Antirust paint emulsion and its preparation method

A technology of anti-rust coatings and emulsions, applied in anti-corrosion coatings, anti-fouling/underwater coatings, coatings, etc., can solve the problems of poor storage stability and high film-forming temperature, and achieve high water resistance and low film-forming temperature of the coating film , storage stability and good film performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

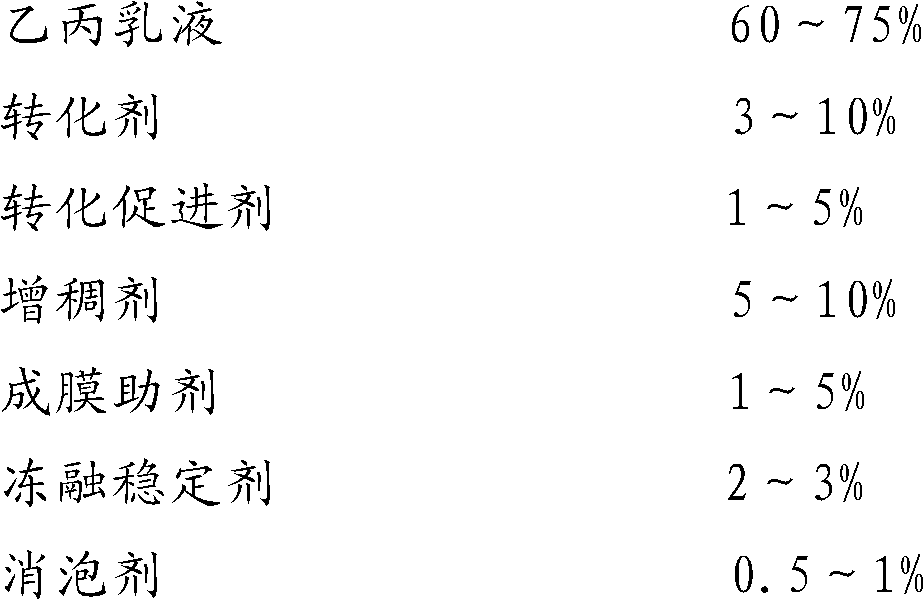

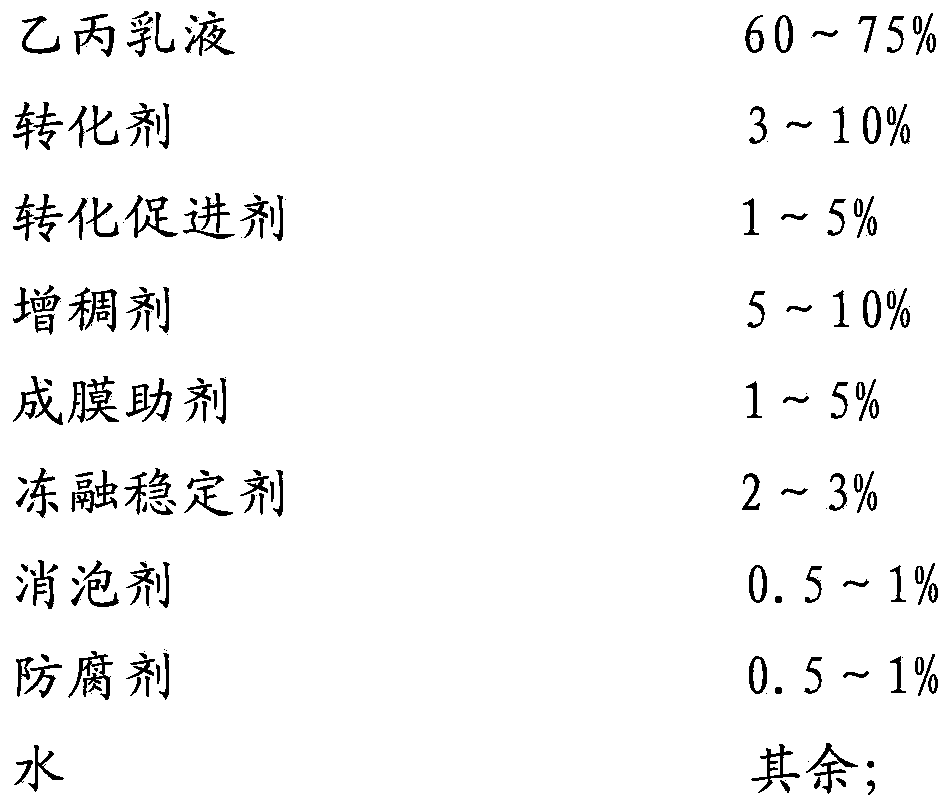

Method used

Image

Examples

Embodiment 1

[0036] The preparation of ethylene-propylene (vinyl acetate-acrylate) emulsion: 240 parts (by weight, the same below) deionized water, 1.0 parts of sodium bicarbonate and 2.2 parts of anionic surfactants are added in the reactor, and then the first step Disperse the monomers, 85 parts of butyl acrylate and 35 parts of vinyl acetate, in the above aqueous solution, raise the temperature to 70°C, add the initiators, namely 0.17 parts of ammonium persulfate and 0.20 parts of sodium bisulfite, and keep stirring for 80 minutes to obtain a mixed emulsion ; Then dropwise the second step monomer at a rate of 20 to 30 milliliters per minute, i.e. the mixed solution after 108 parts of butyl acrylate, 20 parts of vinyl acetate and 12 parts of acrylic acid are combined evenly, after 1 hour, Slowly lower the temperature to 45-55°C, and control the temperature at 50-60°C, and continue to add component 1 dropwise at a rate of 100-120 ml per minute until the drop is complete. Then raise the te...

Embodiment 2

[0040] The preparation of ethylene-propylene emulsion is with embodiment 1.

[0041] The preparation of antirust paint emulsion: the conversion agent (gallic acid) of 8.0 parts, the conversion accelerator (glucinol) of 2.0 parts, the water of 13.0 parts, the film-forming aid (ethylene glycol ethyl ether) of 3.0 parts and 2.5 parts Mix one part freeze-thaw stabilizer (ethylene glycol) together, heat to 50°C and stir for 1 hour, then add it into 65.0 parts of ethylene-propylene emulsion at a rate of 100 ml per minute, maintain the temperature at 50-60°C, add all After that, add 0.5 parts of defoamer (tributyl phosphate), stir for 1 hour, then add 5.0 parts of thickener (14.2% aqueous solution of sodium polyacrylate), stir for 1 hour, then add 1.0 parts of preservative (5% sodium benzoate), stirred for 1 hour to obtain the water-based rust coating.

[0042] The properties of the antirust paint emulsion prepared in this example are as follows: milky white aqueous dispersion, no l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com