Papermaking and composite processing technology for composite liquid absorbing material and equipment thereof

A composite processing and liquid-absorbing material technology, which is applied in the pulp raw material addition process, papermaking, paper machine, etc., can solve the problems of inconvenient permeation width, poor flexibility, and many paper breaks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

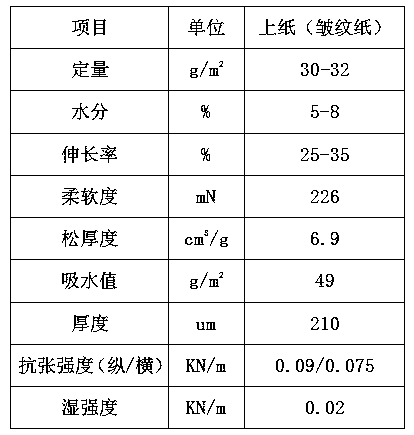

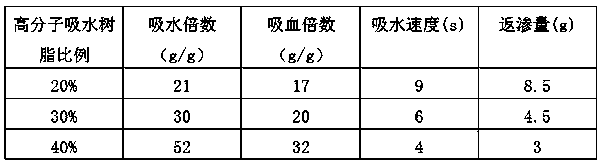

[0048] Example 1 A kind of papermaking and composite processing technology of composite liquid-absorbent material

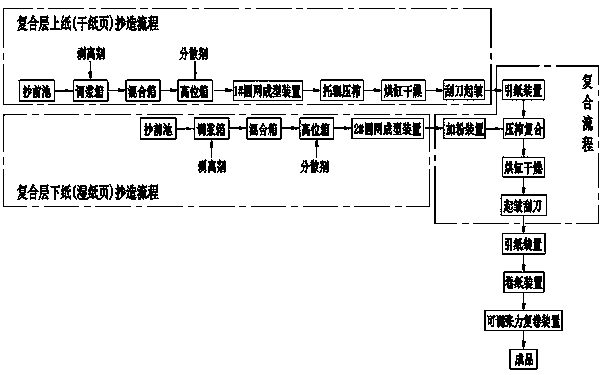

[0049] Such as figure 1 As shown, the papermaking and composite processing technology of a composite liquid-absorbing material provided by the present invention specifically includes the following steps:

[0050] 1. Manufacture of the upper and lower paper of the composite layer:

[0051] (1) Papermaking on the composite layer:

[0052] 1) The pulp is beaten and batched according to the process requirements, and the pulp concentration in the forecaster pool is 2.5-3.5%;

[0053] 2) The pulp concentration obtained in step 1) is adjusted to 1% by the concentration control system, and then pumped into the pulping box, and a stripping agent is added in the pulping box. The stripping agent is an alcohol stripping agent, and the dosage is 1-3kg / ton of pulp ;

[0054] 3) Pump the slurry adjusted in step 2) into the mixing box. During the pumping process, adjust the ...

Embodiment 2

[0083] Example 2 A kind of papermaking and composite processing equipment for composite liquid-absorbing materials

[0084] Such as Figure 5-Figure 8 Commonly shown, the present invention provides a kind of papermaking and compound processing equipment for composite liquid-absorbing materials, including a first cylinder forming mechanism 1, a second cylinder forming mechanism 2, a drying cylinder drying mechanism 3, and a composite drying cylinder drying mechanism 6 With the new adjustable tension rewinding mechanism 8, the first cylinder forming mechanism 1 and the second cylinder forming mechanism 2 are arranged symmetrically and in the opposite direction of rotation, and the drying cylinder drying mechanism 3 and the compound drying cylinder drying mechanism 6 are symmetrically arranged in the opposite direction of rotation ; The pressing compound mechanism 5 is installed directly below the compound dryer drying mechanism 6, and the powder loosening mechanism 4 is installe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com