Splayed cylinder mould sand barrier and construction structure thereof

A figure-eight, mesh cage technology, applied in the engineering field, can solve the problems of large amount of consumables, semi-concealed sand barriers that can only fix sand, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

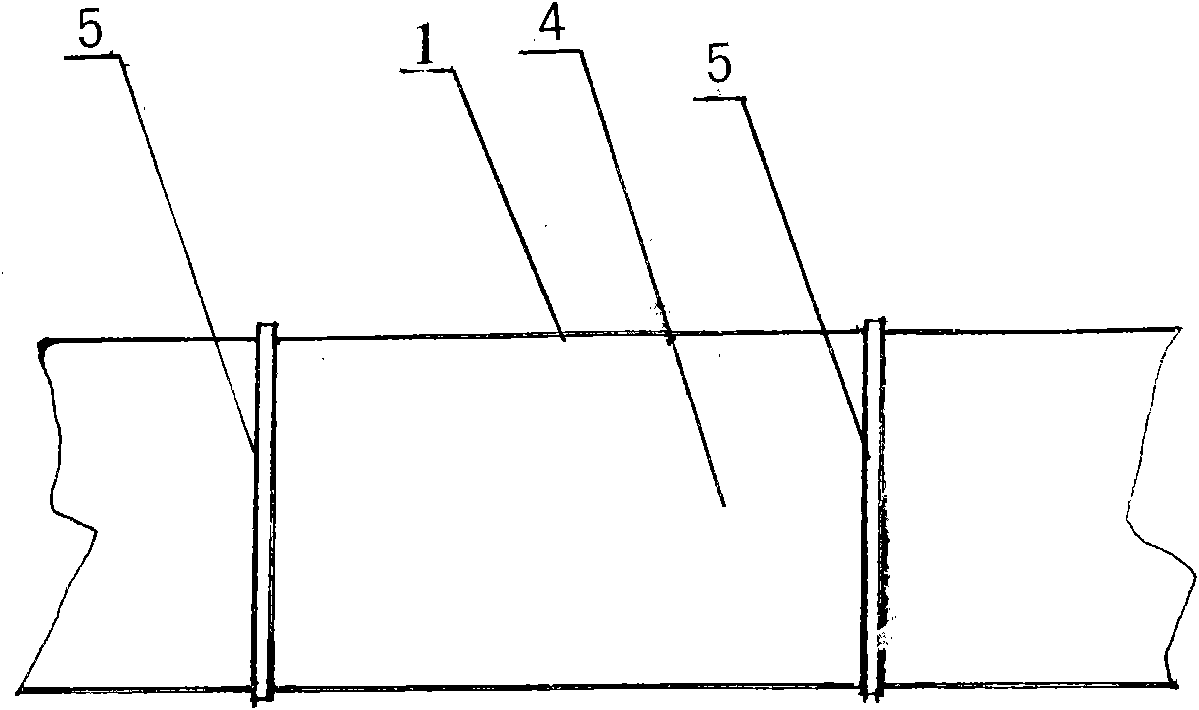

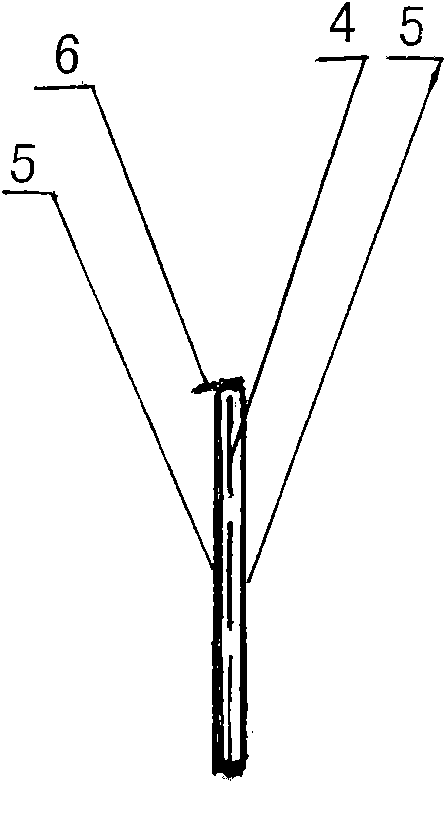

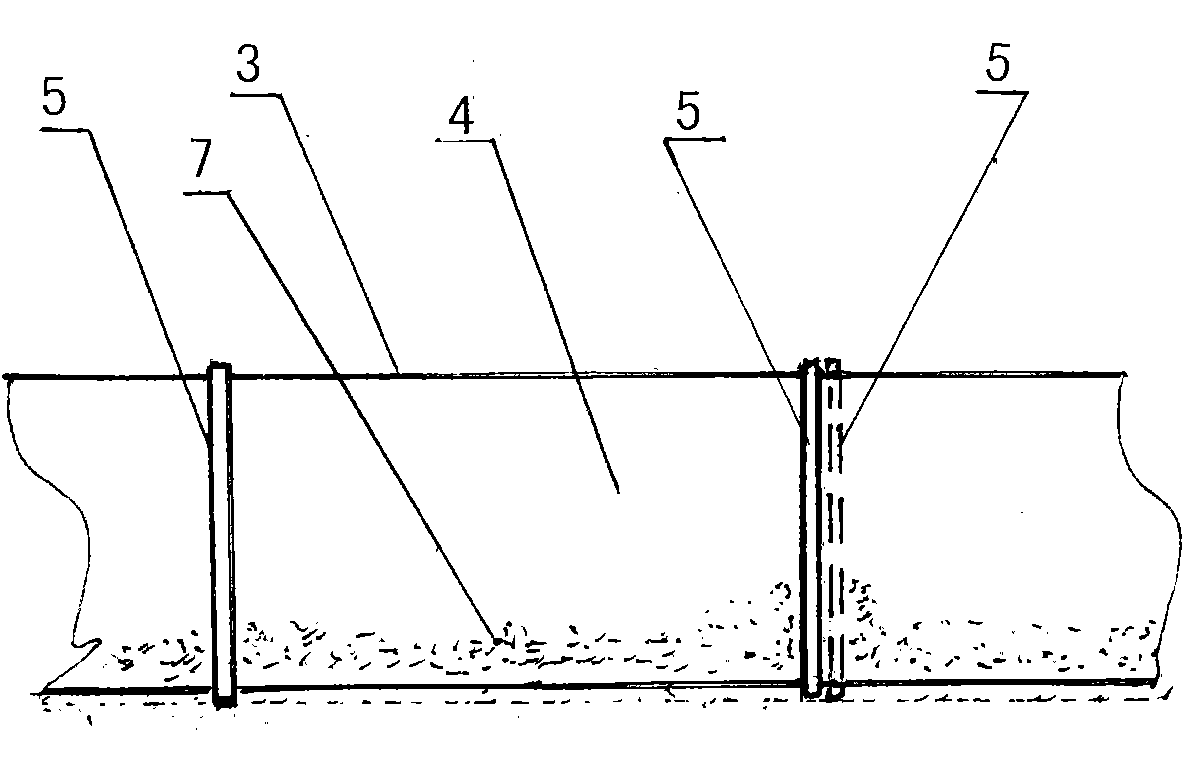

[0015] Show now figure 1 , 2 Further description of the eight-shaped net cage sand barrier of the present invention: the eight-shaped net cage sand barrier is composed of two front and rear net cage pieces, the front net cage piece 1 and the rear net cage piece 2 have the same structure and size, and can be interchanged , the cage sheet is made of a plastic wire mesh with a porosity between 10% and 25% and a width between 25cm and 50cm as the cage surface 4. The porosity and width can be selected within the above range according to needs. Size, interval 50cm is provided with a support rod 5 on the cage surface, and the support rod is tightly stretched on the cage surface, and the top edge and the bottom edge of the support rod and the cage surface vertically intersect and are fixed on the cage surface to form a cage sheet. The support rod 5 longitudinally separates the inner half and the outer half, and the cage surface 4 is tightly embedded in the middle of the inner and out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com