Environmentally-friendly antirust oil for iron-based powder metallurgy parts and preparation method of antirust oil

An iron-based powder metallurgy, anti-rust oil technology, applied in the petroleum industry, lubricating composition and other directions, can solve the problems of environmental and human hazards, poor rust-proof oil-water replacement ability, difficult to enter the gap, etc., and achieves good salt spray resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

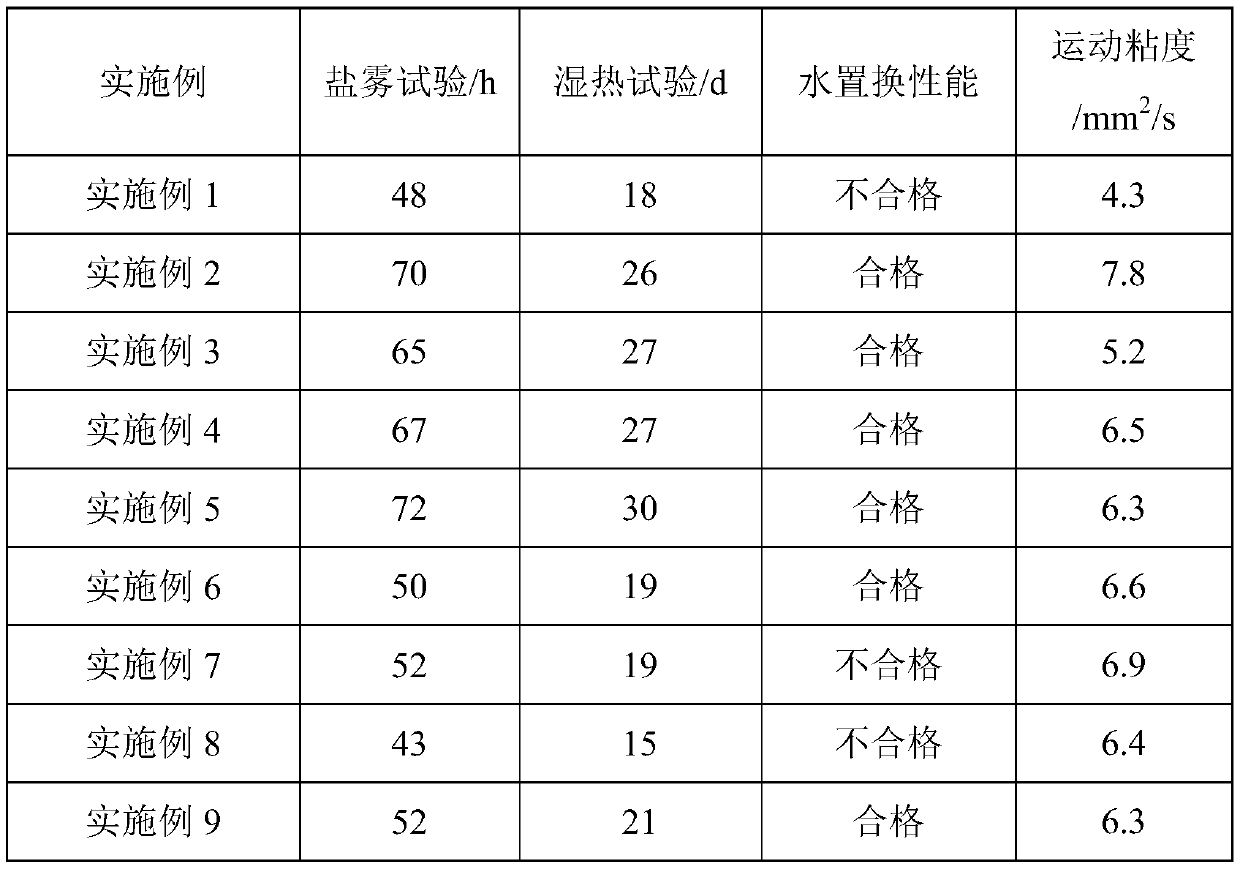

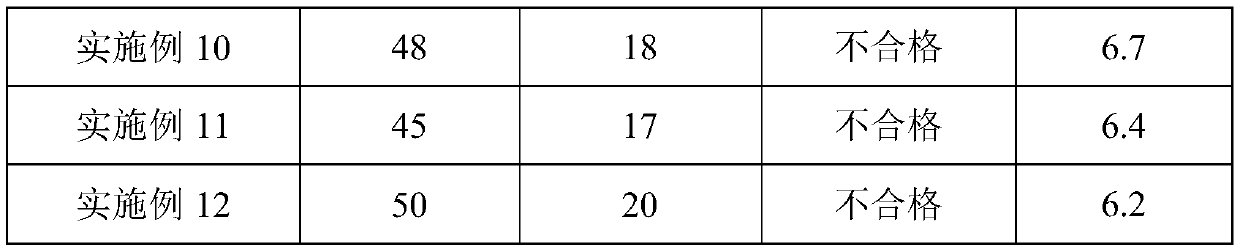

Examples

preparation example Construction

[0069] The second aspect of the present invention provides a method for preparing an environmentally friendly antirust oil for iron-based powder metallurgy parts, the steps comprising:

[0070] (1) Add the base oil into the blending kettle, stir at 40-50°C for 20-40min, and prepare the base oil mixture A;

[0071] (2) Add barium-free sulfonate into the blending kettle, heat up to 110-120°C and stir at constant temperature for 40-60min to prepare barium-free sulfonate mixture B;

[0072] (3) Add the antirust agent into the blending kettle, heat up to 70-80°C and stir at a constant temperature for 20-40min to prepare antirust agent mixture C;

[0073] (4) Add mixtures A, B, C, auxiliary agents and antioxidants into a blending kettle, stir at 40-50°C for 20-40 minutes, filter and pack in a tank to obtain the environmentally friendly anti-rust oil.

Embodiment 1

[0077] Example 1 provides an environmentally friendly antirust oil for iron-based powder metallurgy parts, which includes the following components in parts by weight: 60 parts of base oil, 3 parts of barium-free sulfonate, 2 parts of antirust agent, and 1 part of auxiliary agent part, 0.1 part of antioxidant.

