Drum pulping device and pulping method thereof

A technology of pulping and drumming, which is applied in the direction of textiles and papermaking, raw material separation, papermaking, etc. It can solve the problems of increasing processing load, decreasing physical index of paper, and low fiber length, so as to ensure physical strength, reduce processing load, Less fiber loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

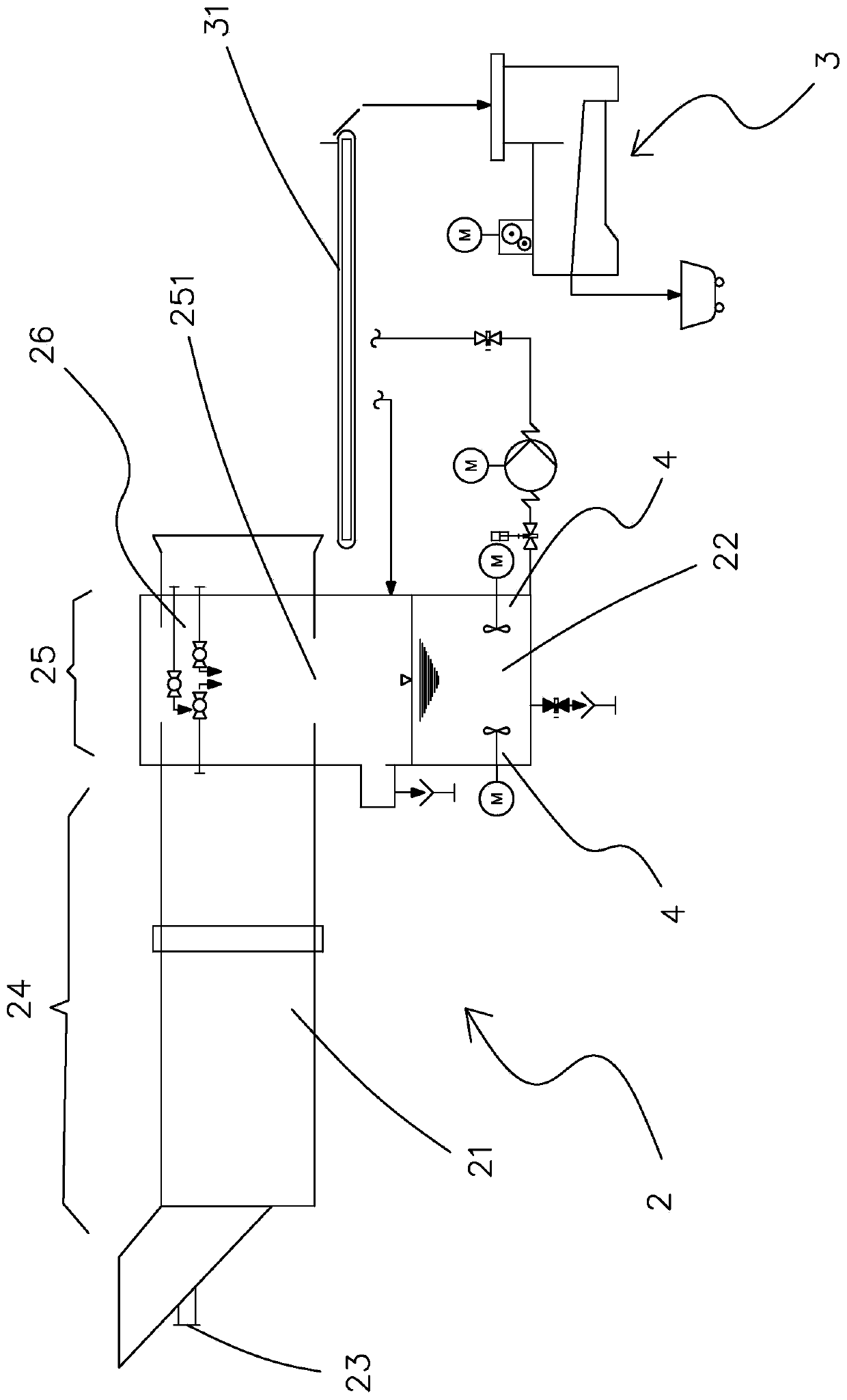

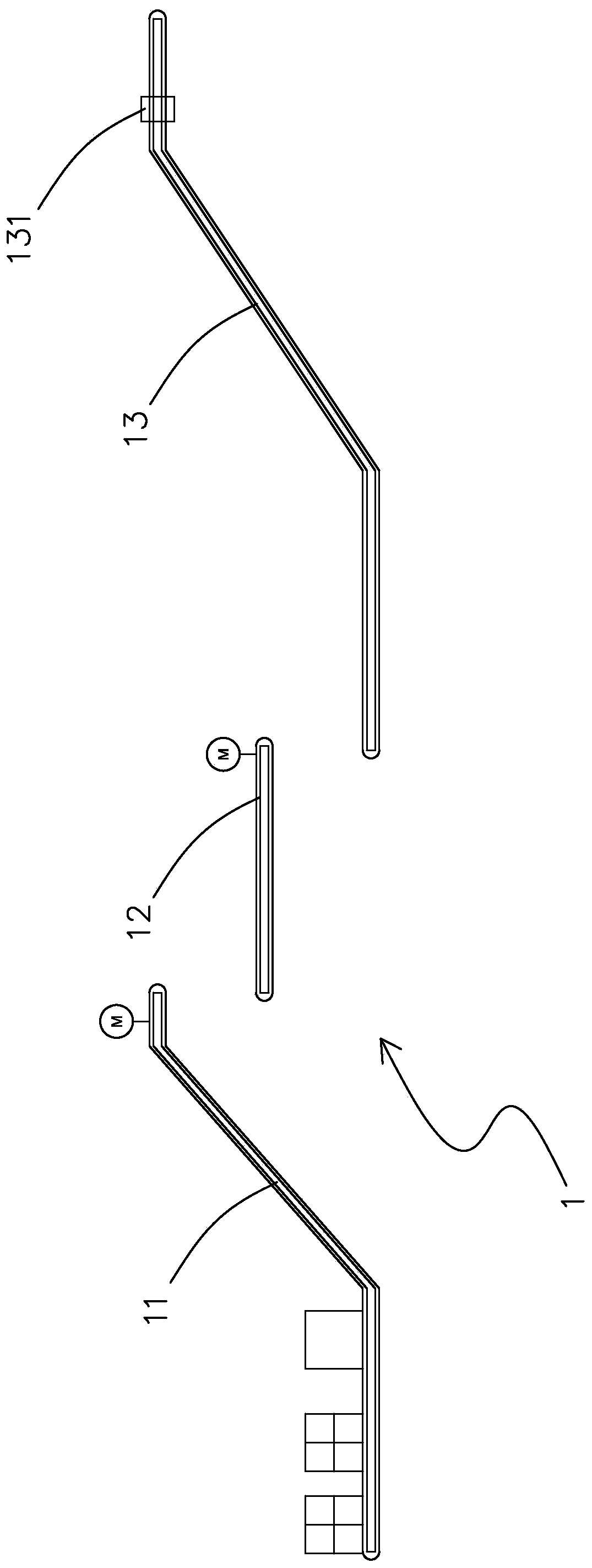

