Static-pressure sectional controllable spreader

A technology of static pressure and coating tank, applied in the direction of paper, etc., can solve the problems affecting the production efficiency and quality of the paper machine, the coating is not easy to dry, and the loss of machine parts, so as to achieve a wide range of coating applications and improve the smoothness of the coating , The effect of saving fiber cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

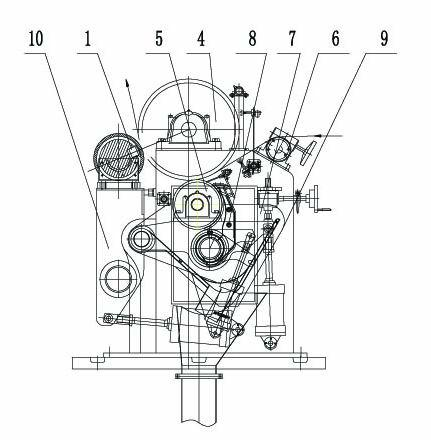

[0020] The static pressure partition controllable applicator is composed of static pressure partition controllable roller 1, hydraulic device 2, control device 3, back roller 4, feeding roller 5, arc roller 6, coating tank 7, deflector 8, machine The frame 9 is composed of a back roller 4 installed on the upper part of the frame 9 through a bearing, one side of the back roller 4 is installed with a static pressure partition controllable roller 1, and the other side of the back roller 4 is installed with an arc-shaped roller 6, and the back roller 4 The lower part of the feed roller 5 is installed, the static pressure zone controllable roller 1 and the feed roller 5 mesh with the back roller 4 respectively, and the deflector 8 and the paint tank 7 are installed on one side of the feed roller 5.

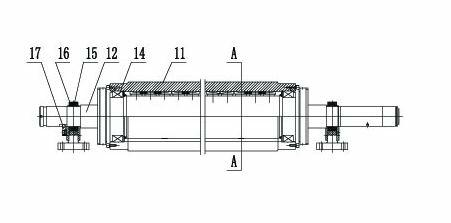

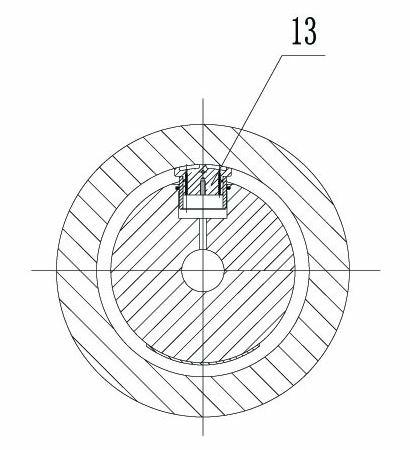

[0021] The static pressure partition controllable roll 1 is compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com