Anti-counterfeiting function packaging film with three-dimensional and dynamic display effect

A dynamic display and packaging film technology, applied in packaging, wrapping paper, transportation and packaging, etc., can solve the problems of high cost, harsh observation conditions, and difficult to judge the authenticity of the logo, and achieve the effect of improving attractiveness and strong anti-counterfeiting characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

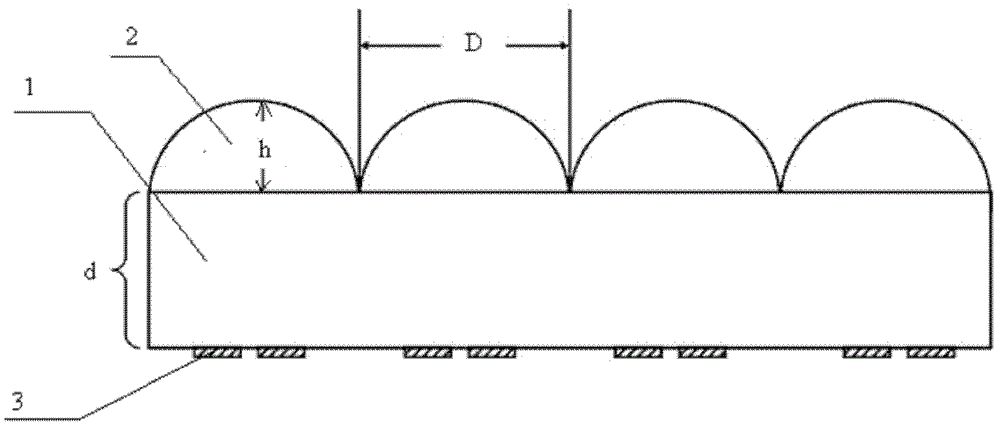

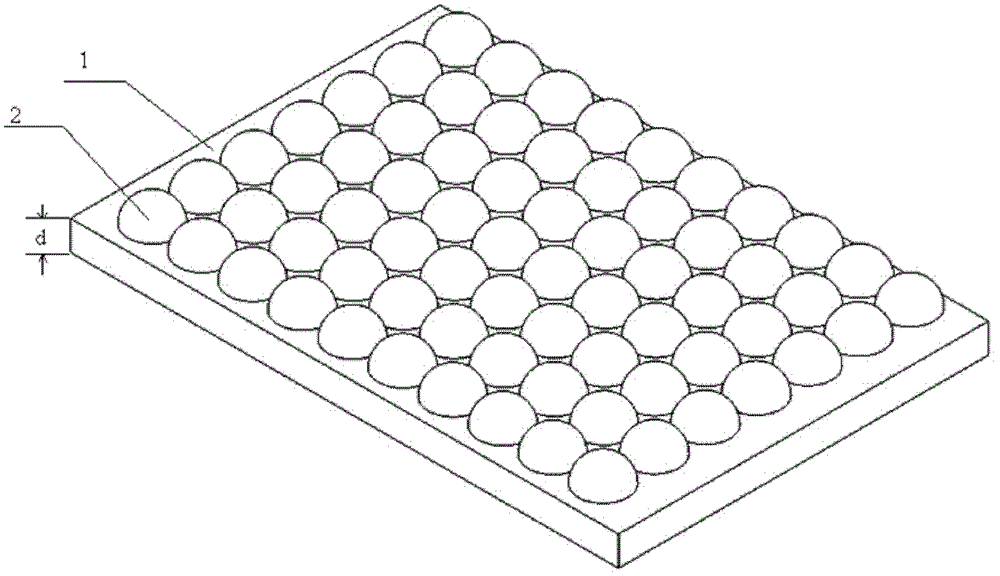

[0037] preparation figure 1 and figure 2 The anti-counterfeiting functional packaging film with three-dimensional and dynamic display effects.

