Patents

Literature

42results about How to "Not easy to pop out" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

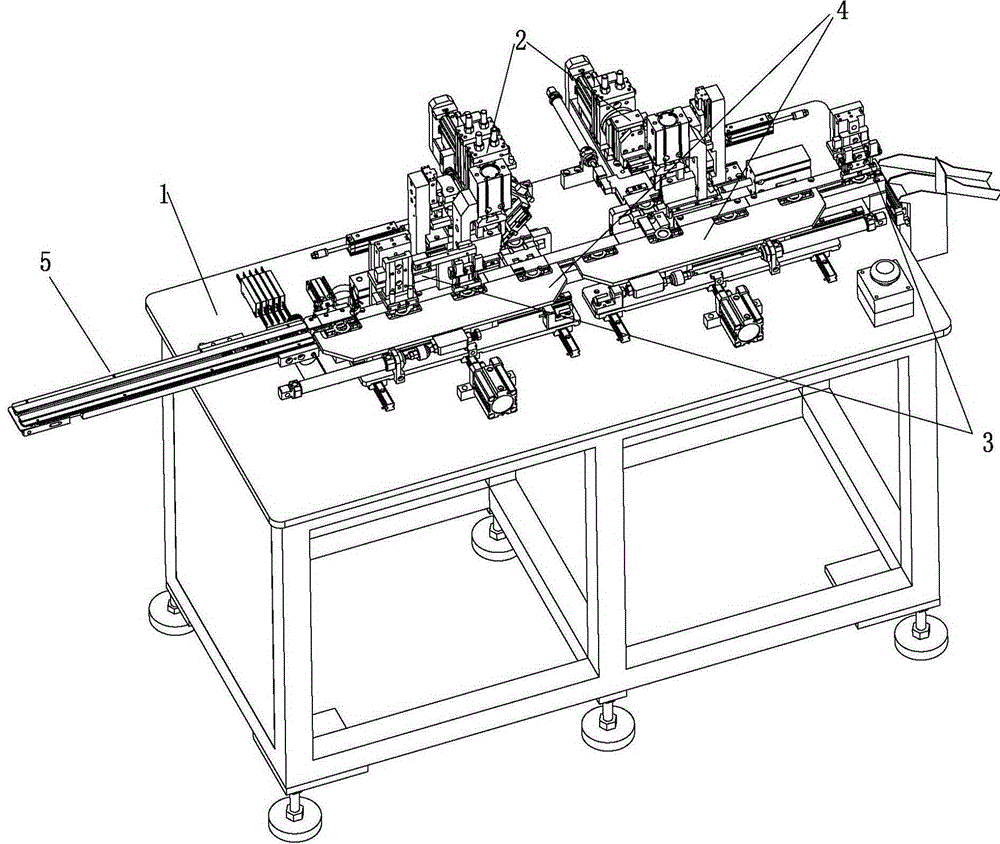

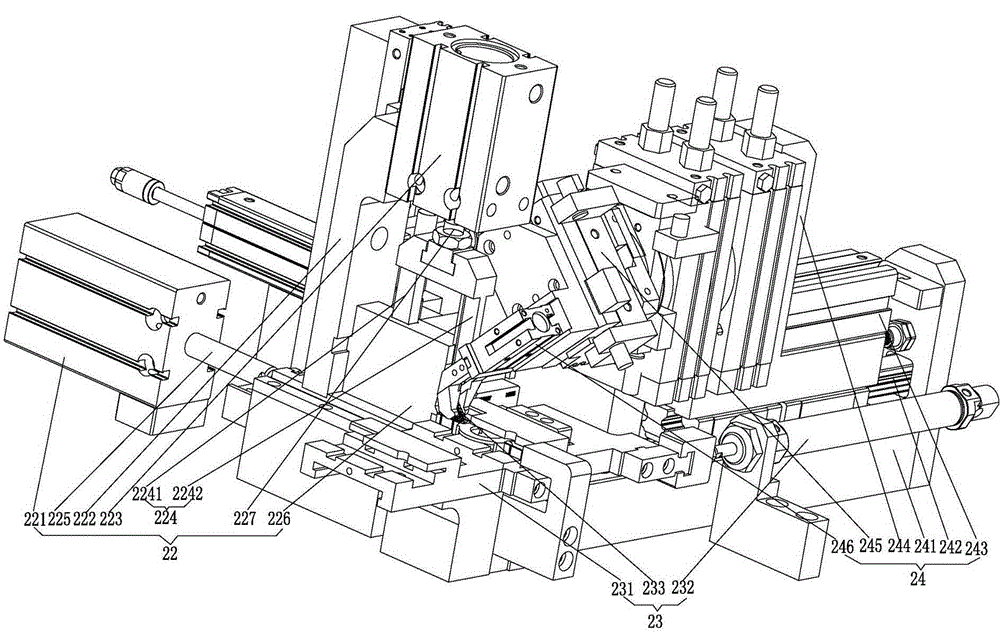

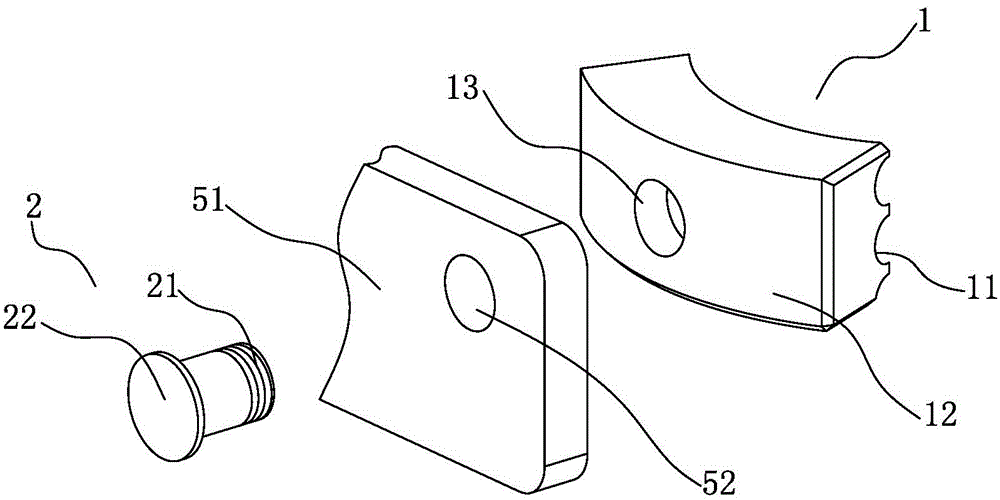

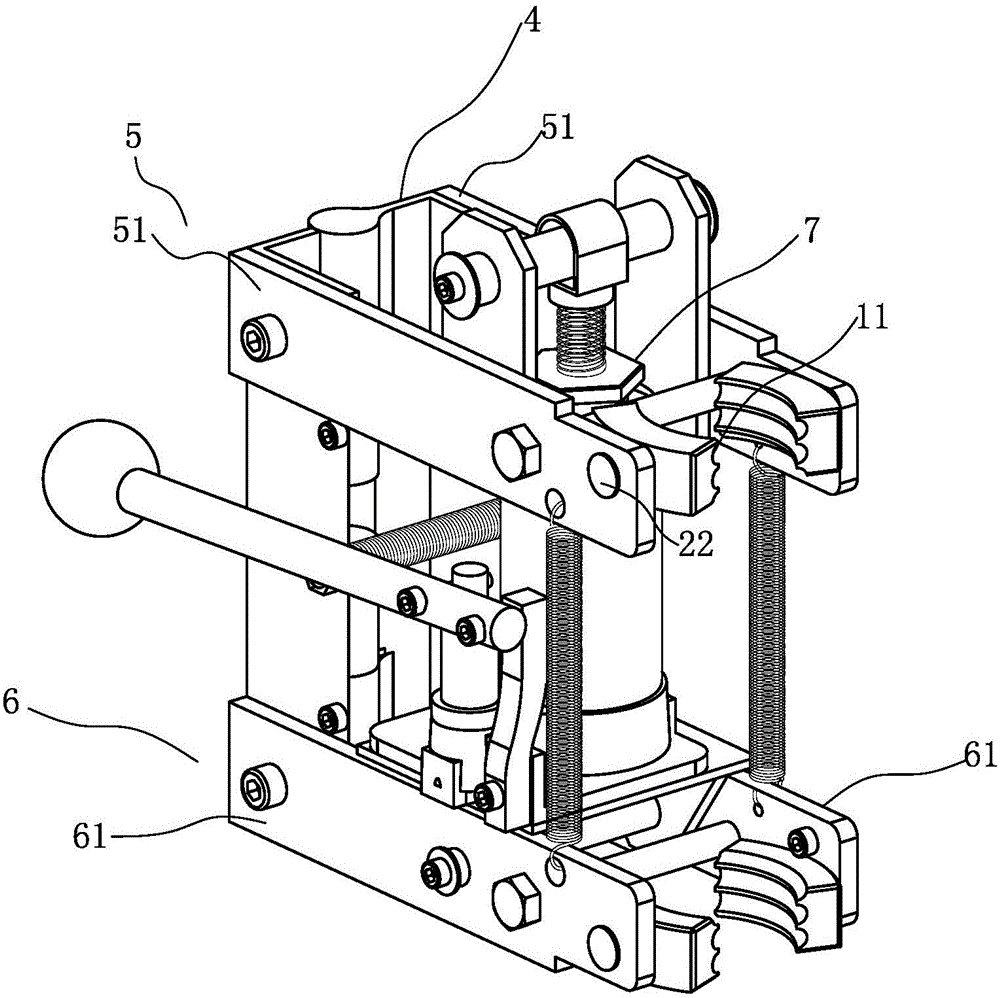

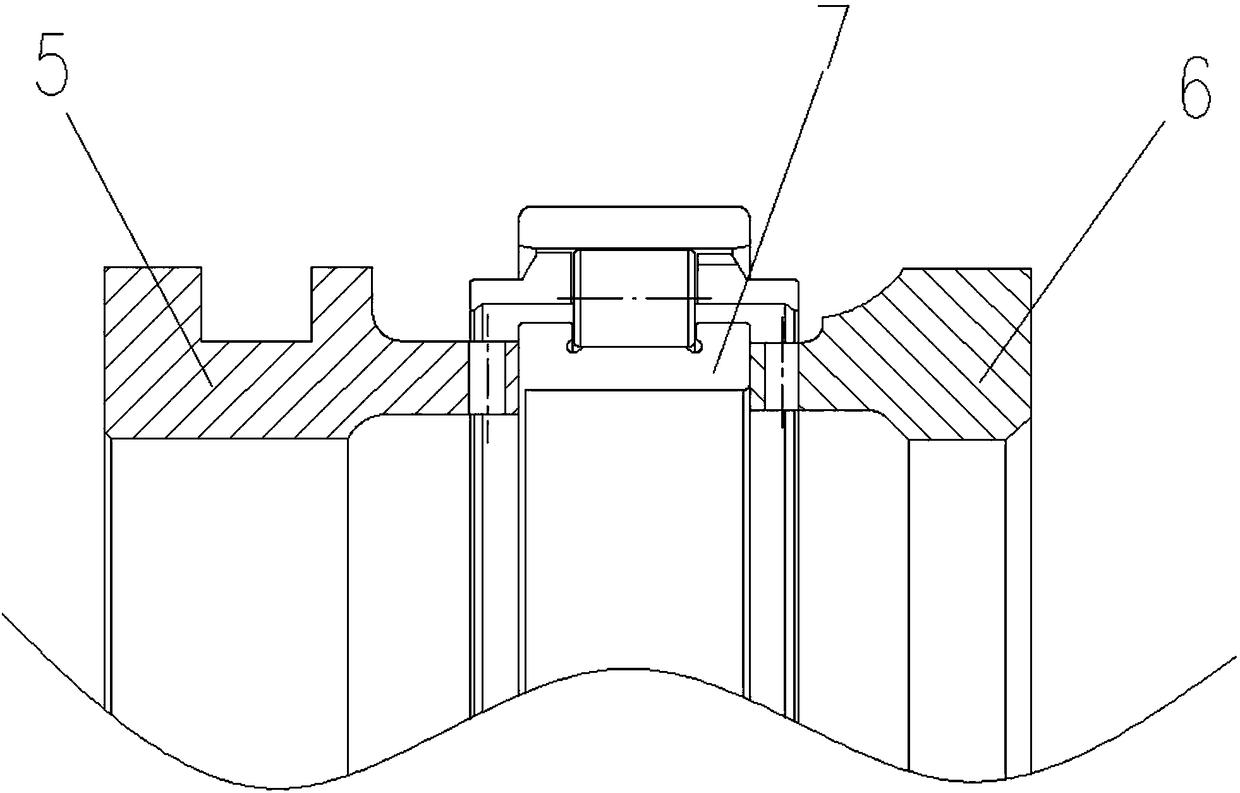

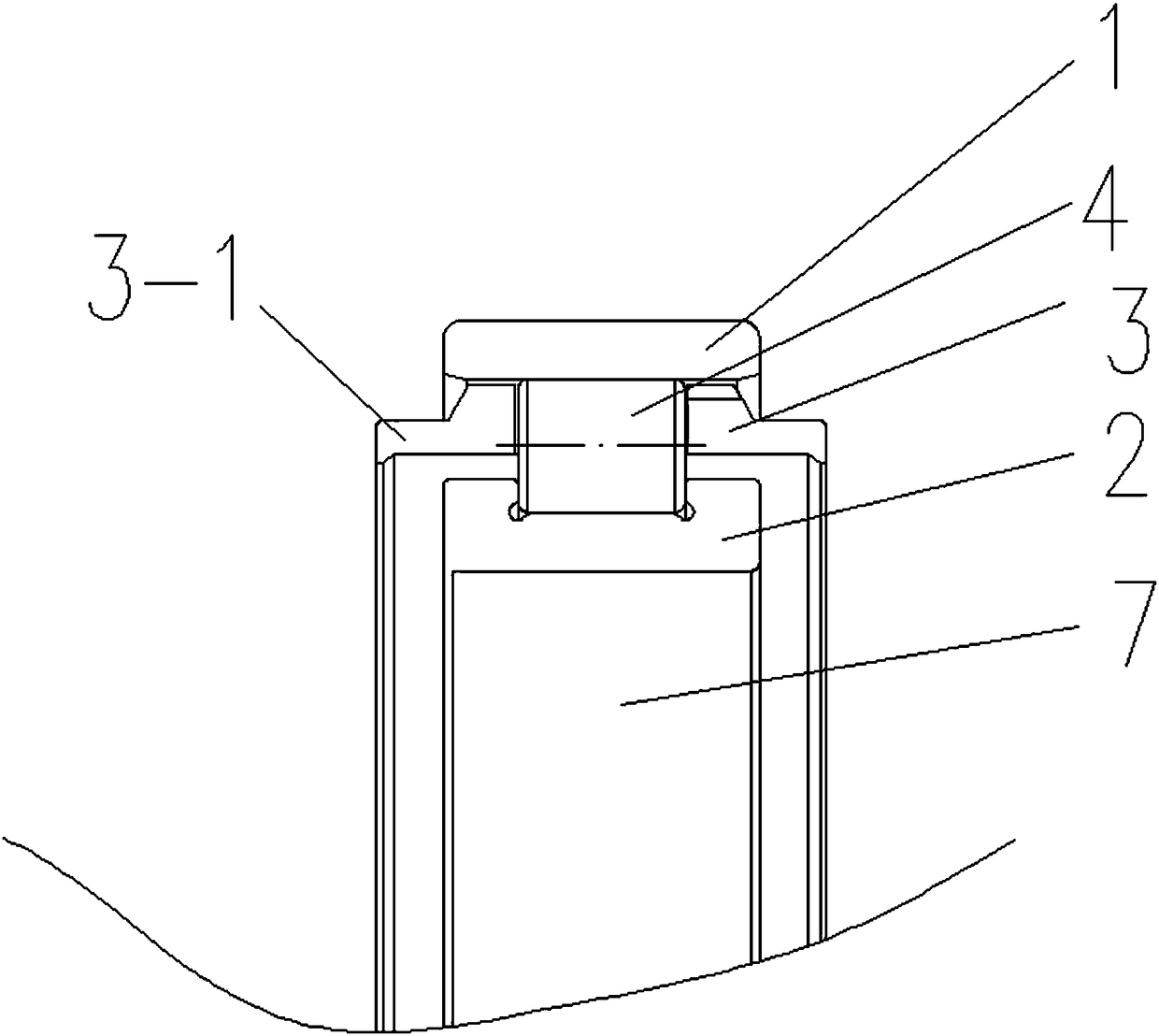

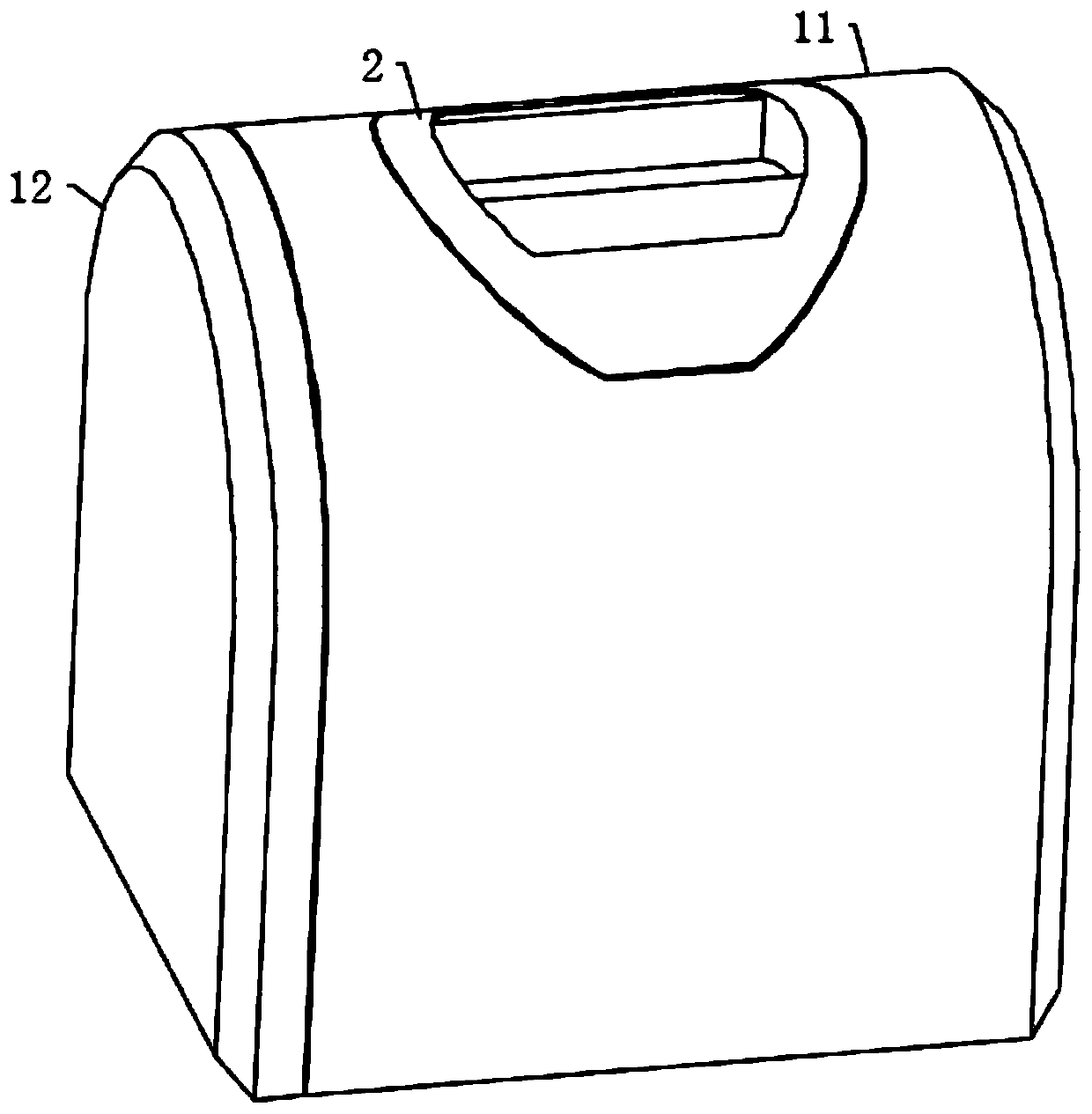

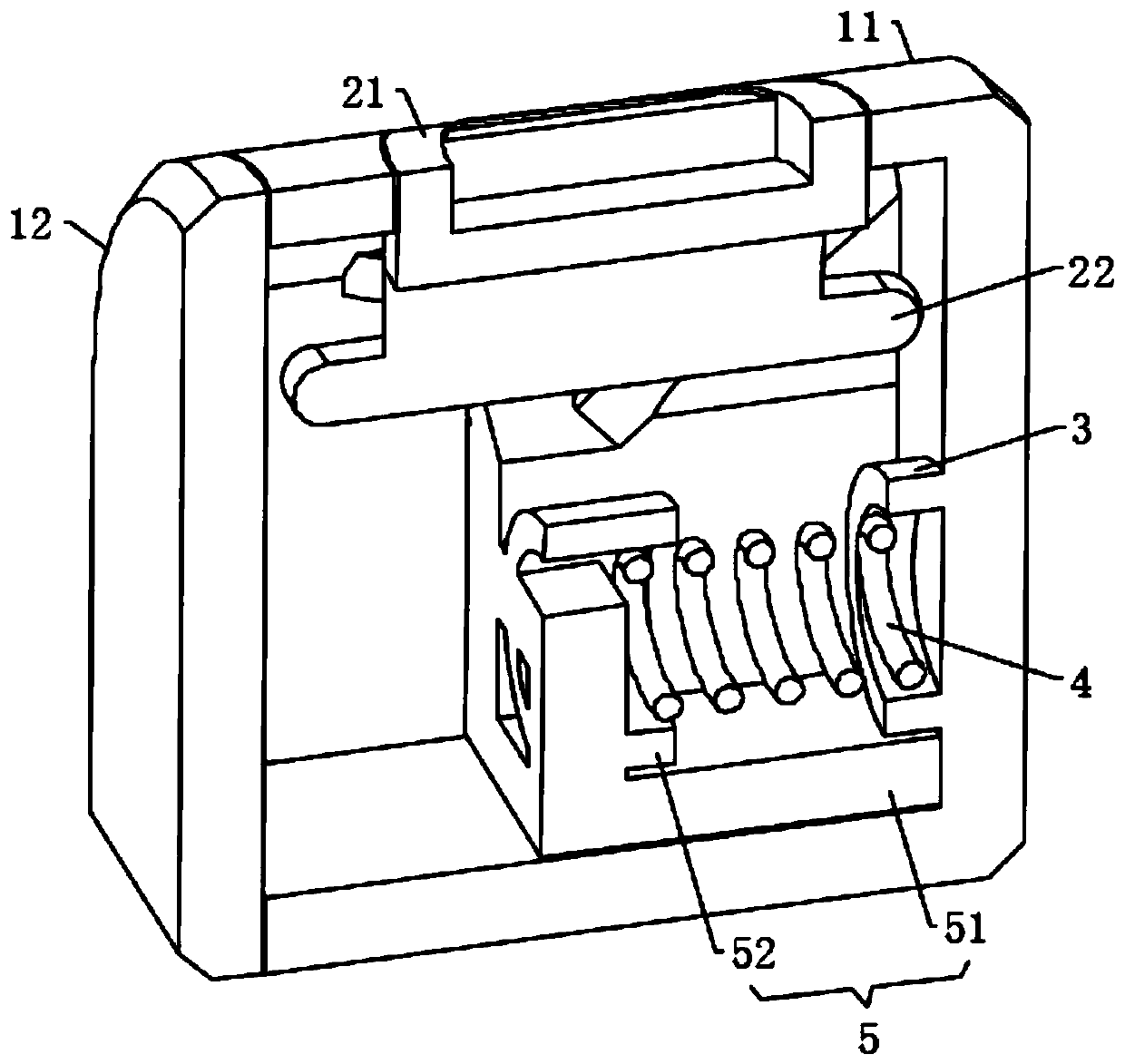

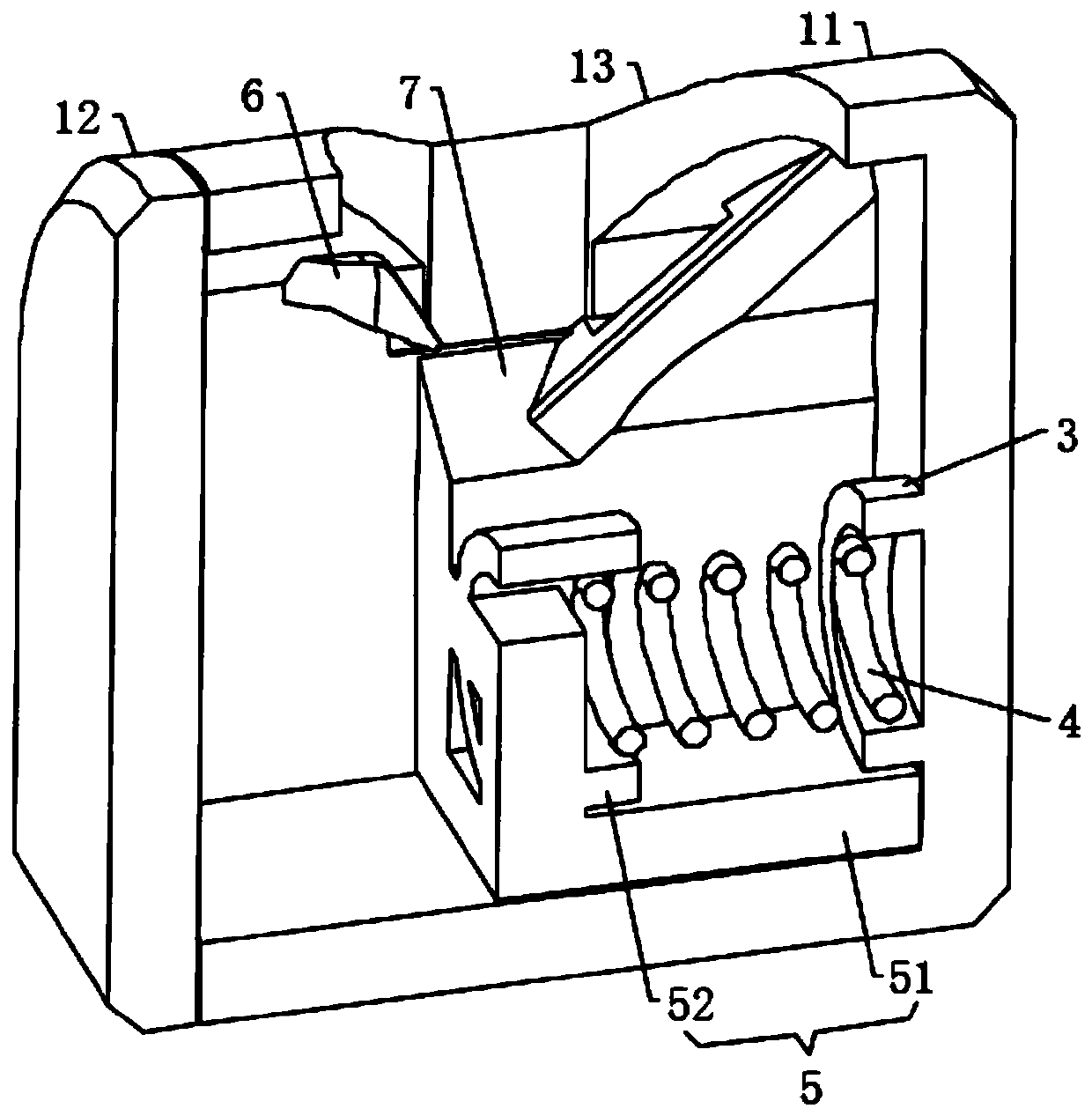

