Tailor welding forming positioning device used for large-sized thin-wall cylinder type shell section

A thin-walled cylinder and positioning device technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment and other directions, can solve the problems affecting the consistency and safety of aerospace products, poor accuracy consistency, etc., to facilitate installation and disassembly, and improve the pass rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

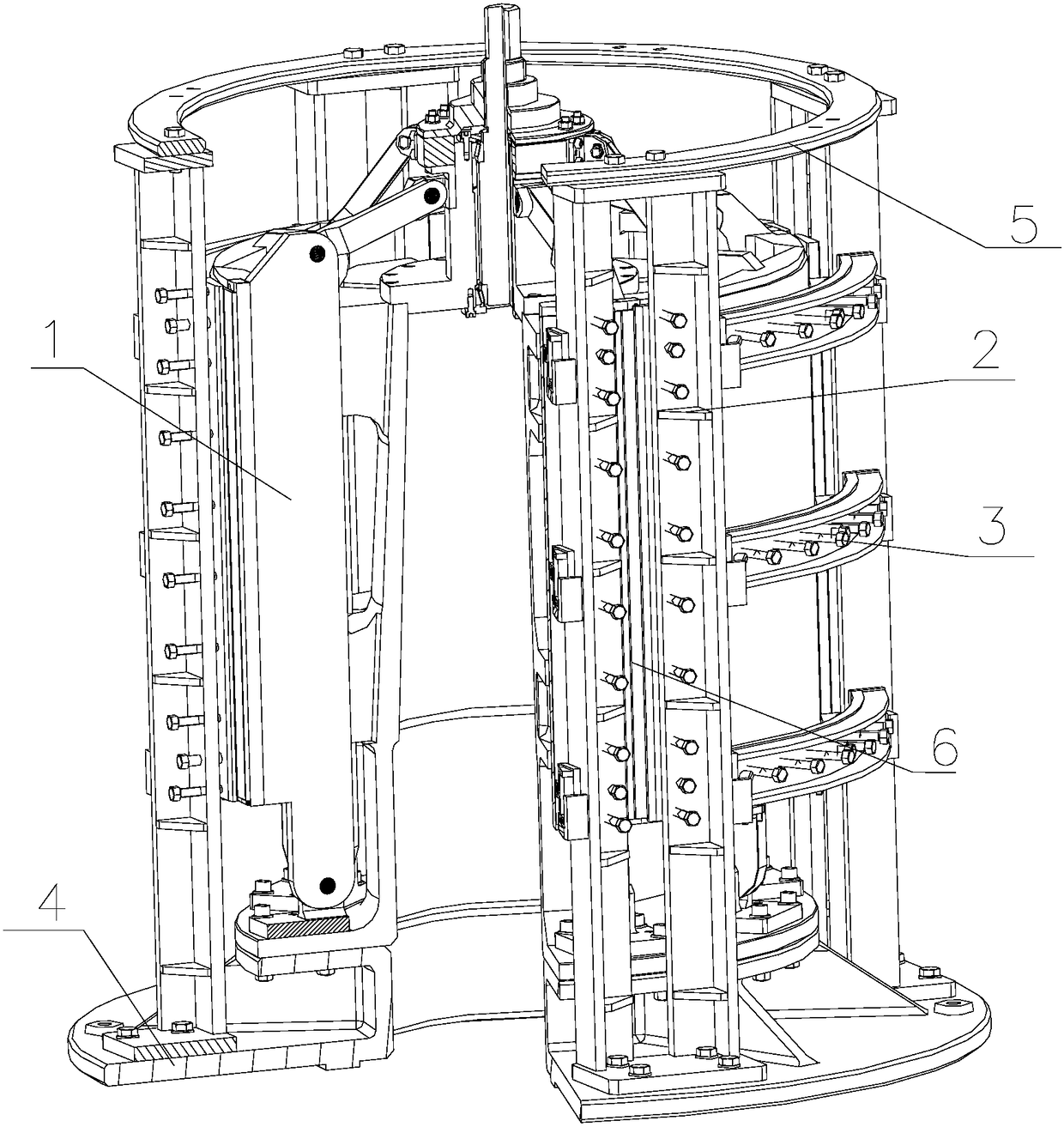

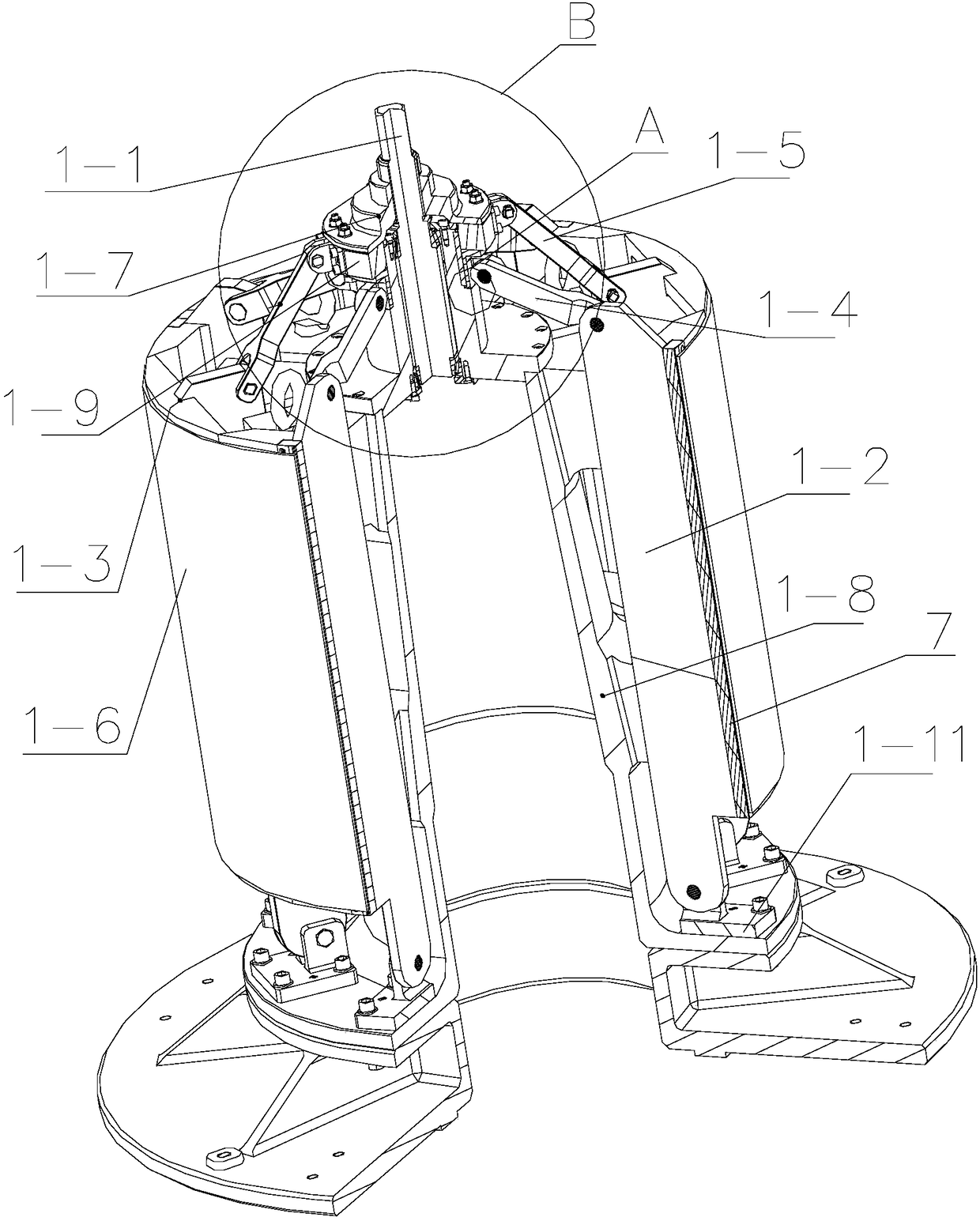

[0034] Example 1: see Figure 1 to Figure 10 , the processing method of the large thin-walled cylindrical shell segment is to splice and position multiple arc-shaped thin-walled plates 1-6, and connect each longitudinal seam 6 by welding. A large thin-walled