Composite vertical compression mould clamping device

A mold clamping device and a composite technology, applied in the field of mold clamping devices, can solve the problems of not being too large in mold opening stroke, large machine length and weight, unable to meet product requirements, etc. , the effect of large bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

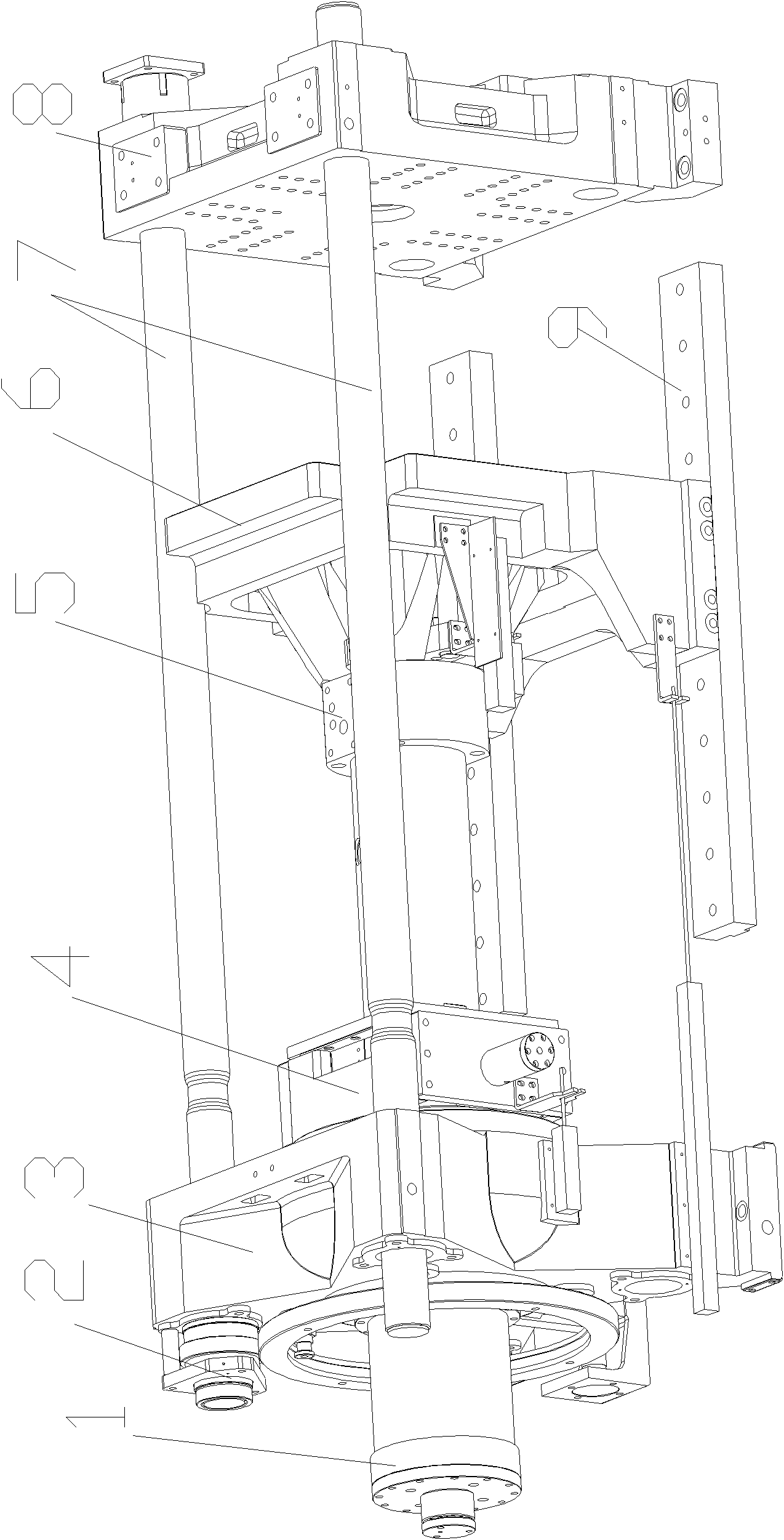

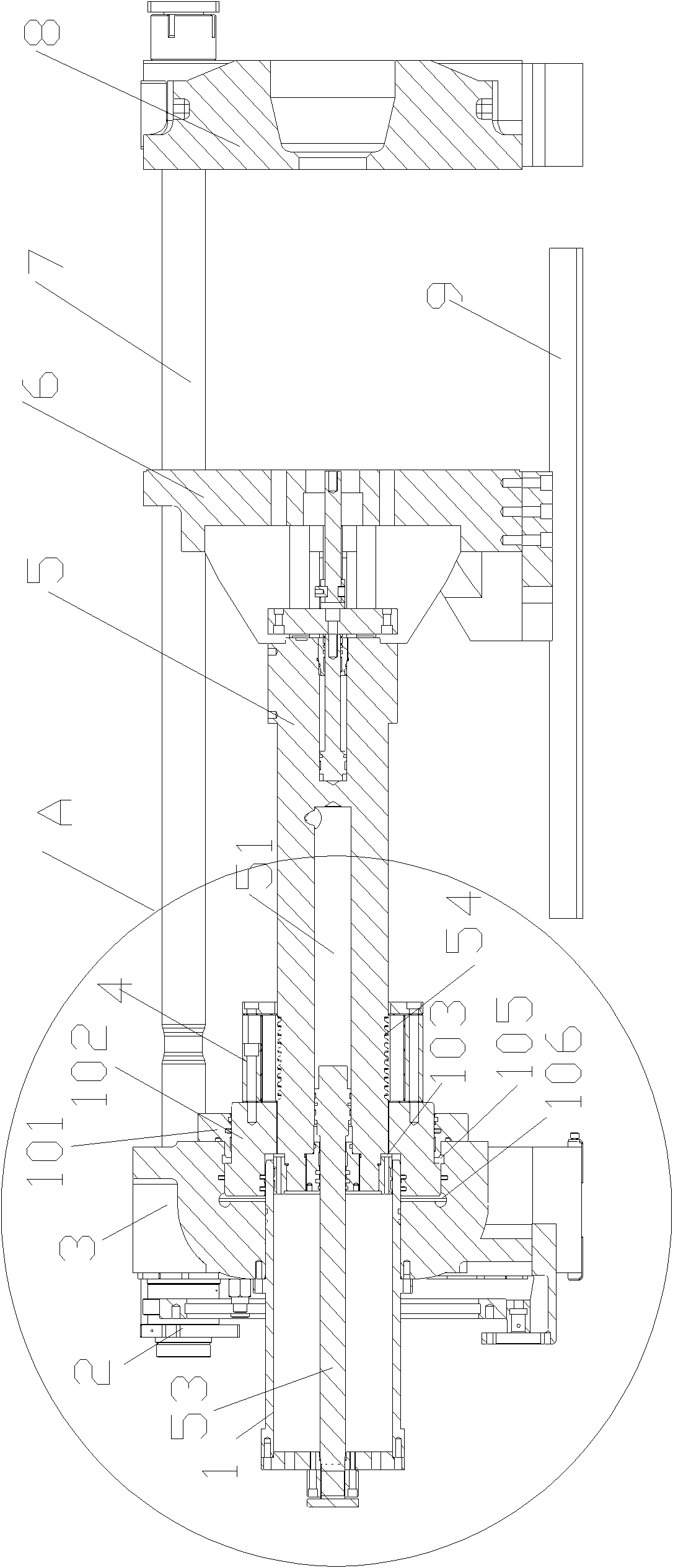

