Anti-counterfeiting environment-friendly transfer paper and manufacturing process thereof

A production process and paper transfer technology, which is applied in papermaking, paper coatings, textiles and papermaking, etc., and can solve problems such as environmental pollution of coated paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

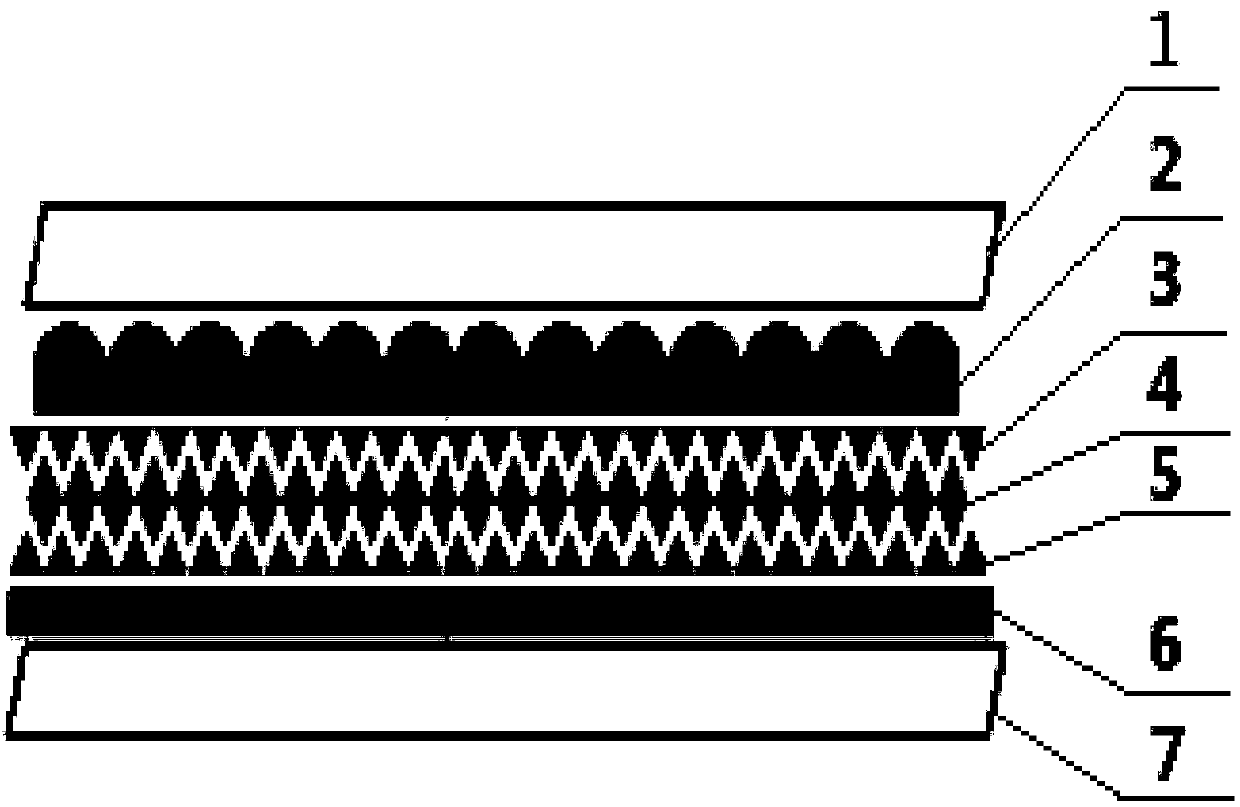

Image

Examples

Embodiment 1

[0033] A manufacturing process of anti-counterfeiting environmental protection transfer paper, comprising the following steps:

[0034] Use a diamond lathe to make a Fresnel lens with a central lens radius of 20cm; copy the obtained Fresnel lens structure on a PET substrate with a UV-curable coating, and then use UV-curing treatment, and the wavelength of the UV light is set to 150-300nm In between, the curing time is 0.1h; the cured PET substrate is electroplated twice in the electroforming tank to obtain a molded working board with the above-mentioned Fresnel lens structure copied. Install the molding work plate on the molding roller.

[0035] Make ultraviolet light transfer coating according to following components and parts by weight: 15 parts of methyl etherified amino resins, 10 parts of hydroxyl acrylic resins, 8 parts of polyvinyl alcohol resins, 2.3 parts of acetic acid, 5.8 parts of sodium salicylate, 26 parts of ethanol, 6 parts of n-butanol, 10 parts of isopropano...

Embodiment 2

[0051] A manufacturing process of anti-counterfeiting environmental protection transfer paper, comprising the following steps:

[0052] Use a diamond lathe to make a Fresnel lens with a central lens radius of 30cm; copy the obtained Fresnel lens structure on a PET substrate with a UV-curable coating, and then use UV-curing treatment, and the wavelength of the UV light is set to 150-300nm In between, the curing time is 0.15h; the cured PET base material is subjected to two electroplating treatments in the electroforming tank to obtain a molded working board with the above-mentioned Fresnel lens structure copied. Install the molding work plate on the molding roller.

[0053] Make the UV light transfer coating according to the following components and parts by weight: 15 parts of methyl etherified amino resins, 11 parts of hydroxyacrylic resins, 8 parts of polyvinyl alcohol resins, 2.2 parts of acetic acid, 5.8 parts of sodium salicylate, 26 parts of ethanol, 6 parts of n-butano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com