A soaking surface sizing process

A surface sizing and crafting technology, applied in the direction of defoaming agent, microorganism/enzyme addition, non-fiber pulp addition, etc., can solve the problems of low production efficiency, paper breakage, etc., to improve efficiency, reduce the probability of paper breakage, reduce The effect of glue leakage phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

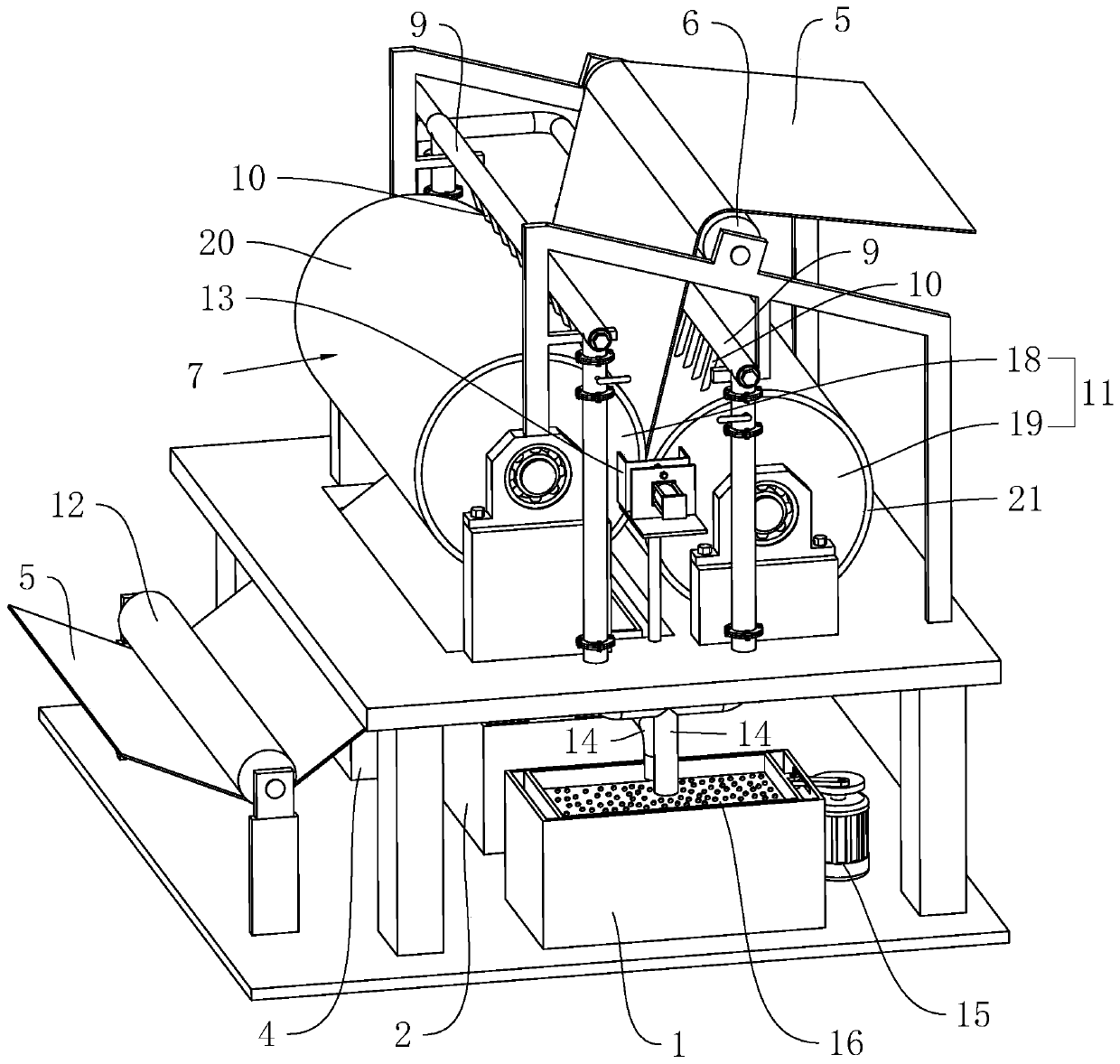

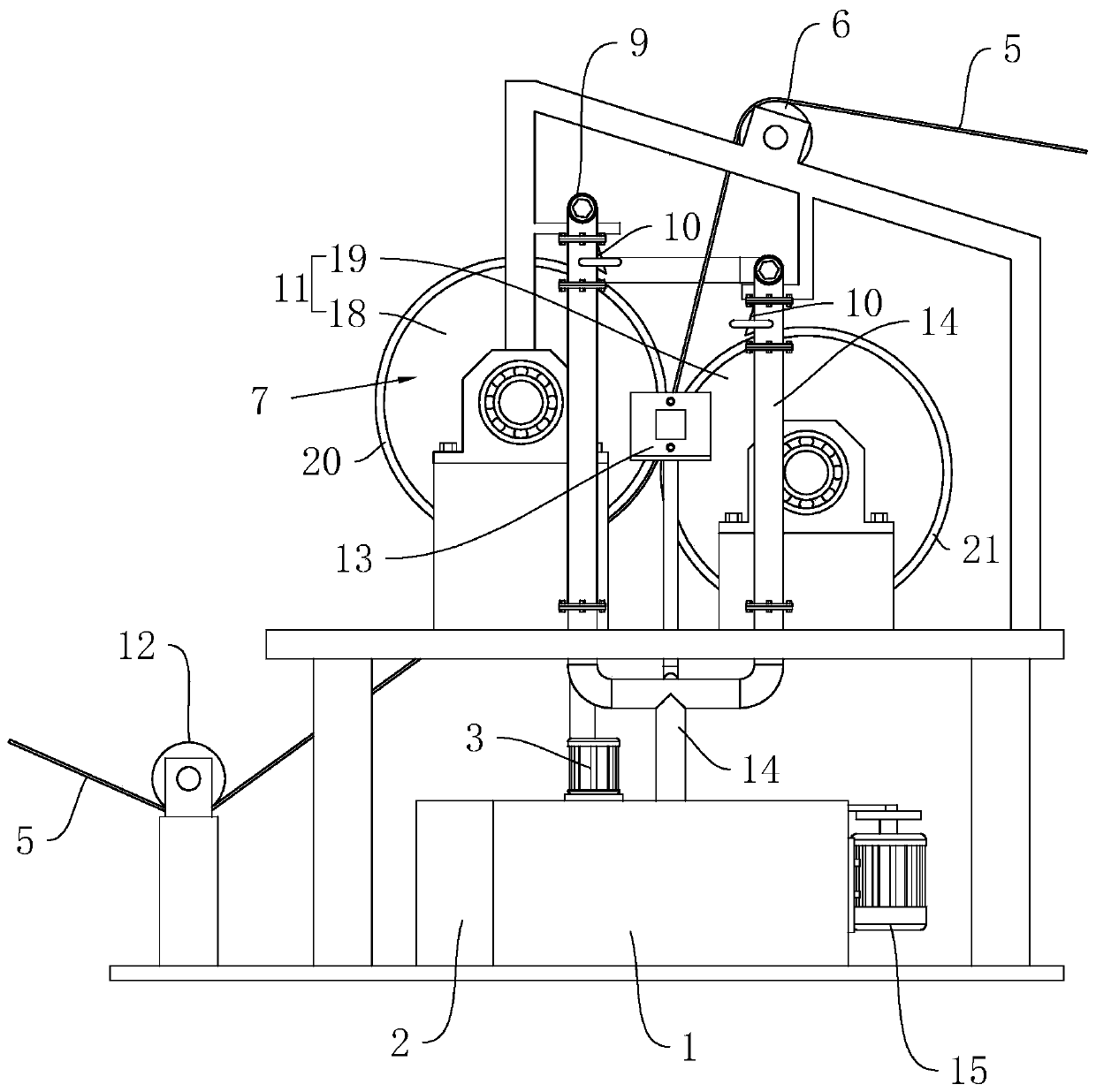

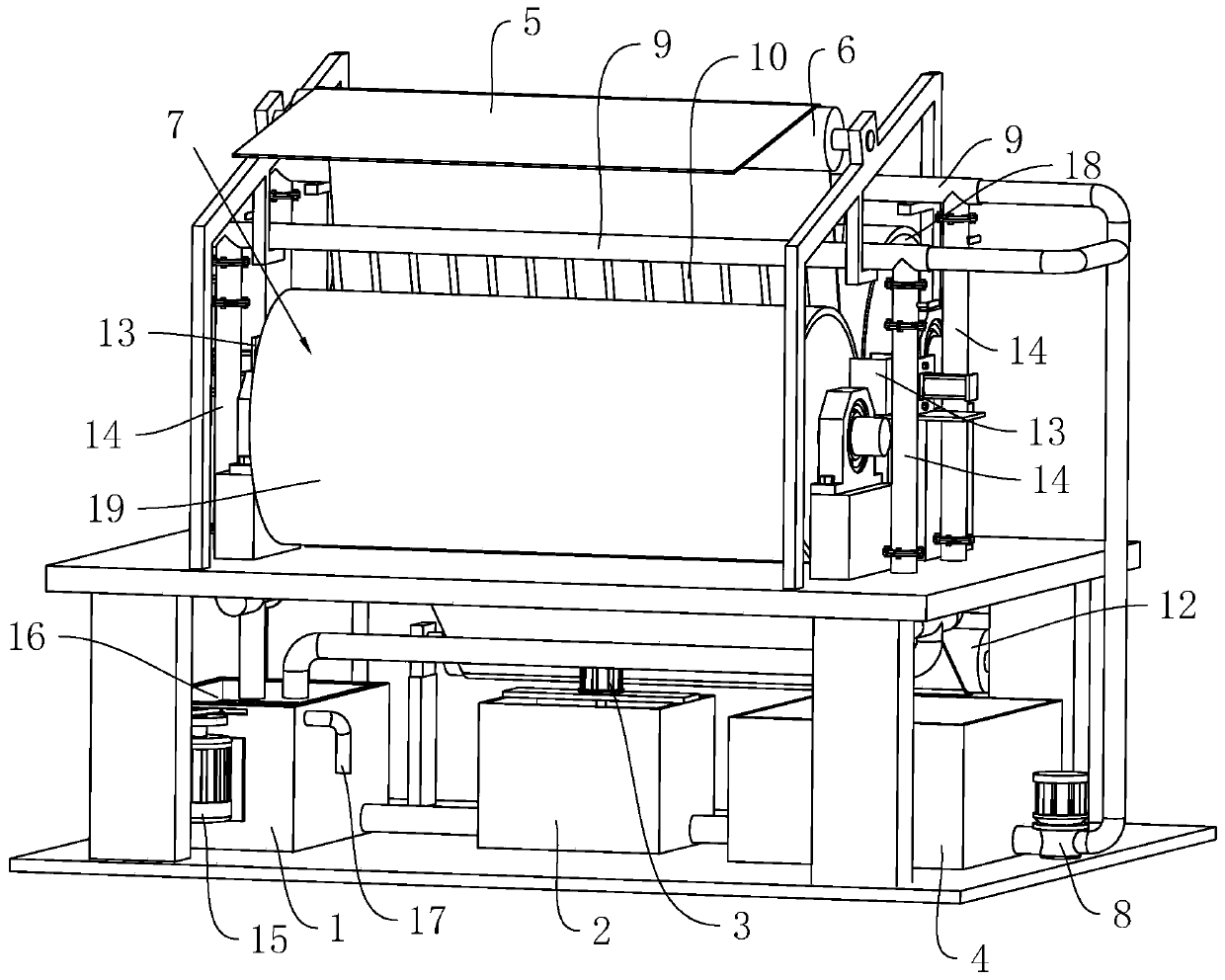

Image

Examples

Embodiment 1

[0043] Embodiment 1: a kind of immersion type surface sizing process, is used for the surface sizing method of AA grade high-strength corrugated base paper, and it comprises the following operation steps:

[0044] Step S1, the configuration of sizing agent: according to the components by weight, the sizing agent includes 100 parts of edible starch, 0.05-0.1 part of amylase, 0.05-0.1 part of propylbenzene sizing agent, and 0.05-0.1 part of aluminum sulfate , 0.02-0.05 parts of defoamer and water balance to make up. Among them, the concentration of edible starch is 4-6%, and its viscosity is 19-25% of 20 rubber rollers; and the model of amylase is: liquid 2589 amylase.

[0045] Step a, put the edible starch and water into the dispersion tank 1 according to the ratio and stir evenly. Wherein, the edible starch is a mixed starch of corn starch and sweet potato starch.

[0046] Step b. Heat the water to 93-95°C and add it to the cooking tank 2, turn on the agitator 3, then put th...

Embodiment 2

[0053] Embodiment 2: A kind of immersion type surface sizing process, the difference with embodiment 1 is: edible starch is the mixed starch of corn starch, sweet potato starch and kudzu root starch.

Embodiment 3

[0054] Embodiment 3: A kind of immersion type surface sizing process, the difference with embodiment 1 is: edible starch is the mixed starch of corn starch, wild acorn starch and kudzu root starch.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com