Electrothermal high-temperature-resistant carbon fiber paper and preparation method thereof

A technology of carbon fiber paper and carbon fiber, which is applied in the direction of synthetic cellulose/non-cellulose material pulp/paper, fiber raw material processing, papermaking, etc., can solve the problems of low temperature resistance level and cannot meet the application requirements of high-end use occasions, and achieve high performance Excellent, improve the flame retardant effect, reduce the effect of paper breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

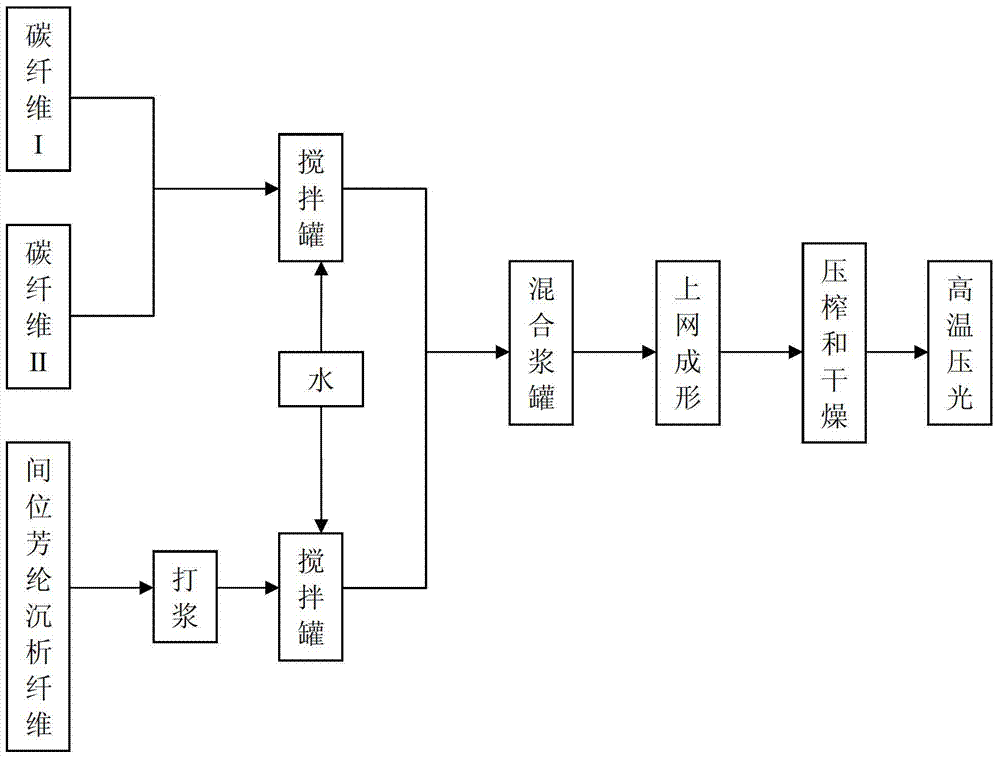

Method used

Image

Examples

Embodiment 1

[0034] A slurry of electric heating and high temperature resistant carbon fiber paper, the fibers in the slurry are composed of the following components by mass percentage: carbon fiber I: 65%; carbon fiber II: 15%; meta-aramid fibrids: 20%; Wherein, the length of the carbon fiber I is 1-5mm, and the fineness is 1.5D; the length of the carbon fiber II is 8-10mm, and the fineness is 1.5D; the beating degree of the meta-aramid precipitated fiber is 40-80 °SR.

[0035] A method for preparing the slurry, comprising the steps of:

[0036] (1) Preparation of three kinds of slurry:

[0037] Preparation of carbon fiber I slurry: add 1 part of carbon fiber I to 100 parts of water, stir and disperse for 5 minutes with a stirrer, the stirring speed is 300r / min, make the mixed liquid have no lumps visible to the naked eye, then add 400 parts of water, and then Use an ultrasonic dispersing device to disperse the mixed solution for 10 minutes, while stirring the mixed solution, so that th...

Embodiment 2

[0047] A slurry of electric heating and high temperature resistant carbon fiber paper, the fibers in the slurry are composed of the following components by mass percentage: carbon fiber I: 70%; carbon fiber II: 5%; meta-aramid fibrids: 25%; Wherein, the length of the carbon fiber I is 1-5mm, and the fineness is 1.5D; the length of the carbon fiber II is 8-10mm, and the fineness is 1.5D; the beating degree of the meta-aramid precipitated fiber is 40-80 °SR.

[0048] A method for preparing the slurry, comprising the steps of:

[0049] (1) Preparation of three kinds of slurry:

[0050] Preparation of carbon fiber I slurry: add 1 part of carbon fiber I to 100 parts of water, stir and disperse for 5 minutes with a stirrer, the stirring speed is 300r / min, make no lumps visible to the naked eye in the mixed solution, then add 300 parts of water, and then Use an ultrasonic dispersing device to disperse the mixed solution for 5 minutes, while stirring the mixed solution, so that ther...

Embodiment 3

[0060] A slurry of electric heating and high temperature resistant carbon fiber paper, the fibers in the slurry are composed of the following components by mass percentage: carbon fiber I: 65%; carbon fiber II: 30%; meta-aramid fibrids: 5%; Wherein, the length of the carbon fiber I is 1-5mm, and the fineness is 1.5D; the length of the carbon fiber II is 8-10mm, and the fineness is 1.5D; the beating degree of the meta-aramid precipitated fiber is 40-80 °SR.

[0061] A method for preparing the slurry, comprising the steps of:

[0062] (1) Preparation of three kinds of slurry:

[0063] Preparation of carbon fiber I slurry: add 5 parts of carbon fiber I to 100 parts of water, stir and disperse for 10 minutes with a stirrer, and the stirring speed is 500r / min, so that there are no lumps visible to the naked eye in the mixed solution, then add 700 parts of water, and then Use an ultrasonic dispersing device to disperse the mixed solution for 10 minutes, while stirring the mixed so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com