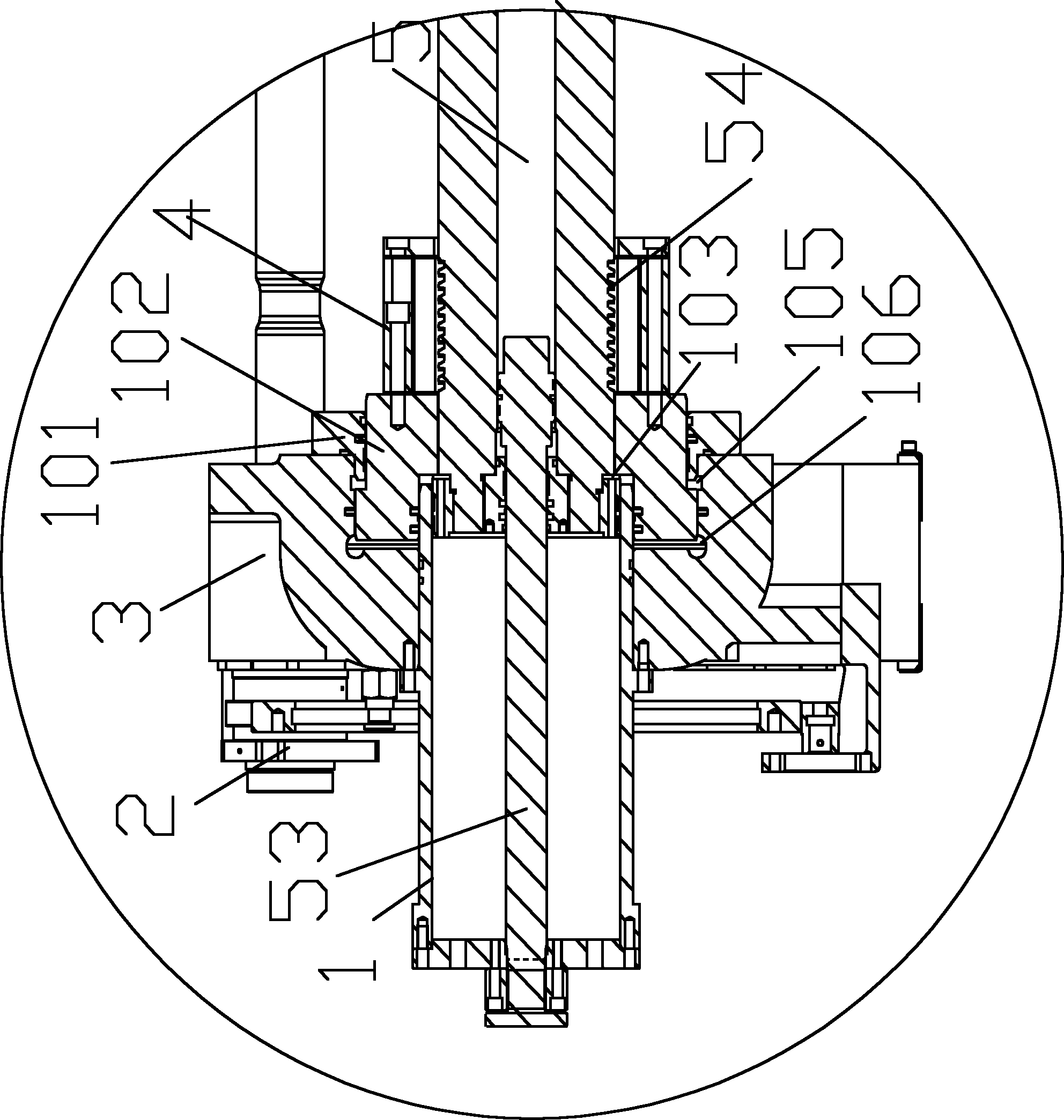

[0021] Such as figure 1 , figure 2 As shown, the composite direct pressure mold clamping device is mainly composed of the following components: ejector column guide sleeve 1, mold adjustment device 2, tail plate 3, entanglement cylinder assembly 4, ejector column 5, second plate 6, tie rod 7, Head plate 8, support plate linear guide 9.

[0022] The above-mentioned two boards 6 are arranged on the linear guide rail 9 and are guided by the linear guide rail 9 .

[0023] The jack post guide sleeve 1 penetrates vertically and is fixed at the central position of the tail plate 3 .

[0024] One end of the above-mentioned ejector column 5 is fixed on the second plate 6, and the other end passes through the clamping piston 102 and placed in the ejector column guide sleeve 1, the ejector column 5 can move in the ejector column guide sleeve 1, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com