[0078] The base oil is composed of D80 solvent oil and No. 10 transformer oil according to the ratio of 1:9;

[0079] The barium-free sulfonate is composed of sodium petroleum sulfonate, calcium dinonylnaphthalene sulfonate, and synthetic calcium sulfonate with high alkali value in a weight ratio of 6:1:1;

[0080] The antirust agent is composed of dodecenylsuccinate half ester, sorbitan oleate, and oxidized paraffin butyl ester in a weight ratio of 1:2:4;

[0081] The auxiliary agent is composed of ethylene glycol butyl ether and fatty alcohol polyoxyethylene ether in a weight ratio of 1:1;

[0082] The antioxidant is 2,6-di-tert-butyl-p-cresol.

[0083] A method fo...

Embodiment 2

[0089] Embodiment 2 provides an environmentally friendly antirust oil for iron-based powder metallurgy parts, which includes the following components in parts by weight: 90 parts of base oil, 20 parts of barium-free sulfonate, 20 parts of antirust agent, and 10 parts of auxiliary agent 1 part, antioxidant 1 part.

[0090] The base oil is composed of D80 solvent oil and No. 10 transformer oil according to the ratio of 1:7;

[0091] The barium-free sulfonate is composed of sodium petroleum sulfonate, calcium dinonylnaphthalene sulfonate, and synthetic calcium sulfonate with high alkali value in a weight ratio of 6:1:1;

[0092] The antirust agent is composed of dodecenylsuccinate half ester, sorbitan oleate, and oxidized paraffin butyl ester in a weight ratio of 1:2:4;

[0093] The auxiliary agent is composed of ethylene glycol butyl ether and fatty alcohol polyoxyethylene ether in a weight ratio of 1:1;

[0094] The antioxidant is 2,6-di-tert-butyl-p-cresol.

[0095] A metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com