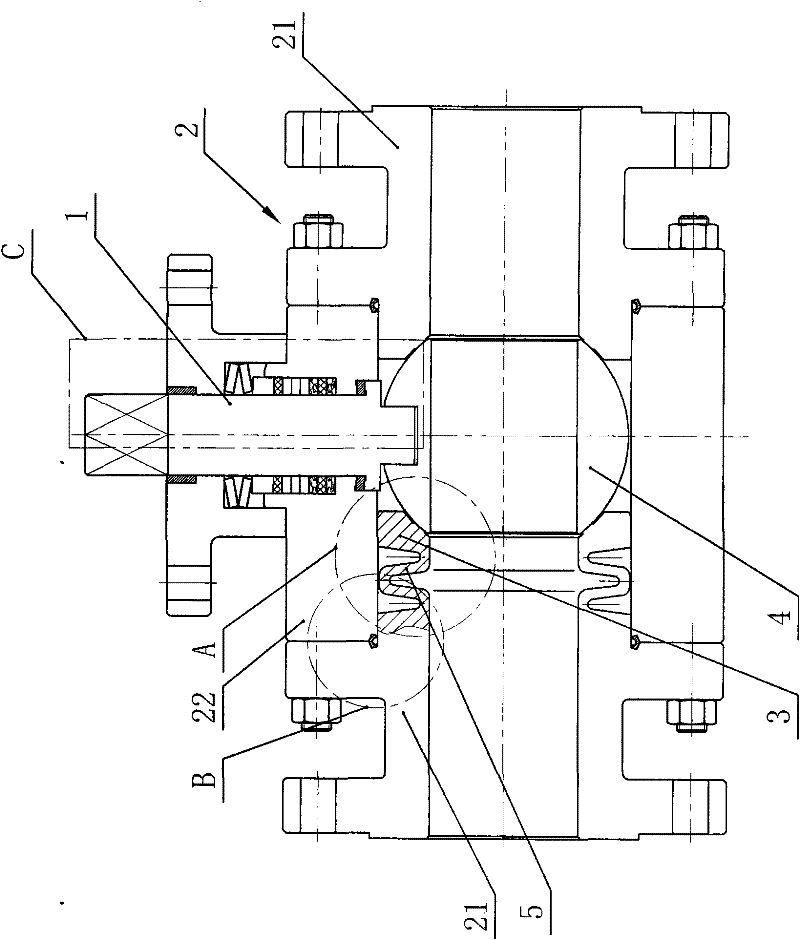

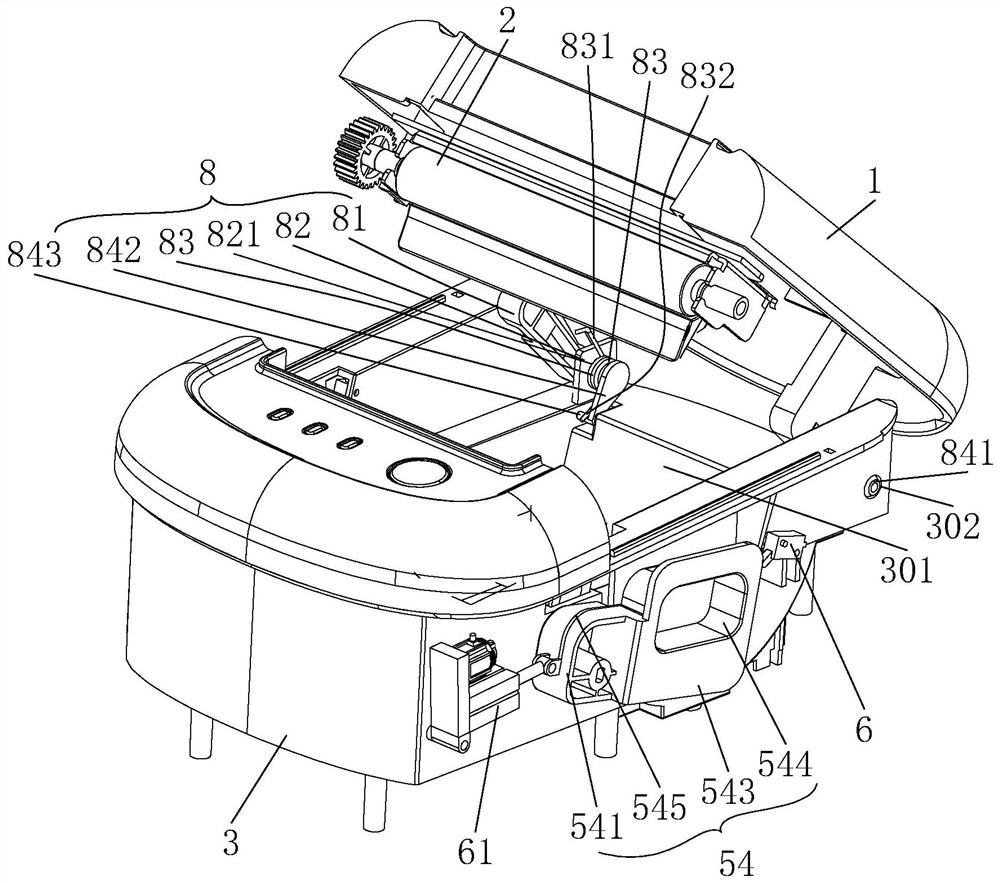

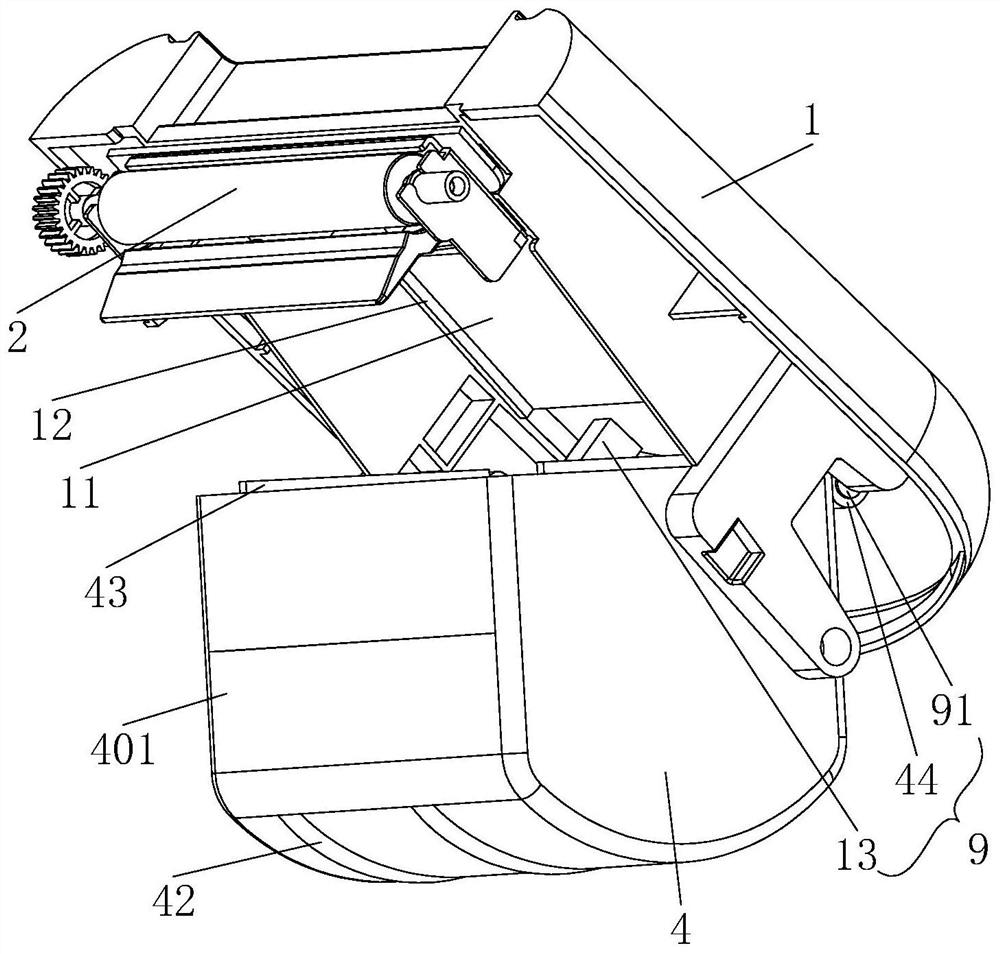

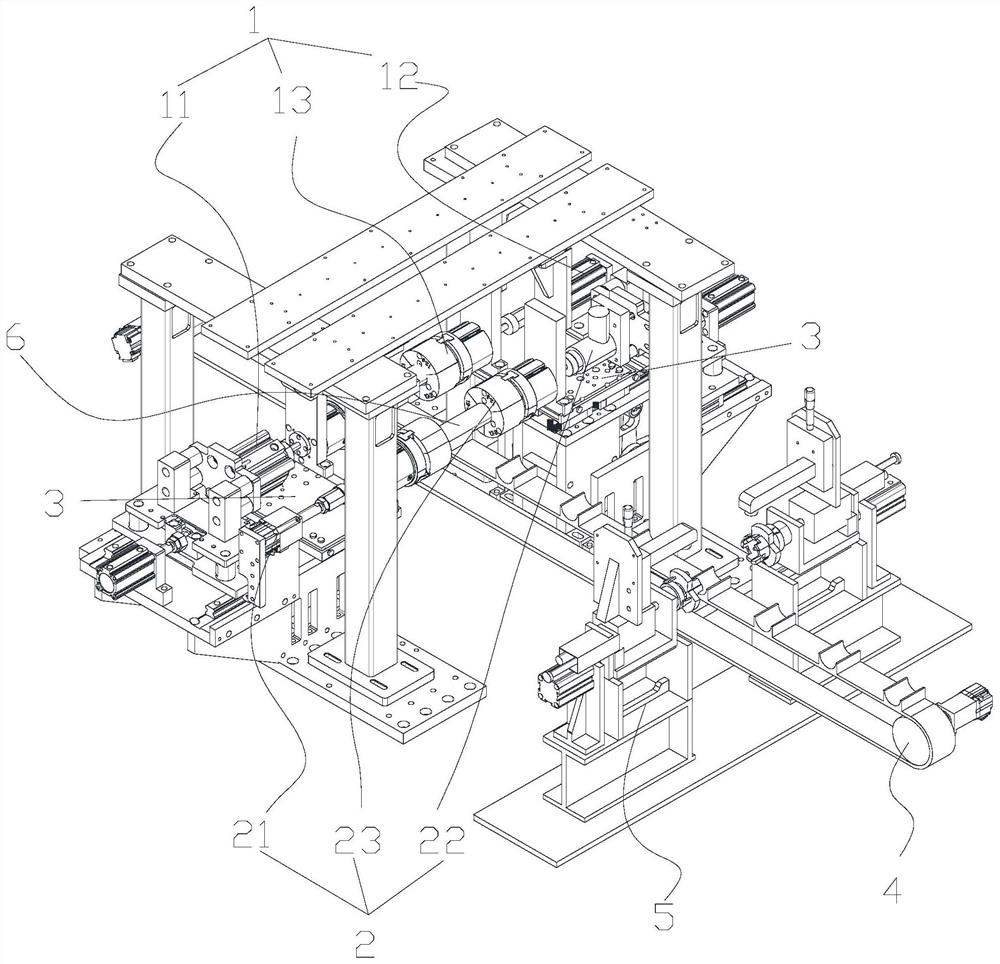

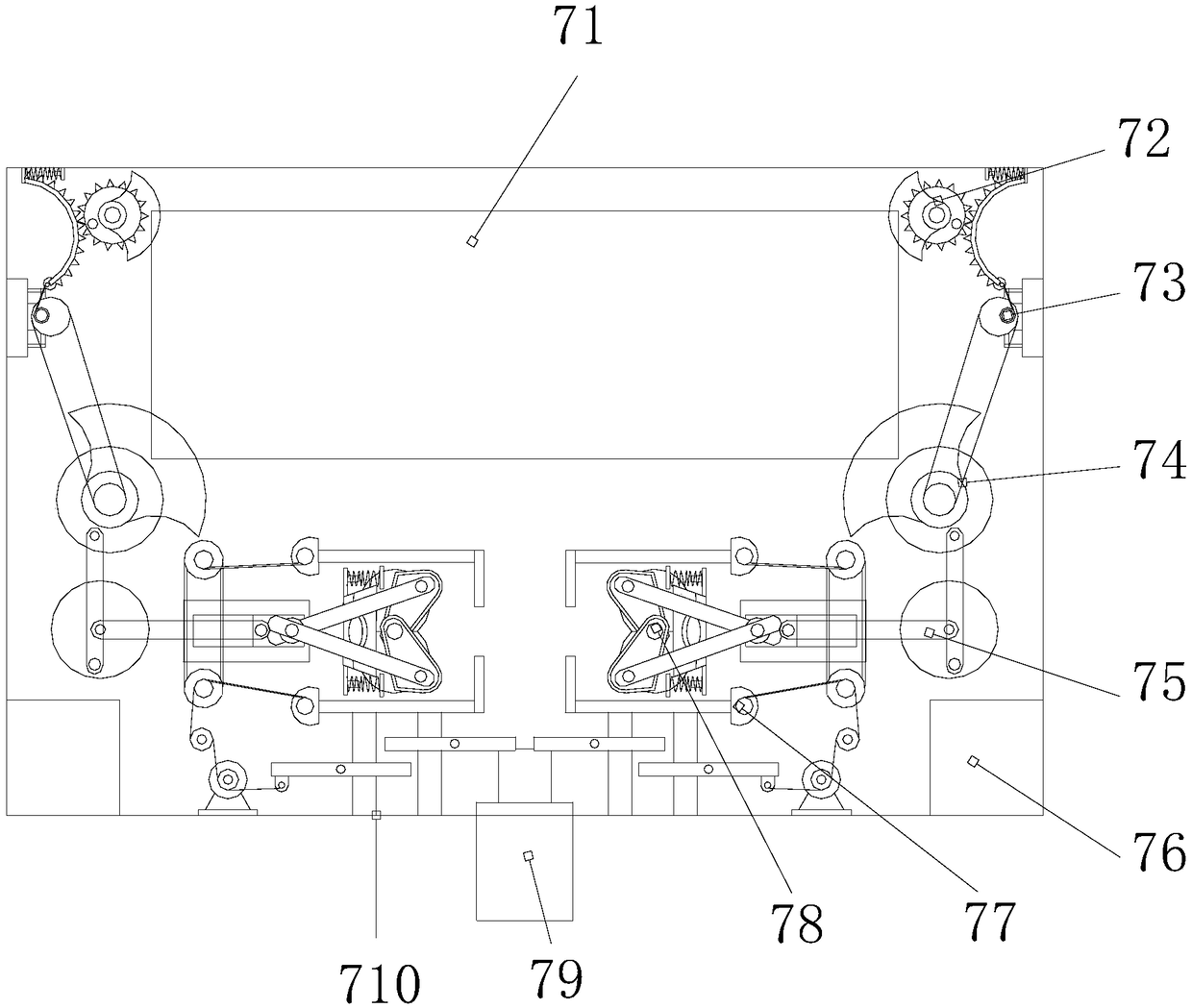

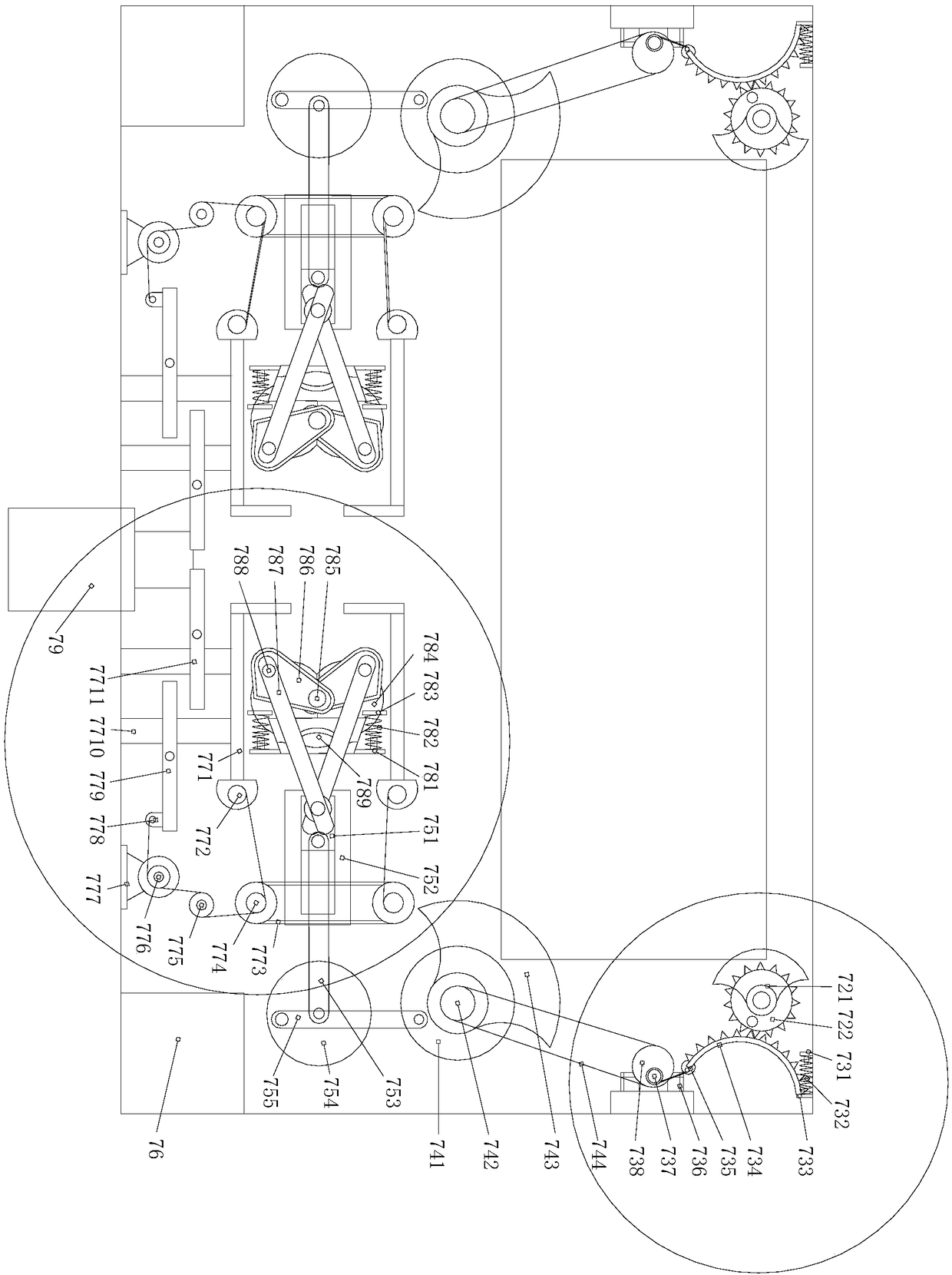

Automatic spring support assembly machine and spring support assembly method thereof

ActiveCN104526343APress fasteningNot easy to pop outAssembly machinesMetal working apparatusSteel ballAssembly machine