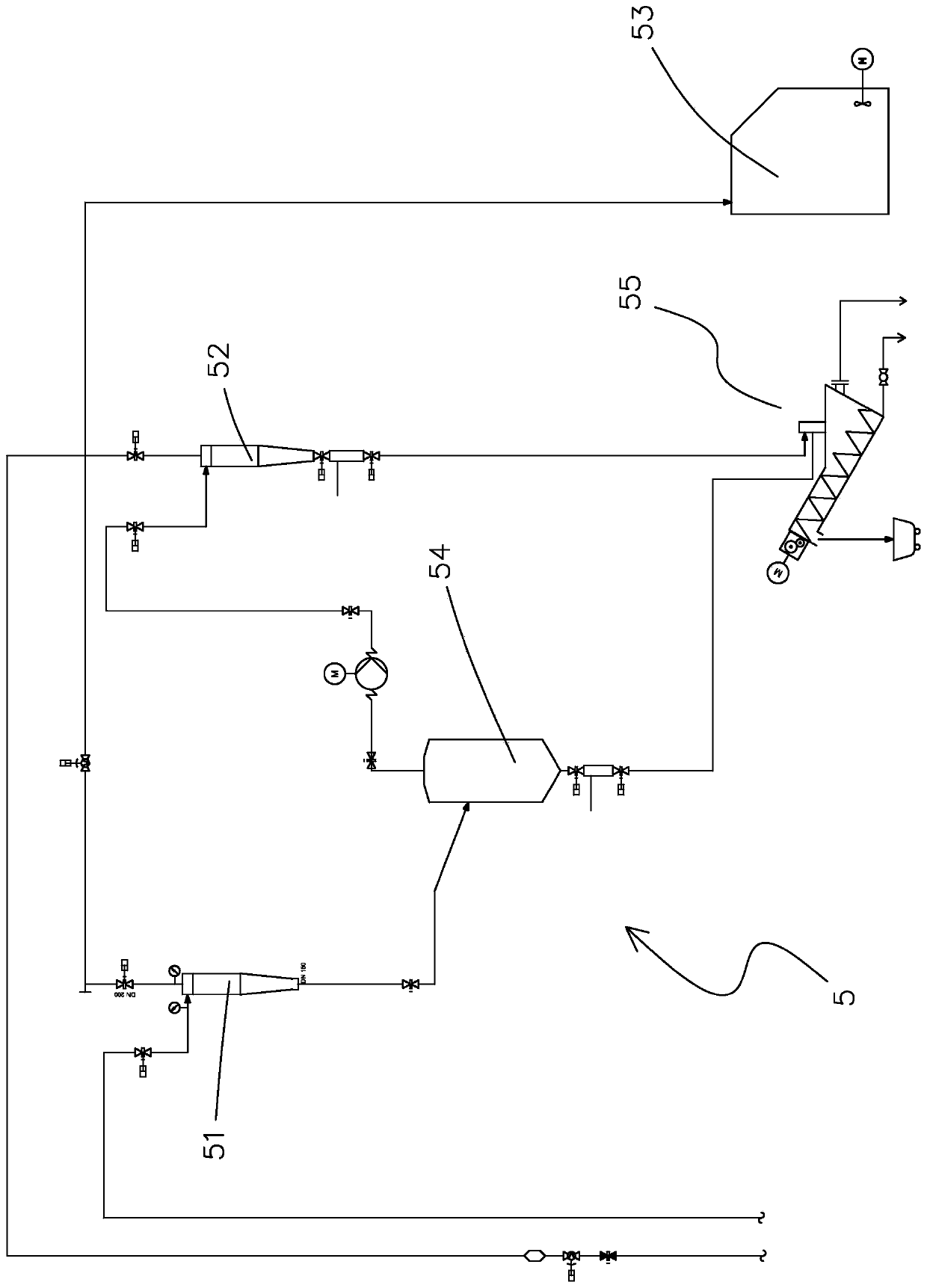

[0032] A drum pulping device, including a chain plate unit 1 for conveying and dispersing domestic OCC waste paper, a drum pulper 2 for making dispersed domestic OCC waste paper into pulp, and a drum pulper 2 It includes a drum 21 and a slurry tank 22 located at the rear and lower side of the drum 21. The front end of the drum 21 is provided with a white water adding port 23, and the front and rear of the drum 21 are respectively a crushing area 24 and a screening area 25. The disintegrating zone 24 is provided with the disintegrating knives (not shown) that are arranged at helical intervals along the inner side wall of the rotating drum 21, and the disintegrating knives can rotate with the rotating drum 21 to disintegrate the waste paper raw materials into pulp and disintegrate the disintegrated waste paper. Slurry advances to the screening area 25, and a white water adding device 26 for adding white water to the screening area 25 is provided in the rotating drum 21. The scree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com