cylindrical shell segment tailor welding positioning device includes a base 4. Inner support component 1, longitudinal compression component 2 and ring compression component 3;

[0035] The base 4 is a horizontally arranged flange, and the flange includes an upper annular disk 4-1 and a lower annular disk 4-2 arranged coaxially, and the outer diameter of the lower annular disk 4-2 is larger than that of the upper annular disk. Disc 4-1 outer diameter;

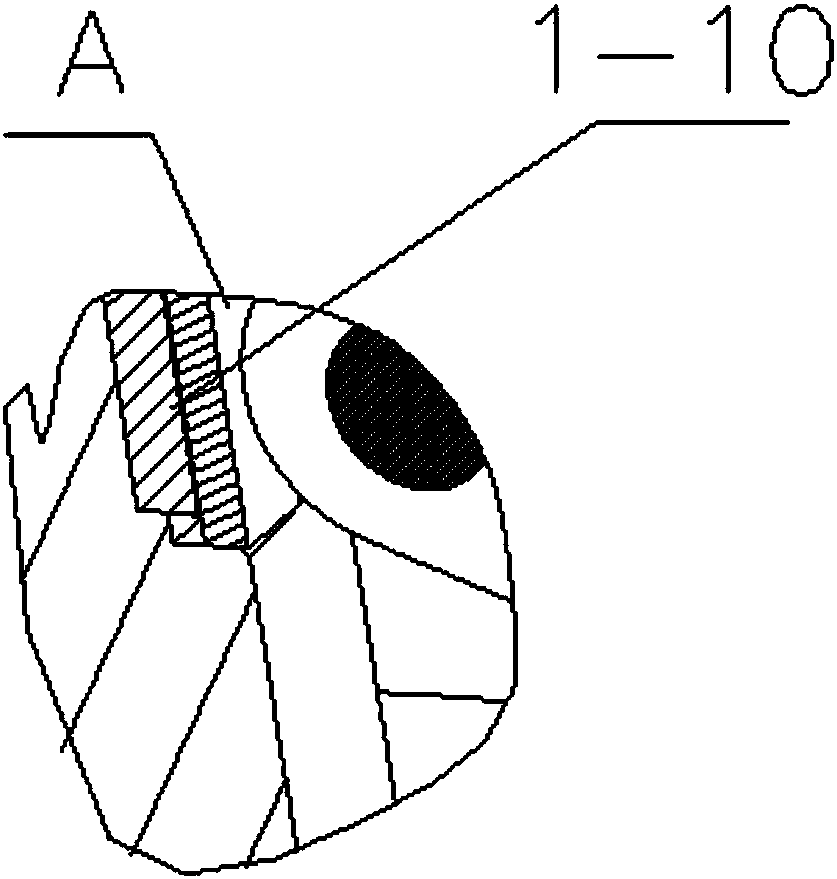

[0036] The inner support assembly 1 includes a central axis 1-8, the central axis 1-8 is hollow and has a small upper part and a larger lower bottom. Axle seat 4-5, the top is fixed with bearing seat 1-13, and described bearing seat 1-13 is provided with bearing 1-12 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com