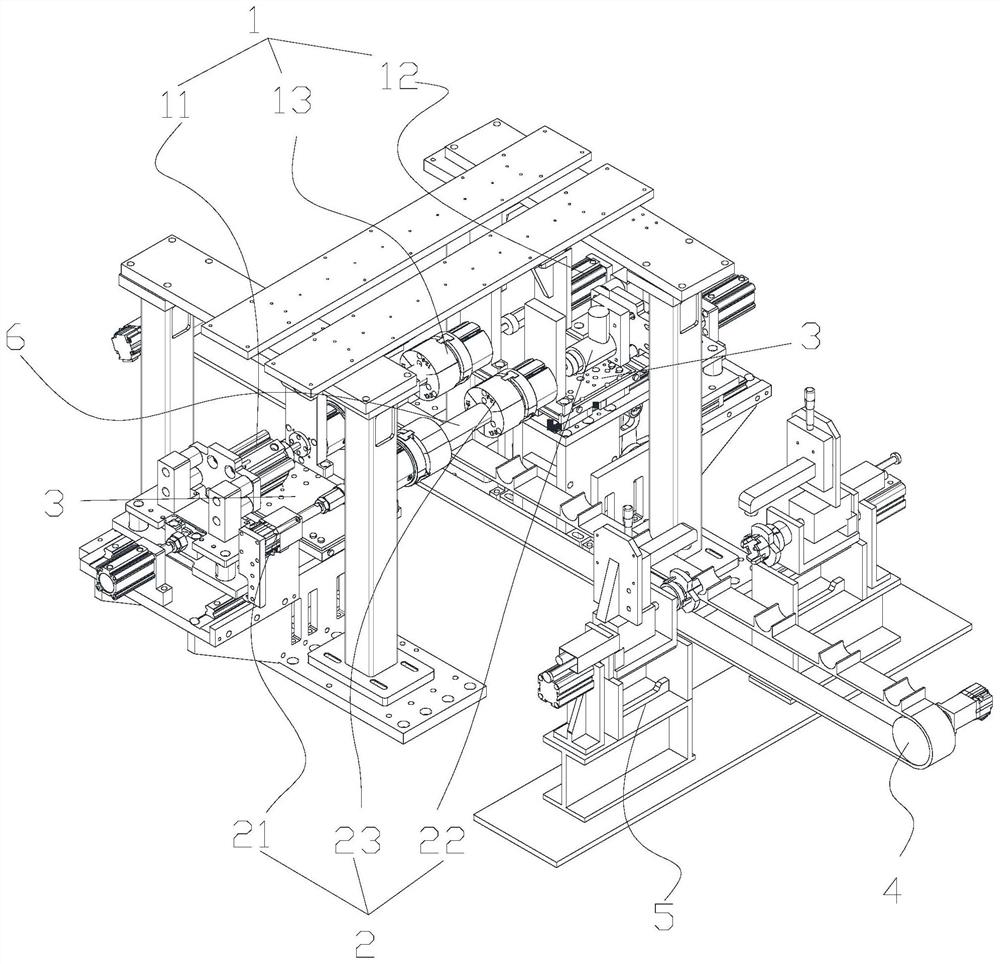

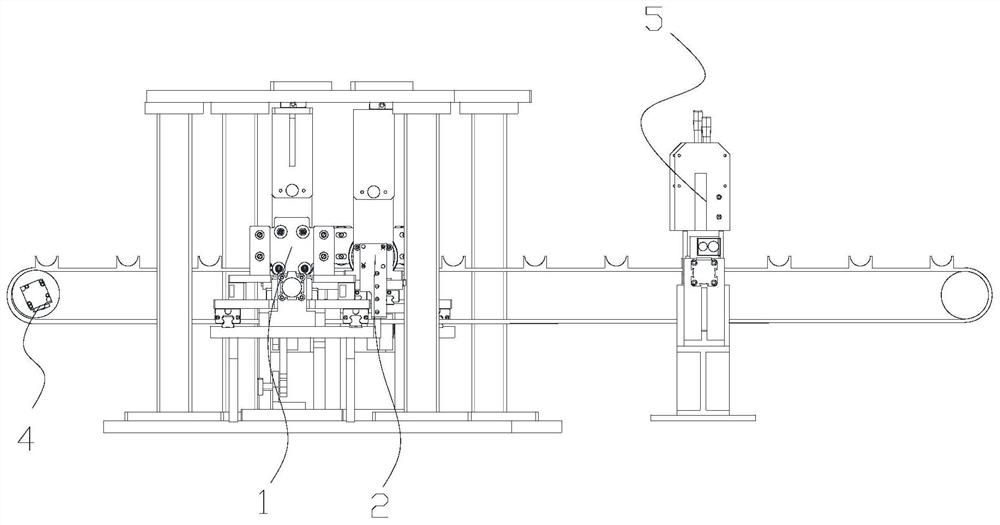

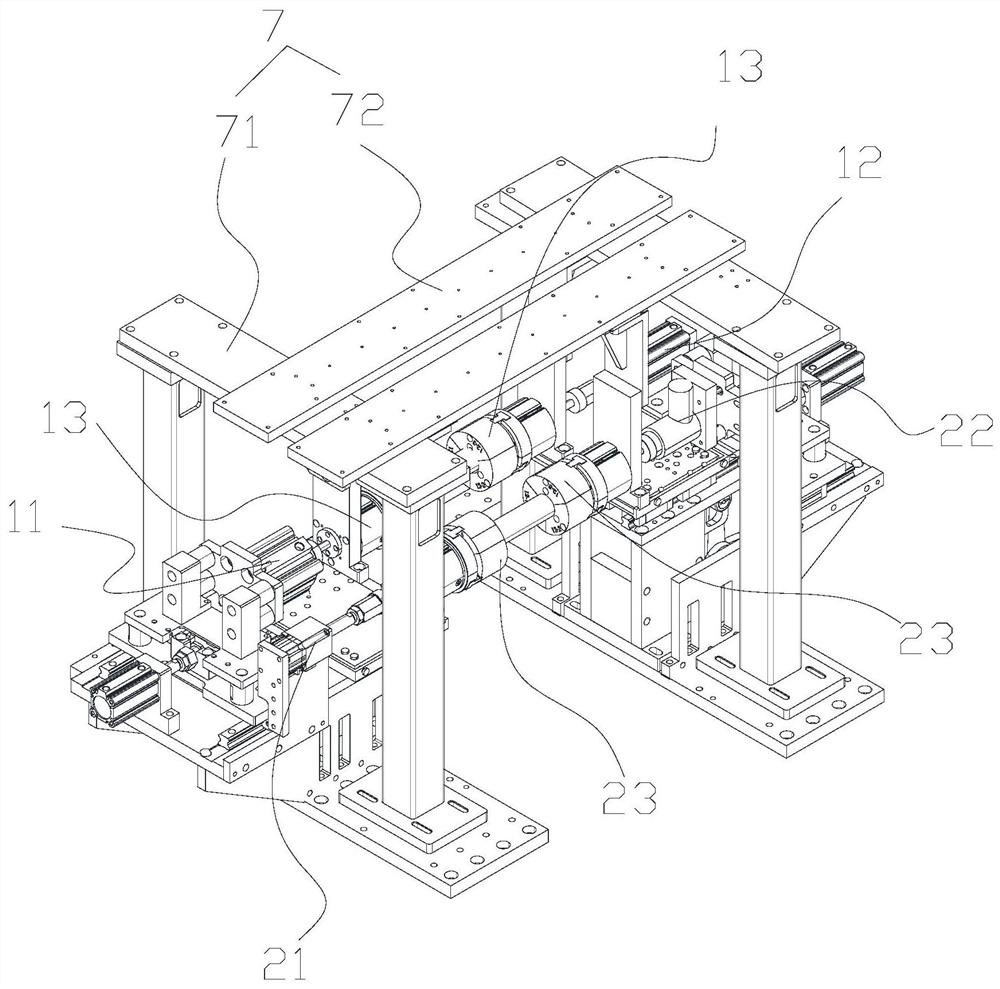

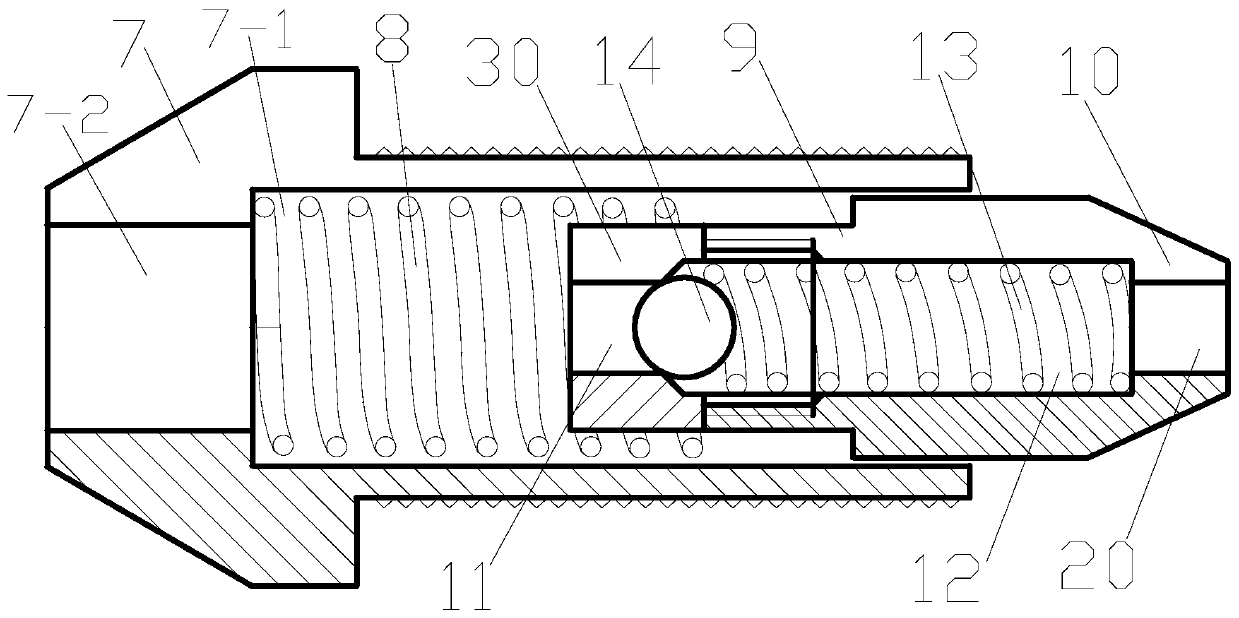

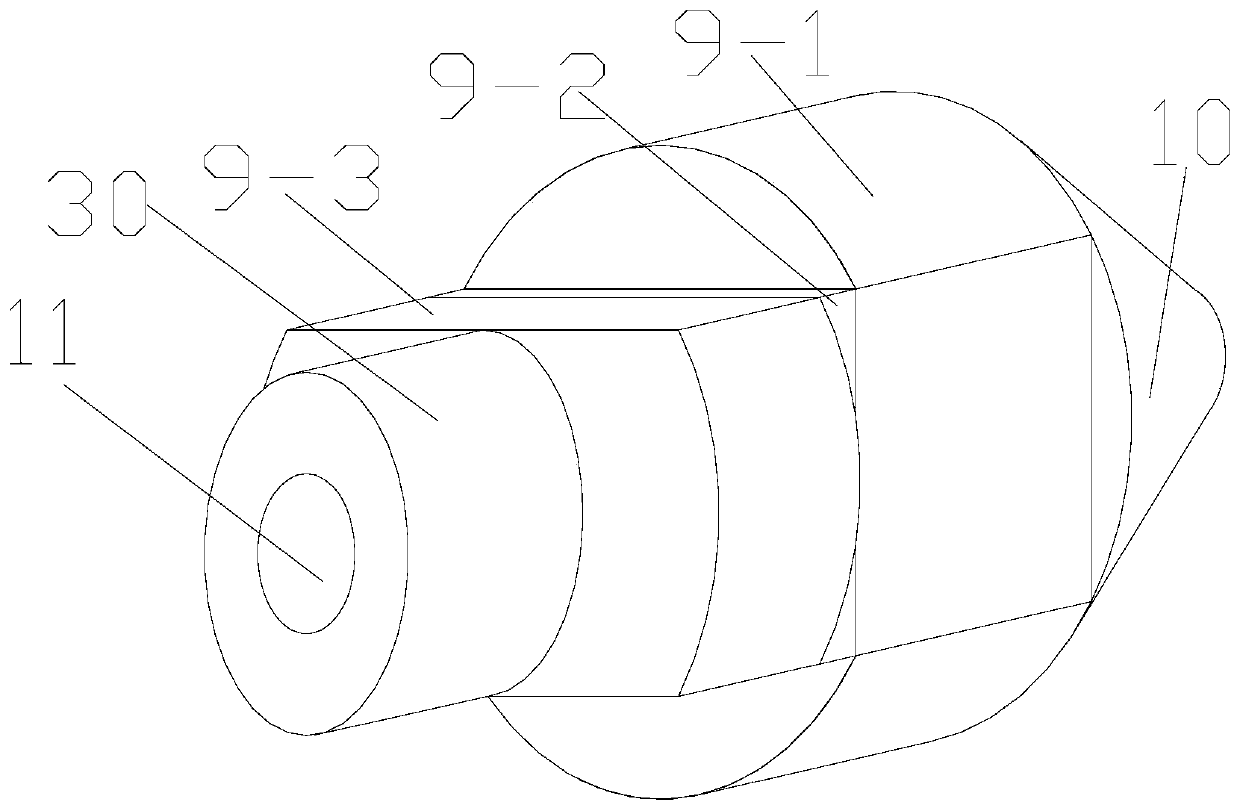

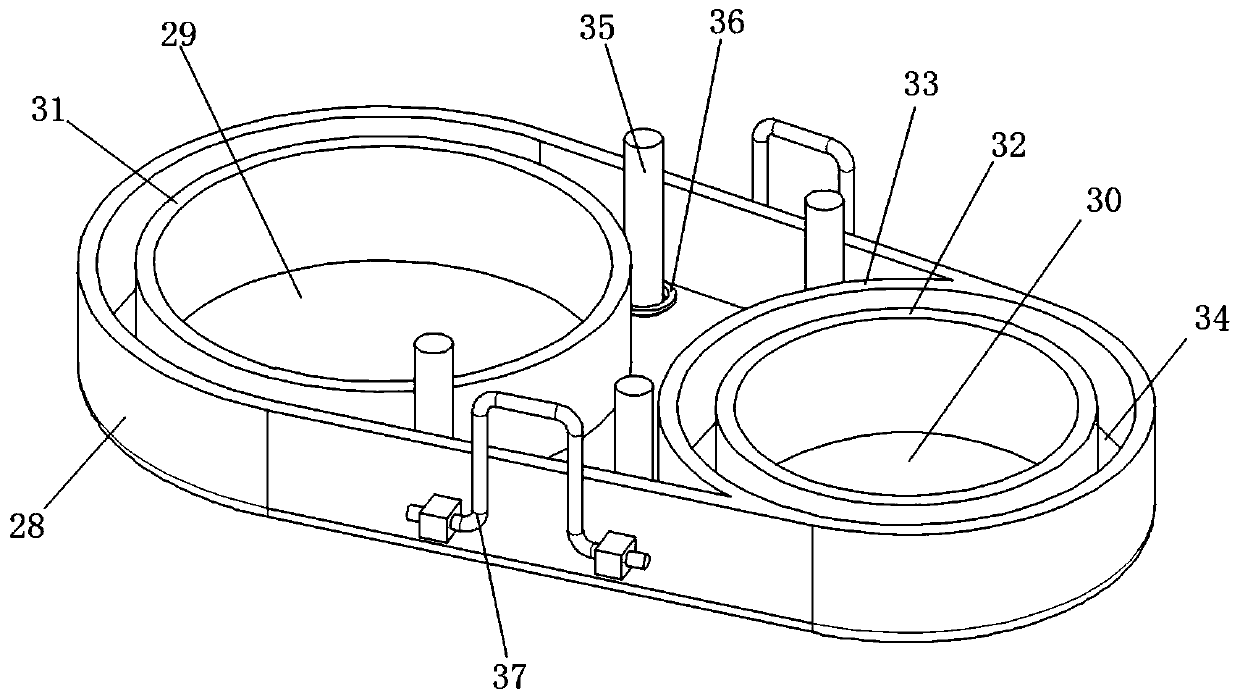

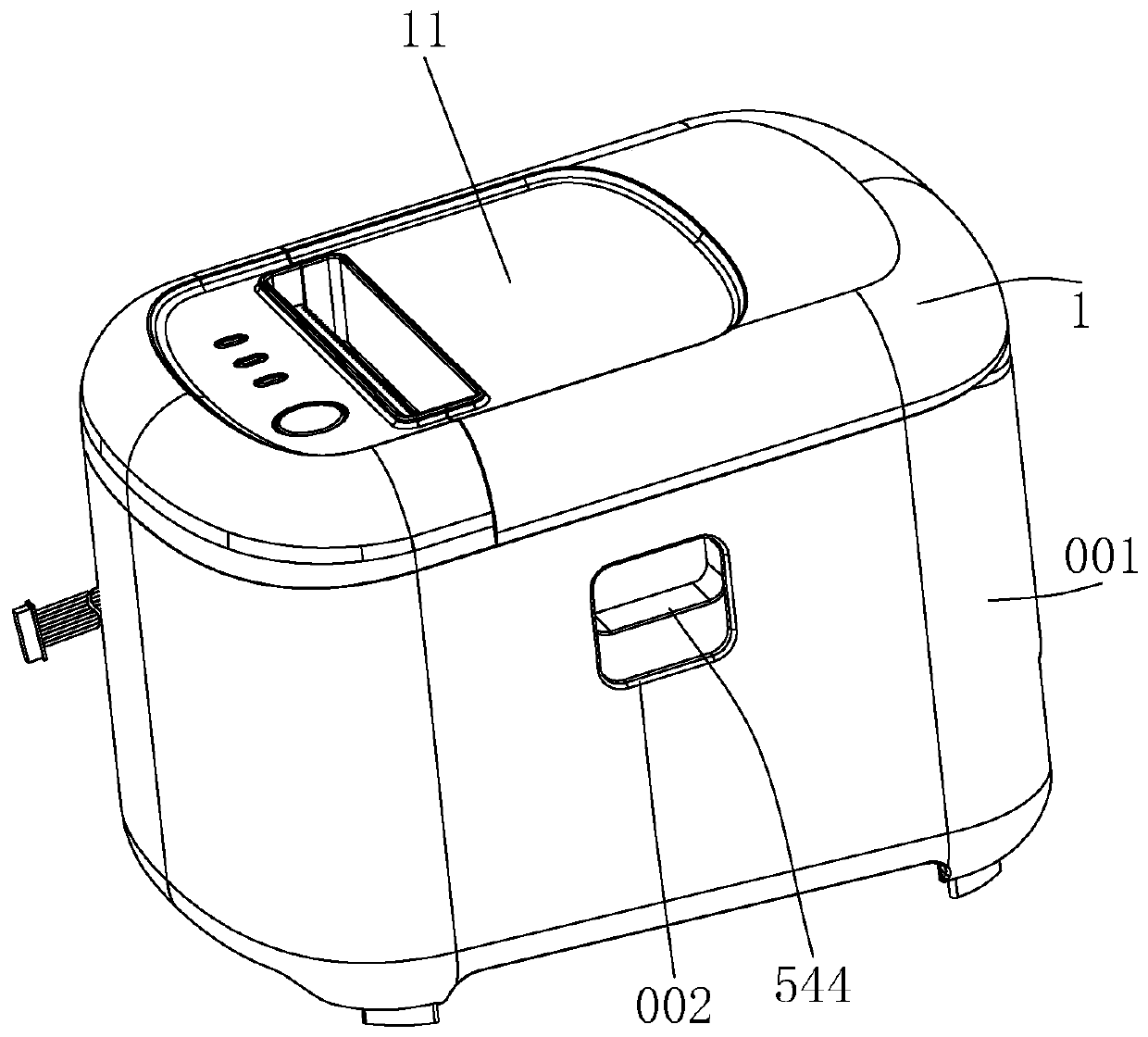

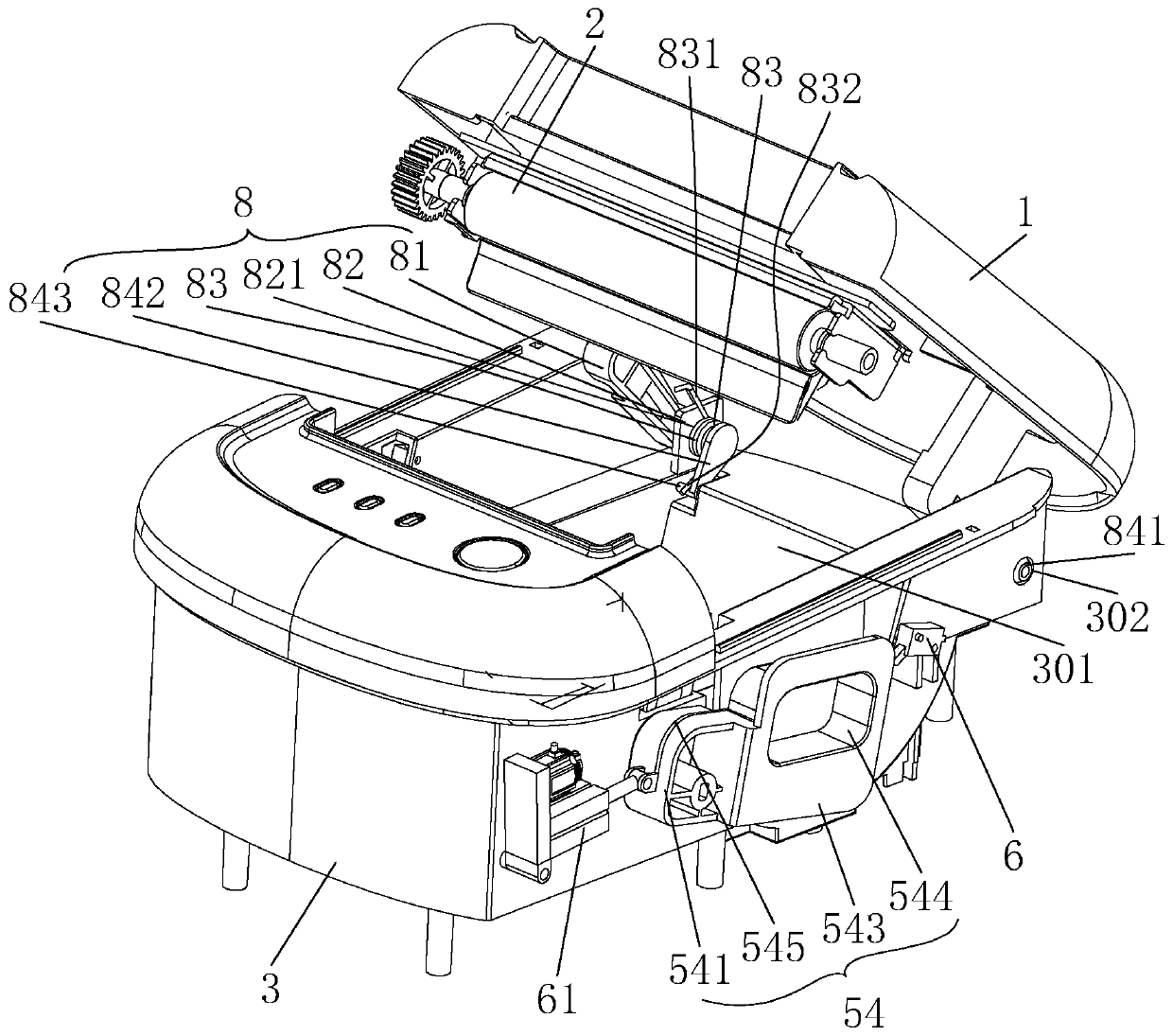

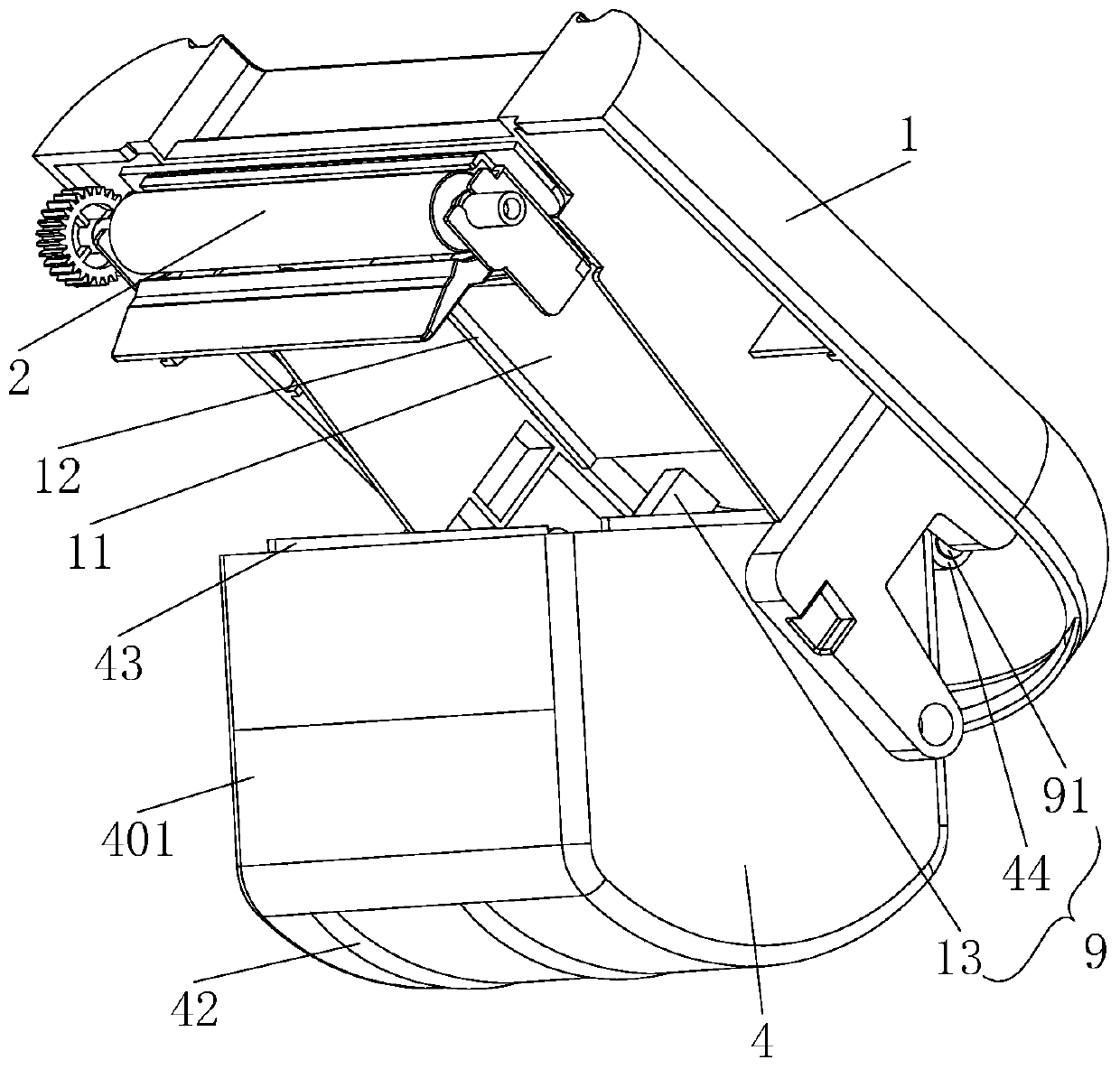

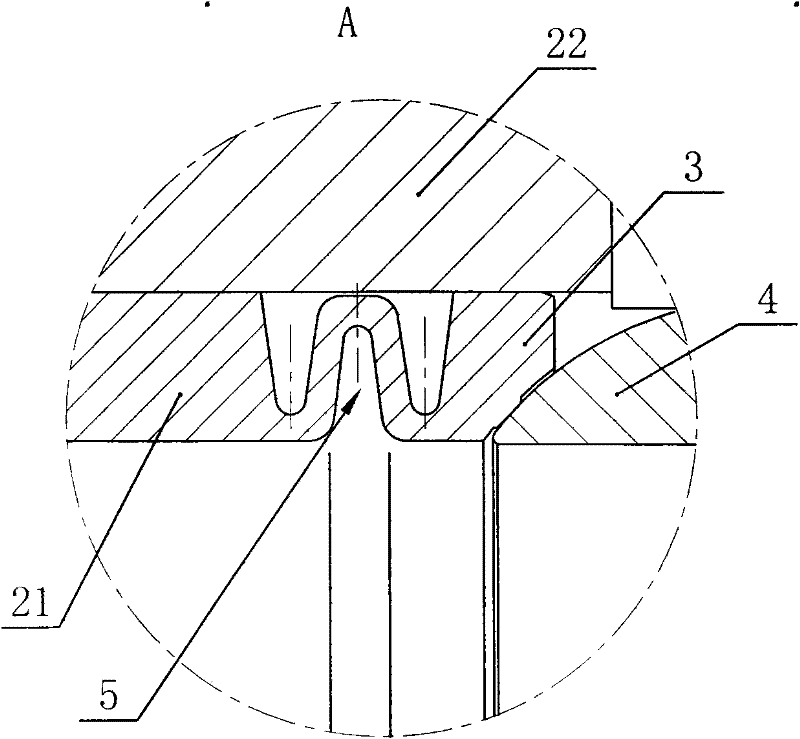

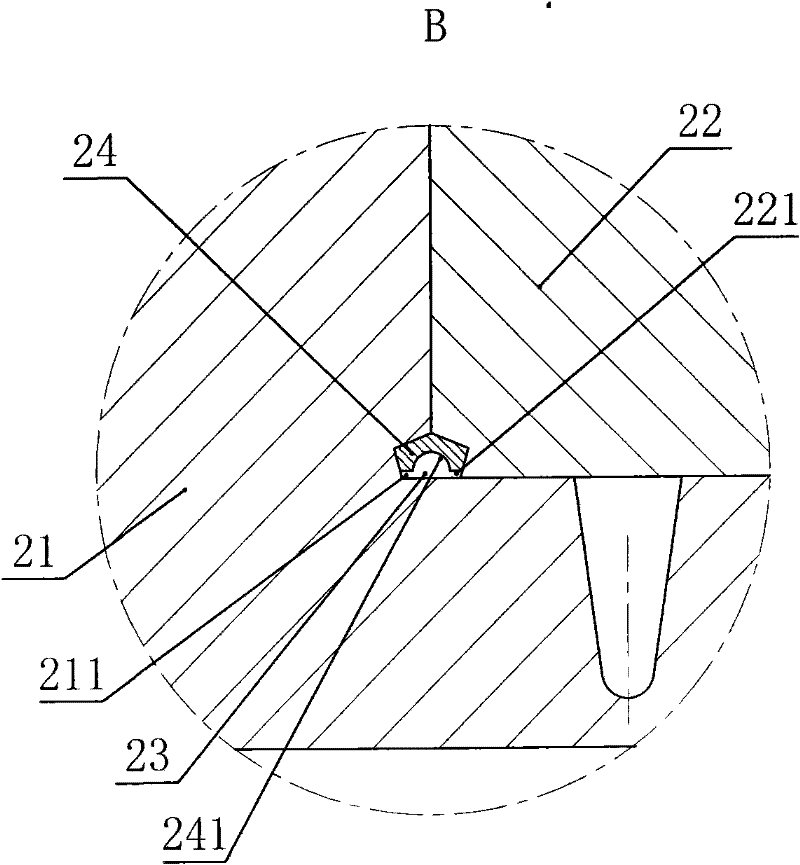

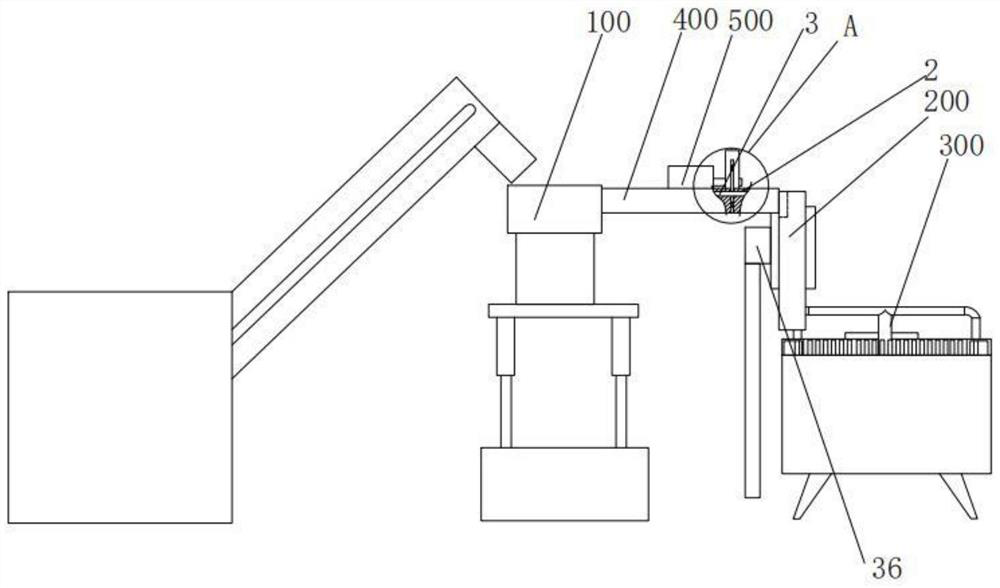

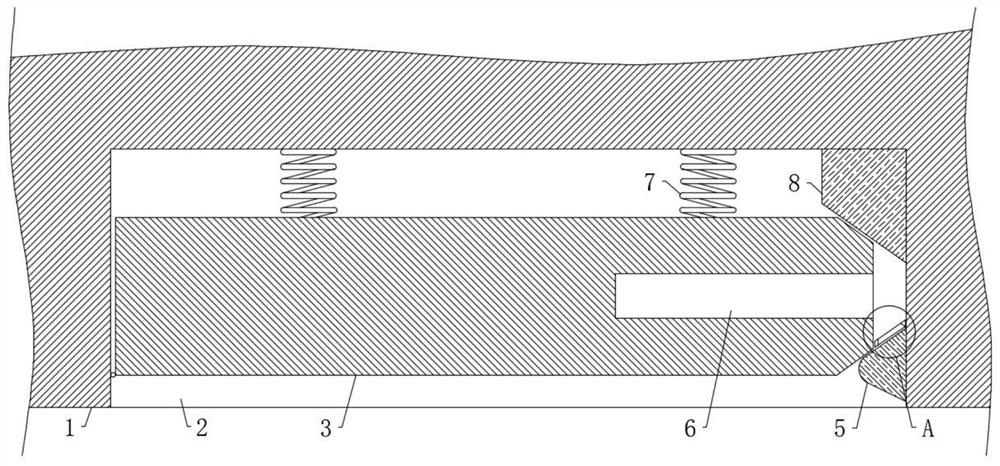

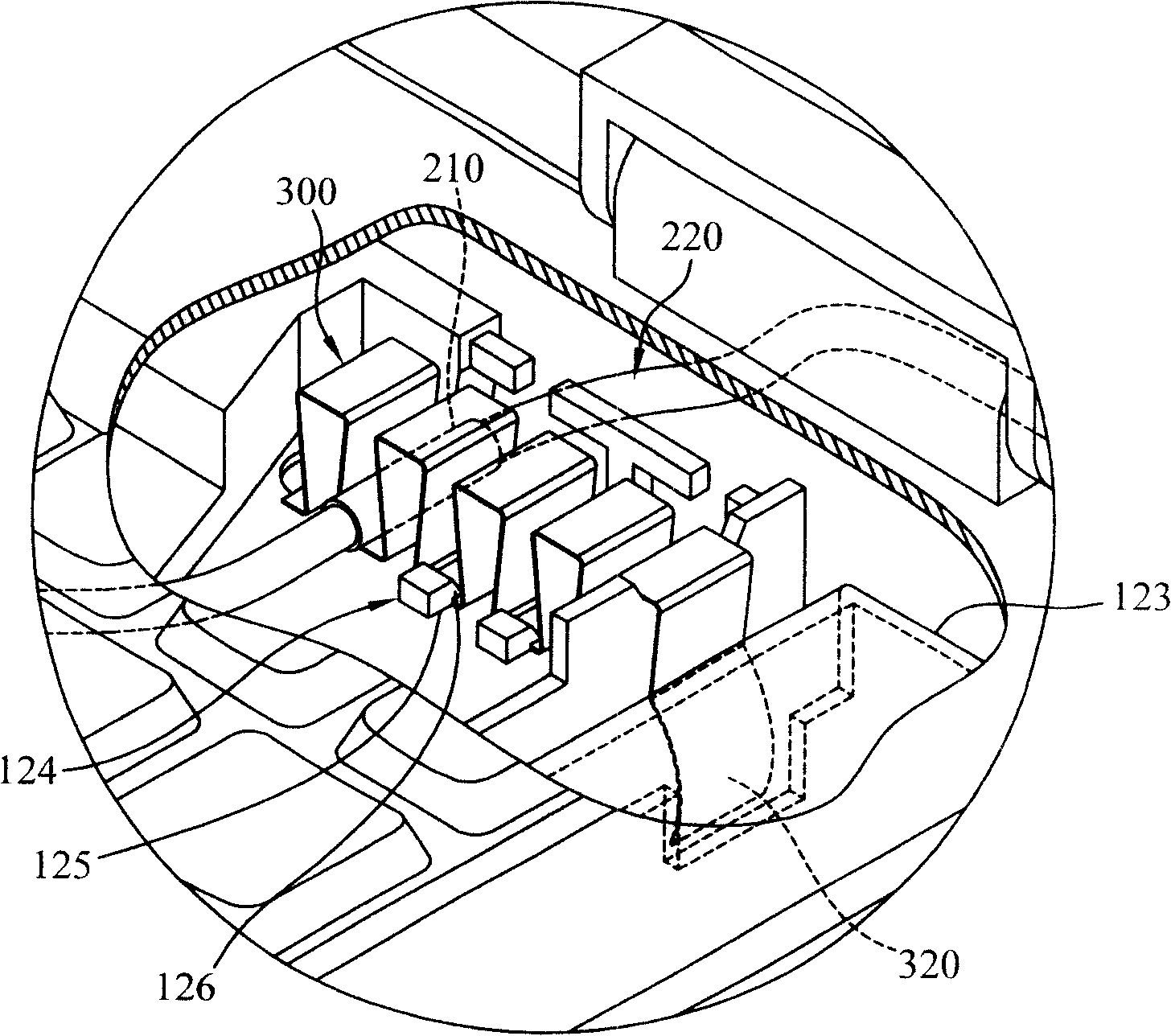

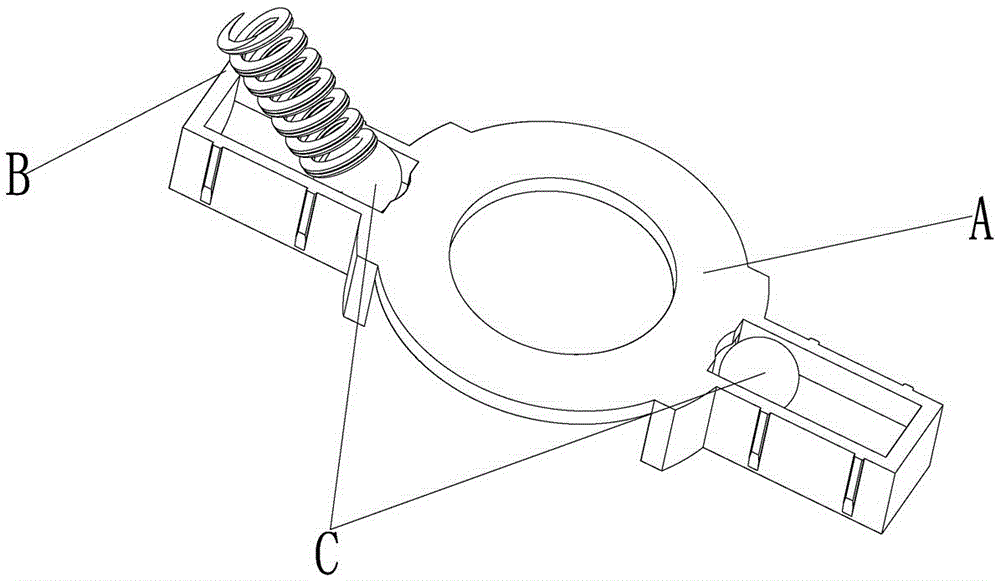

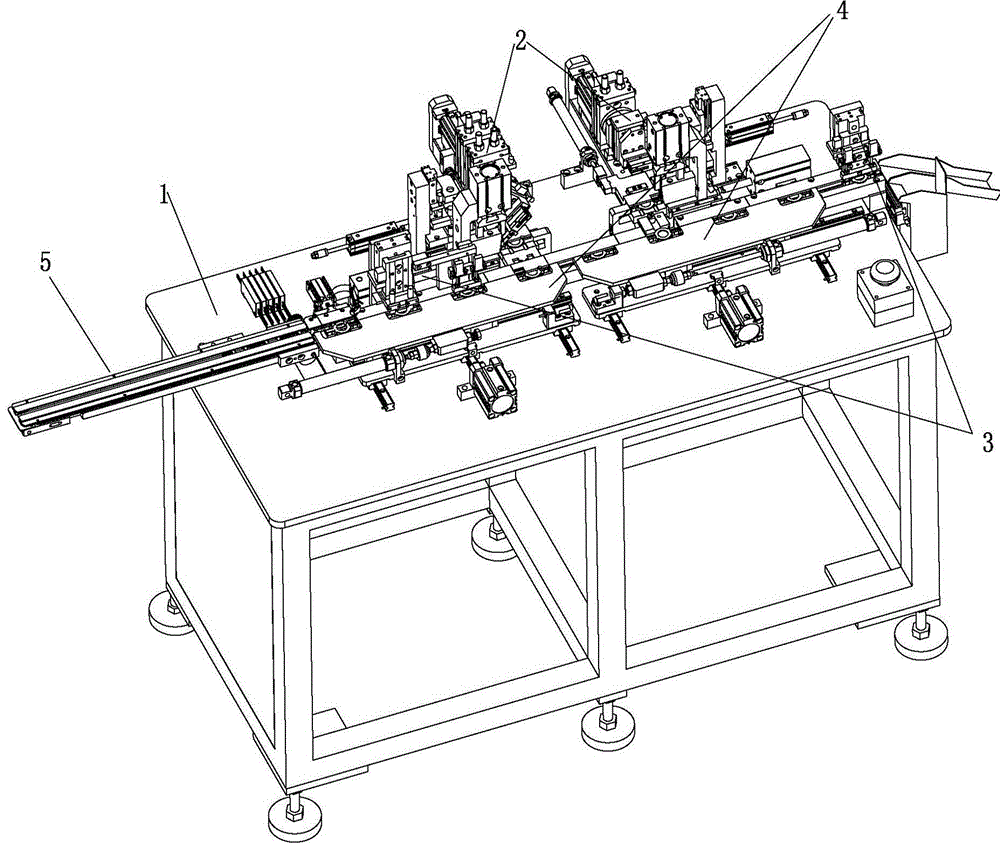

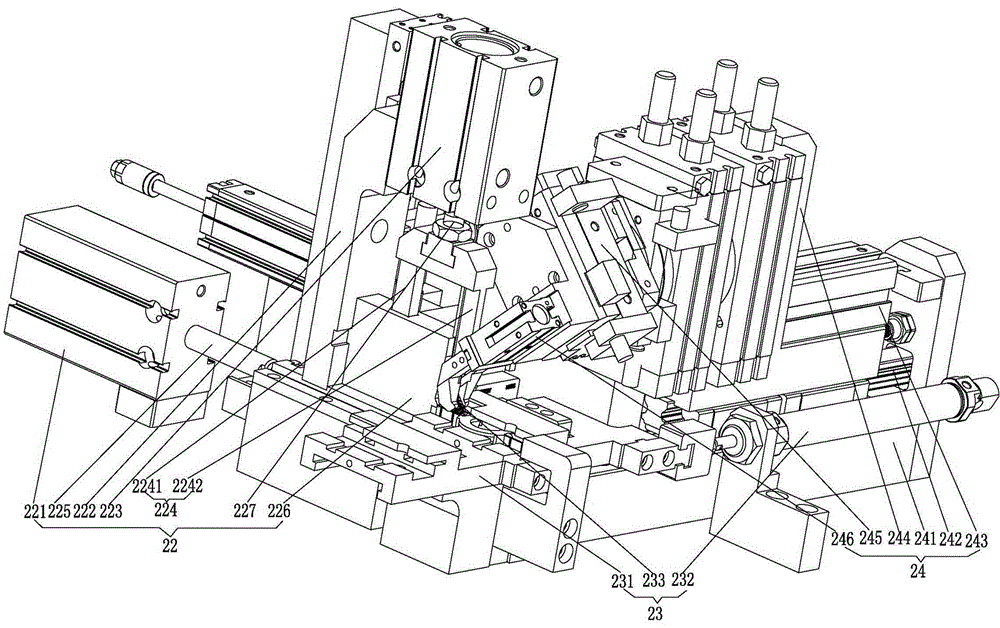

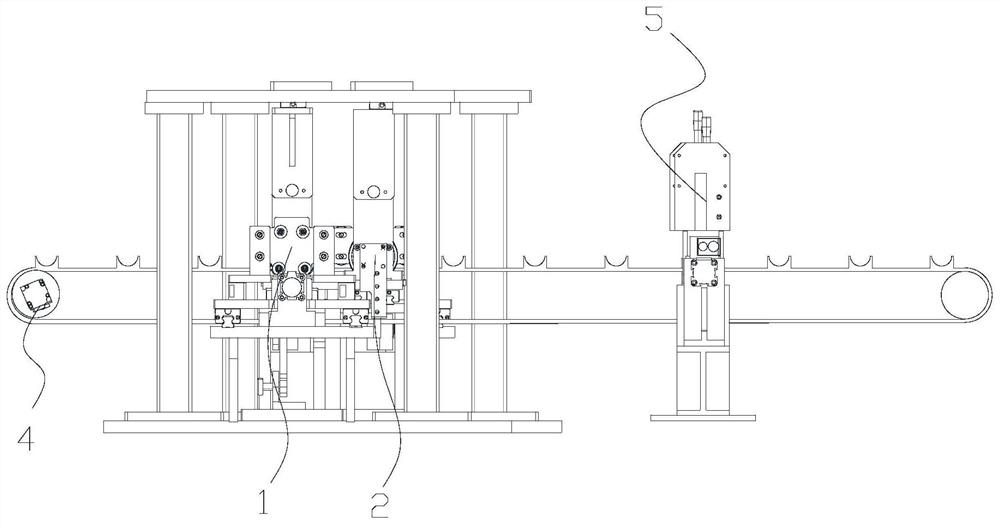

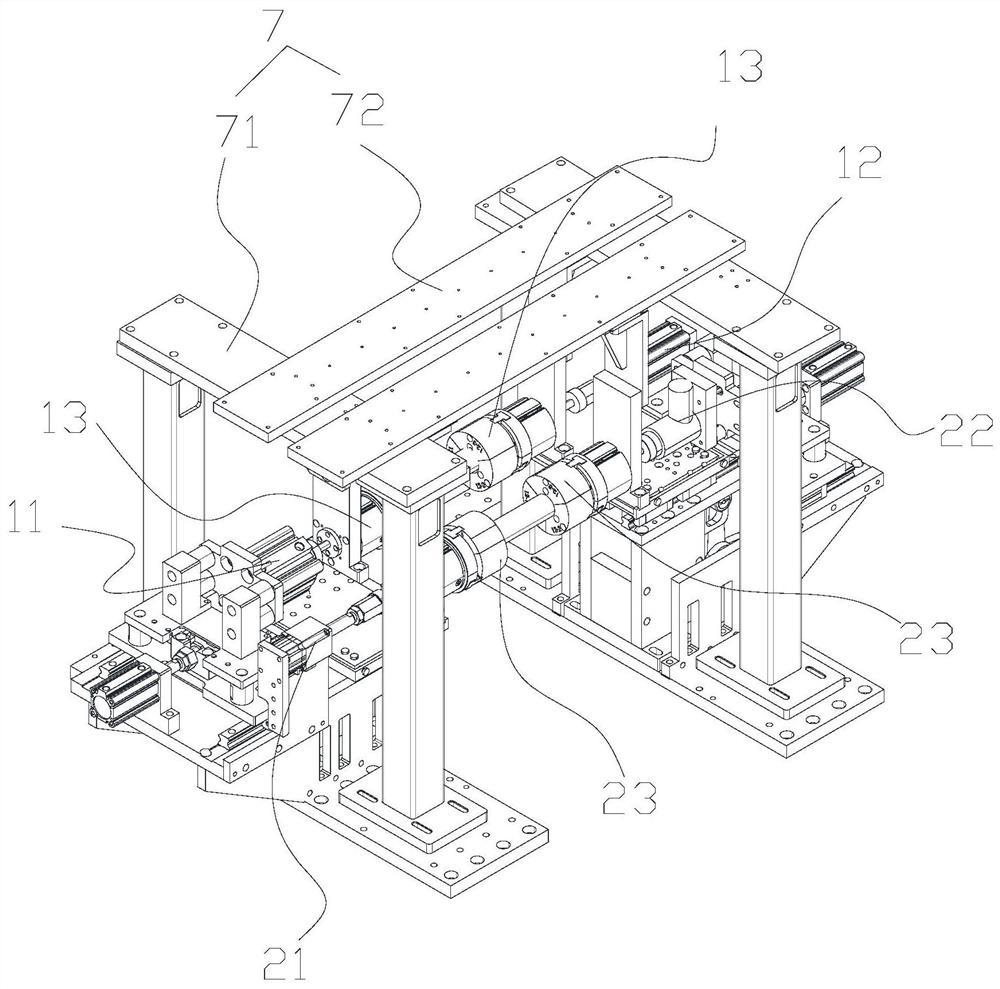

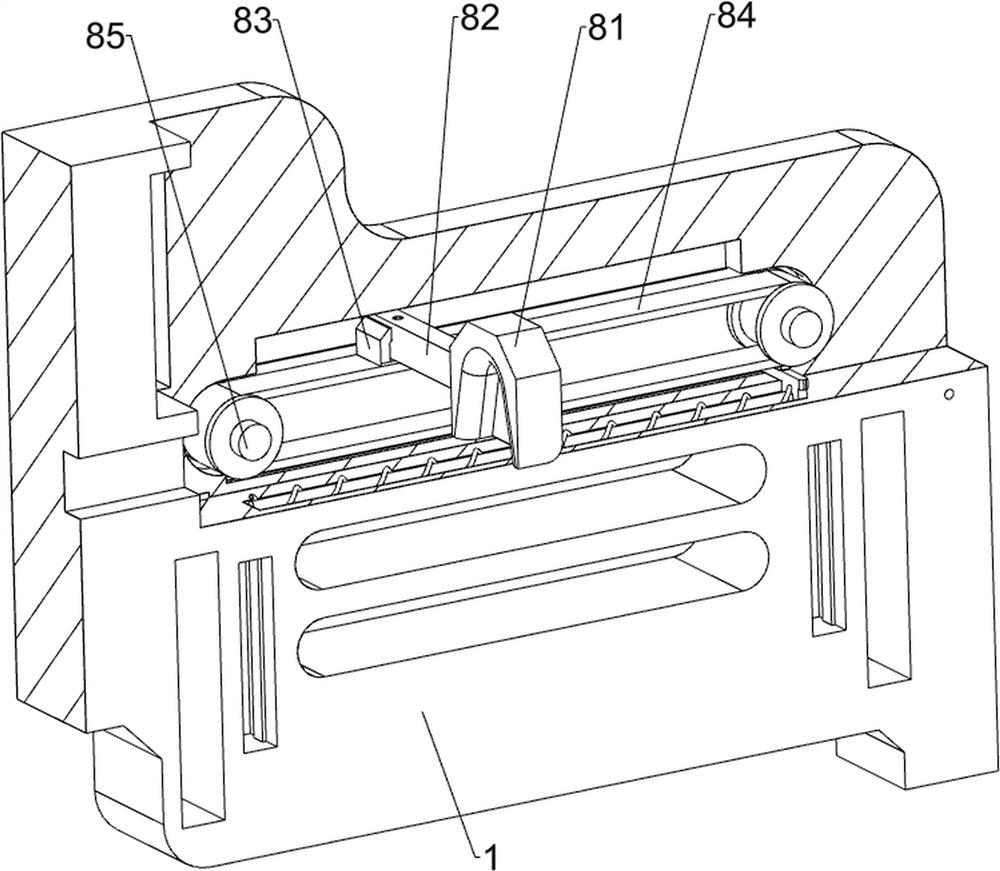

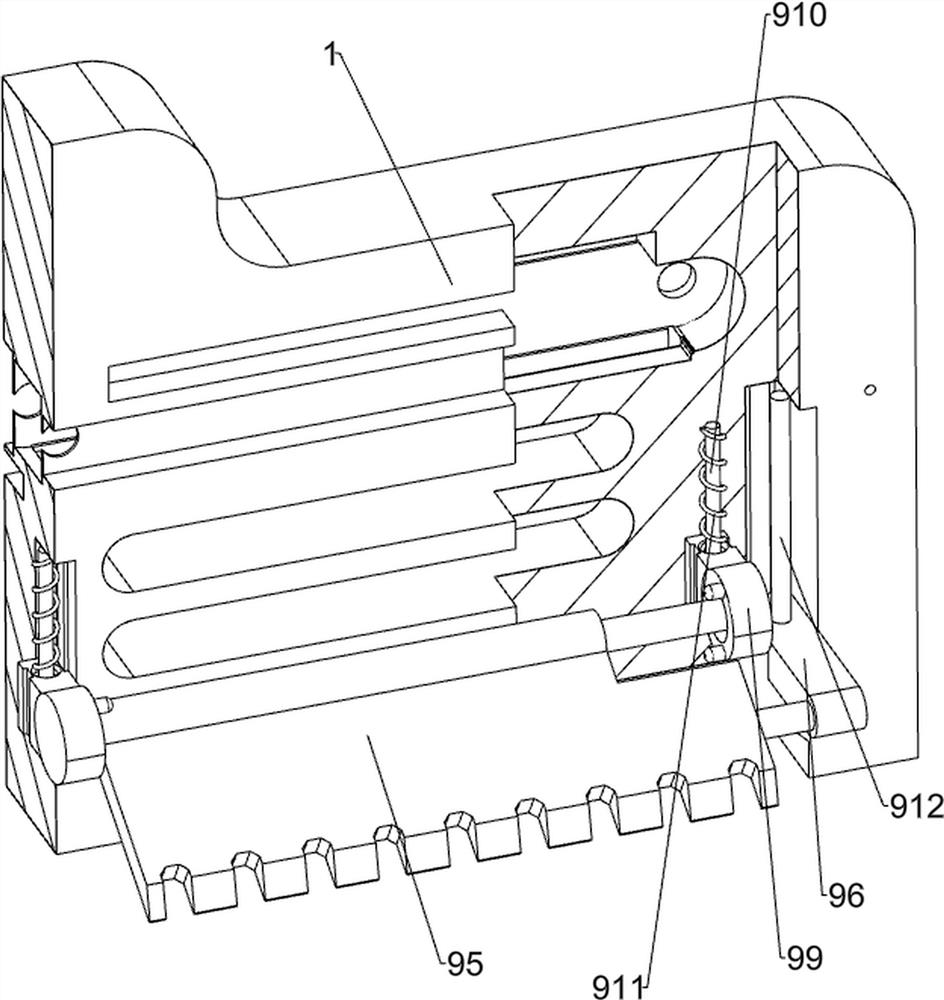

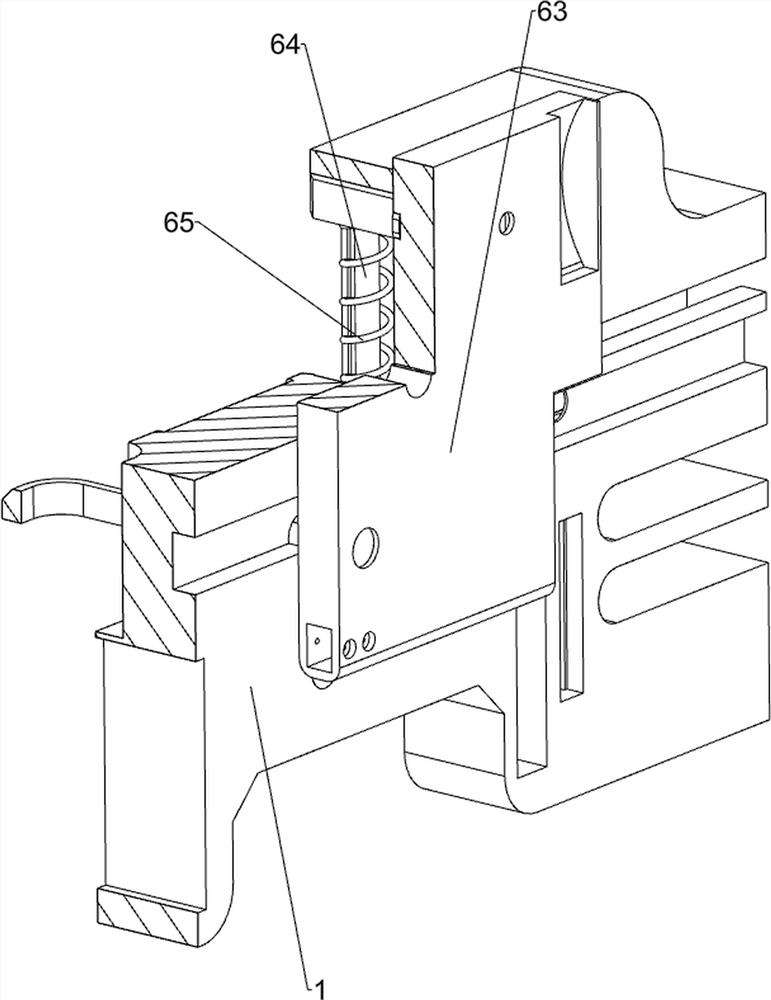

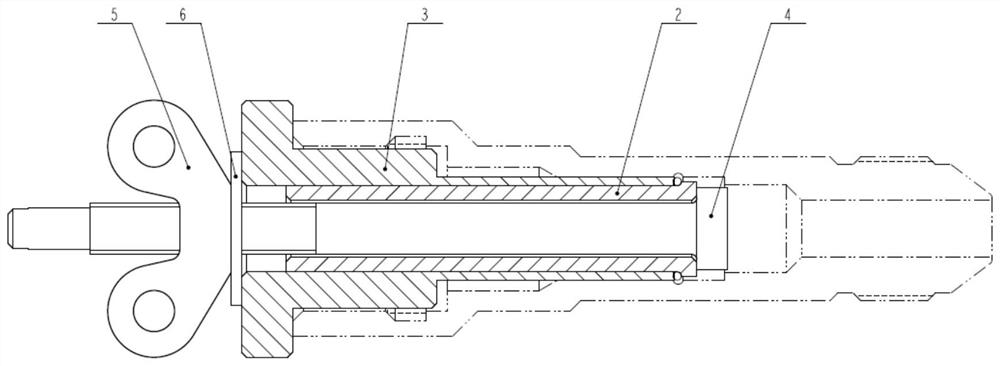

The invention discloses an automatic spring support assembly machine. The automatic spring support assembly machine comprises a machine platform, and two steel ball assembly detection mechanisms, two spring assembly mechanisms and two glue cover transport mechanisms, which are respectively arranged in opposite mode, wherein each spring assembly mechanism comprises a spring feeding component, a pressing component, a fetching component and a material pull component, each spring feeding component and each pressing component are arranged in parallel mode on a front position and a rear position along the transverse direction of the machine platform, and can move back and forth along the radial direction of the machine platform, and each fetching component and each material pull component are oppositely arranged in the vertical direction and both vertical to the moving direction of the spring feeding components and the pressing components. The invention further discloses an assembly method of glue cover conveying