Concrete pipe platform vibration moulding process and device thereof

A vibration molding and vibration device technology, applied in reinforcement molding, ceramic molding machines, manufacturing tools, etc., can solve the problems of poor resonance effect, high rigidity, high energy consumption, etc., to reduce production costs, low power, and low power consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

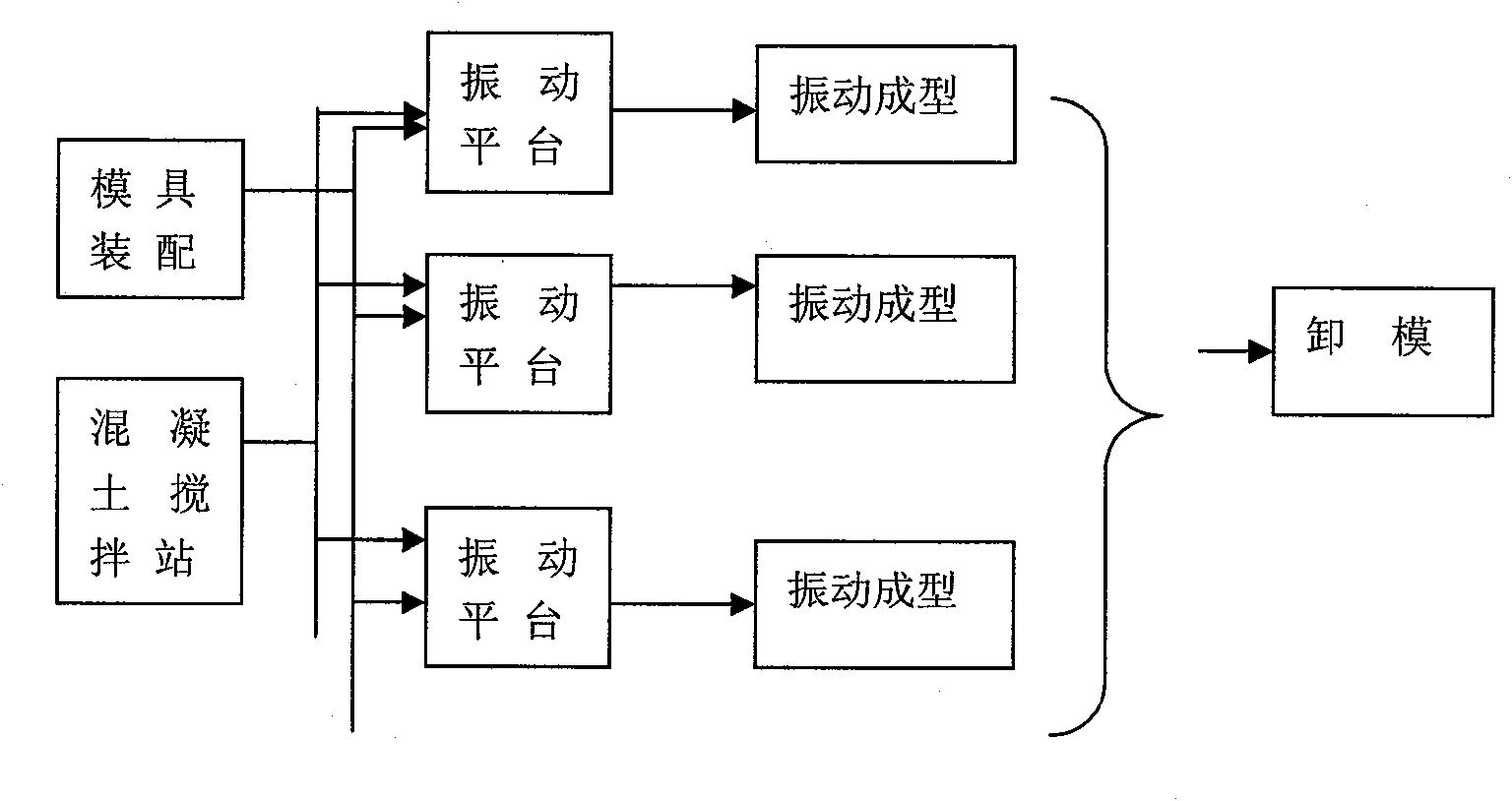

[0026] Example 1: Three-station vertical vibrating concrete pipe production line.

[0027] Concrete mixing station is 1m 3 A set of two.

