AKD (Alkyl Ketene Dimer) reinforcement accelerator for surface glue and preparation method thereof

A technology of accelerator and surface glue, applied in the field of AKD enhancement accelerator for surface glue and its preparation, can solve the problems of easy hydrolysis and deterioration, poor starch temperature adaptability, poor emulsion stability, etc., to improve paper quality and surface printing strength. , Reduce the effect of wet end paper break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

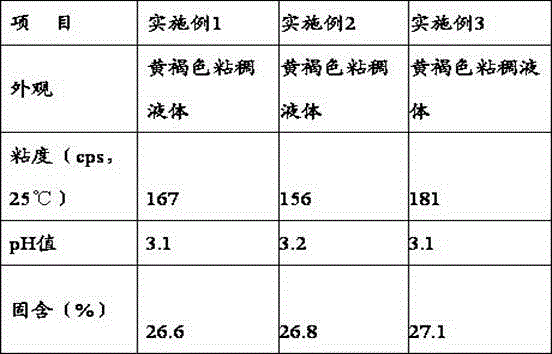

Embodiment 1

[0033] 40 parts of dimethyl diallyl ammonium chloride, 40 parts of acrylic acid for use as an unsaturated organic acid, 10 parts of functional monomers, 2 parts of polyvinyl alcohol with a degree of alcoholysis of 99% and a viscosity of 19 cps, 0.01 part of ammonium persulfate, water 300 parts; Add 80 parts of water to polyvinyl alcohol and stir at room temperature for 1 hour, raise the temperature to 93°C, stir continuously during the heating process, when the temperature reaches 93°C, keep warm for 1 hour to obtain a polyvinyl alcohol solution with a solid content of 5%; in the reaction Add 220 parts of water, 20 parts of dimethyl diallyl ammonium chloride, 40 parts of acrylic acid, and 0.003 parts of ammonium persulfate into the kettle, and stir evenly, then heat up, and keep warm at 50°C for 1 hour; Add 20 parts of dimethyl diallyl ammonium chloride, 10 parts of functional monomers, and 0.002 parts of ammonium persulfate, stir at 50°C, keep warm at 55°C for 2 hours; add pol...

Embodiment 2

[0035] 45 parts of dimethyl diallyl ammonium chloride, 40 parts of methacrylic acid for unsaturated organic acid, 10 parts of functional monomer, 5 parts of polyvinyl alcohol with a degree of alcoholysis of 99.5% and a viscosity of 25 cps, and 0.02 part of ammonium persulfate , 300 parts of water; add 150 parts of water to polyvinyl alcohol and stir at room temperature for 1 hour, heat up to 93°C, stir continuously during the heating process, when the temperature reaches 93°C, keep warm for 1 hour to obtain a polyvinyl alcohol solution with a solid content of 5%; Add 150 parts of water, 20 parts of dimethyl diallyl ammonium chloride, 40 parts of methacrylic acid, and 0.008 parts of ammonium persulfate into the reaction kettle, and stir evenly, then raise the temperature, and keep warm at 55°C for 1 hour; Add 25 parts of dimethyl diallyl ammonium chloride, 10 parts of functional monomers, and 0.004 parts of ammonium persulfate into the reaction kettle, stir at 55°C, and keep war...

Embodiment 3

[0037] 50 parts of dimethyl diallyl ammonium chloride, 50 parts of crotonic acid for unsaturated organic acid, 10 parts of functional monomer, 10 parts of polyvinyl alcohol with alcoholysis degree of 99.8%, viscosity of 27 cps, 0.03 part of ammonium persulfate , 300 parts of water; add 180 parts of water to polyvinyl alcohol and stir at room temperature for 1 hour, heat up to 97°C, stir continuously during the heating process, when the temperature reaches 97°C, keep warm for 1 hour to obtain a polyvinyl alcohol solution with a solid content of 5%; Add 120 parts of water, 30 parts of dimethyl diallyl ammonium chloride, 50 parts of crotonic acid, and 0.01 part of ammonium persulfate into the reaction kettle, and stir evenly, then heat up, and keep warm at 40°C for 1 hour; Add 20 parts of dimethyl diallyl ammonium chloride, 10 parts of functional monomers, and 0.01 part of ammonium persulfate into the reaction kettle, stir at 40°C, and keep warm at 60°C for 2 hours; Add polyvinyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com