[0038] Wherein: the microlens array 2 is arranged in a rectangle, and the aperture of the microlens is 25 microns;

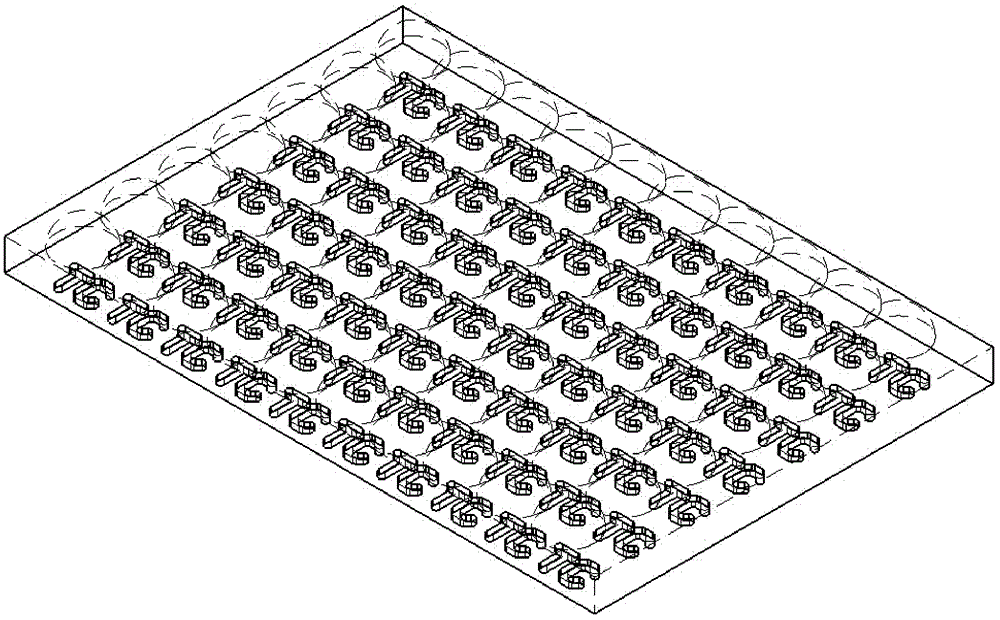

[0039] The information layer 3 is formed by arrangement of miniature letters TC, and the arrangement period is the same as that of the microlens array. The seam width of the miniature letters TC is 3 microns, and the magnification effect is as follows: image 3 , the miniature letter TC constitutes the word TC with a macroscopic size of 10cm*10cm, such as Figure 4 shown.

[0040] The diameter D of the microlens, the height h of the microlens, the refractive index n of the lens material and the thickness d of the film body satisfy the following relationship:

[0041] d = D 2 + 4 ...

Embodiment 2-3

[0053] preparation figure 1 and figure 2 The anti-counterfeiting functional packaging film with three-dimensional and dynamic display effects. The structural parameters of the lens are the same as in Example 1. The lens material and information layer material are UV-curable fatty acid-modified epoxy acrylate or a mixture of styrene and epoxy acrylate. The process is the same as in Example 1.

[0054] in:

[0055] The refractive index n of UV-curable fatty acid modified epoxy acrylate is 1.56;

[0056] The refractive index n of the mixture of styrene and epoxy acrylate is 1.55;

[0057] The size of the macroscopic pattern of the information layer after being extracted and enlarged by the microlens array is 15 mm.

Embodiment 4

[0059] preparation figure 1 and figure 2 The anti-counterfeiting functional packaging film with three-dimensional and dynamic display effects.

[0060] Wherein: the microlens array 2 is arranged in a rectangle, and the aperture of the microlens is 25 microns;

[0061] The information layer 3 is formed by arrangement of miniature letters TC, and the arrangement period is the same as that of the microlens array. The seam width of the miniature letters TC is 3 microns, and the magnification effect is as follows: image 3 , the miniature letter TC constitutes the word TC with a macroscopic size of 10cm*10cm, such as Figure 4 shown.

[0062] The diameter D of the microlens, the height h of the microlens, the refractive index n of the lens material and the thickness d of the film body satisfy the following relationship:

[0063] d = D 2 + 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com