devices, steel ball storage devices, spring storage devices and spring supports, which are arranged at the front segments of the steel ball assembly detection mechanisms. The automatic spring support assembly machine quickly and conveniently assembles springs, achieves high product quality, automatically links all processes in assembly, detects superior and inferior levels of products in the assembly, achieves automatic production, simplifies manual production, and saves labor.

Owner:东莞市创鑫盈精密自动化科技有限公司

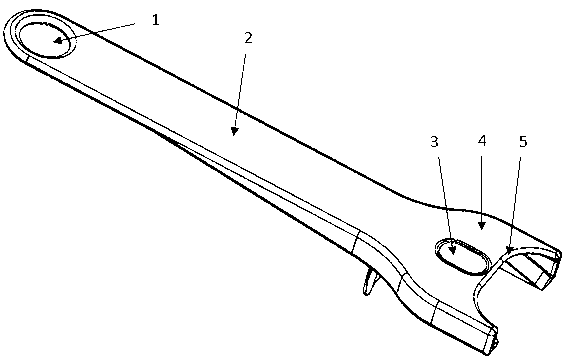

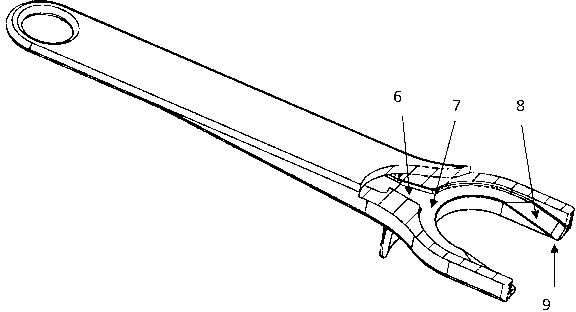

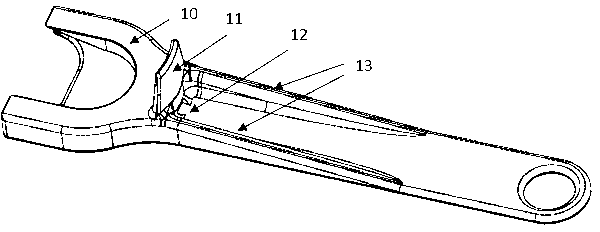

Bottle opener

InactiveCN103274343AEven by forceAvoid deformationFlanged caps removalBottle capChemical engineering

The invention relates to a bottle opener for opening a bottle cover with a skirt-shaped edge. The bottle opener aims at solving the problem that the existing bottle cover with the skirt-shaped edge is difficult to open and unsafe. The bottle opener is formed by a handle, a U-shaped groove with blades and inclined surfaces on two arms, a top cover on the upper portion of the U-shaped groove and a partition board on the lower portion. The blade is firstly inserted into a gap between the skirt-shaped edge of the bottle cover and a bottom opening, then the bottle cover is raised up by enabling the skirt-shaped edge to slide along the inclined surface, then the bottle cover is pried out of the bottle opening, and the bottle opening process is finished. The top cover on the upper portion of the U-shaped groove can prevent the pried bottle cover from bouncing out. The partition board can prevent hands from contacting with the bottle opening. The bottle opener is simple in structure, can safely and quickly open the bottle cover with the skirt-shaped edge, can cover the bottle cover back, prevents the bottle cover from contacting with other objects during the process and prevents materials in the bottle from being polluted.

