A CNC deep hole drilling machine tool for processing group holes on the outer circle of rollers

A technology of deep hole drilling and outer circle, which is applied in the direction of boring/drilling, metal processing equipment, drilling/drilling equipment, etc. It can solve the problem that it is difficult to ensure the straightness and surface finish of the processed holes and reduce the usage rate of rollers. , the smoothness is not high, etc., to reduce the probability of paper breakage, reduce maintenance costs, and achieve the effect of uniform dry humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

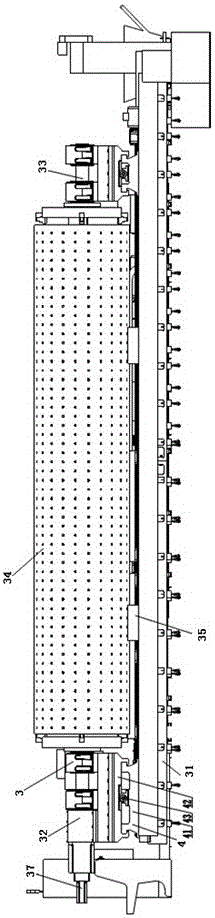

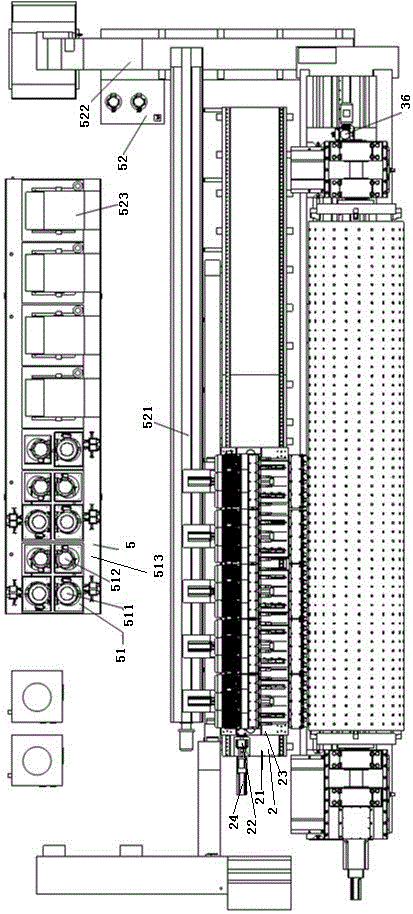

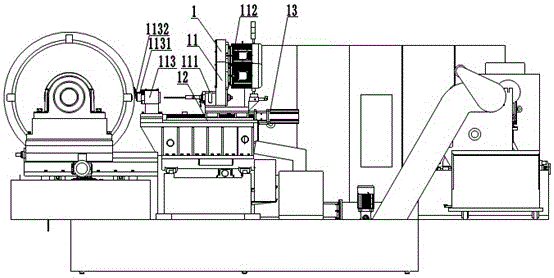

[0018] Attached below figure 1 to attach image 3 The present invention is further described with embodiment. But the protection scope of the present invention is not limited thereto.

[0019] Figure 1 to Figure 3 It shows the specific structure of the CNC deep hole drilling machine tool for processing group holes on the outer circle of the roller of the present invention. The CNC deep hole drilling machine tool includes a drilling motion mechanism 1, a lateral displacement motion mechanism 21, and a workpiece indexing motion mechanism 31. Longitudinal movement mechanism 41, oil supply filter mechanism 51.

[0020] Such as figure 1 with image 3 As shown, the drilling motion mechanism 1 of the CNC deep hole drilling machine of the present invention is composed of five sets of drilling units 11 , five sets of CNC slide tables 12 and five servo motors 13 . The drilling unit 11 is composed of a main shaft part 111, a transmission part 112, and a guide part 113: the six mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com