Tandem cylinder mould for manufacturing sand barrier, sediment storage dam, sand dyke and sand wall

A technology of blocking sand dam and net cage, applied in the field of engineering, can solve the problems of high cost, high cost and damage of steel sand retaining wall in desert highways.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

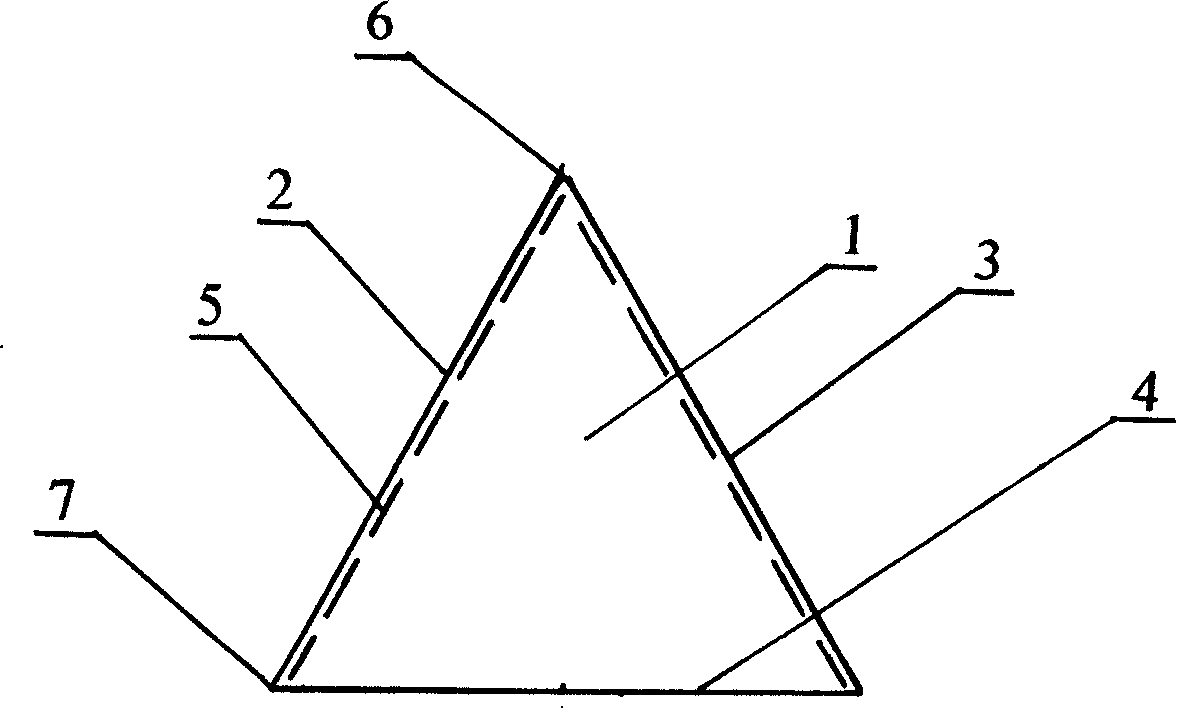

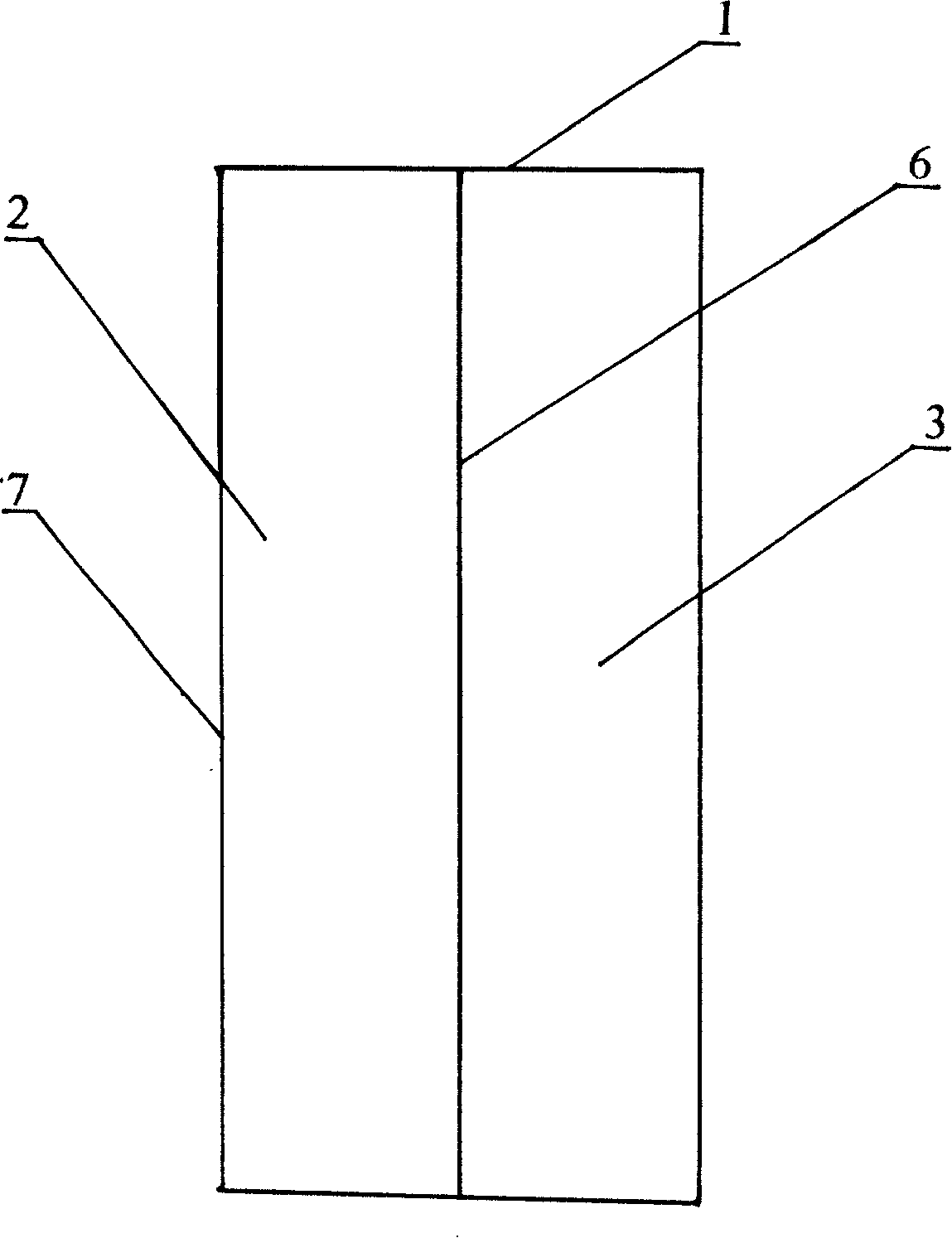

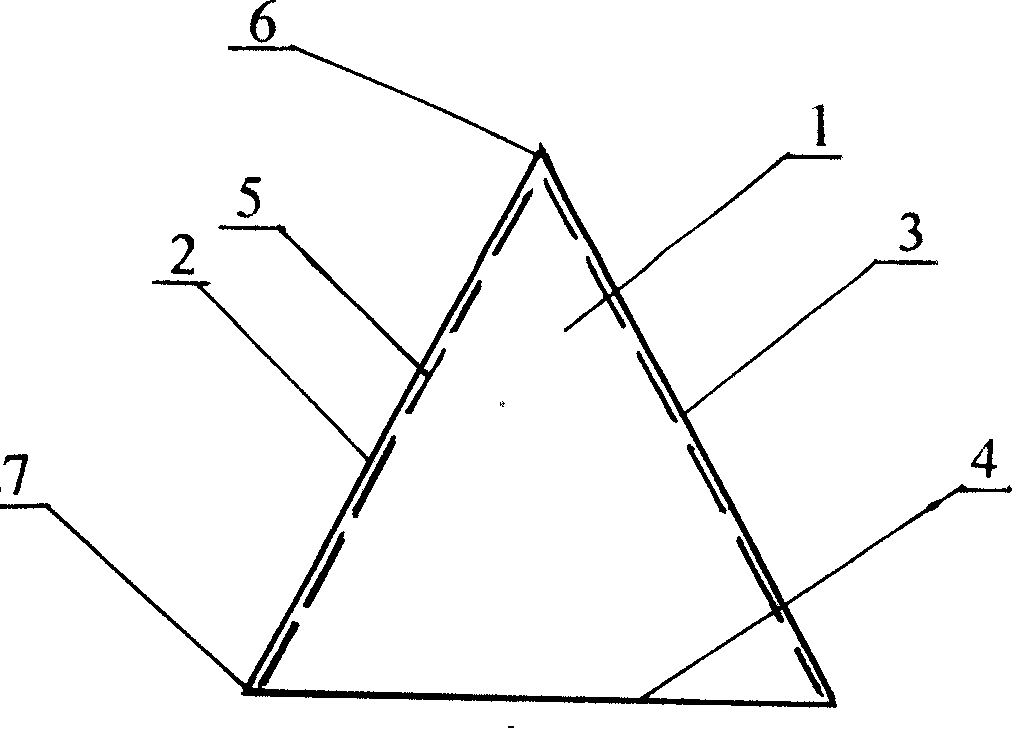

[0019] As shown in the figure, the serial net cage 1 for making sand barriers, sand retaining dams, sand dikes and sand walls is composed of the front side 2 of the net cage, the back side 3 of the net cage and the bottom surface 4 of the net cage to form a triangular cage body; The cage body is made into an equilateral triangle, and the height of the cage body is designed to be less than 90cm. The top edge of the front and the top edge of the back of the cage can be opened or closed and fixed. The front 2 and the back of the cage 3 The inner liner has geotextile 5. Arrange and connect the series net cages for making sand barriers in the desert according to the design of sand barriers, open the top side of the net cage to fill the net cage with desert sand to meet the design requirements, and close the top side to form a net cage sand barrier. To make the series-connected cages for the sand control dam, the cage body is made into an isosceles triangle, and the height of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com