Owner:史运杰

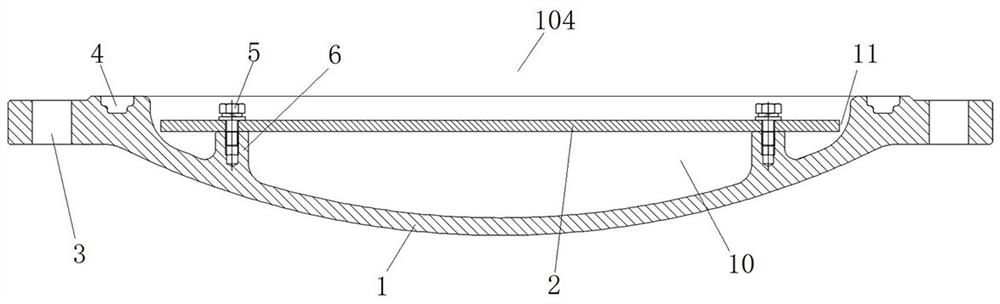

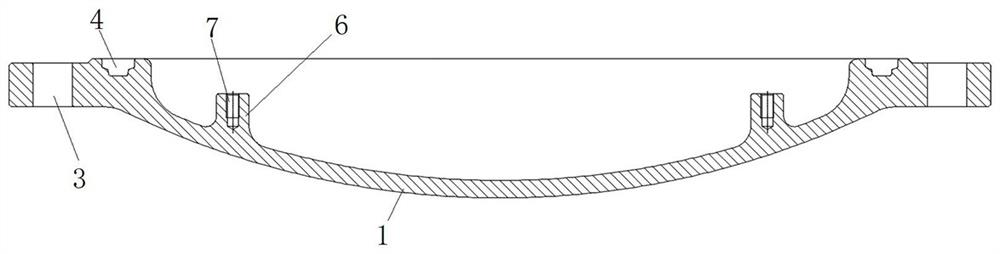

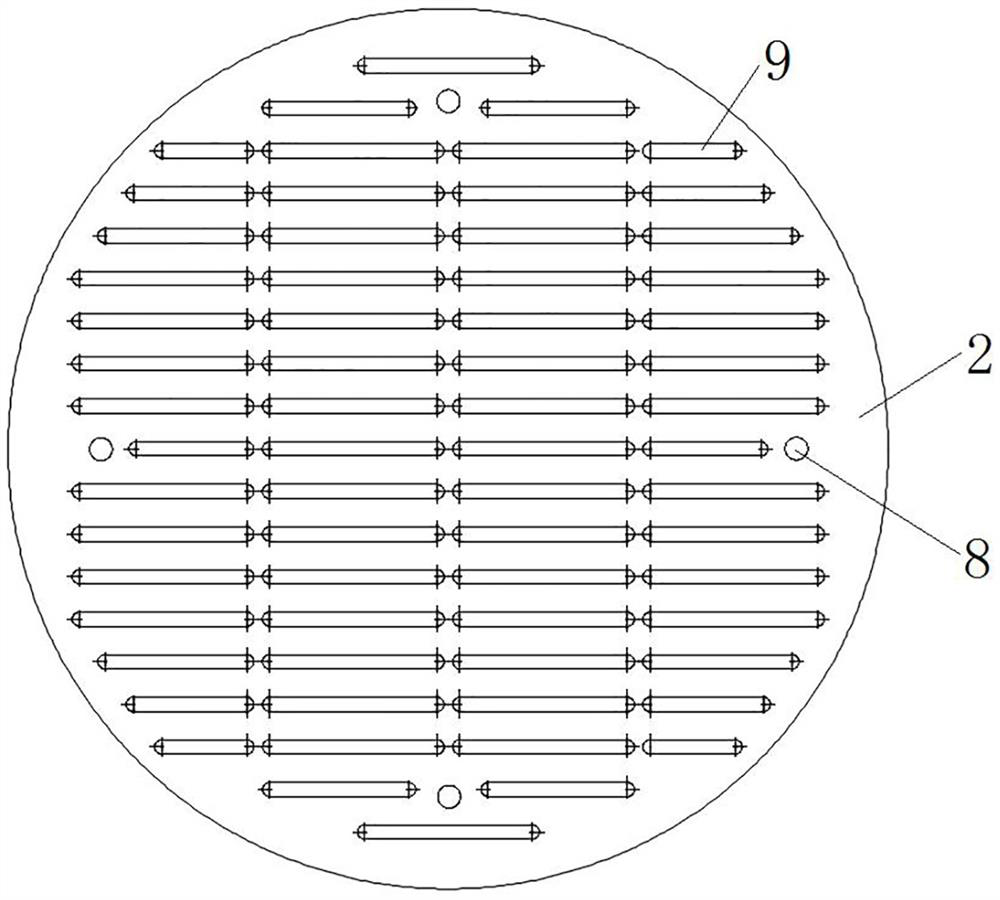

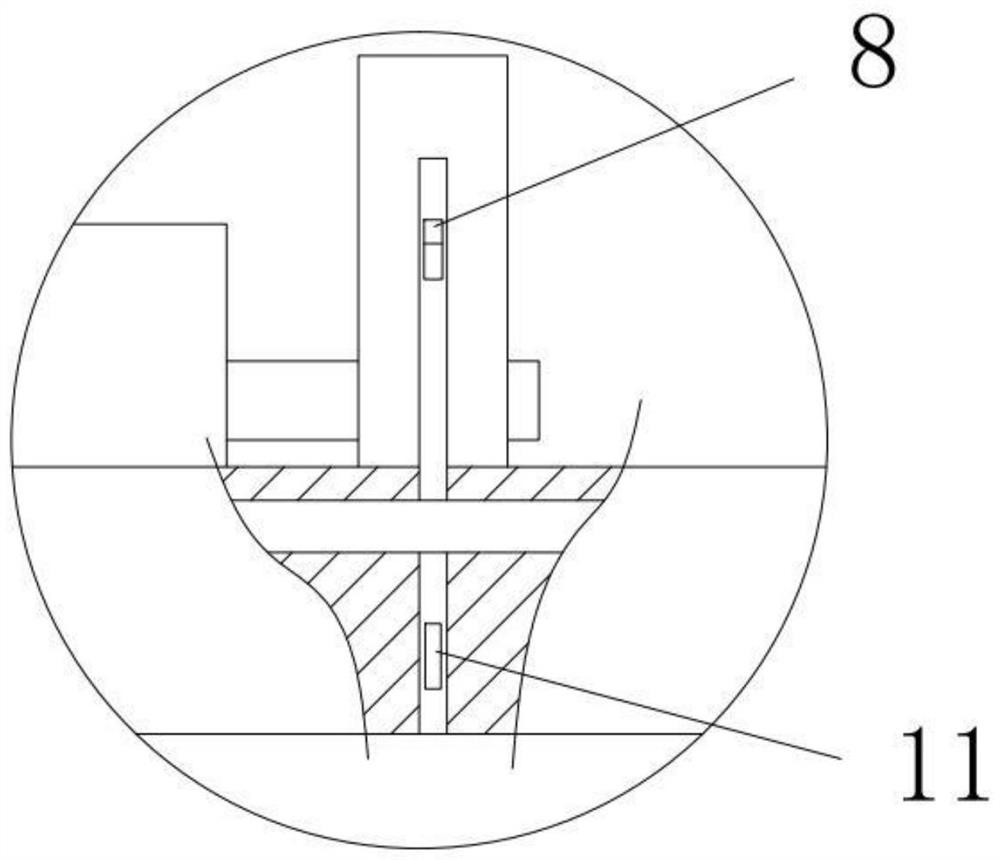

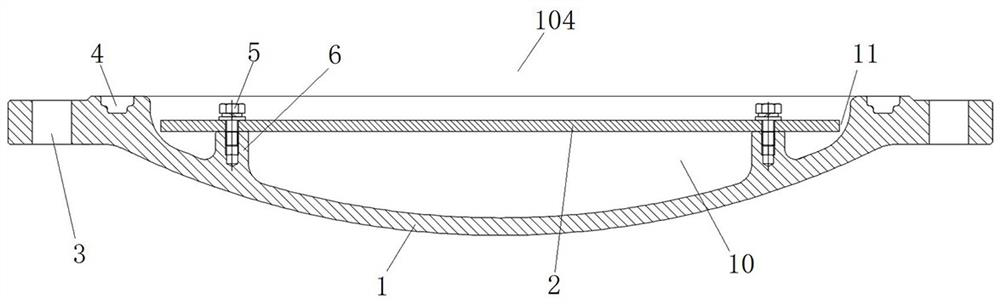

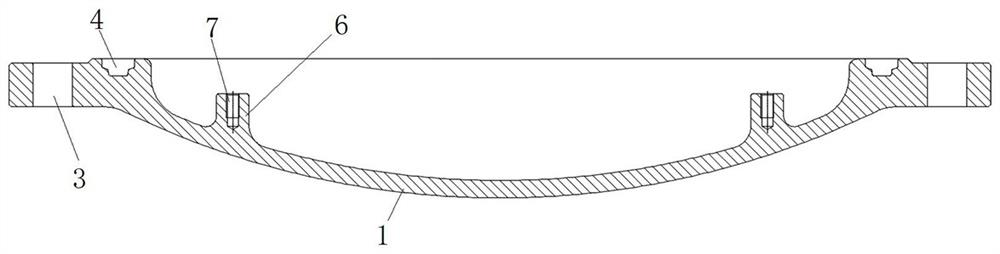

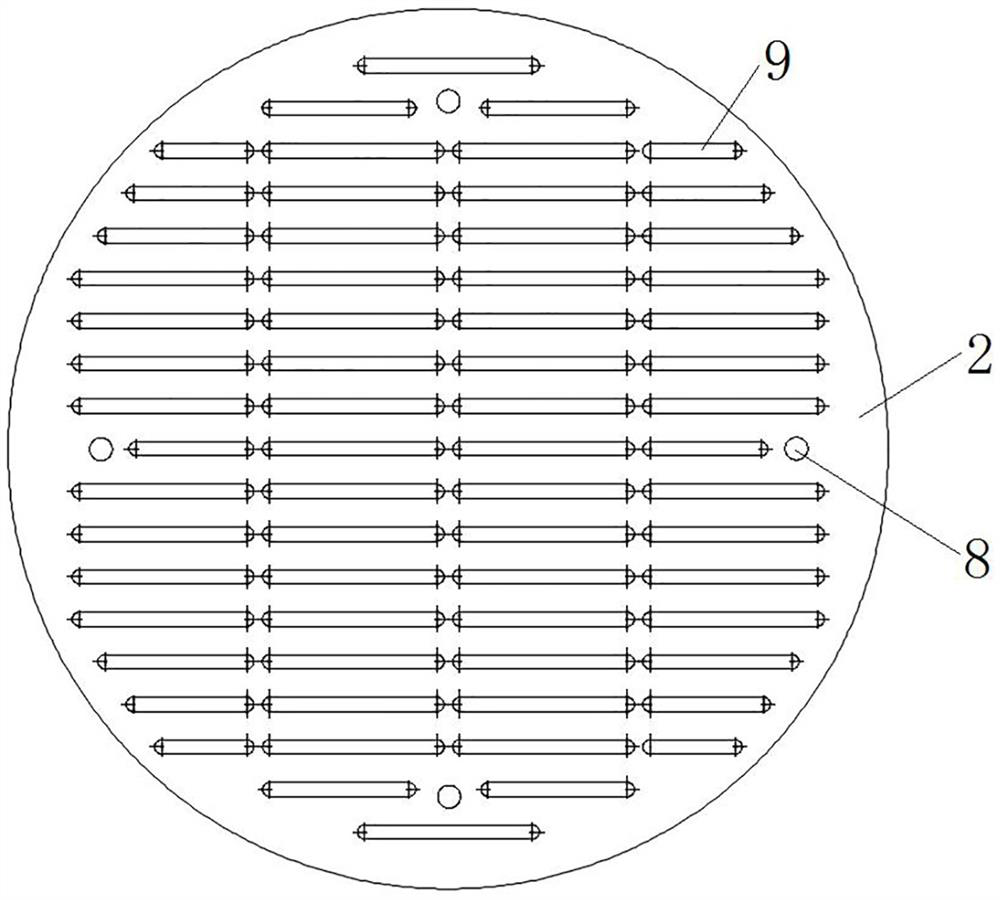

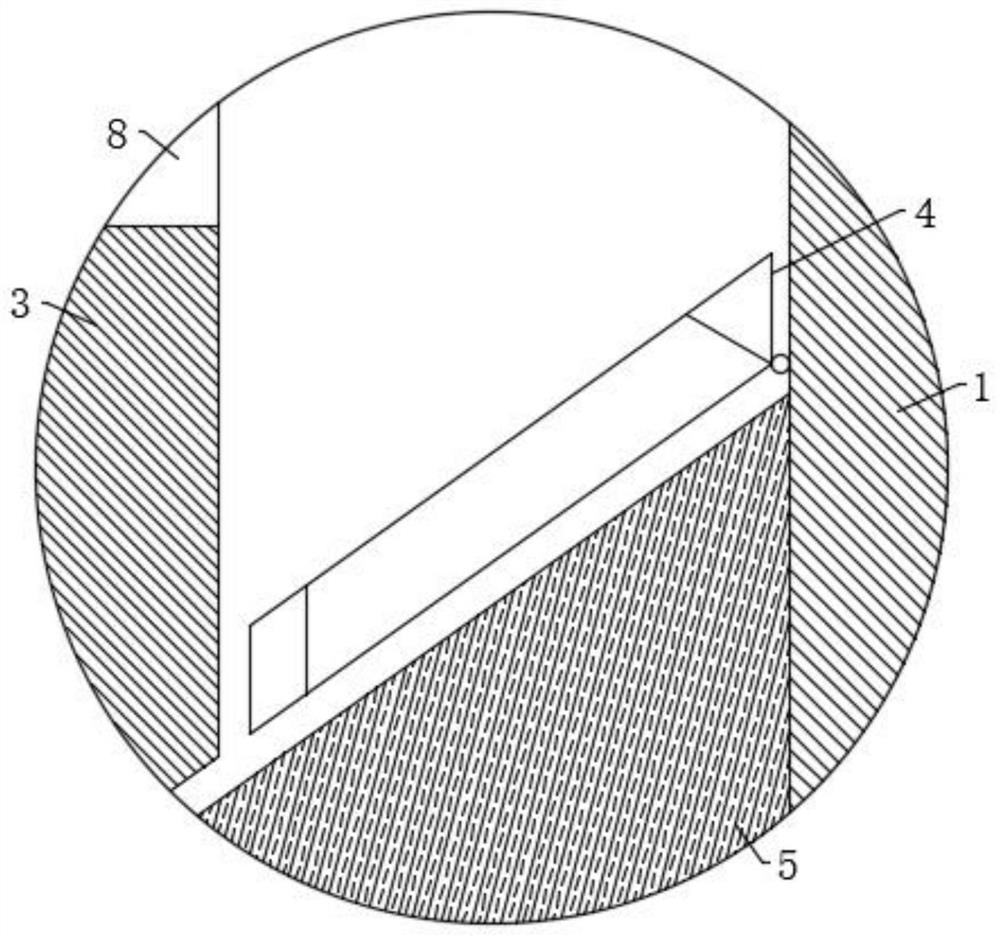

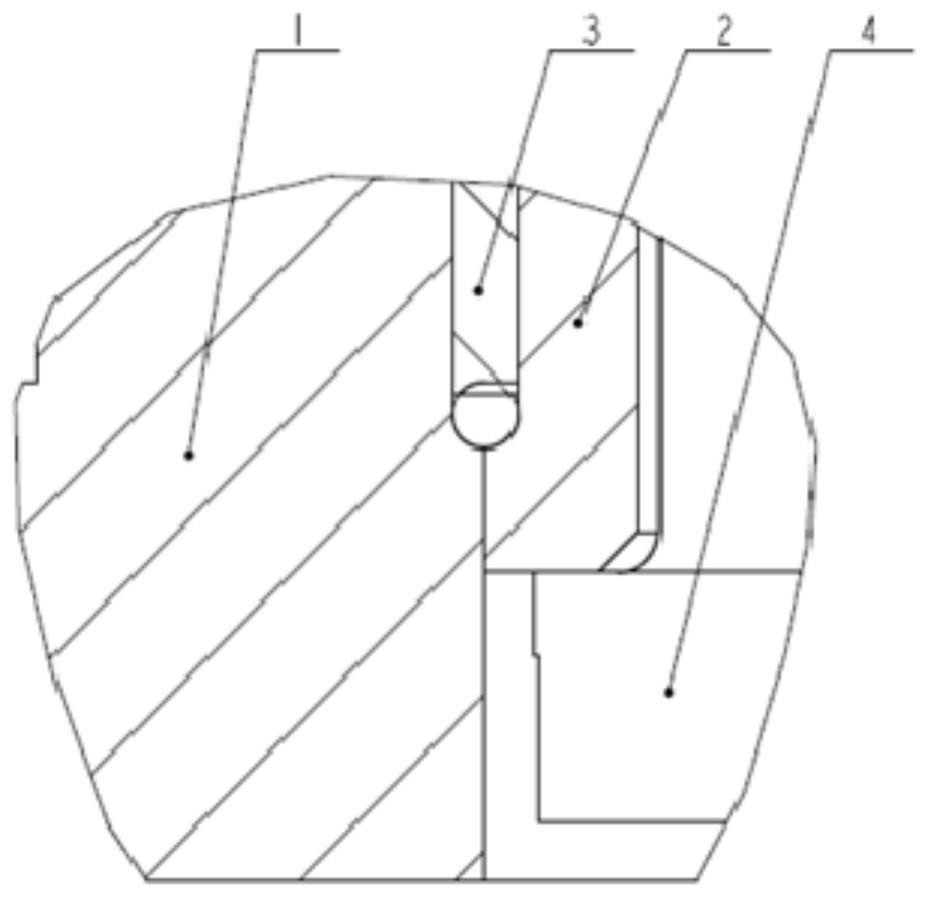

Particulate filter and cylinder body structure for GIS/GIL

The invention relates to a particulate filter and a cylinder body structure for GIS / GIL. The particulate filter comprises a trap cover plate and a trap grid plate; a cover plate connecting structure is arranged on the trap cover plate, the trap cover plate is used for being detachably and fixedly connected to the opening of the cylinder wall of a cylinder body through the cover plate connecting structure; and the trap grid plate is detachably connected to the trap cover plate so that an equipotential area can be formed between the trap grid plate and the trap cover plate, grid holes are distributed in the trap grid plate, and the grid holes allow metal particulates to pass through so that the metal particulates can enter the equipotential area. After the trap cover plate is fixedly connected to the corresponding cylinder body, under the action of alternating-current high voltage, the metal particulates in the cylinder body can move under the action of an electric field and finally passthrough the grid holes to enter the equipotential area, so that the metal particulates are not affected by the electric field any more, the metal particulates stop moving, and capturing of the metalparticulates is achieved; moreover, the trap cover plate and the trap grid plate are both of plate-shaped structures, so that the structure of the particulate filter is simplified.

Owner:PINGGAO GRP +2

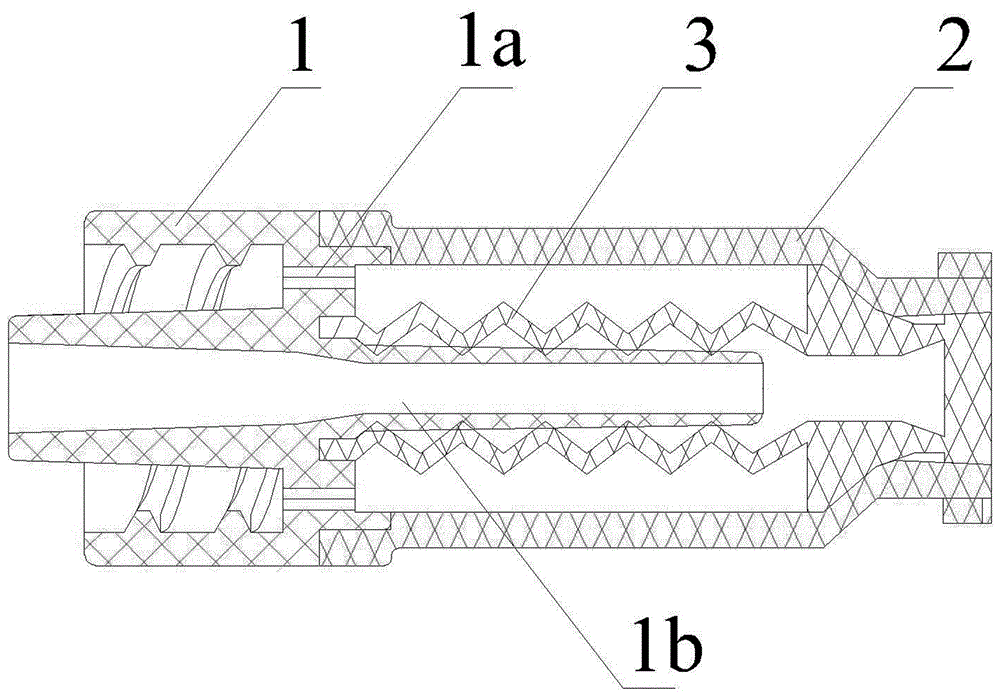

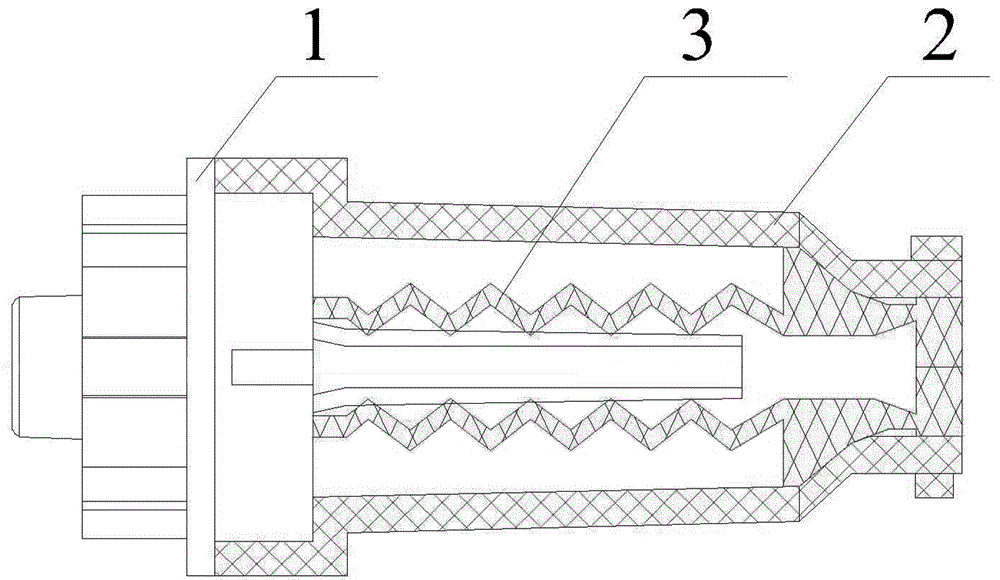

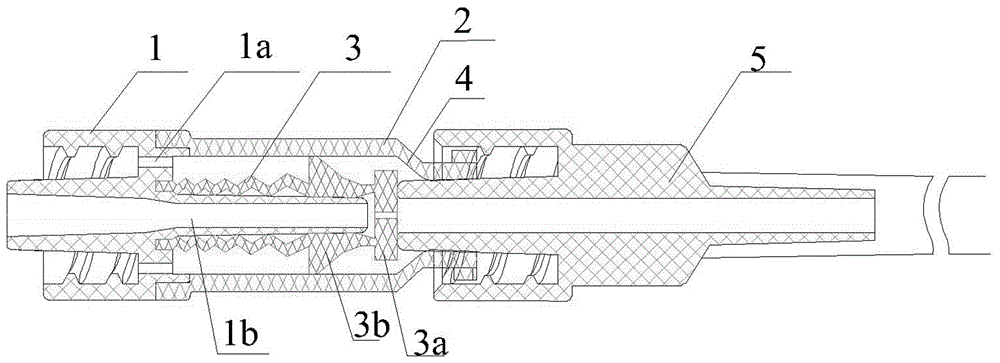

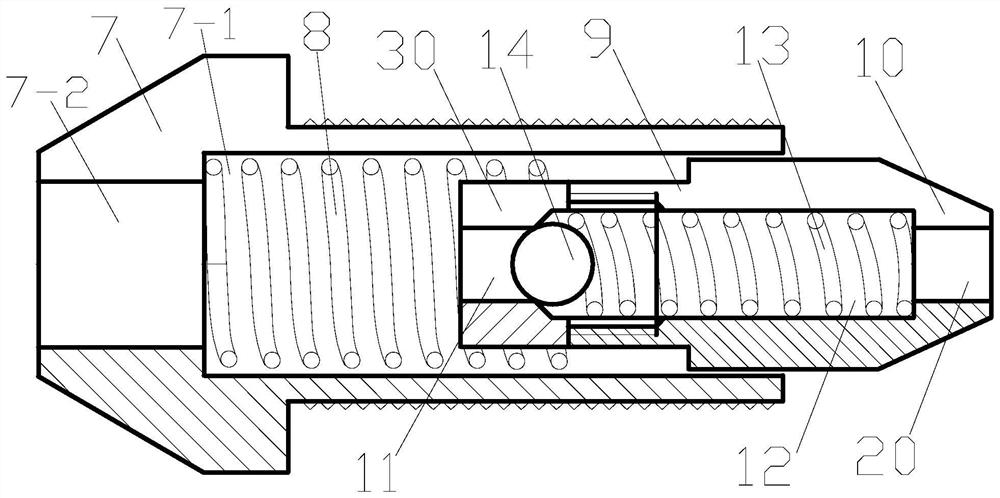

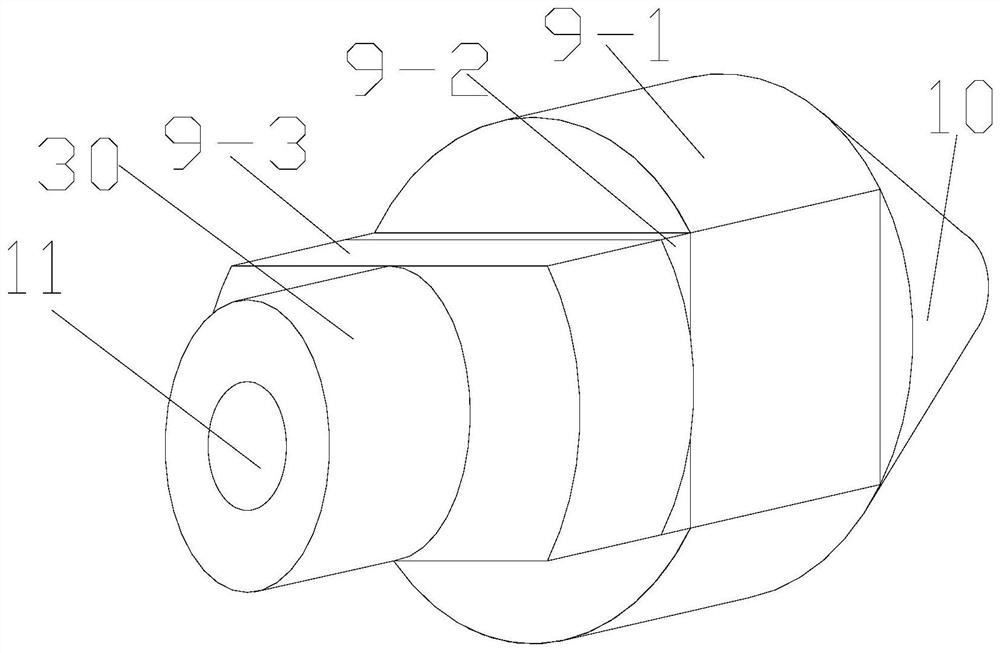

Needle-free connector for infusion

PendingCN106730119AReasonable structural designSmall form factorInfusion devicesTube connectorsEngineeringShort axis

A needle-free connector for infusion comprises an outer cover, an elastic capsule and a base. The end of the outer cover is round. A channel for liquid medicine to flow through is formed in the middle of the base. The elastic capsule is arranged on the outer wall of the channel in a sleeving mode, the end of the elastic capsule is oval, the length of the short axis of the oval is larger than the diameter of the end of the outer cover, a drainage opening is formed in the short axis direction of the oval, the drainage opening comprises two outward-protruding curves symmetrically distributed along the two sides of the short axis, and the distance between the two curves in the long axis direction is gradually reduced from the center of the drainage opening to the two ends of the short axis. A shoulder part for limiting the end of the elastic capsule is arranged on the inner side of the upper portion of the outer cover, and a stop part is in sealing fit with the shoulder part. The base is provided with a connection part, and exhaust grooves are formed along the two radial sides of the channel. The needle-free connector for infusion is reasonable in structural design; due to the round end of the elastic capsule, a good sealing effect is achieved; due to sealing fit between the stop part of the elastic capsule and the shoulder part of the outer cover, the airtightness of a liquid medicine delivery system is ensured, and meanwhile the end of the elastic capsule is not likely to pop out of the end of the outer cover under the elastic force of the elastic capsule.

Owner:LUOHE SHUGUANG HUIZHIKANG BIOTECH

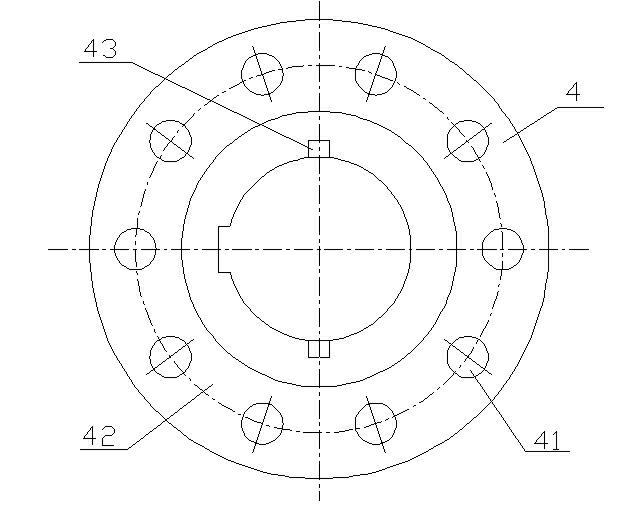

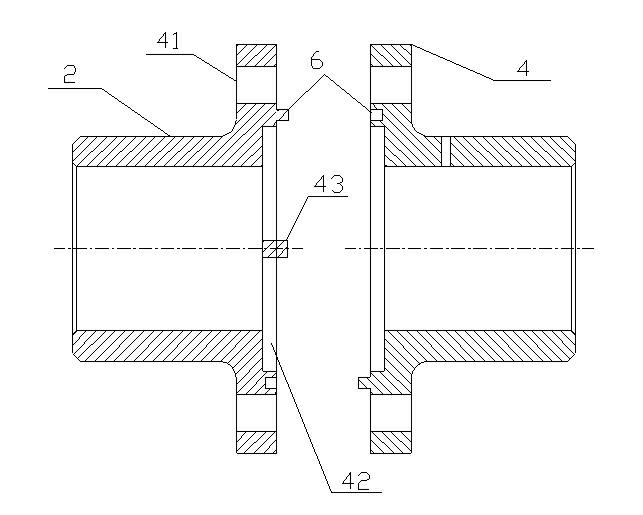

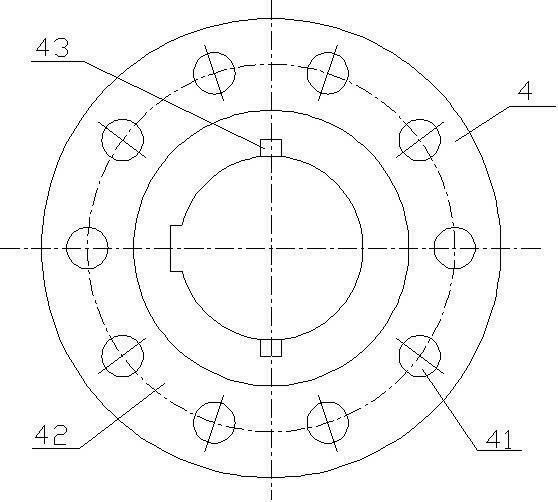

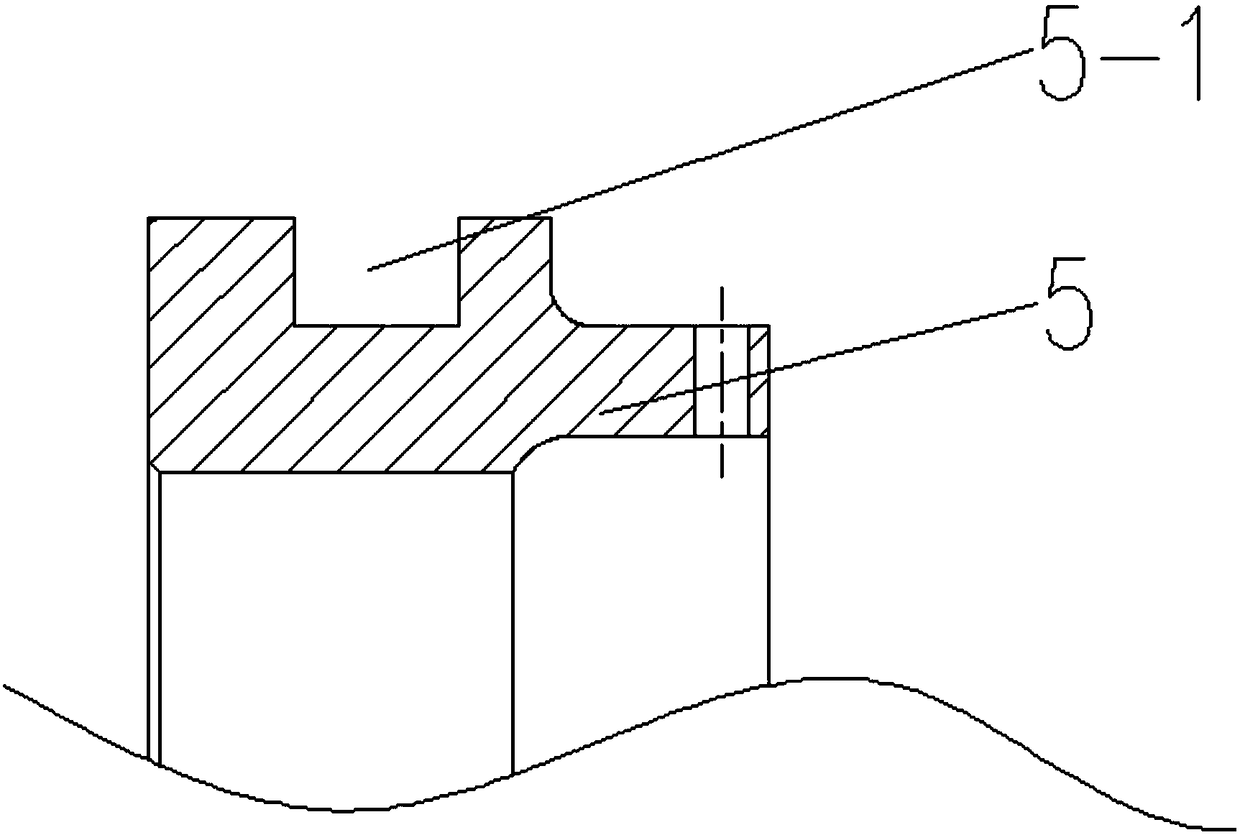

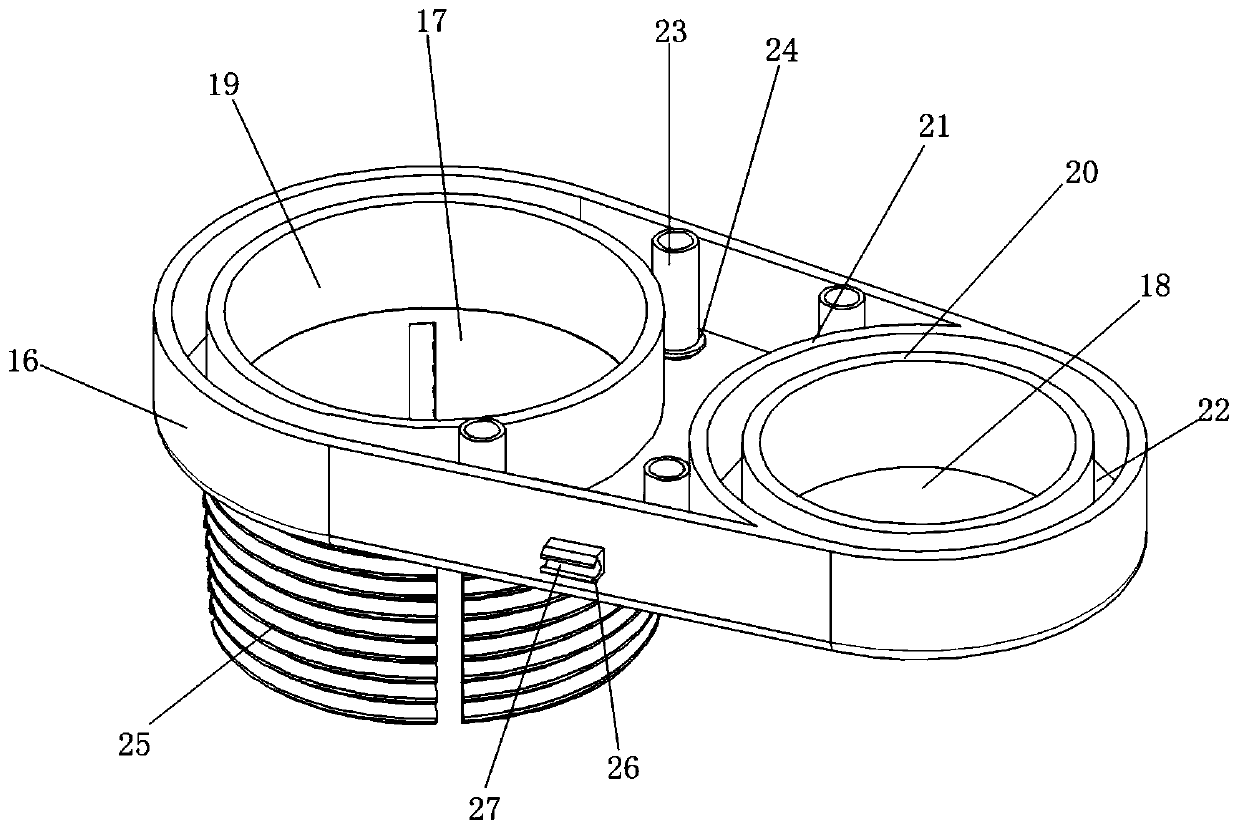

Coupling for stirring device

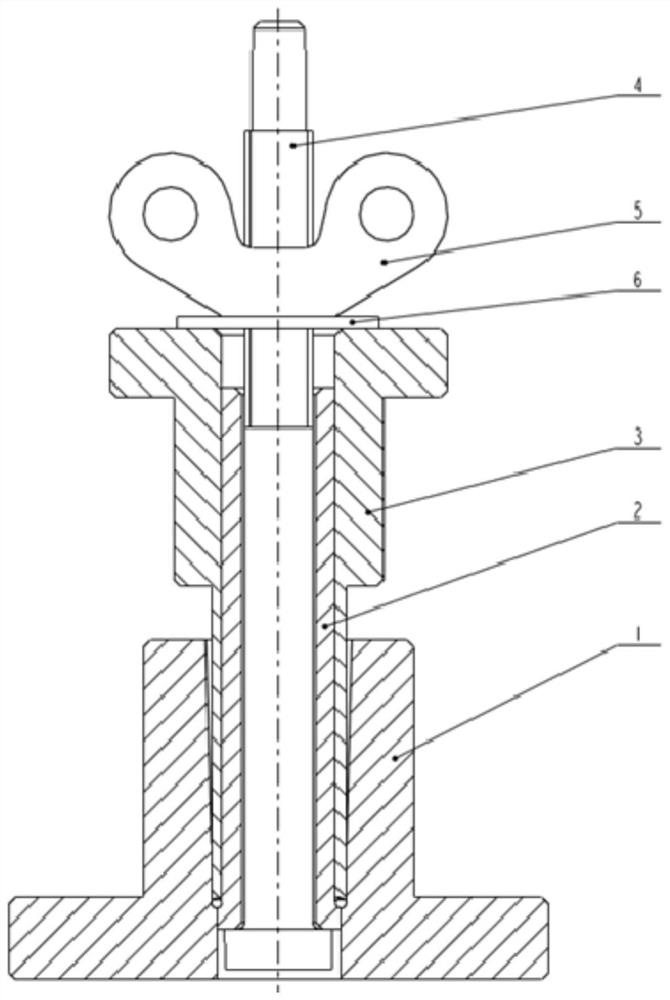

InactiveCN102644672APrecise positioningNot easy to pop outCouplings for rigid shaftsEngineeringDrive shaft

The invention relates to a coupling for a stirring device. A driving shaft and a driven shaft which are used for being connected with the stirring device rotate jointly so as to transmit torque. The coupling comprises two hollow half-coupling barrels, one end of each half-coupling barrel is provided with a boss extending outwards from a side wall of the barrel, and the two bosses are provided with fixing holes corresponding to each other. The coupling is characterized in that identical annular grooves are arranged on planes of the two bosses, and at least one axial limiting protrusion is arranged in the annular grooves. The grooves for placing annular elastic pieces are arranged in the bosses of the coupling, simultaneously the limiting protrusion is arranged, the positioning action on the elastic pieces is enhanced, the elastic pieces are fixed easily in installation, and the elastic pieces cannot jump out easily in dismantling so that the loss is avoided. Inserting structures matched with each other can be arranged on the two half couplings, assist a thread connecting piece in enlarging friction between the two half couplings, and reduce stress and consumption of the thread connecting piece.

