Film transfer sizing method of oil-proof paper

A technology of film transfer sizing and oil-proof paper, which can be used in paper, papermaking, paper coating, etc., and can solve the problems of poor bonding between surface sizing agent and fiber.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

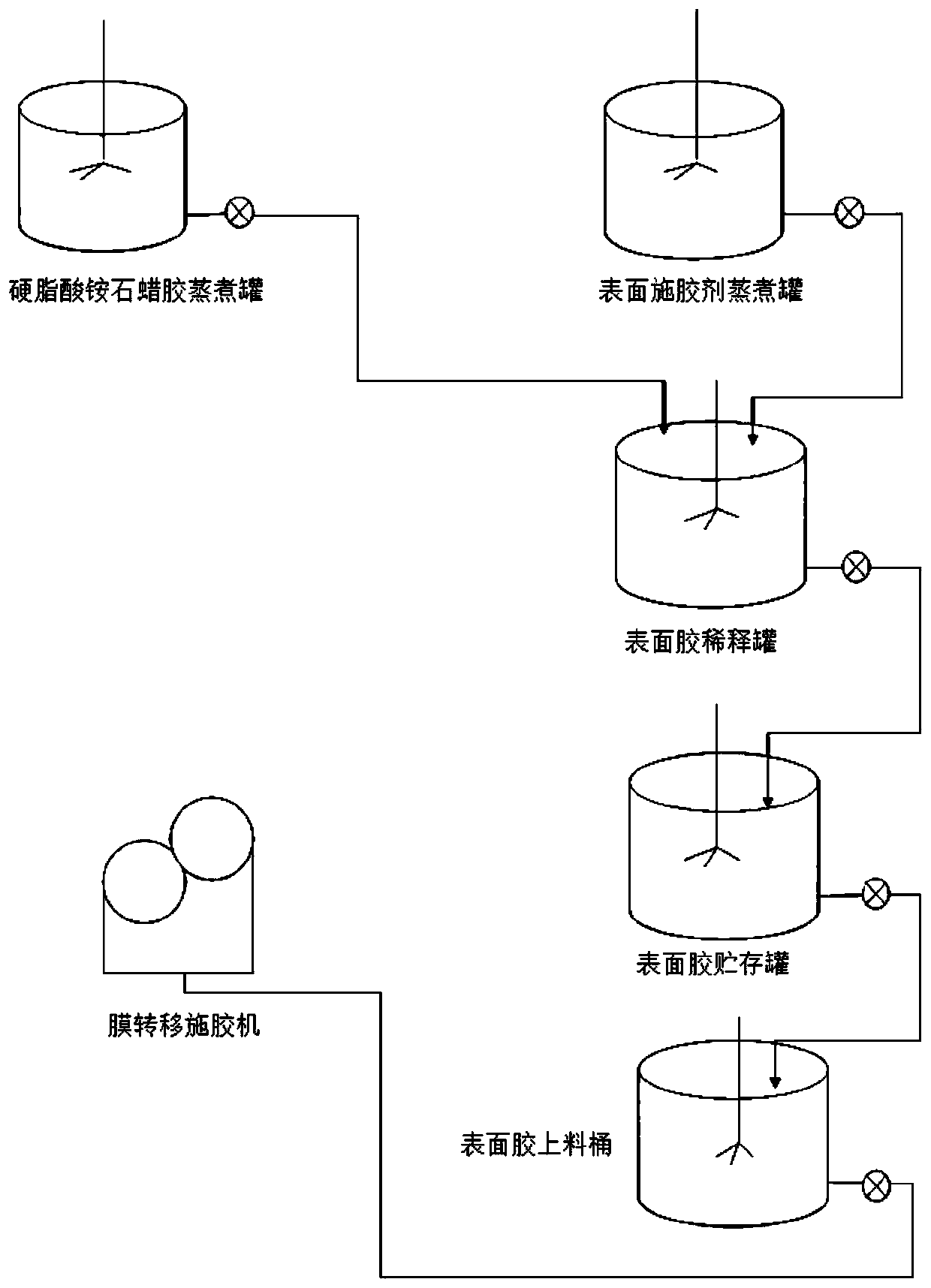

[0024] A film transfer sizing method for oil-proof paper, its technological process is as follows figure 1 shown.

[0025] 1. This method uses a new type of surface sizing agent:

[0026] 1. Raw materials: cationic surface tapioca starch, polyvinyl alcohol, stearic acid, paraffin, 5% ammonia water, anionic oil repellent.

[0027] 2. Formula and preparation: 100kg cationic surface tapioca starch + 8kg polyvinyl alcohol + 10kg anionic oil repellent + 80kg ammonium stearate paraffin glue solution + 600kg clear water. Stir and steam in the surface glue cooking tank to 95°C, keep warm for 20 minutes, and then add 60°C warm water to dilute in the dilution tank to make a surface sizing agent solution with a concentration of 12%.

[0028] 3. The quality standard of the new surface sizing agent solution: concentration 12±0.2%, viscosity 18-20mpa.s, ph7-7.5 temperature 65-70℃.

[0029] 4. Formula and preparation of ammonium stearate paraffin wax: stearic acid 100kg + paraffin wax 100...

Embodiment 2

[0039] A film transfer sizing method for greaseproof paper, the surface sizing agent used in the method comprises the following components by weight: 100 parts of cationic surface tapioca starch, 8 parts of polyvinyl alcohol, 80 parts of anionic oil repellent, stearic acid Ammonium paraffin gum solution 80 parts, water 600 parts.

[0040] Wherein, the ammonium stearate paraffin wax gum comprises the following components in parts by weight: 100 parts of stearic acid, 100 parts of paraffin wax, 80 parts of 5% ammonia water, and 880 parts of water.

[0041] The ammonium stearate paraffin wax gum is prepared by the following method: mix stearic acid, paraffin wax, 5% ammonia water and water in the prescribed amount, stir with steam, heat up to 75° C., and continue to boil for 90 minutes.

[0042] The ammonium stearate paraffin wax solution is prepared by the following method: mix the stearic acid, paraffin, 5% ammonia water and water in the formula quantity, ventilate and stir, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com