Gravel pre-filling sand prevention pipe

A sand control pipe and pre-filling technology, which is applied in the direction of production fluid, wellbore/well parts, earthwork drilling and production, etc., can solve the problems of complex gravel packing construction technology in horizontal wells, unstable production capacity of open hole completion, etc., and avoid sand control pipes Clogging, prevention of casing clogging, effect of preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0020] as attached Figures 1 to 3 Shown, the concrete implementation technical scheme of the present invention is:

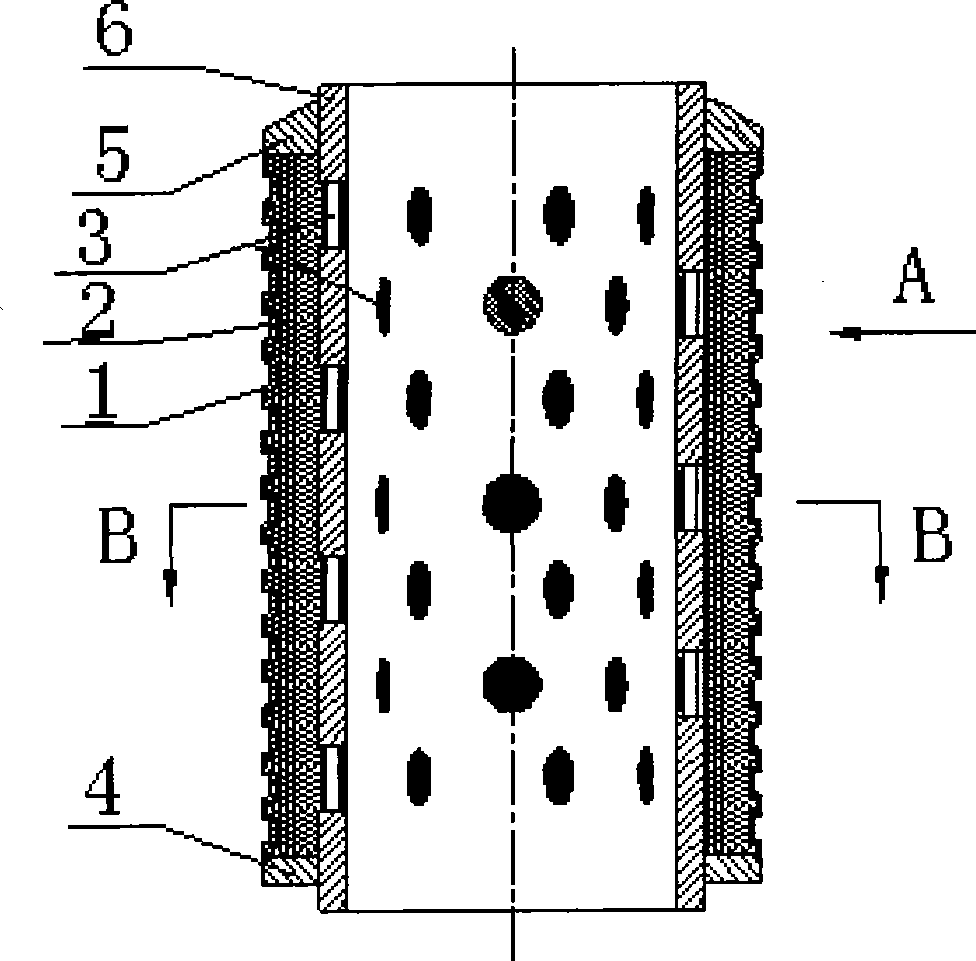

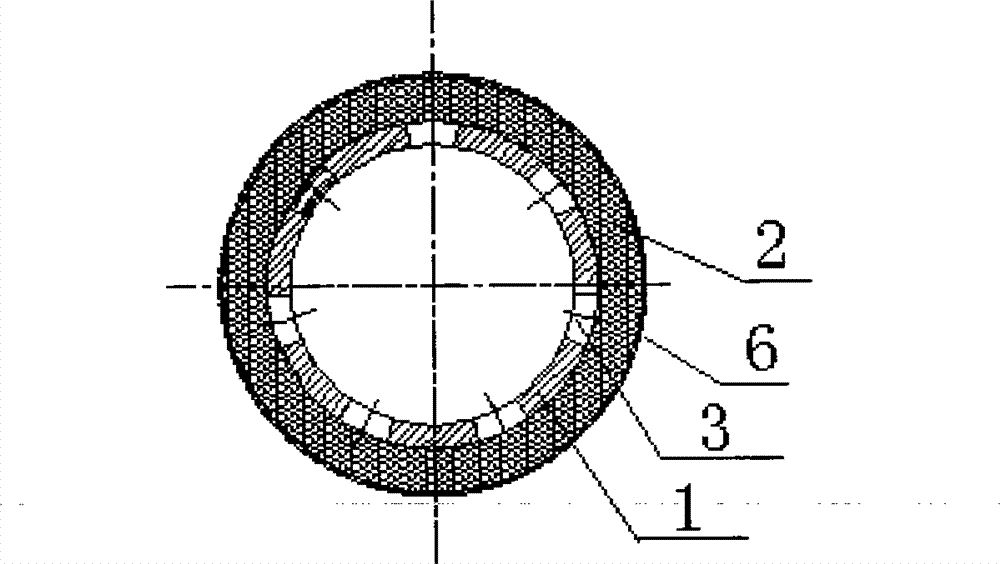

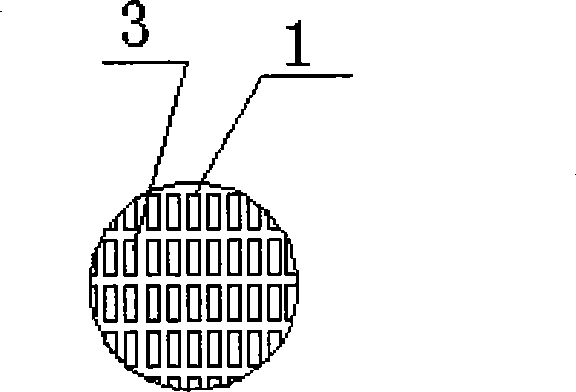

[0021] A sand control pipe pre-filled with gravel comprises a base pipe 6, a sand control pipe shell 1 set outside the base pipe 6, and a gravel layer 2 is filled between the base pipe 6 and the sand control pipe shell 1, Several diversion holes 3 are provided on the pipe wall of the base pipe 6 and the pipe wall of the sand control pipe shell 6 .

[0022] In the present invention, the sand control pipe casing 1 is arranged between the sealing base 4 and the sealing cover 5 .

[0023] In the present invention, the sealing base 4 is fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com