Owner:SUZHOU JINXIANG TITANIUM EQUIP

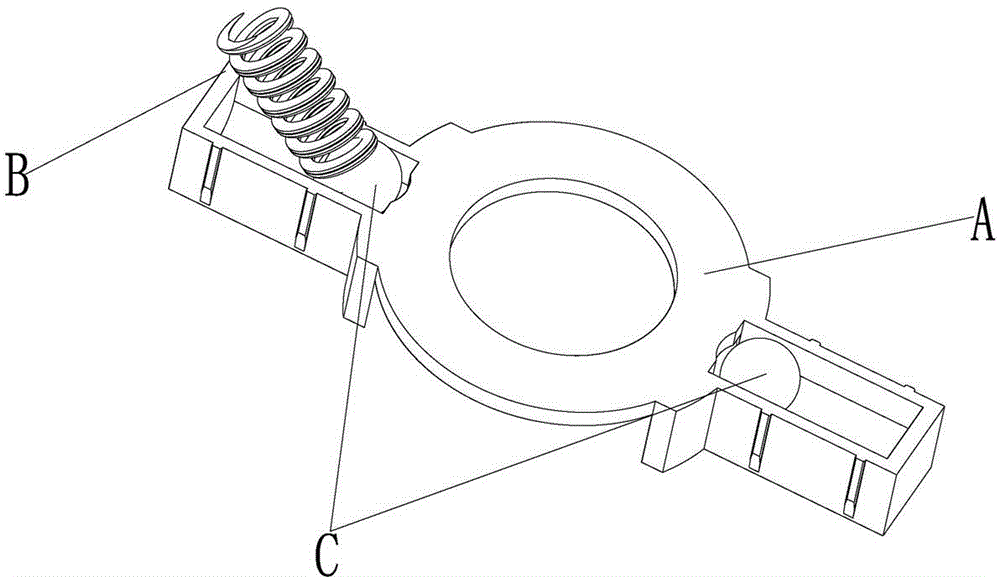

Spiral spring fixture

Owner:STATE GRID CORP OF CHINA +2

Aviation engine bearing and oil receiving ring connection structure

The invention provides an aviation engine bearing and oil receiving ring connection structure and particularly relates to the aviation engine bearing and oil receiving ring connection structure. The aviation engine bearing and oil receiving ring connection structure comprises a bearing, a left oil receiving ring and a right oil receiving ring, the left oil receiving ring and the right oil receiving ring are concentrically arranged on two sides of the bearing correspondingly, the bearing comprises an outer ring, an inner ring, a bearing holder and a plurality of rollers, two sides of the bearing holder are concentrically provided with two oil blocking rings, the outline of the left oil receiving ring is in a circular ring shape, the periphery of the outer surface of the left oil receiving ring is provided with an annular groove, the side, close to the bearing, of the left oil receiving ring is provided with a plurality of through holes in an evenly distributed manner, the outline of theright oil receiving ring is in a circular ring shape, the side, close to the bearing, of the right oil receiving ring is provided with a plurality of through holes in an evenly distributed manner, and the left oil receiving ring and the right oil receiving ring communicate with the rollers through the through holes and an annular gap formed by the bearing holder and the inner ring. The aviation engine bearing and oil receiving ring connection structure is used for aviation engine bearing lubrication.

Owner:AVIC HARBIN BEARING

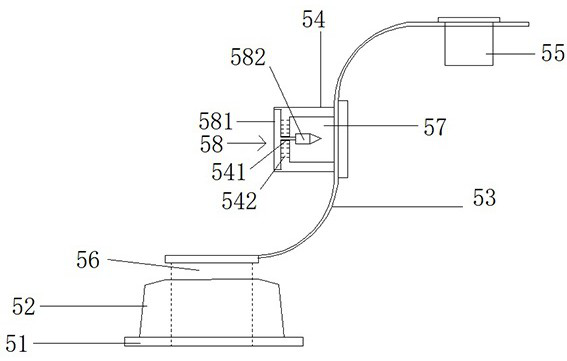

Box cover spot welding mechanism for cylindrical battery and method

ActiveCN113182685AGuaranteed success rateQuality improvementFinal product manufactureLaser beam welding apparatusElectrical batteryStructural engineering

The invention discloses a box cover spot welding mechanism for a cylindrical battery. The mechanism comprises a box cover pre-assembly, a box cover assembly, coaxiality adjusting assemblies, a battery transfer assembly and a laser spot welding assembly, wherein the battery transfer assembly sequentially penetrates through the box cover pre-assembly, the box cover assembly and the laser spot welding assembly, and the coaxiality adjusting assemblies are located on the two sides of the battery transfer assembly respectively. The box cover pre-assembly comprises a first positioning assembly, a first knocking assembly and a first three-jaw positioning assembly. The box cover assembly comprises a second positioning assembly, a second knocking assembly and a second three-jaw positioning assembly. The bottoms of the first three-jaw positioning assembly and the second three-jaw positioning assembly which are located on the same side are installed on the same coaxiality adjusting assembly. The invention further discloses a method adopting the box cover spot welding mechanism for the cylindrical battery. The method has the beneficial effects that a cover plate and an aluminum shell are positioned, preliminarily shaped and knocked, so that the percent of pass of box covers is ensured; and battery transfer, battery cover closing and laser spot welding can be automatically completed, and the production efficiency is remarkably improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

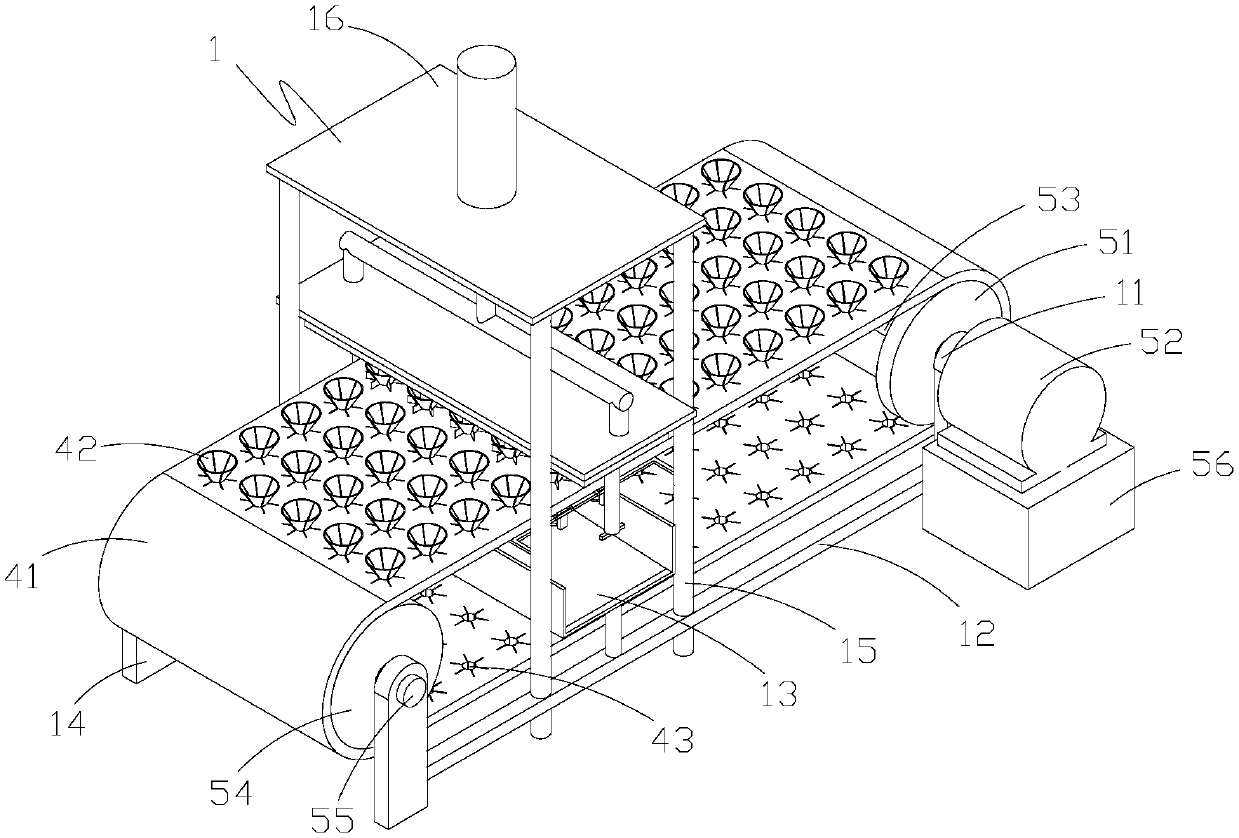

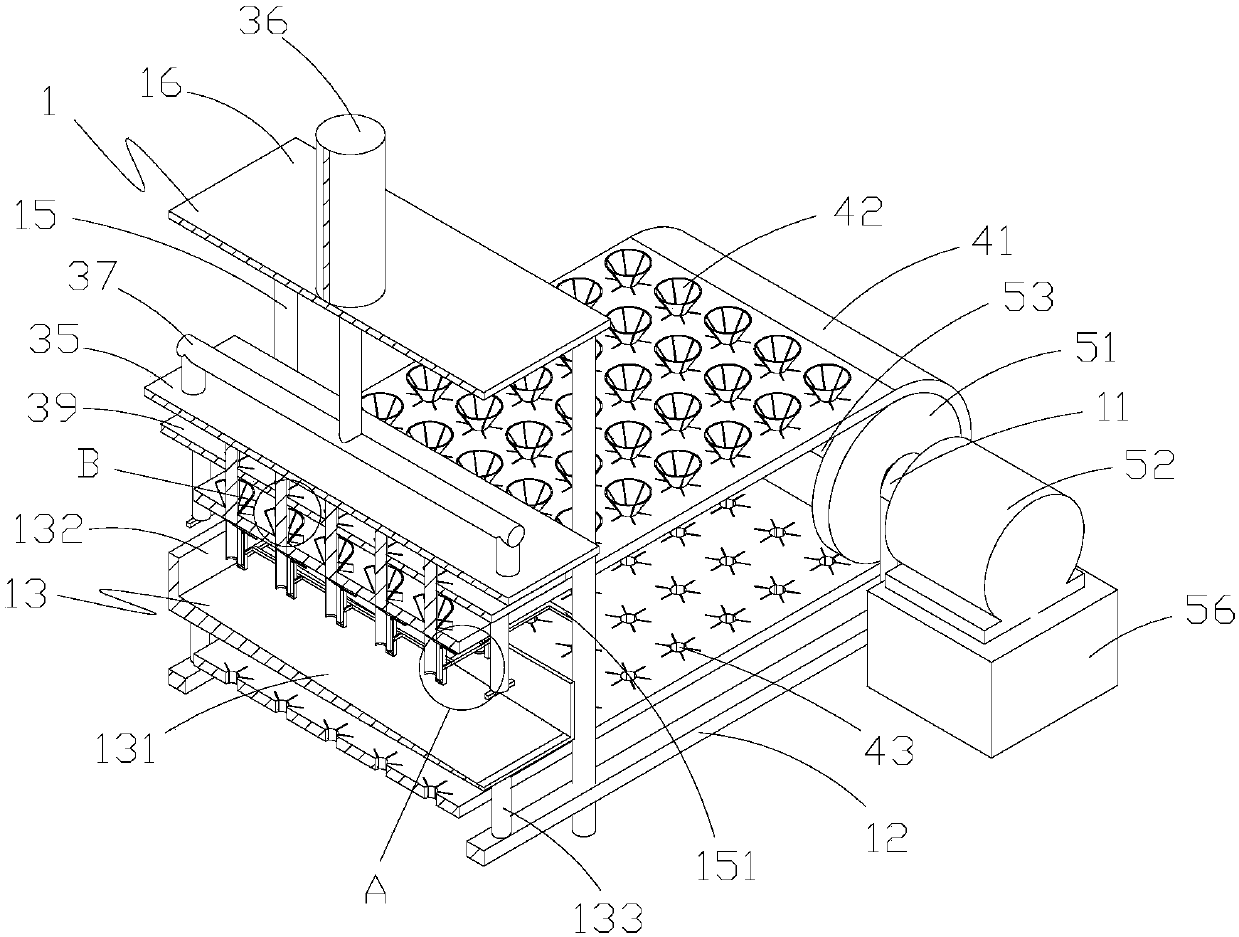

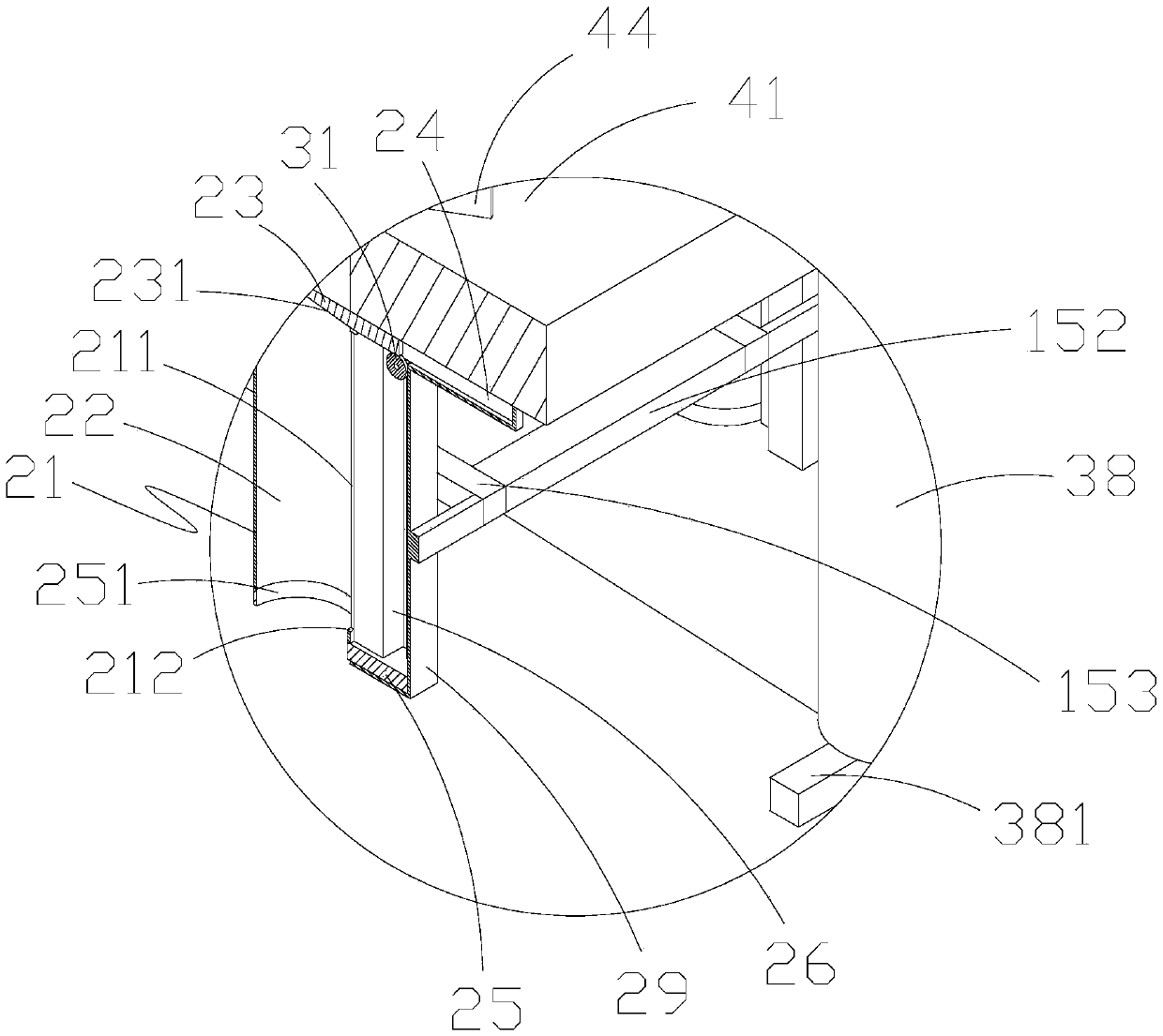

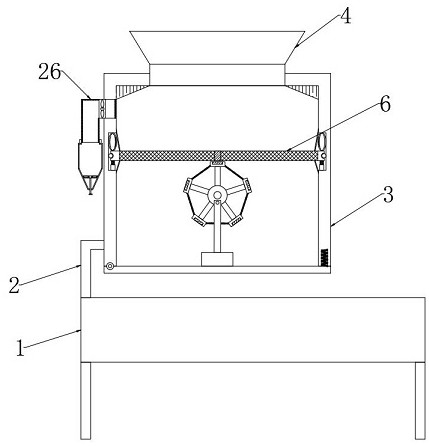

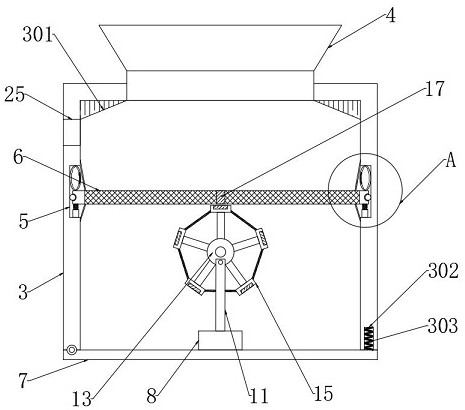

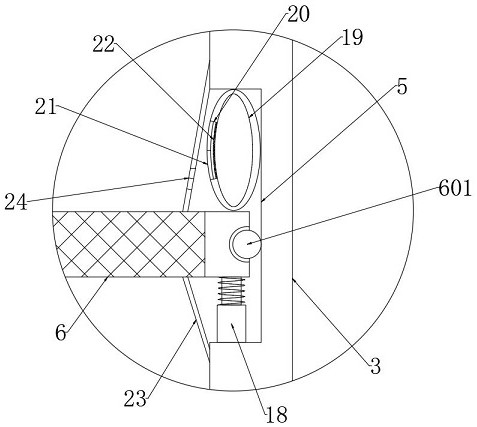

Pretreatment apparatus for producing preserved fruits

The invention discloses a pretreatment apparatus for producing preserved fruits. The apparatus comprises a support frame, a conveying device for conveying a material, a driving device for driving theconveying device to move the material, and a treatment device for denucleating and slicing fruits; the driving device includes a driving wheel that can move back and forth, a driving member for driving the driving wheel to move back and forth, and a driving shaft in standstill locking fit with the driving wheel; and the support frame includes a main rod in rotating fit with the driving shaft, a reinforcing rod detachably connected to the main rod, and a guiding basket matched with the treatment device. The arrangement of the guiding basket makes fruit kernels, taken out by the treatment device, unitively collected and discharged by the guiding basket, so obstruction and even damages of the apparatus, caused by random falling of the fruit kernels, are avoided, bacteria are prevented from growing, and the cleanness and the hygiene of treated fruits are ensured.

Owner:杭州云物科技有限公司

High-pressureholepacking and pressure relief protection method for coal strata

ActiveCN111425175ARealize in-situ pressure holding and decompressionRealize pressure maintenance and pressure reliefFluid removalWell/borehole valve arrangementsHigh pressure waterControl valves

The invention discloses a high-pressure holepacking and pressure relief protection method for coal strata. The method comprises the following steps: firstly, a hole is drilled, and a hole packer is extended into thedrilled hole; secondly, water is injected into thehole to pack thehole; thirdly, the hole packer keeps pressure of the packed hole to fracture the coal strata; fourthly, fracturing is stopped; fifthly, the hole packer keeps pressure and reduces and releases pressure stage by stage; and sixthly, the hole packer is recovered. A one-way safety valve is changed into a two-way safety valve, the valve is controlled by cooperation with a pipe, conventional high-pressure water can be injected into the drilled hole to seal the hole and fracture the coal strata, pressure keeping and relief of the hole packer can be conducted, and water pressure in the drilled hole is acquired by a pressure gauge; when fracturing is stopped, the two-way safety valve of the hole packer cooperates withtheone-way valve to maintain pressure of the hole packer stopping water injection; stage-by-stage pressure relief is achieved by adjusting an external pipe cut-off valve and a pressure regulating valve,high-pressure water infracturing holes can flow out through the two-way safety valve, in-situ pressure maintenance and pressure relief of the hole packer is achieved, a high-pressure rubber expansionhose is less likely to be ejected from the drilled hole,high-speed friction with the fractured holes is prevented, and the service life is long.

Owner:XIAN UNIV OF SCI & TECH +1

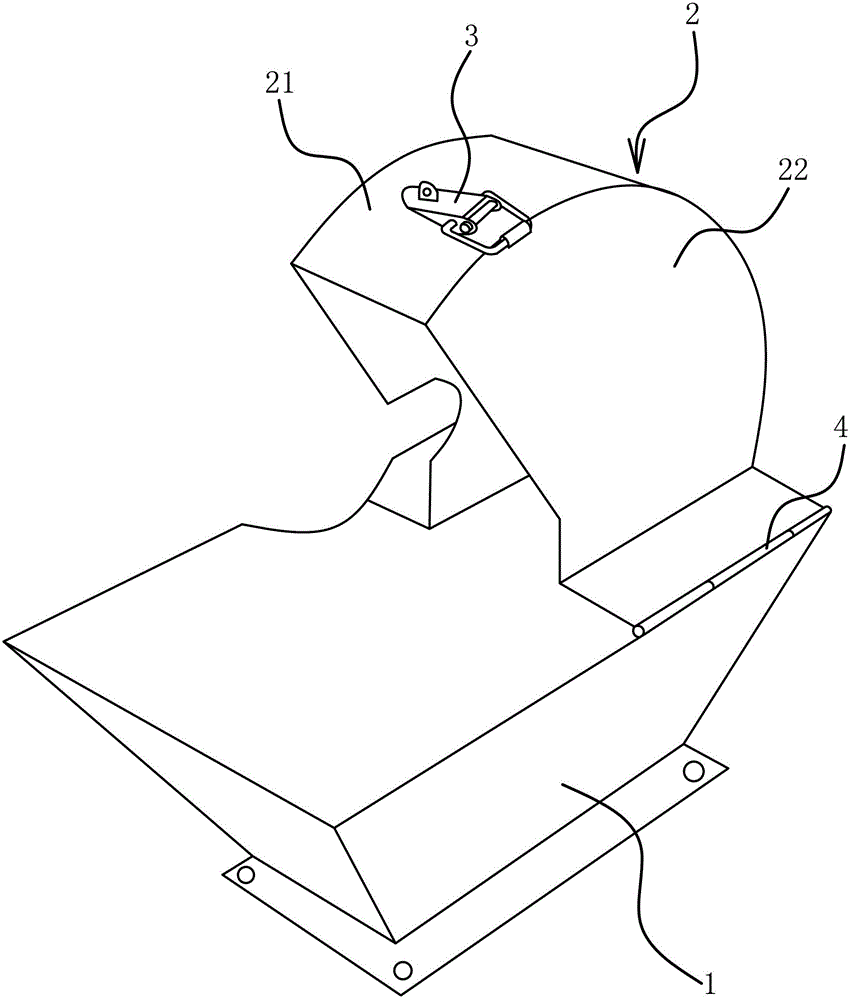

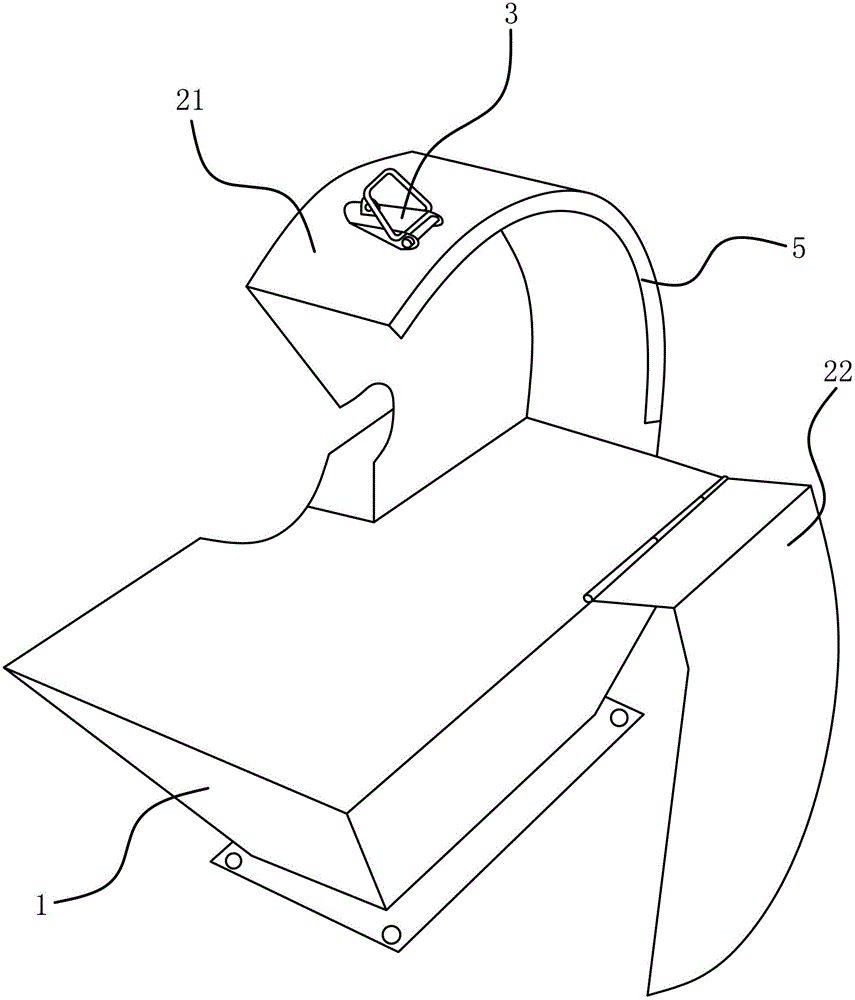

Dust collecting cover of grinding machine

ActiveCN102873642AEasy to change the grinding wheelReduce the difficulty of operationGrinding/polishing safety devicesGrinding wheelPulp and paper industry

The invention provides a dust collecting cover of a grinding machine, which belongs to the technical field of machinery and is used for solving the technical problems of difficulty in disassembling and assembling and the like existing in the conventional dust collecting cover of a grinding machine. The dust collecting cover of the grinding machine is characterized by comprising a substrate covered at the bottom of a grinding wheel and a cover body assembly covered on the top and the back side part of the grinding wheel; the cover body assembly comprises a fixed cover plate and a movable cover plate positioned on one side of the fixed cover plate; the fixed cover plate is fixedly connected with the substrate; and the movable cover plate is connected with the substrate and / or the fixed cover plate of the cover body assembly through a locking structure which can be used for separating the movable cover plate from the fixed cover plate. According to the dust collecting cover of the grinding machine, the grinding wheel can be replaced only by separating the movable cover plate from the fixed cover plate by operating the locking structure without detaching the entire dust collecting cover, so that the dust collecting cover has the advantages of convenience in replacing the grinding wheel, reduction in the operating difficulty, and increase in the replacing efficiency; and repeated integral disassembly and assembly of the dust collecting cover are avoided, the damaging possibility of the dust collecting cover is lowered, and the service life of the dust collecting cover is prolonged.

