Application of a kind of vapor phase antirust paper

A technology of vapor-phase anti-rust paper and paper rope, which is applied to impact-sensitive items, packaging, and types of packaging items. rust protection effect and other issues, to achieve the effect of improving rapid response or operational efficiency, saving the consumption of non-renewable resources, and ensuring cleanliness requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

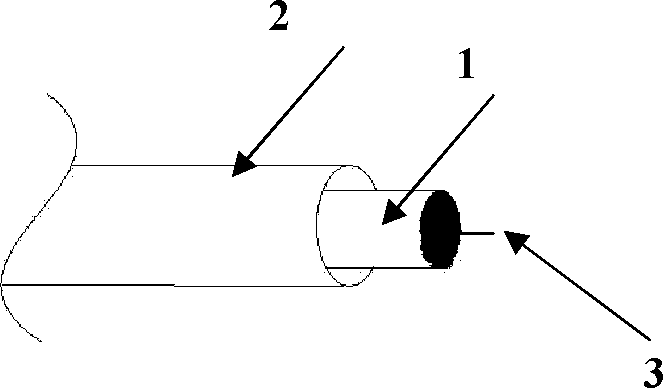

Embodiment 1

[0019] Adopt the SF / H104-82PO type 82 grams quantitative gas phase antirust paper for steel produced by Shenyang Antirust Packaging Materials Co., Ltd., cut it into strips with a width of 30mm, and make a single strand of gas phase with a diameter of 3mm on an automatic paper rope machine Anti-rust paper rope. The paper rope has excellent gas-phase anti-rust performance, tested according to the GB / T16267 standard, and the anti-rust performance can reach level 0 (no rust at all). It is cut into a length of 850mm and put into a gun barrel with an inner diameter of 7.62mm. The mouth of the barrel is sealed, which can meet the anti-rust storage requirements of more than 10 years.

Embodiment 2

[0021] Adopt the SF / D308-112PO polymetallic vapor-phase antirust paper with a quantitative weight of 112 grams produced by Shenyang Antirust Packaging Materials Co., Ltd., cut into strips with a width of 20mm, and make double strips with a diameter of 5mm on an automatic paper rope machine. Strand paper rope. The paper rope has excellent gas-phase antirust performance on steel, copper and copper alloys, etc., and is tested according to the gas-phase corrosion inhibition ability test in the QB / T 1319-2010 standard, and has no rust. Put it into the engine cooling water pipeline and seal it, which can protect the cooling water system from rust for more than 2 years.

Embodiment 3

[0023] Use the SF / T502-52PO vapor phase antirust paper for copper with a weight of 52 grams produced by Shenyang Antirust Packaging Materials Co., Ltd., cut it into paper strips with a width of 20mm, and process it into three strands of paper with a diameter of 6mm on a paper rope machine rope. The paper rope has excellent vapor phase anti-rust effect on copper and copper alloys. According to the gas phase anti-rust screening test in the QB / T1319-2010 standard, the brass has no rust for 9 cycles. Insert it into a copper tube with an inner diameter of 10-100mm. After sealing the tube mouth, it can protect the inner cavity of the copper tube from rust for more than 8 years.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com