Rust-proof soft film composition and preparation method thereof

A technology of soft film composition and antirust agent, which is applied in the direction of lubricating composition, petroleum industry, additives, etc., and can solve the problem of destroying the original appearance of the metal surface when it can only be used indoors in a natural environment without rain and light. , high surface treatment requirements, etc., to achieve excellent salt spray resistance and heat and humidity resistance, avoid premature failure, and excellent overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

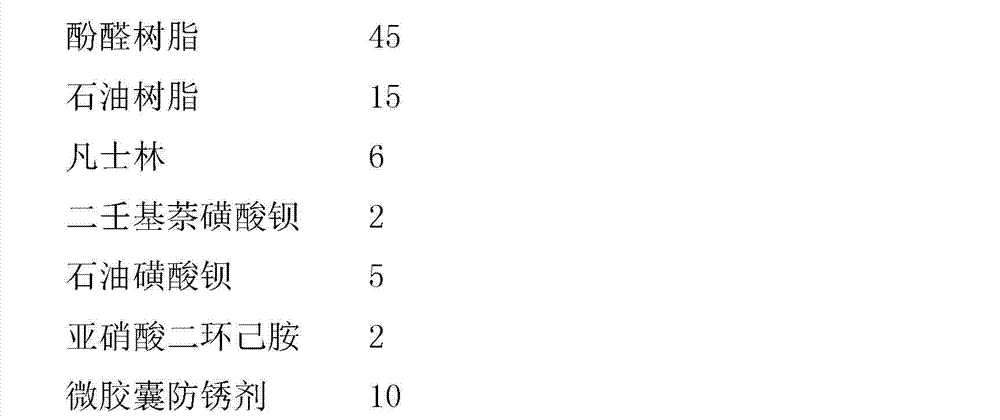

[0045] A kind of translucent antirust soft film composition of the present invention, its composition and mass percent are:

[0046]

[0047] The rheological agent is selected from polyamide modified castor oil derivatives,

[0048] Specifically used is LUVOTIX HT 2.5 from Lefus Chemical Company

[0049] Antifoaming agent is selected from modified polysiloxane,

[0050] Specifically, Deqian Chemical Company Defom6500 0.5

[0051] Xylene 8

[0052] n-Butanol 4

[0053] According to the above preparation method, add xylene, n-butanol, phenolic resin, petroleum resin, and vaseline into the reactor, stir and raise the temperature to 60°C, and keep it warm for 30 min. After the film-forming agent is completely dissolved, cool down to 45°C, and then Add barium dinonylnaphthalene sulfonate, barium petroleum sulfonate, dicyclohexylamine nitrite, microcapsule antirust agent, rheological agent, and defoamer, and continue stirring for 30 min at 45°C to obtain a uniform liquid . ...

Embodiment 2

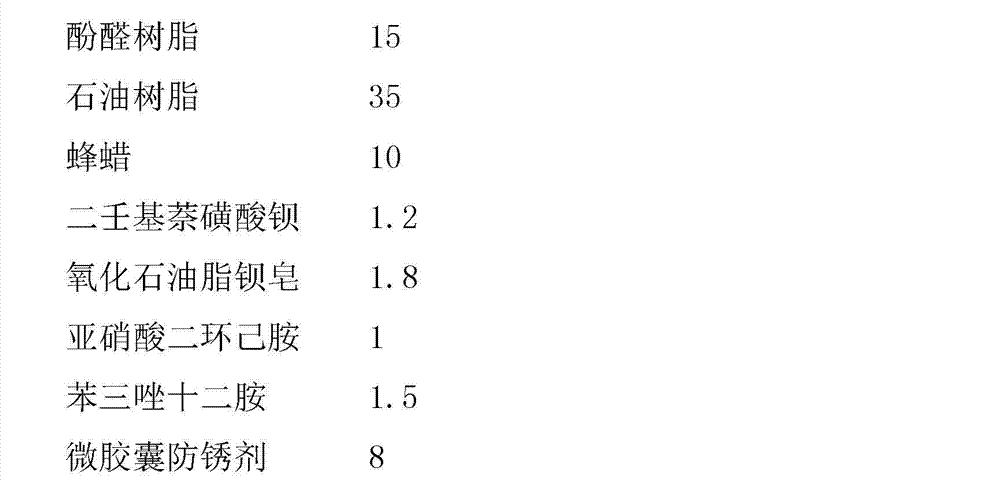

[0055] A kind of black antirust soft film composition of the present invention, its composition and mass percent are:

[0056]

[0057]

[0058] The rheological agent is selected from polyamide modified castor oil derivatives,

[0059] Specifically used is LUVOTIX HT 2.5 from Lefus Chemical Company

[0060] Antifoaming agent is selected from modified polysiloxane,

[0061] Specifically, Deqian Chemical Company Defom6500 0.5

[0062] Xylene 14

[0063] n-Butanol 8

[0064] The above preparation method is as follows: add xylene, n-butanol, phenolic resin, petroleum resin, and beeswax into the reactor, stir and heat up to 60°C, keep it warm for 30 minutes, and cool down to 45°C after the film-forming agent is completely dissolved. Add barium dinonylnaphthalene sulfonate, barium oxidized petroleum tallow soap, dicyclohexylamine nitrite, benzotriazole dodecylamine, microcapsule antirust agent, carbon black, rheological agent, defoaming agent in sequence, at 45°C Under th...

Embodiment 3

[0066] A kind of blue antirust soft film composition of the present invention, its composition and mass percent are:

[0067]

[0068] The rheological agent is selected from polyamide modified castor oil derivatives,

[0069] Specifically used is LUVOTIX HT 2.5 from Lefus Chemical Company

[0070] Antifoaming agent is selected from modified polysiloxane,

[0071] Specifically, Deqian Chemical Company Defom6500 0.5

[0072] Xylene 6

[0073] n-Butanol 2.5

[0074] According to the above preparation method, add xylene, n-butanol, phenolic resin, petroleum resin, and beeswax into the reactor, stir and raise the temperature to 60°C, and keep it warm for 30 minutes. After the film-forming agent is completely dissolved, cool down to 45°C, and then Add barium dinonylnaphthalene sulfonate, magnesium lanolin soap, 2-ethyl-4-methylimidazole, benzotriazole dodecylamine, microcapsule rust inhibitor, phthalocyanine blue, rheological agent, defoamer, Stirring was continued for 30 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com