Compound watermark anti-counterfeiting paper and manufacturing method thereof

A manufacturing method and technology of anti-counterfeiting paper, applied in chemical instruments and methods, papermaking, paper, etc., can solve the problems of unsatisfactory anti-counterfeiting effect and anti-counterfeiting strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] Example 1 Composite of two mesh cages with graphic or text watermarks of the same diameter

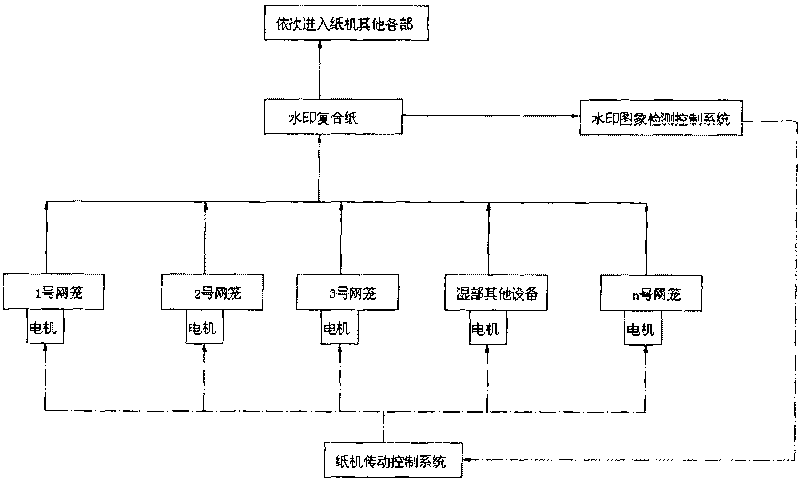

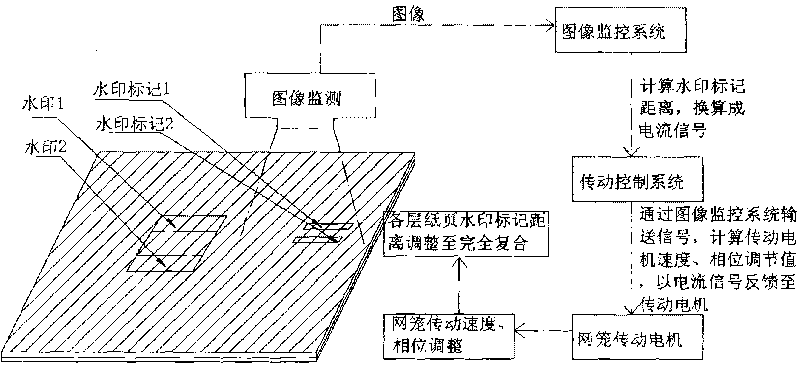

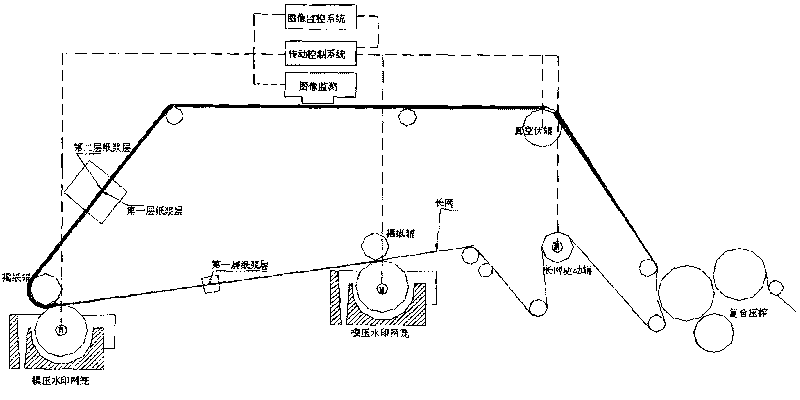

[0088] It consists of two cages of the same diameter with watermark graphics or text in fixed positions. The formed pulp layer on each cage is lifted and compounded by the paper roll, and the image monitoring system installed in the wet part of the paper machine is used to monitor each. Composite accuracy of watermark graphics marked on each screen cage. After information feedback, use the synchronous drive technology of the wet end equipment of the paper machine such as screen cages to adjust the speed of each screen cage and corresponding rollers and the phase of the motor to adjust the longitudinal watermark composite position. , see Figure 1-b for synchronous control. The image monitoring system monitors and calculates the distance of the watermark mark, which is converted into a current signal and sent to the transmission control system. The speed and phase adjustment value ...

Embodiment 2

[0090] Example 2 Two cages with graphic or text watermarks of the same diameter are combined with one common cage without watermarks

[0091] a. Ordinary non-watermarked mesh cage forming pulp layer on the surface layer or bottom layer

[0092] It consists of two cages of the same diameter with watermark graphics or text in fixed positions and one common cage without watermarks, where the two cages of the same diameter with watermark graphics or text in fixed positions are in the same position Adjacent, or two are arranged in front of or behind the common cage. The formed pulp layer on each cage is uncovered and recombined by the paper roll, and the composite accuracy of the watermark pattern on each cage is monitored through the image monitoring system installed in the wet part of the paper machine. After the information is fed back, the paper machine such as the cage is used. The synchronous driving technology of the wet end equipment is used to adjust the rotation speed of...

Embodiment 3 3

[0095] Example 3 Compositing of three mesh cages with graphic or text watermarks

[0096] It consists of three cages of the same diameter with watermark graphics or text in fixed positions. The formed pulp layer on each cage is lifted and compounded by the paper roll, and the image monitoring system installed in the wet part of the paper machine is used to monitor each. Composite accuracy of watermark graphics marked on each screen cage. After information feedback, use the synchronous drive technology of the wet end equipment of the paper machine such as screen cages to adjust the speed of each screen cage and corresponding rollers and the phase of the motor to adjust the longitudinal watermark composite position. , use the cage horizontal position adjustment technology to adjust the position of the horizontal watermark composite, so that the watermark graphics or text formed on the latter cage can be composited with the watermark graphics or text formed on the previous cage at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com