[0028] Mold assembly can generally be assembled on the vibrating platform or outside the vibrating platform.

[0029] Two groups of 4500×4500mm and one group of 3000×3000mm are installed on the vibration platform at the same time.

[0030] This production line can produce all types (φ1000-φ3600mm) pipes of vertical vibration forming.

[0031] Process concrete steps of the present invention:

[0032] a. Set up the vibration platform: choose a flat desktop fixed platform. The vibration source is a mechanical vibrator. The selection of platform specifications and vibration machine energy should generally consider product specifications, and products can be divided into large, medium and small, that is, large and medium specifications φ2200~3600mm and medium and small specifications φ1000~2000mm. The external dimension of the vibrating pl...

Embodiment approach

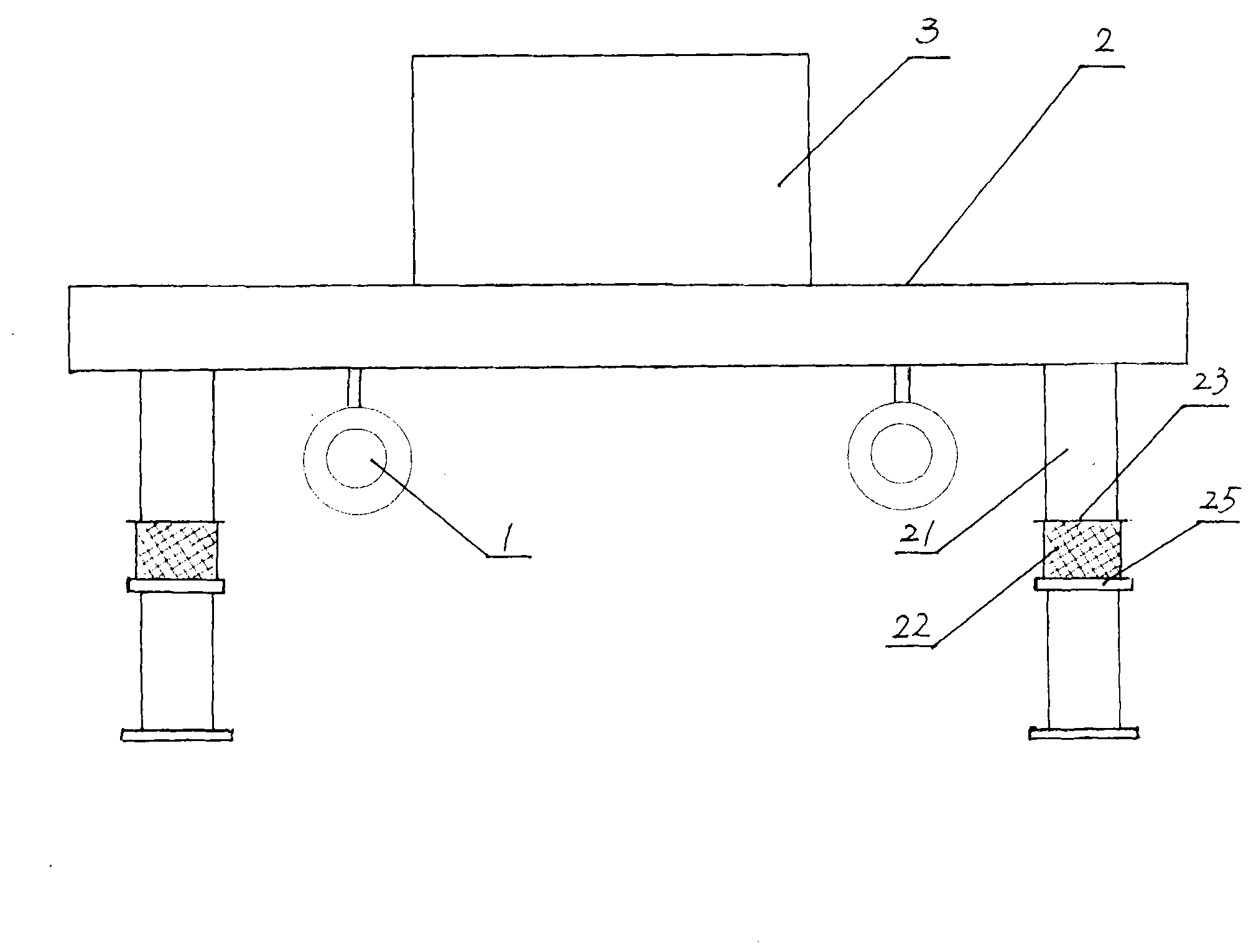

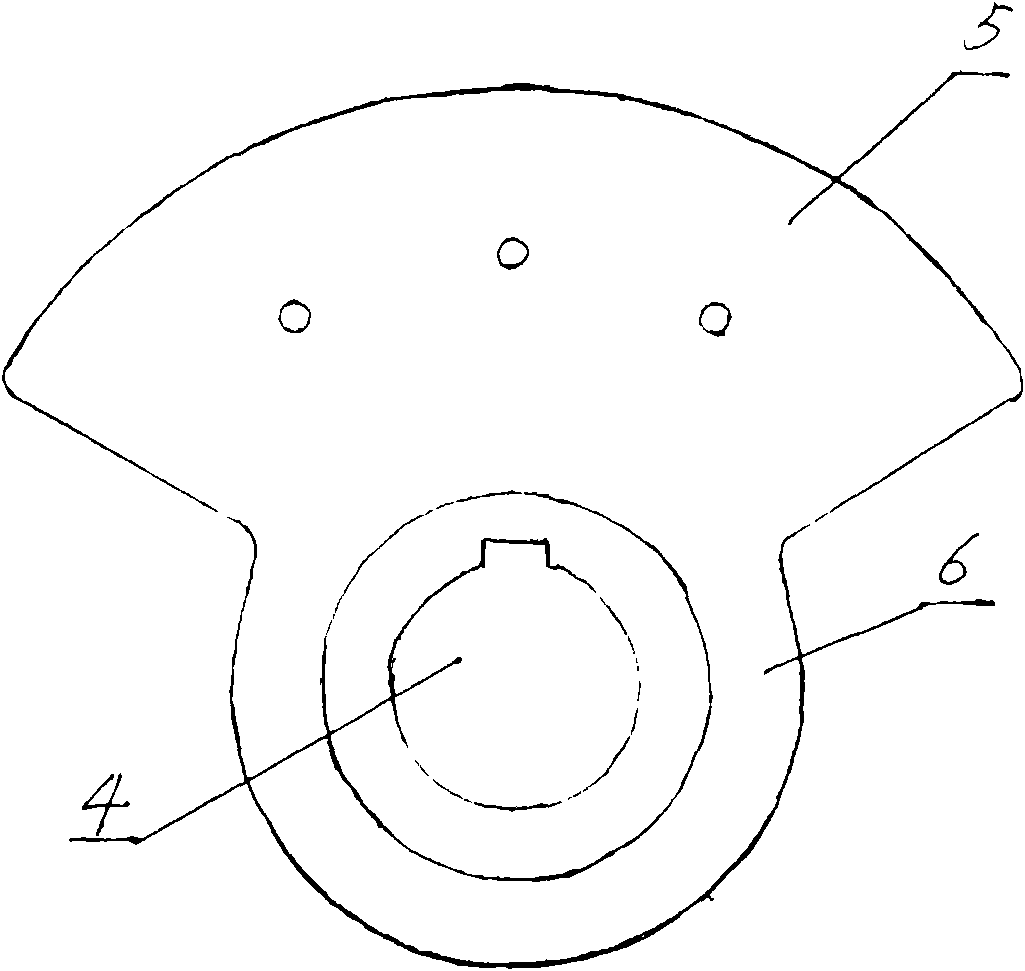

[0041] Such as figure 1As shown, the vibrating table of the device of the present invention is composed of platen 2 and supporting legs 21 to form a vibrating platform, so that the platen and supporting legs 21 are integrated, and the mold 3 to be vibrated is placed on the table; motor 15 kilowatts) mechanical vibrating machine 1, when vibrating machine 1 was running, the eccentric wheel on the output shaft of the vibrating machine drove the platen to vibrate, and the mold 3 placed on the table top also vibrated synchronously with the platen; A vibrating rubber pier 22 is installed between the legs 21. The vibrating rubber pier 22 is cylindrical and is made of natural rubber or reclaimed rubber; an upper and lower guard plate 23 is set on the contact surface between the rubber pier and the supporting leg 21, and the outer edge of the lower guard plate 25 is greater than the peripheral dimension of the vibrating rubber pier 22, and the height of the outer edge is designed to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com