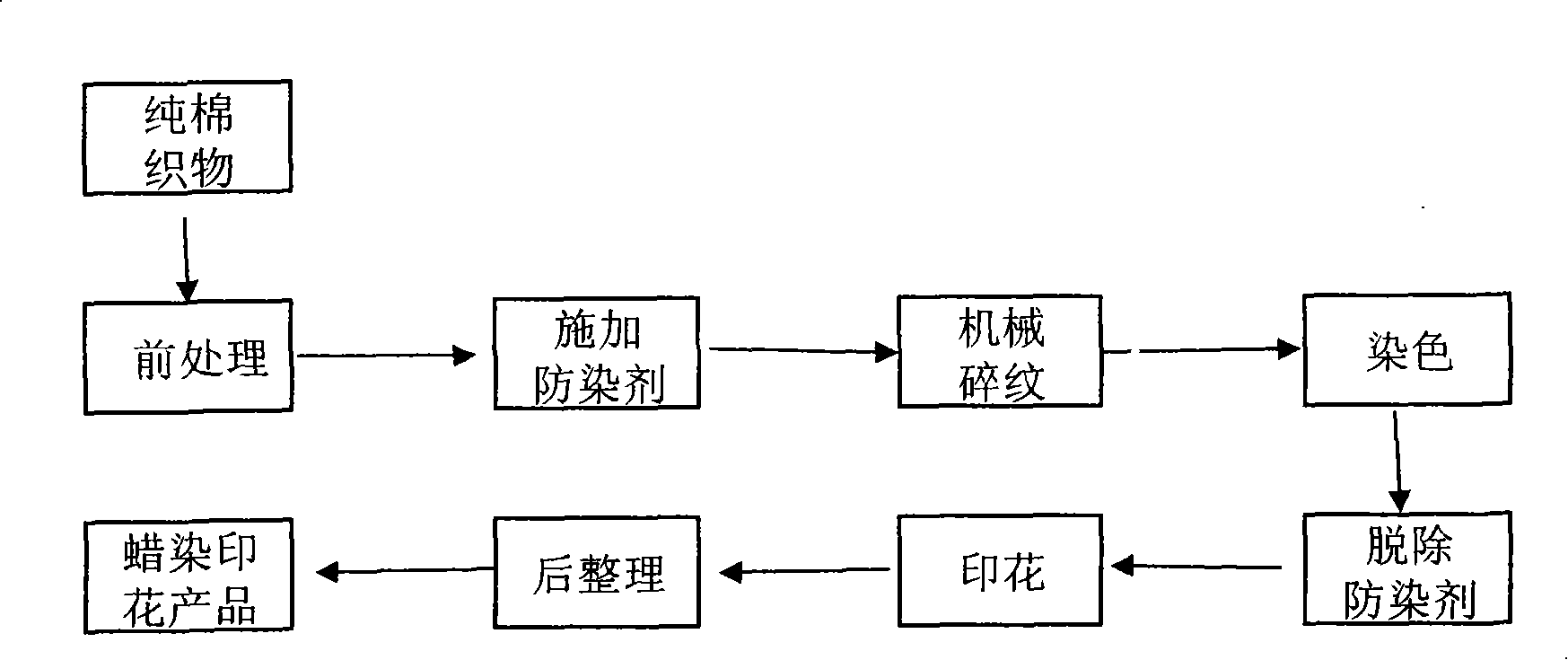

Process for continuously printing patterns on purified cotton textiles by wax printing

A technology of pure cotton fabric and printing, applied in dyeing method, textile and papermaking, etc., can solve the problems of incapable of mechanized continuous printing production, and achieve good economic benefits, reduce processing costs, and improve economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Select 40 / 40 pure cotton fine woven fabrics, after conventional pretreatment of singeing, desizing, scouring, mercerizing, and bleaching processes, apply anti-staining agent by padding, and the anti-staining agent is paraffin: wax printing modifier The mixed molten liquid of PK-202=70:30 (weight percentage), after the mechanical crushing treatment, dyes the wax pattern with traditional indigo, and then suspends and separates the anti-dyeing agent in 6 tanks of 95°C hot water, and then passes through the traditional Soap washing, printing, steaming, washing, drying and other processes can get batik printed pure cotton fine textile fabric with fine wax patterns.

Embodiment 2

[0024] Select 21 / 21 pure cotton plain weave fabric, after conventional pretreatment of singeing, desizing and scouring process, apply anti-dyeing agent in the way of rotary screen flat coating, the anti-dyeing agent is paraffin: wax printing modifier PK-202 = 90:10 (weight percent) mixed molten liquid, after mechanical grain breaking treatment, dye wax pattern with traditional indigo, then suspend and separate in 4 tanks of hot water at 90 °C to remove the dye resist, and then wash with traditional soaping and water , printing, steaming, washing, drying and other processes, you can get batik printed pure cotton plain fabric with fine wax patterns.

Embodiment 3

[0026] 60 / 60 pure cotton poplin is selected, after conventional pretreatment of singeing, desizing, scouring, mercerizing and bleaching, the anti-dyeing agent is applied by padding. The anti-dyeing agent is paraffin: wax printing modifier PK- 202 = 80:20 (weight percent) mixed molten liquid, after the mechanical chipping treatment, dye the wax pattern with Indian blue dye, then suspend and separate the anti-dyeing agent through 5 tanks of 95 ° C hot water, and then wash it with traditional soap Washing, printing, steaming, washing, drying and other processes, you can get batik printed cotton poplin with fine wax patterns.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com