Spongy dextromethorphan hydrobromide film agent with micro-pore and preparation method thereof

A dextromethorphan hydrobromide and sponge-like technology, which can be used in medical preparations containing non-active ingredients, medical preparations containing active ingredients, and tablet delivery, etc., can solve the problem of increasing the proportion of plasticizers and slowing down dissolution , unable to achieve rapid effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

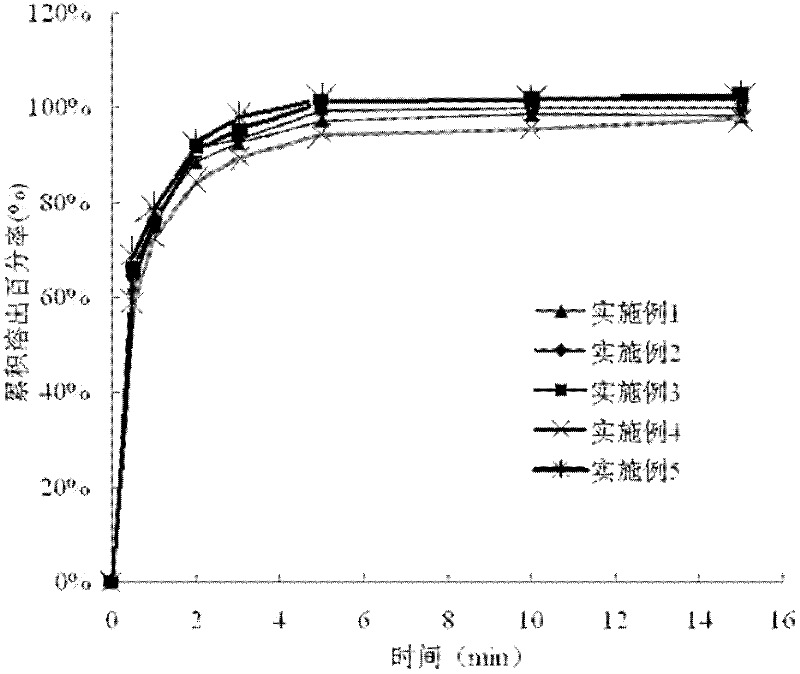

Examples

Embodiment 1

[0060] 80 g of PVA with a molecular weight of 130,000 Daltons and 20 g of HPC with a molecular weight of 600,000 Daltons were dissolved in 500 g of water to form a water slurry.

[0061] Add 100g of pore-forming agent, 10g of dextromethorphan hydrobromide, 2g of aspartame, 5g of glycerin and 3g of titanium dioxide into the above water slurry, fully stir and mix evenly.

[0062] The components of the pore-forming agent include chitin with a particle size of 0.5 μm and acetone adsorbed thereon, and the parts by weight of chitin and the parts by weight of the solvent are:

[0063] Chitosan 100 parts

[0064] Acetone 400 parts

[0065] (2) Then adopt the method reported in the literature of the research on nitroglycerin membrane (Chinese Journal of Pharmaceutical Industry, 1977, 12 (5)), apply and form a membrane, and obtain a thin film precursor;

[0066] (3) Dry the film precursor obtained in step (2) at 80° C. to obtain the film for the drug film preparation, with a thickness...

Embodiment 2

[0074] 16 g of HPMC with a molecular weight of 20,000 Daltons and 64 g of PEO with a molecular weight of 7,000,000 Daltons were dissolved in 500 g of water to form a water slurry.

[0075] Add 200g of pore-forming agent, 50g of dextromethorphan hydrobromide, 5g of sucralose and 0.1g of sunset yellow pigment into the above water slurry, fully stir and mix evenly.

[0076] The component of described pore-forming agent comprises the sodium polystyrene sulfonate of 10 μ m and the ethanol adsorbed on it, the parts by weight of sodium polystyrene sulfonate and the parts by weight of solvent are:

[0077] Sodium polystyrene sulfonate 100 parts

[0078] Ethanol 100 parts

[0079] Others are the same as embodiment 1.

[0080] The weight ratio of each component:

[0081] Low molecular weight water-soluble polymer material: high molecular weight water-soluble polymer material=1:4;

[0082] Water-soluble polymer material: water-insoluble micropowder = 1:1.25;

[0083] The diameter of...

Embodiment 3

[0086] Dissolve 60 g of sodium alginate with a molecular weight of 32,000 Daltons and 120 g of CMC-Na with a molecular weight of 700,000 Daltons in 700 g of water to form a water slurry.

[0087] Add 90g of pore-forming agent, 50g of dextromethorphan hydrobromide, 5g of cyclamate, 5g of PEG400 and 3g of titanium dioxide into the above water slurry, fully stir and mix evenly.

[0088] The components of the pore-forming agent include CaCO3 with a particle size of 1 μm and ethanol adsorbed thereon, and the parts by weight of CaCO3 and the parts by weight of the solvent are:

[0089] CaCO3 100 parts

[0090] Ethanol 100 parts

[0091] Others are the same as embodiment 1.

[0092] The weight ratio of each component:

[0093] Low molecular weight water-soluble polymer material: high molecular weight water-soluble polymer material=1:2;

[0094] Water-soluble polymer material: water-insoluble micropowder = 1:0.25;

[0095] The diameter of the micropores is 10 nm.

[0096] Perfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com