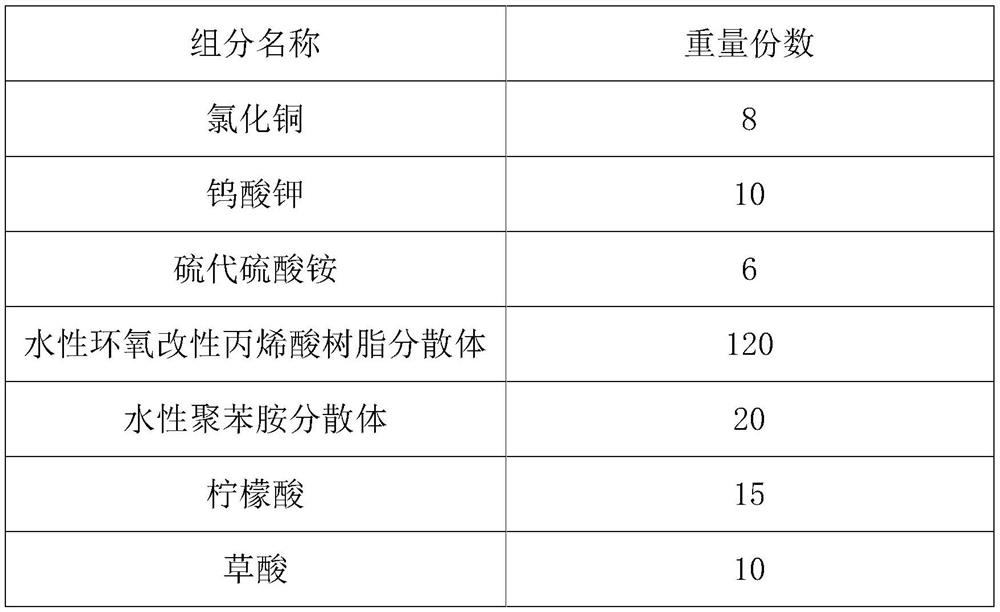

[0026] Embodiment 3 compares with embodiment 1 and 2, only the mass percent distribution ratio of each component changes, and the proportioning of each component in embodiment 3 is as follows:

[0027] component name parts by weight Copper chloride 10 Potassium tungstate 20 ammonium thiosulfate 8 Waterborne Epoxy Modified Acrylic Resin Dispersion 50 Aqueous Polyaniline Dispersion 5 citric acid 20 oxalic acid 25 Disodium Hydroxyethylidene Diphosphonate 5

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com