Built-in prefabricated concrete heat-storage body energy-storage tank

A technology of concrete and energy storage tank, applied in the field of solar energy storage, can solve the problems of high cost of use, high freezing point of molten salt, unstable energy storage, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solution of the present invention will be further described in detail below through specific embodiments and in conjunction with the accompanying drawings.

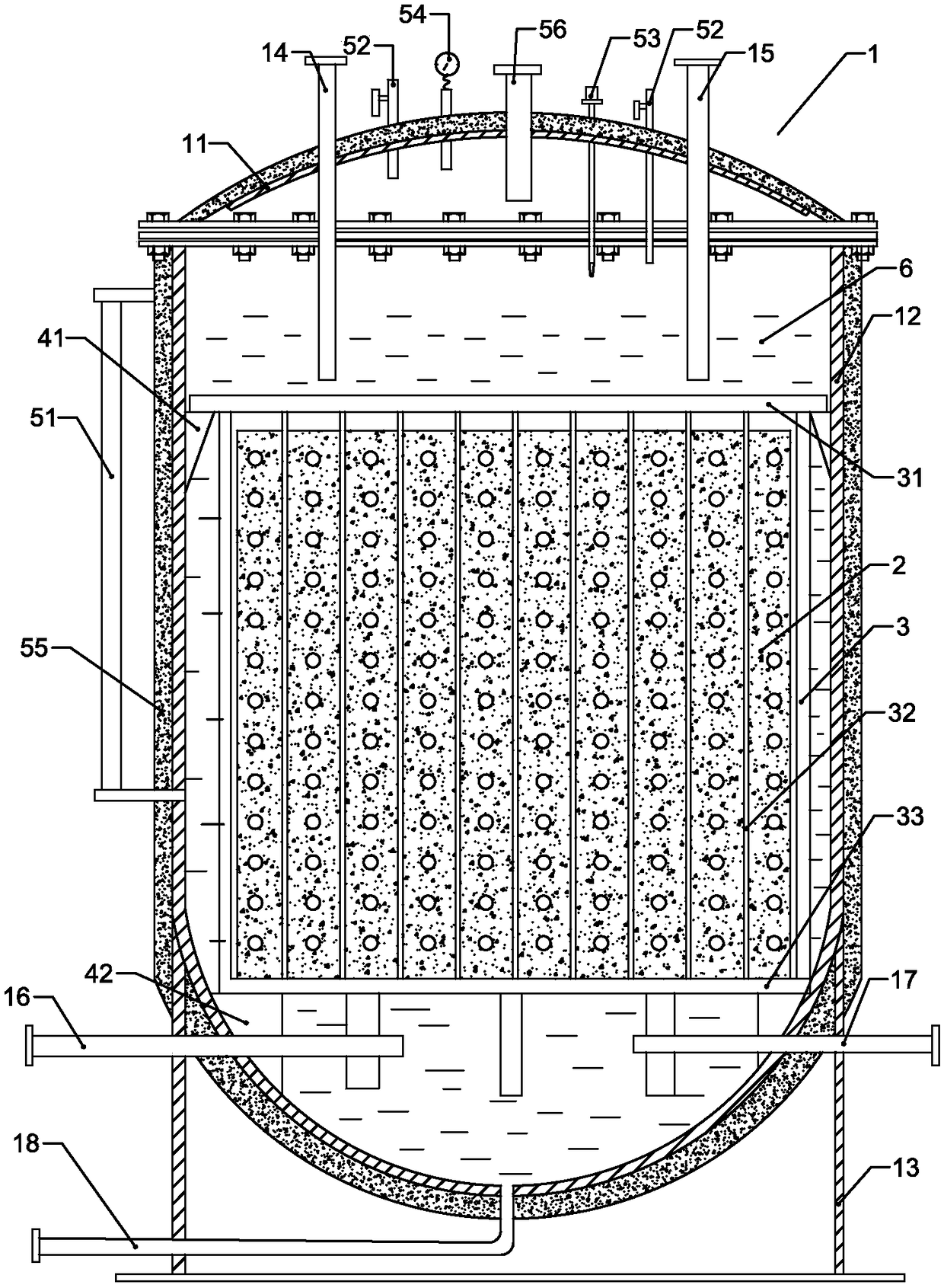

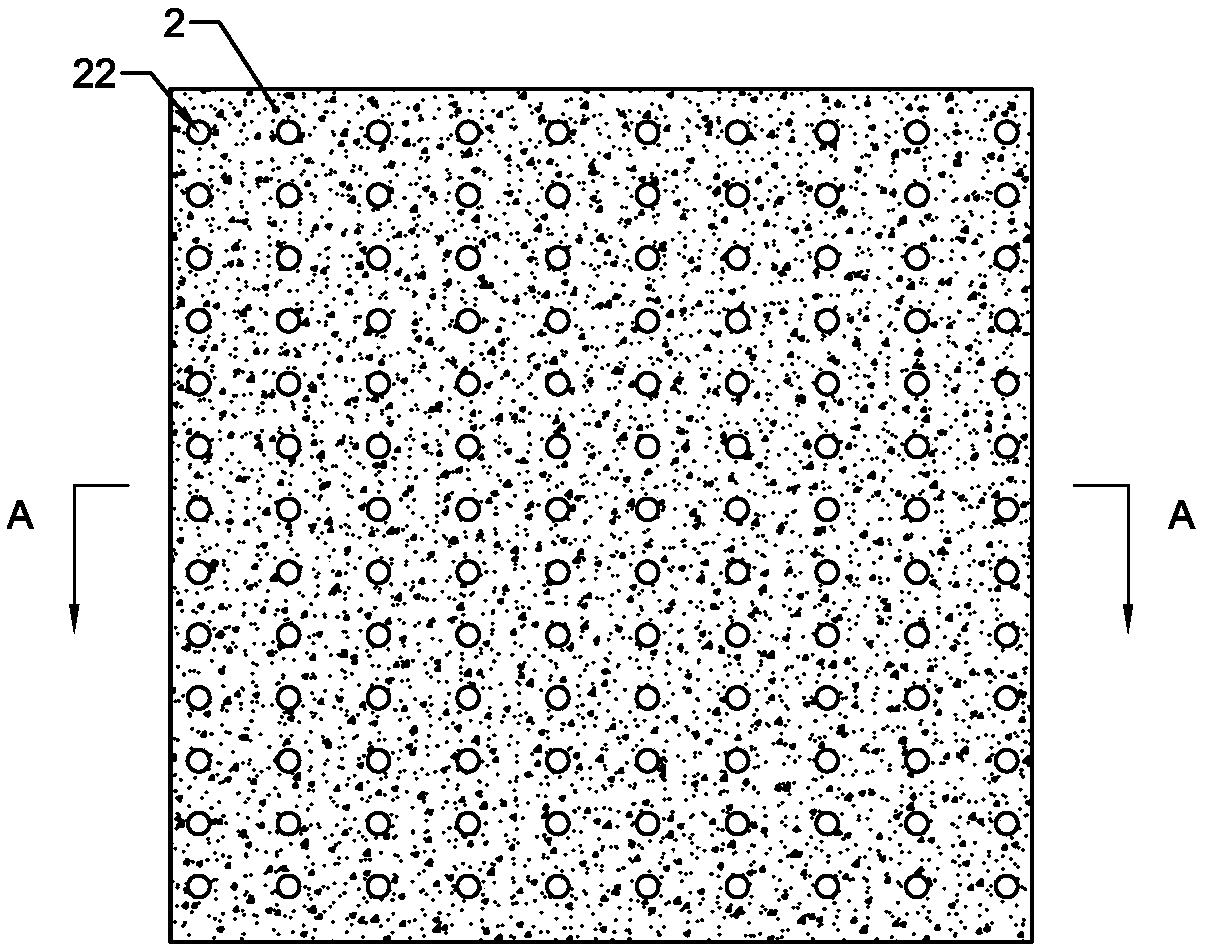

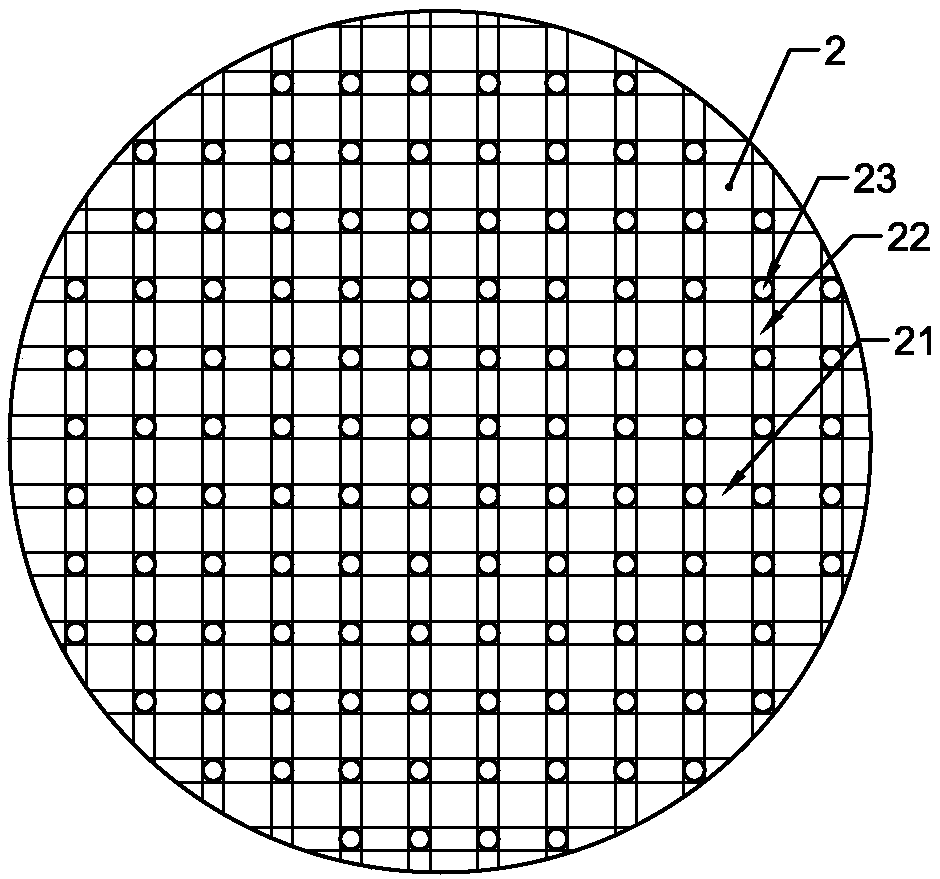

[0035] like figure 1 As shown, an energy storage tank with a built-in prefabricated concrete heat storage body includes a tank body 1, a base 13, a prefabricated concrete heat storage body 2, a heat transfer oil 6, and a mesh cage arranged on the periphery of the prefabricated concrete heat storage body 2 3. The tank body 1 is set on the base 13, the precast concrete heat storage body 2 is set in the tank body 1, and the heat transfer oil 6 is submerged in the precast concrete heat storage body 2.

[0036] Said tank body 1 comprises an upper cover 11 and a tank body body 12, and the upper end of the upper cover 11 and the tank body body 12 are tightly connected by bolts. The upper cover 11 is provided with a thermal oil inlet pipe 14 connected with the solar heat collector, a heat transfer oil outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com