High-speed vacuum cylinder paper machine

A vacuum and rotary wire technology, applied in paper machine, wet end of paper machine, paper making, etc., can solve the problems of easy paper breaking, poor paper forming quality, easy paper breaking of wet paper web, etc. Good quality and reduced paper breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] Embodiment: a kind of high-speed vacuum cylinder paper machine.

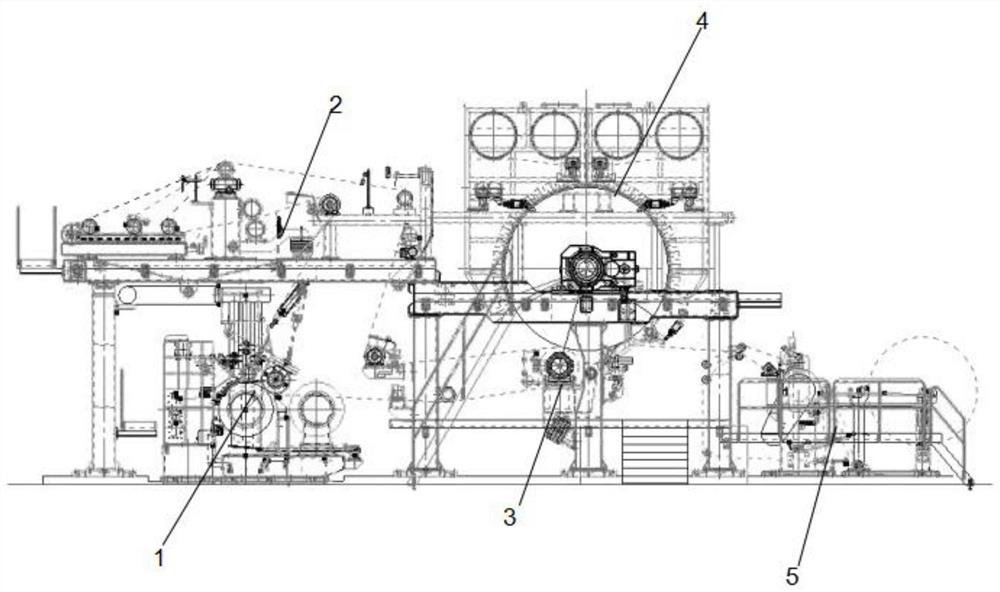

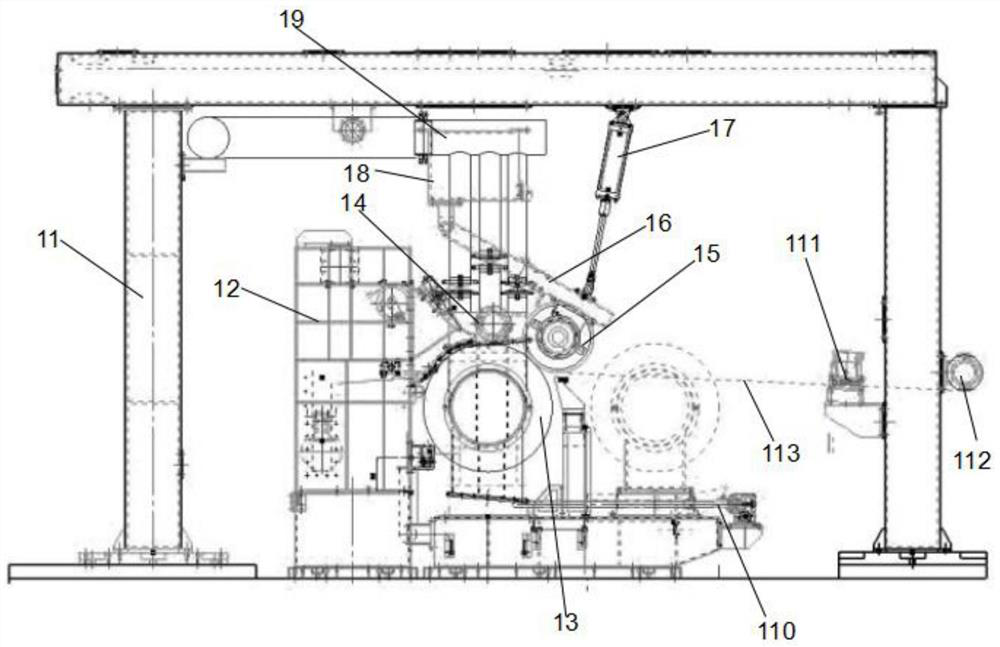

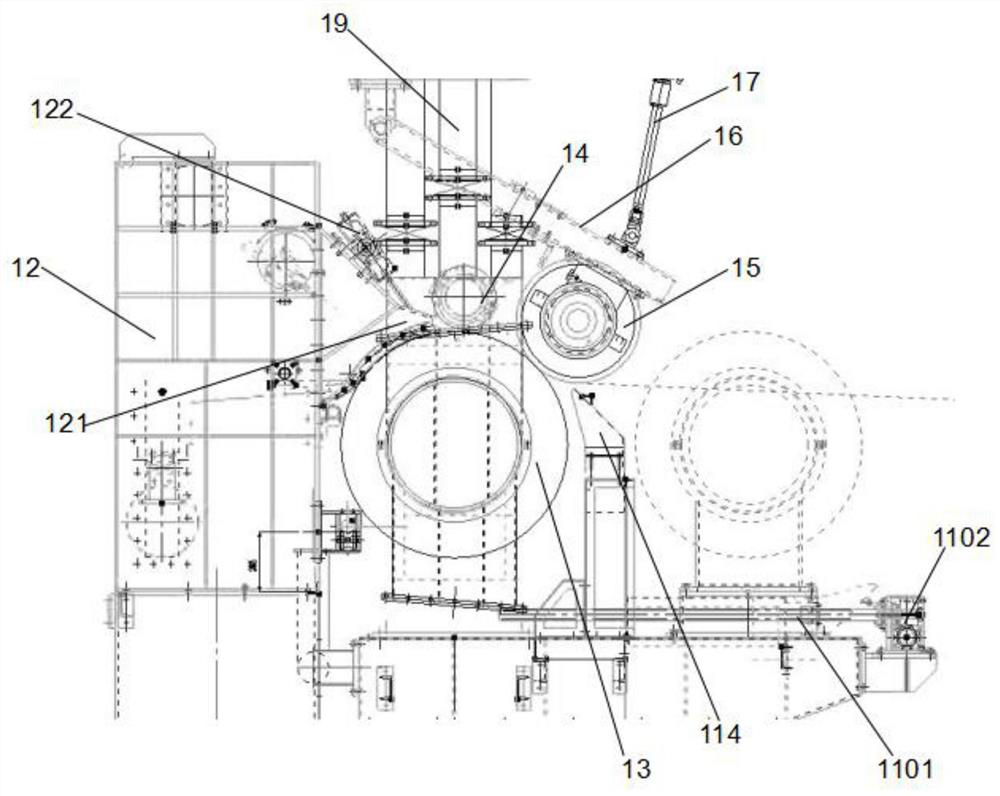

[0043] refer to Figure 1 to Figure 10 Shown, a high-speed vacuum cylinder paper machine, including

[0044] Vacuum cylinder forming part 1 (refer to figure 2 and image 3 As shown), the vacuum cylinder forming part 1 includes a forming part frame 11, a headbox 12 is installed on one side of the forming part frame 11, and an adjustable Weir plate 121, the weir plate 121 is equipped with a weir plate adjustment rod 122, the spray angle of the weir plate 121 can be precisely adjusted through the weir plate adjustment rod 122, so as to better adjust the contact between the pulp and the vacuum cylinder 13 when spraying and feeding In order to achieve the best dehydration efficiency and forming uniformity, a vacuum cylinder 13 is installed on one side of the headbox 12, and the vacuum cylinder 13 is connected to the vacuum system through a vacuum tube 19. The base of the vacuum cylinder 13 is installed wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com