Owner:陈美青

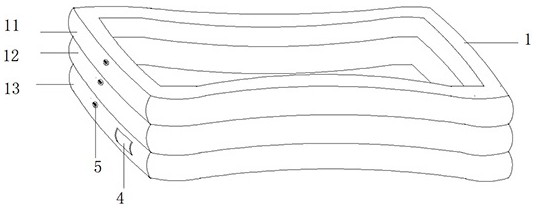

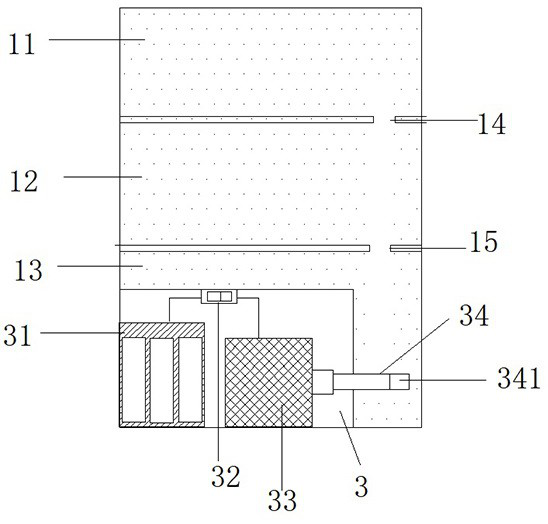

Inflatable swimming pool facilitating drainage

PendingCN111764707AMeet the needs of outdoor useSimple designSynthetic resin layered productsGymnasiumEngineeringControl switch

The invention provides an inflatable swimming pool facilitating drainage. The inflatable swimming pool comprises an air chamber layer and a bottom cushion. The air chamber layer is approximately rectangular, the two long sides of the rectangular air chamber layer are recessed inwards, and the bottom plane of the air chamber layer is sealed through the bottom cushion to form a pool structure. Afterthe portion between the air chamber layer and the bottom cushion is filled with water, the two long sides of the air chamber layer can expand outwards to form a straight rectangular pool. The air chamber layer is further provided with a storage cavity, the outdoor part of the storage cavity is provided with a closing cover, the storage chamber is internally provided with a power supply module, acontrol switch and an air inflation pump, the inflation pump communicates with an inner cavity of the air chamber layer through an inflation communication pipe, and a control switch can control the inflation pump to be started or stopped. The inflatable swimming pool is more convenient to use, better in drainage efficiency and capable of being automatically inflated.

Owner:陶青平

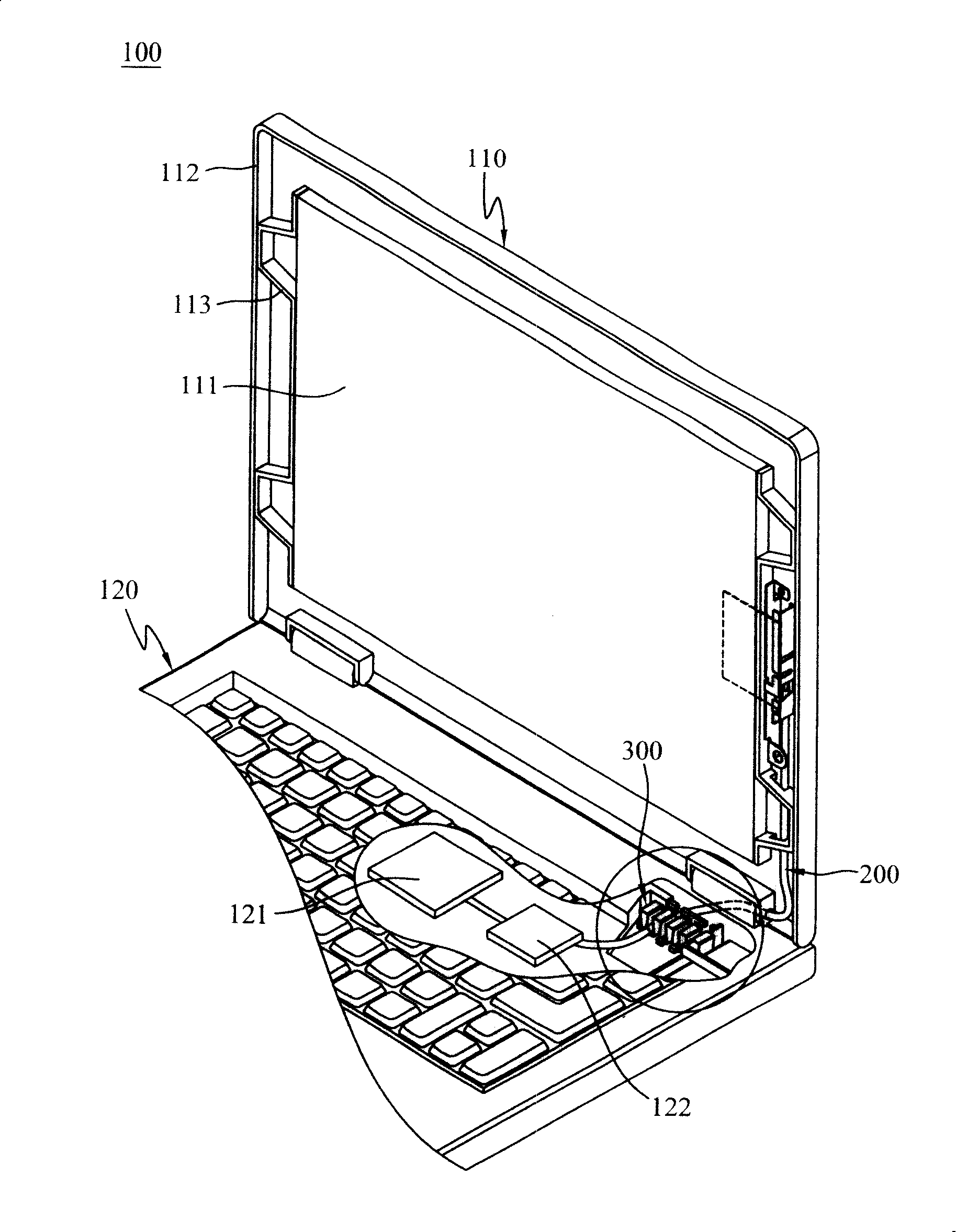

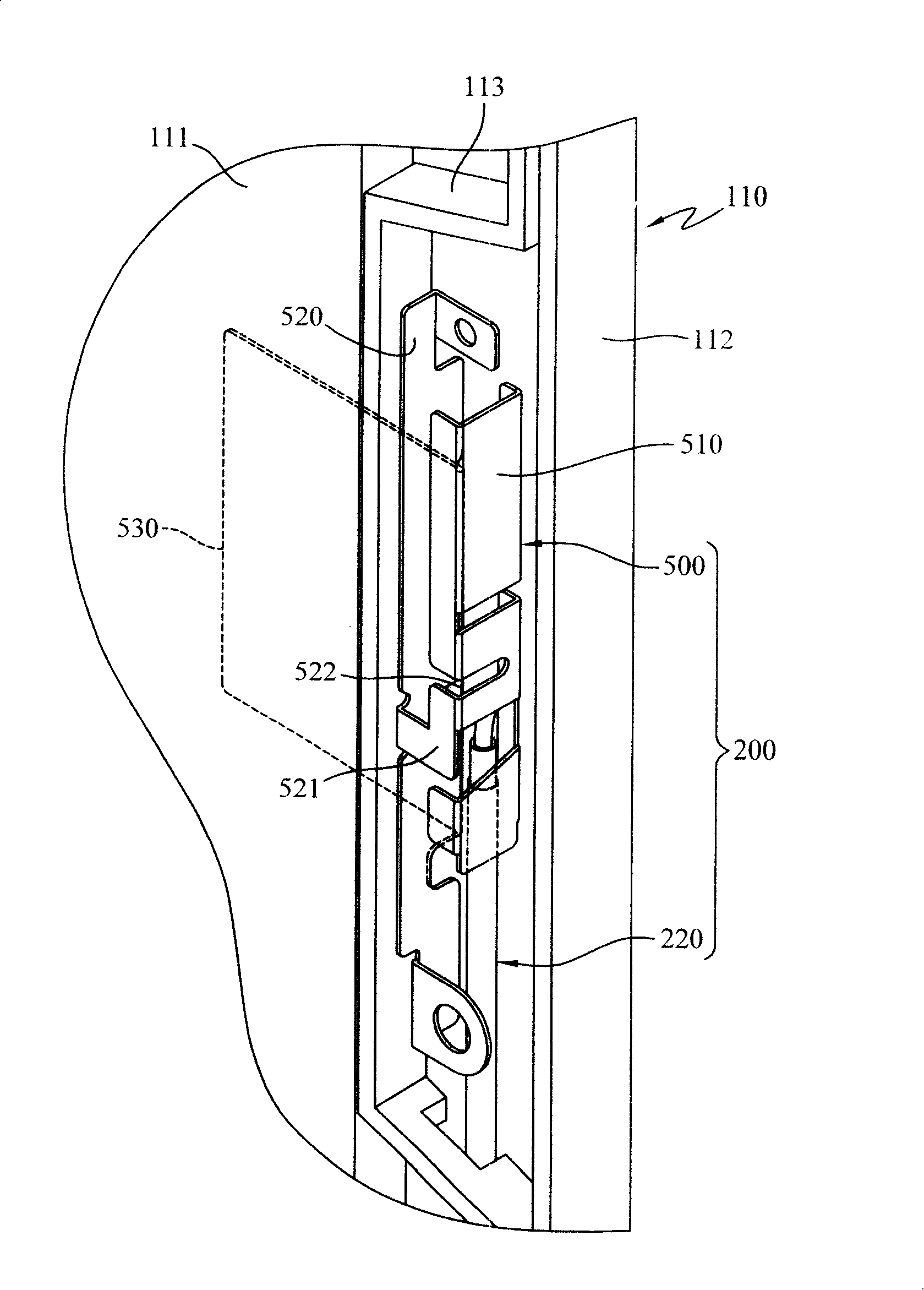

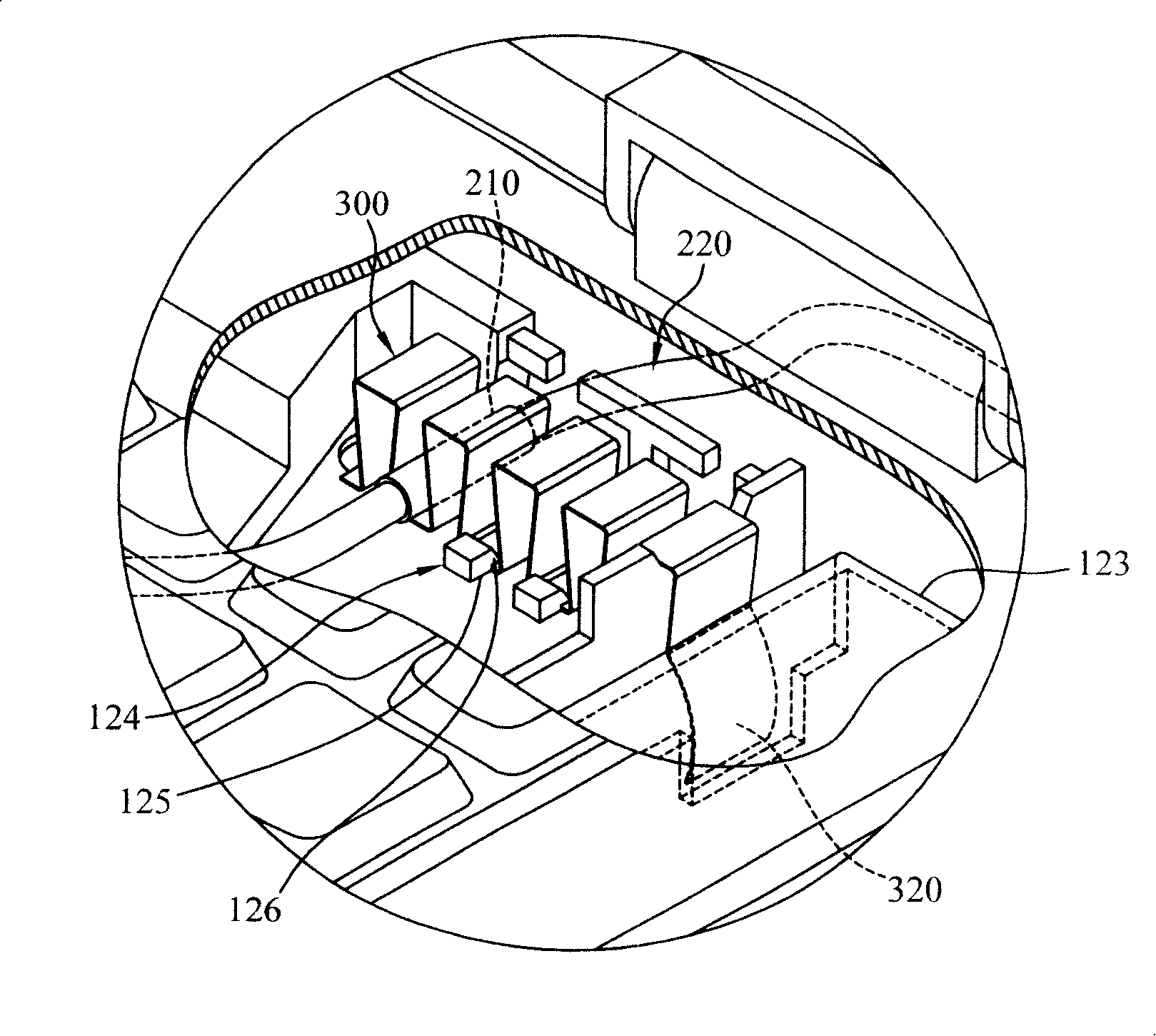

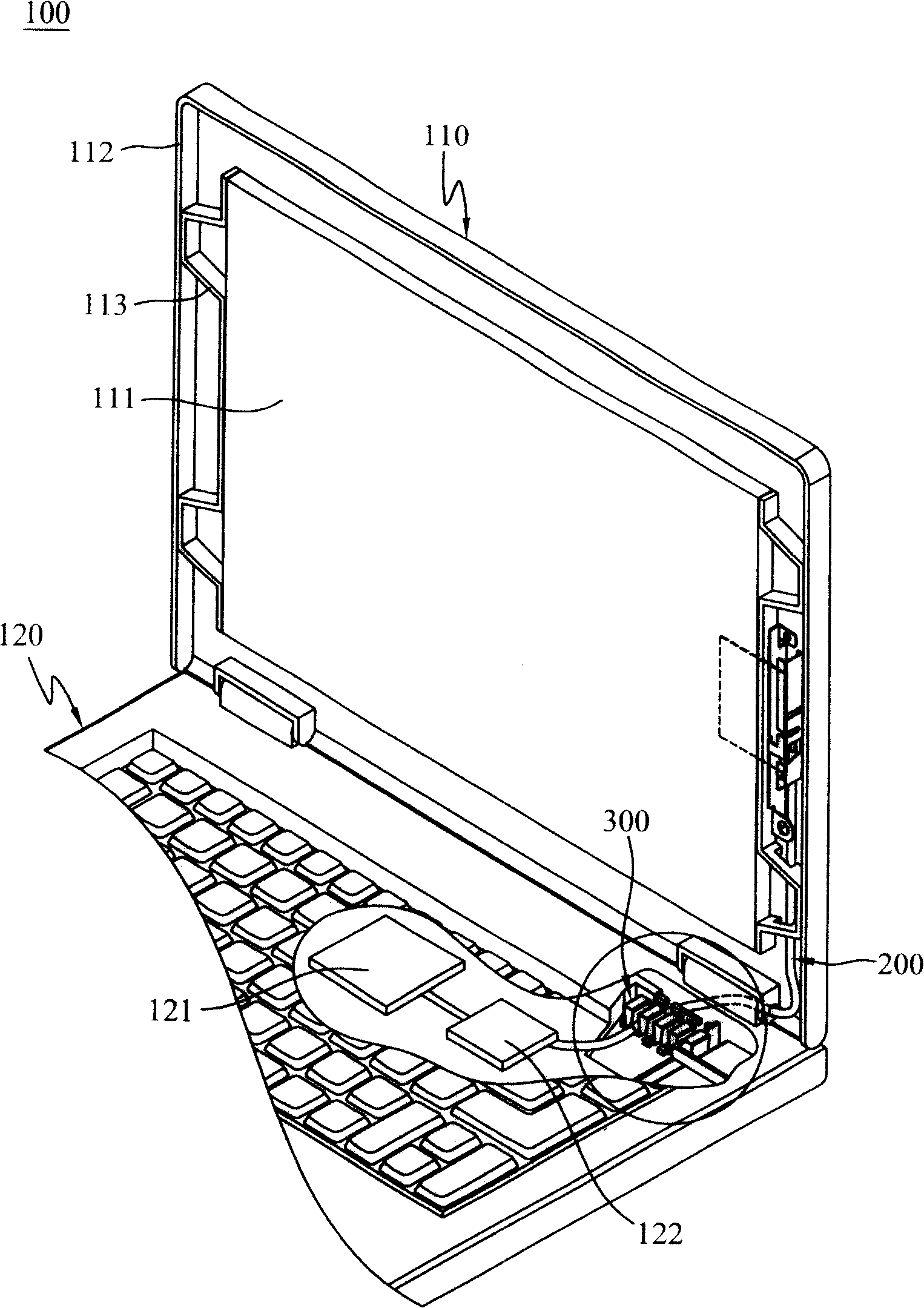

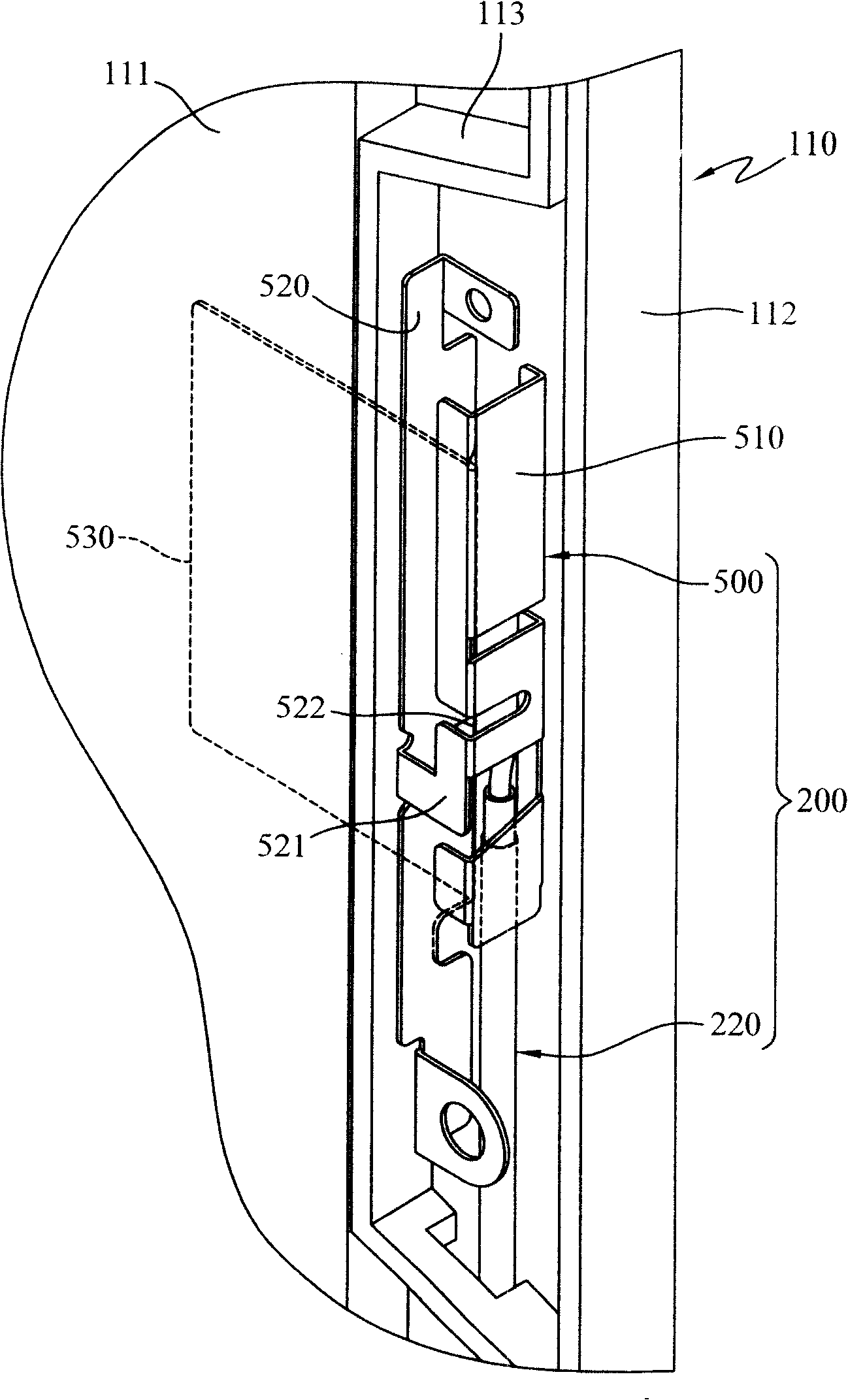

Antenna structure

InactiveCN101202371AEliminate Interference SignalsImprove qualityAntenna supports/mountingsAntenna earthingsEngineeringHost machine

The invention provides an antenna structure which is applied to a notebook computer. The notebook computer comprises a display screen and a host computer. The host computer of the notebook computer is provided with a grounding part; the antenna structure comprises an antenna and a grounding component; one end of the antenna is arranged at the screen of the notebook computer and the other end thereof is extended to the host computer; the antenna is provided with a grounding section. The grounding component is arranged beside the grounding part and comprises a clamping part and a pushing part which extends from the clamping part; the clamping part clamps and is electrically connected with the grounding section; the pushing part is contacted with the grounding part, thus leading the antenna to be electrically conductive with the grounding part to form a grounding loop, thereby improving the grounding effect and being convenient for assembly.

Owner:赵艳杰 +3

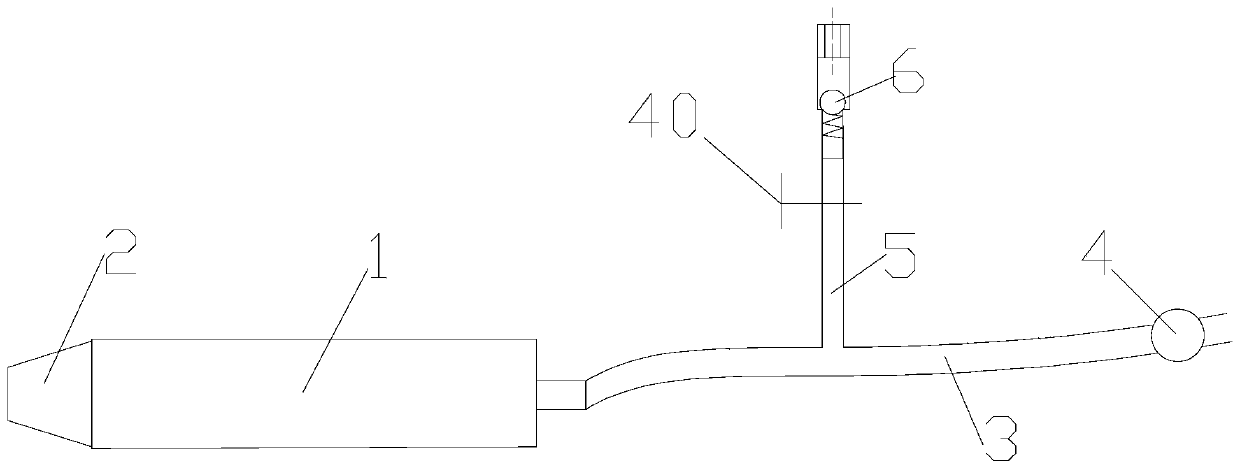

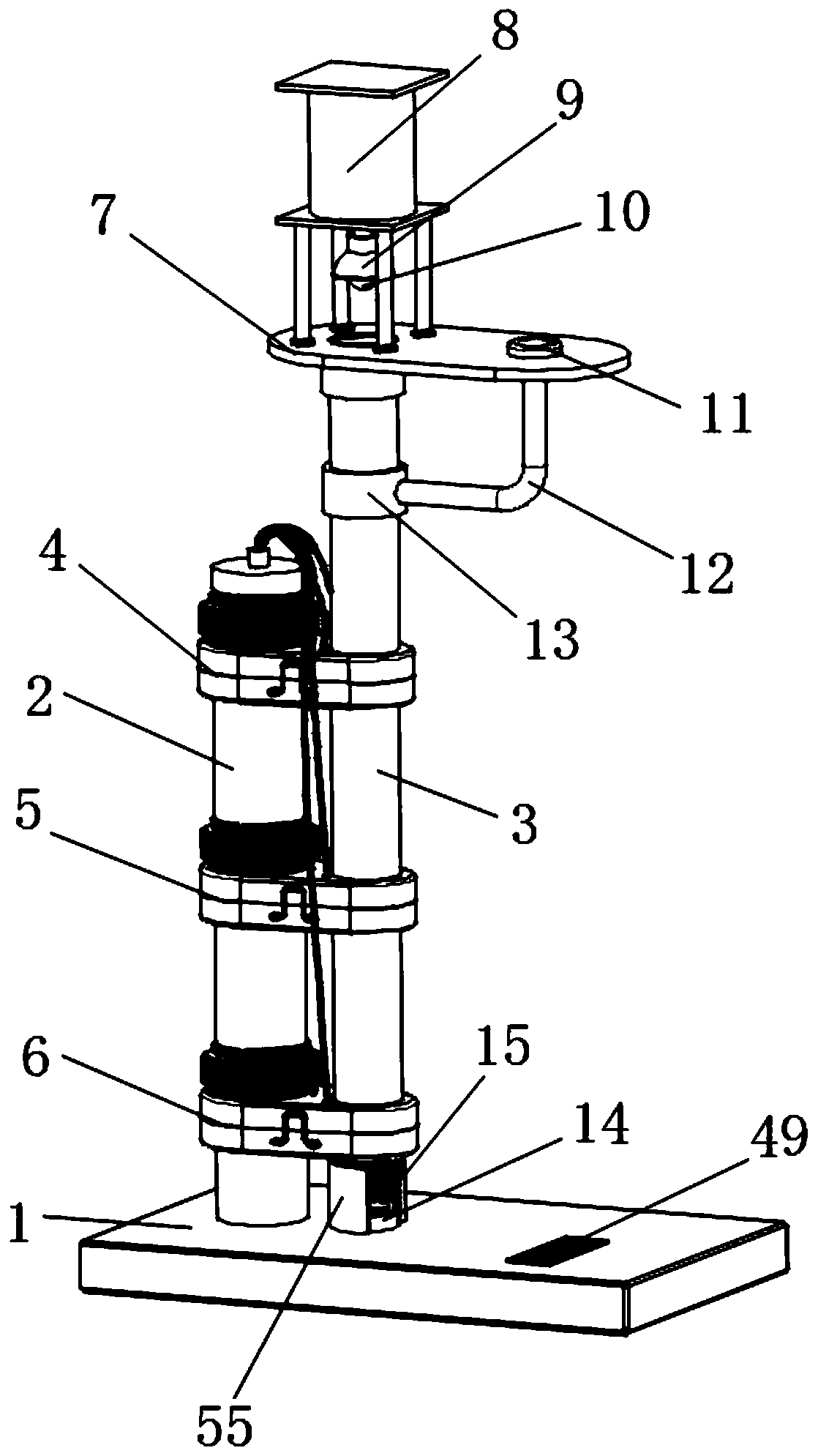

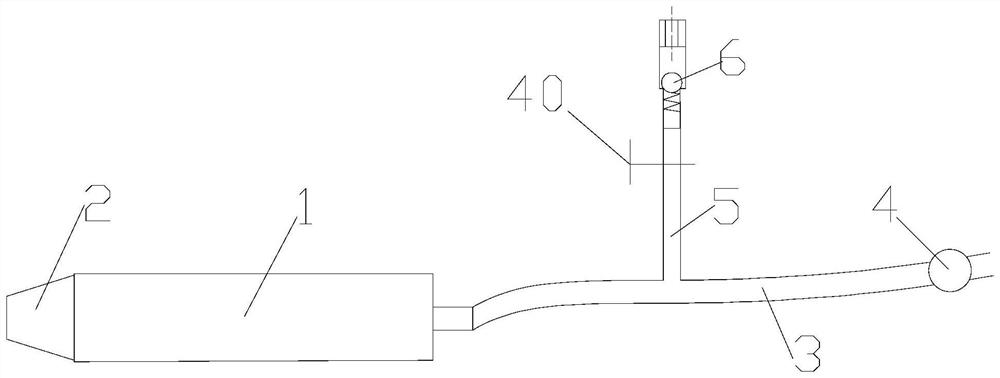

Free falling device based on electromagnetic induction coil and acclamation measurement method

