Fiber anti-counterfeit element anti-counterfeit paper forming and making with pulp method and paper making with pulp production line

A technology of anti-counterfeiting paper and mesh cage, applied in paper, paper making, paper machine and other directions, can solve the problems of low anti-counterfeiting degree, narrow paper gram weight range and poor anti-counterfeiting element effect, so as to improve the difficulty of anti-counterfeiting, ensure printing quality and smoothness beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing, technical scheme of the present invention is described further:

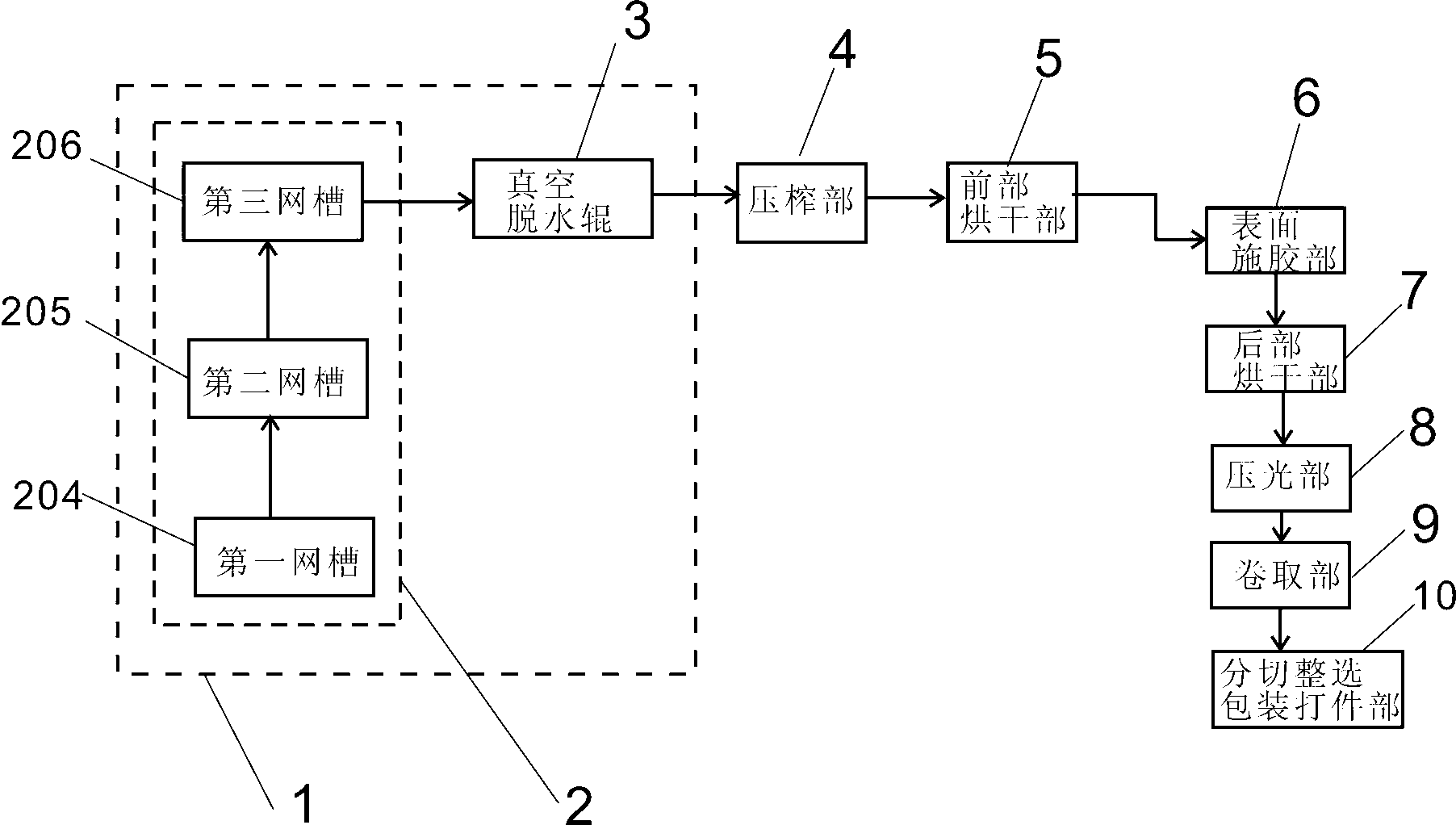

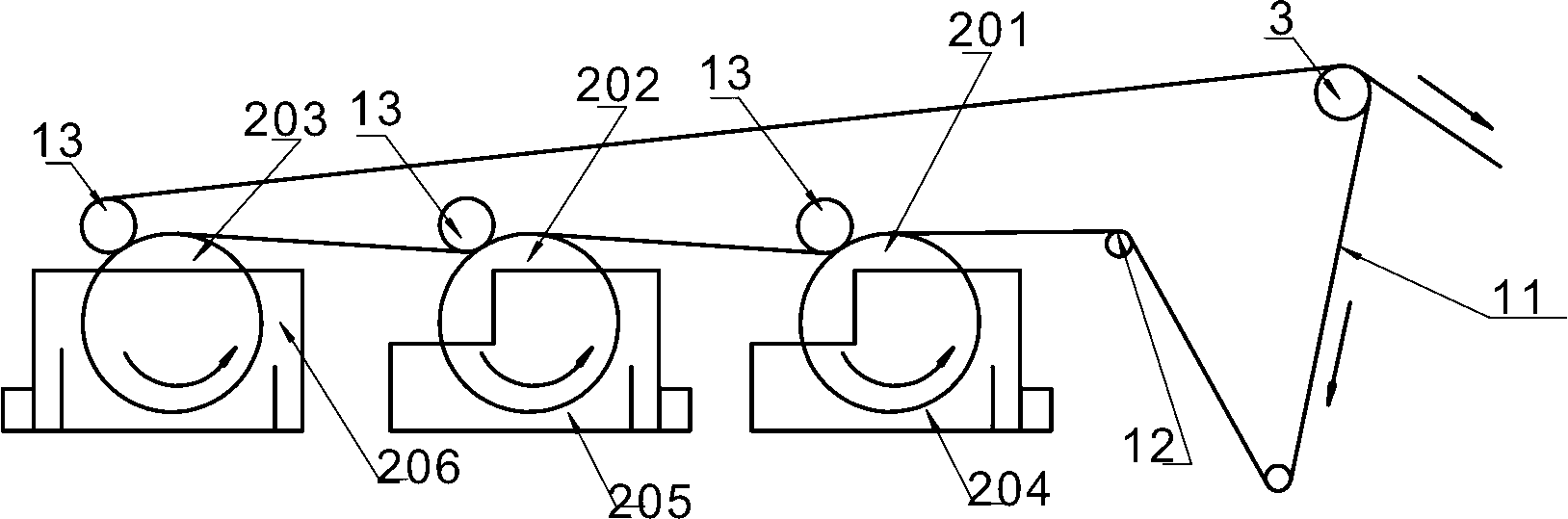

[0023] like figure 1 , 2 Shown: figure 1 It is a block diagram of the production line for fiber anti-counterfeiting element anti-counterfeiting paper three-net cage forming and copying. figure 2 It is a schematic diagram of the structure of the wet part of the production line. The production line is mainly composed of a wet section 1, a pressing section 4, a front drying section 5, a surface sizing section 6, a post drying section 7, a calendering section 8, a coiling section 9, a cutting section, a packaging section 10 Wait for several major components. The improvement of the present invention is to improve the wet part 1, mainly adopting three mesh cages in the wet part 1 to form. Specifically, the wet section 1 includes a slurry mixing flow delivery system 2 and a vacuum dewatering roller 3, and the vacuum dewatering roller 3 is located at the rear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com