Method for reproducing antibacterial corrugated paper from high-salinity high-hardness waste paper sludge

A high-hardness, high-salinity technology, applied in pulp beating/refining methods, papermaking, paper machines, etc., can solve problems such as difficult dehydration, generation of waste water and waste gas, and decrease in operating rate, so as to improve the operating rate of paper machines, Effects of reducing chemical level components and reducing paper machine breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The following are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

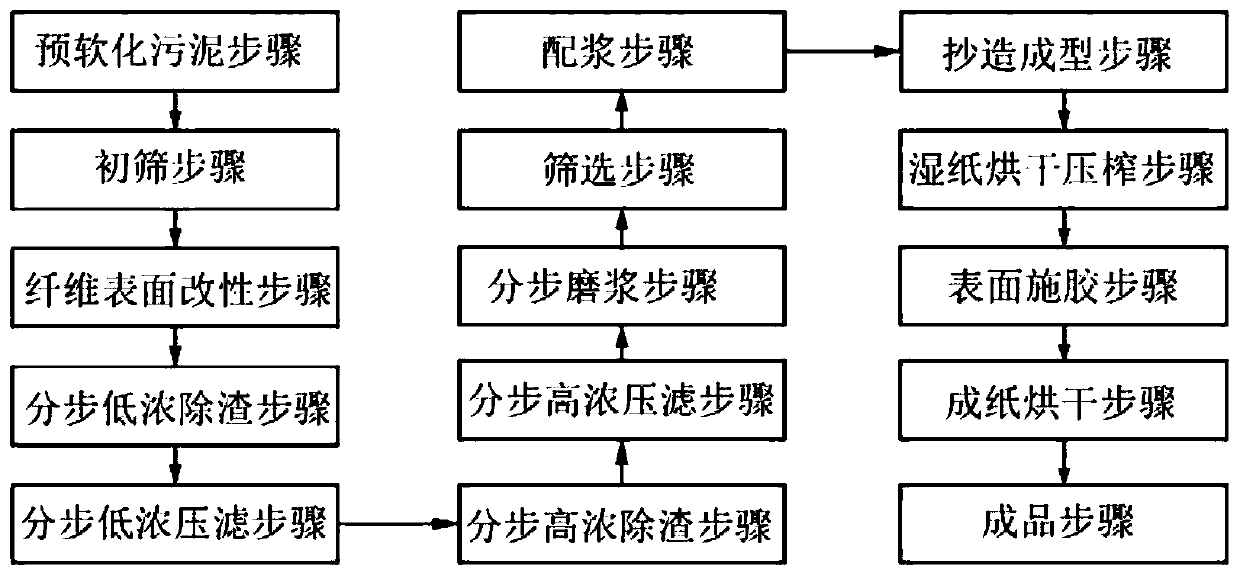

[0055] A method for remanufacturing antibacterial corrugated paper from waste paper sludge with high salinity and high hardness, characterized in that it includes the following steps:

[0056] In the pre-softening sludge step, the high-salinity and high-hardness waste paper sludge is transported to the reactor, and the circulating water of the papermaking enterprise and lime powder are injected into the reactor, and the stirring is uniform to obtain the pre-softened wastewater. The water content of the pre-softened wastewater is The control is 50-70%;

[0057] In the primary screening step, the pre-softened wastewater that has been pre-softened is transported to a multi-stage coarse screening device for screening, so as to remove the hard and soft impurities in the pre-softened wastewater to obtain the primary screening pulp;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com