InactiveCN110136550AReduce suctionIncrease diversityEducational modelsGravitational wave measurementConvertersFree falling

The invention discloses a free falling device based on an electromagnetic induction coil and an acclamation measurement method. The device comprises a control base, a wire column and a hollow column are arranged on the control base and provided with a first coil fixing device, a second coil fixing device and a third coil fixing device, and the first coil fixing device, the second coil fixing device and the third coil fixing device are internally provided with a first coil, a second coil and a third coil respectively; a fixing rack is arranged at the top of the hollow column, a button and a magnet exciting coil are arranged on the fixing rack, a magnet is arranged in the magnet exciting coil, an attraction sleeve is connected to the bottom of the magnet, and a steel ball is arranged in theattraction sleeve; the first coil, the second coil and the third coil are connected with a signal amplifier, the signal amplifier is connected with an A / D converter, the A / D converter is connected with the controller, and the controller is connected with a display screen, a timer and the button. According to the device, the acceleration of the steel ball during free falling can be measured, a numerical value is displayed, and the richness of a teaching experiment is improved.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

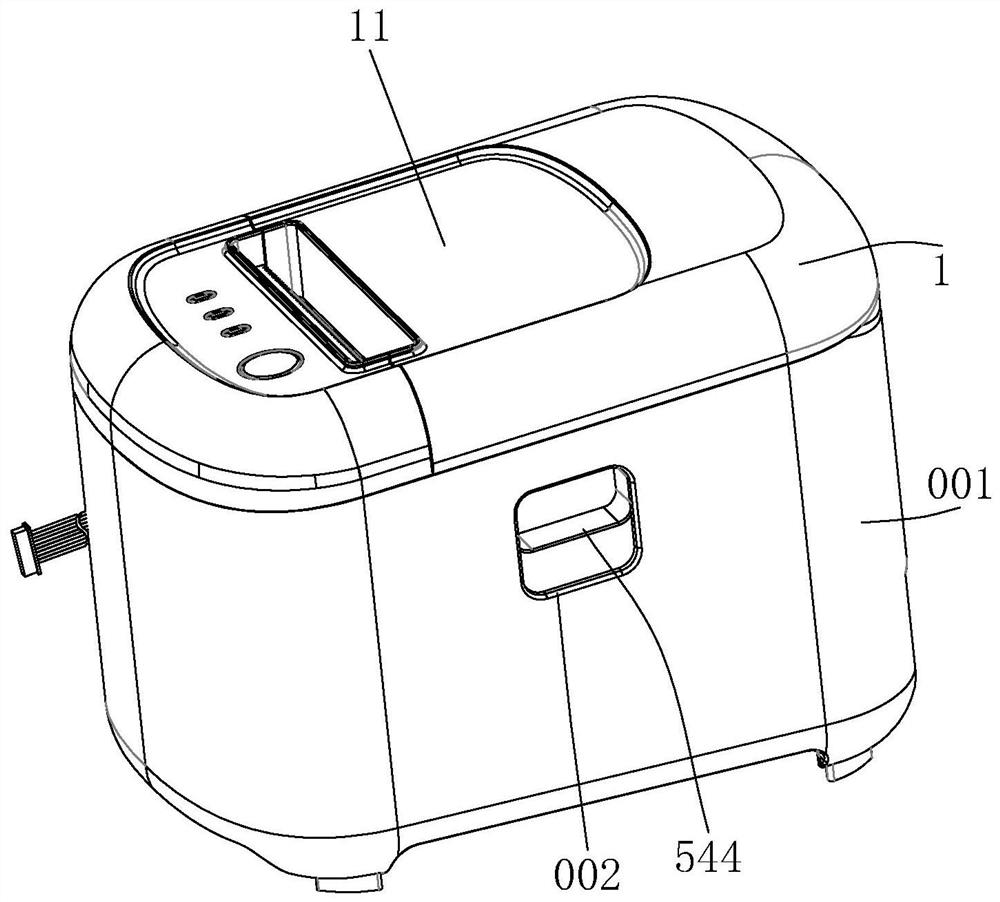

Thermal printer

ActiveCN111332025ATimely replacementStrong feedbackOther printing apparatusComputer printingEngineering

Owner:深圳市易联达商用设备有限公司

Pressing self-locking structure and pressing pen adopting same

The invention discloses a pressing self-locking structure, which belongs to the technical field of pressing self-locking. The pressing self-locking structure comprises a left frame body and a right frame body fixedly arranged at the rear part of the left frame body, wherein a sliding connecting piece is arranged in the left frame body; the inner wall of the front part of the left frame body is fixedly provided with a barrel; a return spring is sleeved between the sliding connecting piece and the barrel; the upper part of the left frame body is provided with a pressing piece for driving the sliding connecting piece to axially and relatively slide in the left frame body; axial movement of the sliding connecting piece in the right frame body can be realized by pressing the pressing piece; andfurther, the sliding connecting piece is promoted to drive an external part to move, and a use state and a non-use state of the external part can be realized. The operation is simple and convenient,the flexibility is stronger, and the pressing piece is not easy to move downwards in the right frame body when the external acting force is smaller, so that the triggering of the whole device is not easy to cause, the device is kept in the non-use state, and unnecessary troubles caused by external mistaken touch are reduced.

Owner:HANGZHOU JIANYI TECHNOLOGY CO LTD

Integrated high-temperature high-pressure metal seal ball valve

InactiveCN101813201BReasonable structureFlexible opening and closingSpindle sealingsPlug valvesFiberEngineering

The invention relates to a valve, in particular to an integrated high-temperature high-pressure metal seal ball valve. The invention adopts the following scheme: the integrated high-temperature high-pressure metal seal ball valve comprising a valve rod, a valve body, a valve seat and a valve core ball, characterized in that the valve seat is connected to the valve core ball crossing an auxiliary body, two groups of ring chambers are arranged between the valve rod and the auxiliary valve body, wherein the ring chamber close to the valve core ball side is provided with tungsten carbide metal pads, and the other chamber is covered with an executer platform, metal ducts are arranged between the executer platform and the valve rod, the chamber is provided with a ceramic ring pad, a carbon fiber weaving ring pad, a ceramic ring pad, a graphite, a carbon fiber weaving ring pad, a pressing block and a disc spring. By adopting the above scheme, the product has reasonable structure, flexible opening and closing, high efficiency and good seal effect.

Owner:浙江宏明阀门有限公司

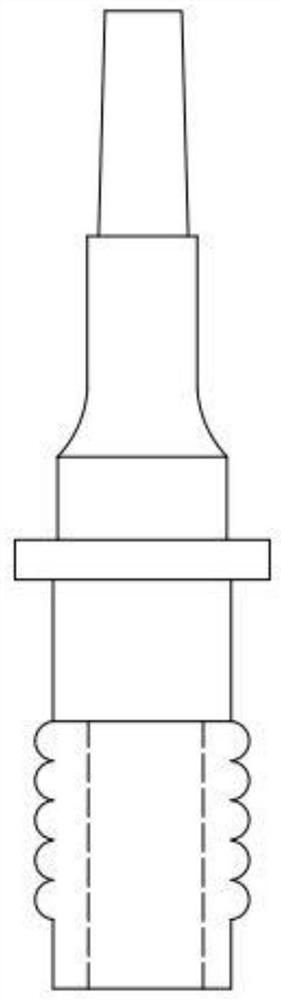

Automatic glazing process for spark plug ceramic parts

The invention discloses an automatic glazing process for spark plug ceramic parts. The automatic glazing process comprises the following steps that 1) the spark plug ceramic parts to be glazed are poured into a vibration feeding tray machine, and a tray body of the vibration feeding tray machine is rotated to sequentially arrange materials and discharge the materials from a discharge port; 2) the spark plug ceramic parts are erected above a material passing groove and move forwards along with vibration after entering a vibration channel, then a sealing piece arrives at the position of an automatic inserting and embedding disc along with the vibration channel, the spark plug ceramic parts are moved into a clamping groove, and then the ceramic parts start to rotate along with the automatic inserting and embedding disc; and 3) along with the rotation of the automatic inserting and embedding disc, the spark plug ceramic parts automatically enter a glazing machine. The automatic glazing process solves the problems that in the process of manually inserting and connecting the ceramic parts into a bearing seat in the existing automatic glazing process of the spark plug ceramic parts, the sealing parts of the ceramic parts are in contact with the edge of the bearing seat due to misalignment caused by operation errors, consequently, the glaze which is left on the edge due to long-term glazing on the edge of the bearing seat adheres to the sealing parts of the ceramic parts.

Owner:宁波纽时达火花塞股份有限公司

Particle trap and cylinder structure for gis/gil

Owner:PINGGAO GRP +2

A kind of jack hidden electronic product

ActiveCN111342297BEffective protectionNot easy to influenceCasings/cabinets/drawers detailsCouplings bases/casesMechanical engineeringElectrical and Electronics engineering

The invention discloses a socket concealed electronic product, which belongs to the technical field of electronic products. A socket concealed electronic product comprises an electronic product body and a mounting groove opened at the front end of the electronic product body. The left inner wall of the mounting groove is rotatably connected with a An adapter plate, at least one compression spring is provided between the adapter plate and the inner bottom of the installation groove, and the right end of the adapter plate is provided with a socket for docking with the plug of the electronic product for charging the electronic product, and the upper and lower outer ends of the adapter plate are respectively With the first cut surface and the second cut surface, the jack can be set on the adapter board. When there is no need to charge the electronic product, the adapter board can be placed in the installation groove, so that the jack is hidden and not easy to charge. Being directly exposed to the air can effectively protect the jack, is not easily affected by the external environment, improves the service life of its internal circuit, and is easy to operate, simple in structure, and easy to reduce production costs.

Owner:浙江艾慧围界科技有限公司

a thermal printer

ActiveCN111332025BTimely replacementStrong feedbackOther printing apparatusThermodynamicsComputer printing

Owner:深圳市易联达商用设备有限公司

Antenna structure

InactiveCN101202371BEliminate Interference SignalsImprove qualityAntenna supports/mountingsAntenna earthingsEngineeringHost machine

The invention provides an antenna structure which is applied to a notebook computer. The notebook computer comprises a display screen and a host computer. The host computer of the notebook computer is provided with a grounding part; the antenna structure comprises an antenna and a grounding component; one end of the antenna is arranged at the screen of the notebook computer and the other end thereof is extended to the host computer; the antenna is provided with a grounding section. The grounding component is arranged beside the grounding part and comprises a clamping part and a pushing part which extends from the clamping part; the clamping part clamps and is electrically connected with the grounding section; the pushing part is contacted with the grounding part, thus leading the antenna to be electrically conductive with the grounding part to form a grounding loop, thereby improving the grounding effect and being convenient for assembly.

Owner:赵艳杰 +3

An automatic spring frame assembly machine and a method for assembling the spring frame

ActiveCN104526343BPress fasteningNot easy to pop outAssembly machinesMetal working apparatusSteel ballEngineering

The invention discloses an automatic spring support assembly machine. The automatic spring support assembly machine comprises a machine platform, and two steel ball assembly detection mechanisms, two spring assembly mechanisms and two glue cover transport mechanisms, which are respectively arranged in opposite mode, wherein each spring assembly mechanism comprises a spring feeding component, a pressing component, a fetching component and a material pull component, each spring feeding component and each pressing component are arranged in parallel mode on a front position and a rear position along the transverse direction of the machine platform, and can move back and forth along the radial direction of the machine platform, and each fetching component and each material pull component are oppositely arranged in the vertical direction and both vertical to the moving direction of the spring feeding components and the pressing components. The invention further discloses an assembly method of glue cover conveying devices, steel ball storage devices, spring storage devices and spring supports, which are arranged at the front segments of the steel ball assembly detection mechanisms. The automatic spring support assembly machine quickly and conveniently assembles springs, achieves high product quality, automatically links all processes in assembly, detects superior and inferior levels of products in the assembly, achieves automatic production, simplifies manual production, and saves labor.

Owner:东莞市创鑫盈精密自动化科技有限公司

A dual-axis synchronous vibrating screen for mine solid waste particles

The invention discloses a dual-axis synchronous vibrating screen for mine solid waste particles, which belongs to the field of vibrating screens. It is a dual-axis synchronous vibrating screen for mine solid waste particles. When it is inside, it will fall on the first filter first, and the ore falling on the first filter will control the rotation of the turntable at the same time, so that the turntable will drive the top block to rotate and jack up the first filter. At the same time, the main magnet block and The repulsion of the auxiliary magnet block makes the first filter screen lame more. When the first filter screen is lame up and down, the extension rod will drive the rotating plate to move up and down. After the rotating plate moves down, the mineral material will be introduced into the vibrating screen. Inside the body, when the first filter screen moves up and down, it will squeeze the air bag, so that the gas will be ejected and blow the impurities in the mineral material on the first filter screen through the air outlet. Through the above operations, the poured mineral material can be controlled , and when the efficiency needs to be increased, the speed of the mineral material shaken off by the first filter screen can be controlled by controlling the rotation speed of the turntable.

Owner:NANTONG ZHENQIANG MACHINERY MFG

Lid spot welding mechanism and method for cylindrical battery

ActiveCN113182685BGuaranteed success rateQuality improvementFinal product manufactureLaser beam welding apparatusStructural engineeringSpot welding

The invention discloses a box cover spot welding mechanism for a cylindrical battery, which includes a pre-box cover assembly, a box cover assembly, a coaxiality adjustment assembly, a battery transfer assembly, and a laser spot welding assembly. The box cover assembly, the box cover assembly, the laser spot welding assembly, and the coaxiality adjustment assembly are respectively located on both sides of the battery transfer assembly; the pre-box cover assembly includes the first positioning component, the first knocking component, the second A three-claw positioning assembly; the lid assembly includes a second positioning assembly, a second knocking assembly, and a second three-claw positioning assembly; the bottoms of the first three-claw positioning assembly and the second three-claw positioning assembly on the same side are installed on the On the same coaxiality adjustment assembly. The invention also discloses a method for adopting the box cover spot welding mechanism of the cylindrical battery. The invention has beneficial effects: the cover plate and the aluminum shell are positioned, preliminarily shaped, and knocked to ensure the qualification rate of the box cover; battery transfer, battery cover closing and laser spot welding can be automatically completed, and the production efficiency is significantly improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

A protection method for high-pressure hole sealing and pressure relief in coal and rock formations

ActiveCN111425175BRealize in-situ pressure holding and decompressionRealize pressure maintenance and pressure reliefFluid removalWell/borehole valve arrangementsEngineeringHigh pressure water

The invention discloses a pressure relief protection method for high-pressure sealing holes in coal rock formations, comprising the steps of: 1. drilling and extending a hole sealing device into the drilling; 2. injecting water into the drilling and sealing the holes; 3. protecting the hole sealing device Sealing holes and fracturing coal formations; 4. Stop fracturing; 5. Keep the pressure of the hole sealer step by step to reduce the pressure; 6. Recover the hole sealer. The invention transforms the one-way safety valve into a two-way safety valve, and cooperates with the pipeline control valve to meet the requirements of conventional high-pressure water injection into the drilling hole sealing and fracturing of the coal rock formation. The water pressure in the borehole is obtained from the table. When the fracturing is stopped, the two-way safety valve of the hole sealer cooperates with the one-way valve to maintain the pressure of the hole sealer that stops water injection, and the pressure is relieved step by step by adjusting the external pipeline stop valve and pressure regulating valve. , and the high-pressure water in the fracturing hole can flow out through the two-way safety valve, which realizes the in-situ pressure maintenance and relief of the hole sealer, ensures that the high-pressure rubber expansion hose is not easy to pop out of the drilling hole, avoids high-speed friction with the fracturing hole, and has a long service life.

Owner:XIAN UNIV OF SCI & TECH +1

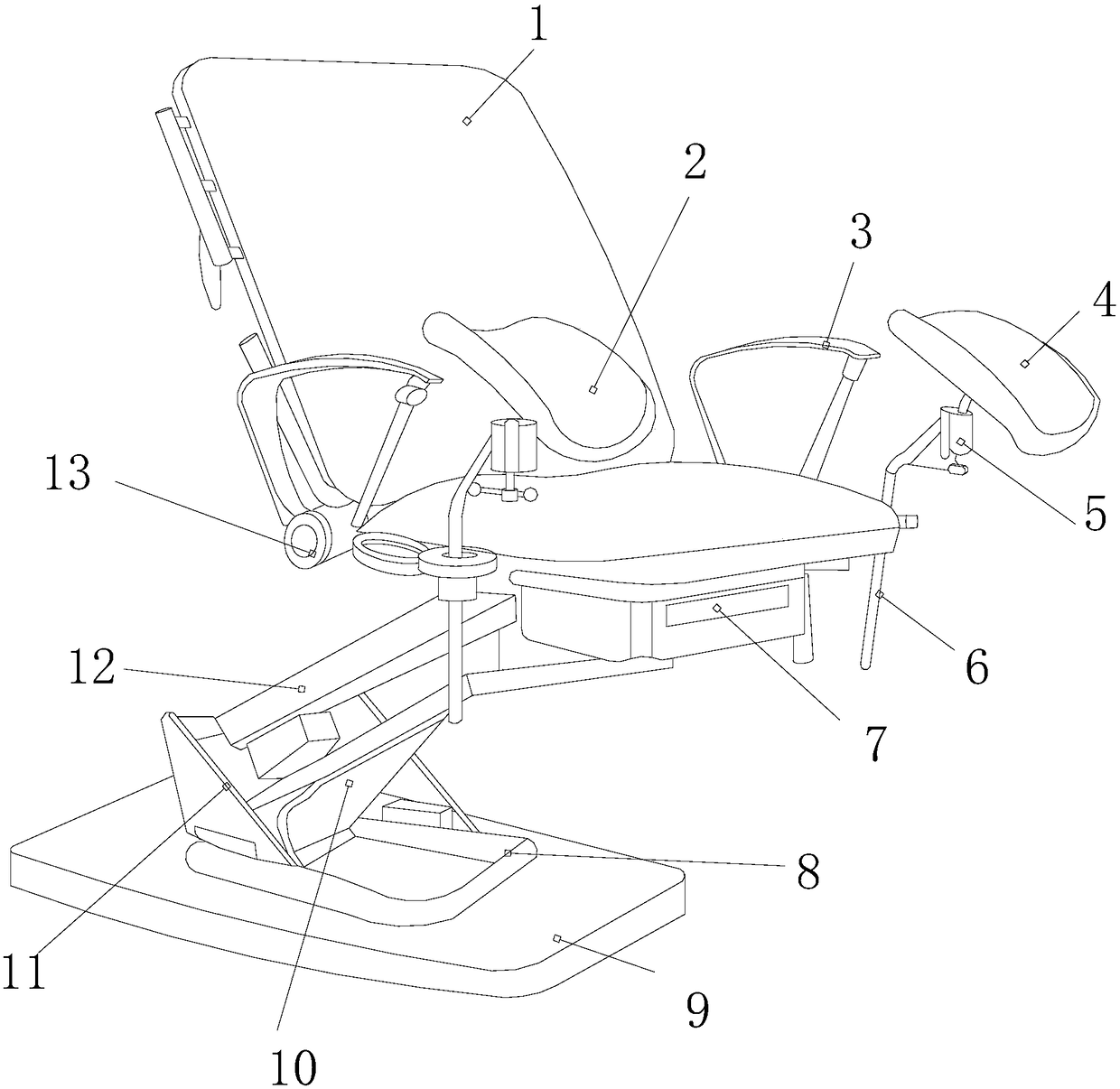

Novel gynecological disease examination device

The invention discloses a novel gynecological disease examination device. The structure comprises a seat, a first foot placing frame, armrests, a second foot placing frame, movable joints, fixing struts, an administration set, a fixing splint, a chassis, a fixing bottom plate, a folding bottom, a folding rod, and a movable column. The top surface of the chassis is provided with the fixing splint.The fixing splint is connected with the folding rod through the fixing bottom plate and the folding bottom in a mechanical manner. A first end of the folding rod is fixedly connected with the bottom of the seat. The device is provided with a first foot pressing structure, a second foot pressing structure, and other structures. A pressing block is pressed upward, and then a starting structure pushes a linkage structure to rotate the second foot pressing structure, and meanwhile, through transmission of a transmission structure, the first foot pressing structure rotates. A medicine box losses pressing of an intermittent wheel dish and a second intermittent wheel dish and is ejected by a rigid spring, and speed is fast. When the medicine box is not ejected, four edges and corners of the medicine box are pressed by the intermittent wheel dishes and second intermittent wheel dishes, and the medicine box does not easily eject, and locking effect is good.

Owner:李江鸿

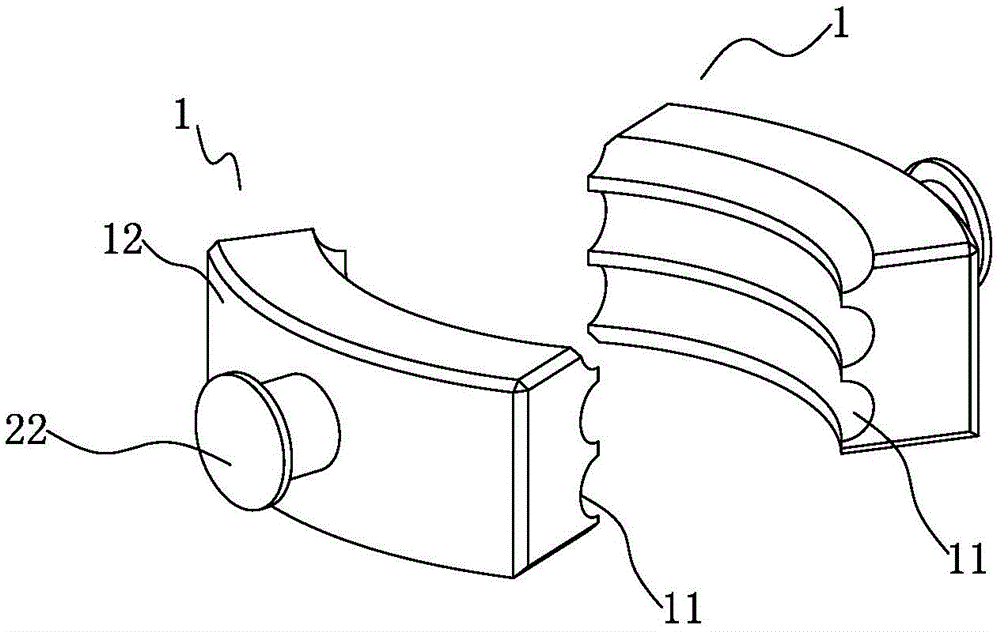

A horizontal layerer for plant propagation

InactiveCN104221770BWon't fall offNot easy to pop outCultivating equipmentsPlant propagationMechanical engineering

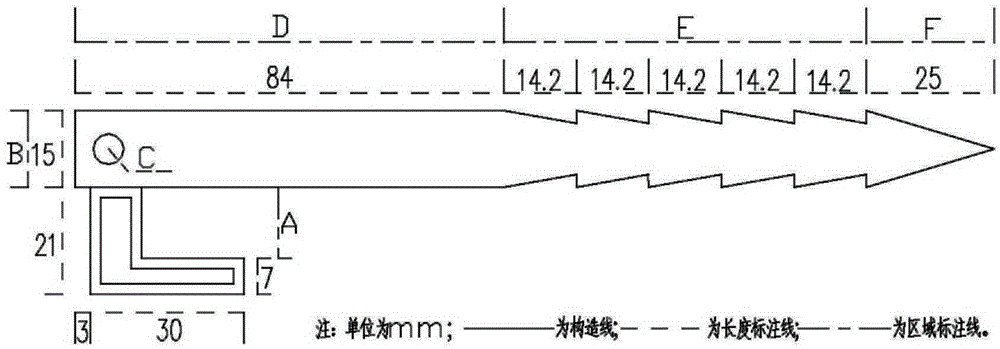

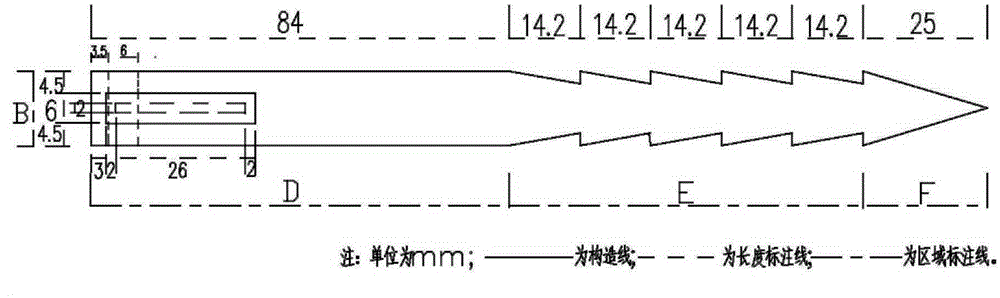

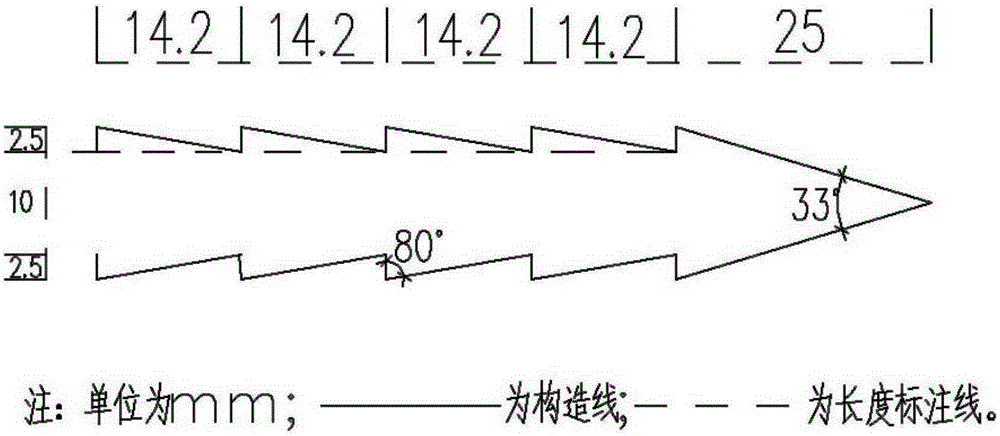

The invention relates to a continuous layering device for plant propagation. The device comprises a press block, a fixing hook and a body, wherein the body consists of a strip column-shaped body tail end, a sawtooth-shaped body middle end and a tip body front end which are sequentially connected into a whole, the strip column-shaped body tail end is in a cylinder shape, the top part of the strip column-shaped body tail end is fixedly provided with the press block, the fixing hook is arranged at one side of the connecting part of the press block and the strip column-shaped body tail end, and is in an L shape, an opening of the fixing hook faces the tip body front end, and the part, near the press block, of the strip column-shaped body tail end is provided with a line penetrating hole. The device has the advantages that the structure is simple, the manufacturing is easy, the cost is lower, the repeated use is realized, and the problems of low working efficiency of layering operation, easiness in pop-out of layered branches, and unable reutilization of a layering tool of in the production process are solved.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Quantitative cutting device for construction steel bars

The invention relates to a cutting device, in particular to a quantitative cutting device for construction steel bars. By means of the quantitative cutting device for the construction reinforcing steel bars, the reinforcing steel bars are not prone to popping up to injure workers in the reinforcing steel bar cutting process of people. A building steel bar quantitative cutting device comprises a supporting back plate, supporting vertical frames, a placing plate and a limiting bottom block, the supporting vertical frames are fixedly connected to the middle of the front side face of the supporting back plate in a bilateral symmetry mode, the placing plate is fixedly connected between the tops of the supporting vertical frames on the left side and the right side and fixedly connected with the supporting back plate, and the limiting bottom block is fixedly connected to the left side of the top of the placing plate. A steel bar moves rightwards to drive a limiting vertical block to move rightwards, a mounting bottom block moves rightwards to drive a limiting bottom plate to move leftwards through a positioning belt assembly, and a second reset spring is compressed, so that a cutting electric saw cuts the steel bar, the limiting vertical block can prevent the steel bar from bouncing, and in this way, people can conveniently cut the steel bar in the steel bar cutting process. And the reinforcing steel bars are not easy to pop out to injure workers.

Owner:曾咏梅

Assembling device for steel wire check ring for hole

The invention discloses an assembling device for a steel wire check ring for a hole. The assembling device comprises a sleeve, a mandrel, an ejector rod, a fastening bolt, a butterfly nut and a gasket; an inner hole of the sleeve is a conical hole section, an arc-shaped groove and a straight hole section; the mandrel penetrates through the inner hole of the sleeve and an inner hole of the ejector rod; the arc-shaped groove is formed in the shaft section of the mandrel; the outer portion of the ejector rod is in a stepped shaft type; the thin shaft end penetrates into the conical hole section of the sleeve; the fastening bolt is in a stepped shaft type; the thick shaft end face makes contact with the end face of the mandrel; the thin shaft end is provided with a thread; the two ends of the thin shaft end are provided with linear grooves; the butterfly nut is matched with the mandrel; and the two end faces of the gasket make contact with the thick shaft end face of the ejector rod and the end face of the butterfly nut respectively. On the basis that the product surface quality requirement, the small product hole diameter and the deep hole position are considered, the assembling device for the steel wire check ring for the hole is provided, the assembling accuracy and the assembling efficiency of the steel wire check ring for the hole are improved, the product surface is prevented from being damaged, the product percent of pass is greatly increased, and the rejection rate of the check ring is reduced.

Owner:SICHUAN AEROSPACE LONG MARCH EQUIP MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com