Preparation method for composite processed absorbent paper by using cylinder mould machine

A compound processing and paper machine technology, applied in paper machines, paper making, textiles and paper making, etc., can solve problems such as poor liquid permeability, high equipment maintenance costs, unstable product quality, etc., to reduce consumption and production costs, increase The effect of using the area of the factory building and shortening the length of the production line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to illustrate the features of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

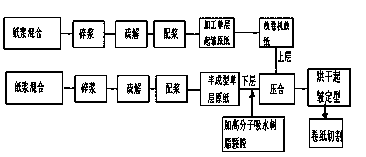

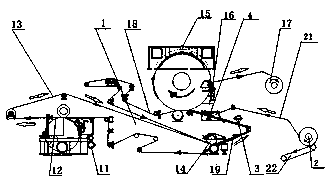

[0021] Inquire figure 1 figure 2 , a method for preparing water-absorbing paper compositely processed by a cylinder paper machine, comprising the following process steps: (1) mixing wood pulp and fluff pulp in a ratio of 1.5:1. (2) Pulp the mixed slurry through a hydraulic pulper and then enter the deflagging machine for fiber deflaking. (3) The decomposed slurry is pumped into the pulp mixing tank, and in the pulp mixing tank, the dispersant is added sequentially at an interval of 10-15 minutes, the dosage is 2-4kg / ton of paper; the softener, the dosage is 4kg / ton of paper; the swelling agent, the dosage 5kg / ton of paper; wet strength agent, dosage 8kg / ton of paper, sodium carboxymethyl cellulose, dosage 1kg / ton of paper; polyvinyl alcohol fiber, dosage 15kg / ton of paper; fully stirred an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com