Aviation engine bearing and oil receiving ring connection structure

An aero-engine and connection structure technology, applied in the field of aviation accessories, can solve problems such as poor lubrication of bearings, and achieve the effects of easy processing, simplified structure, and good lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

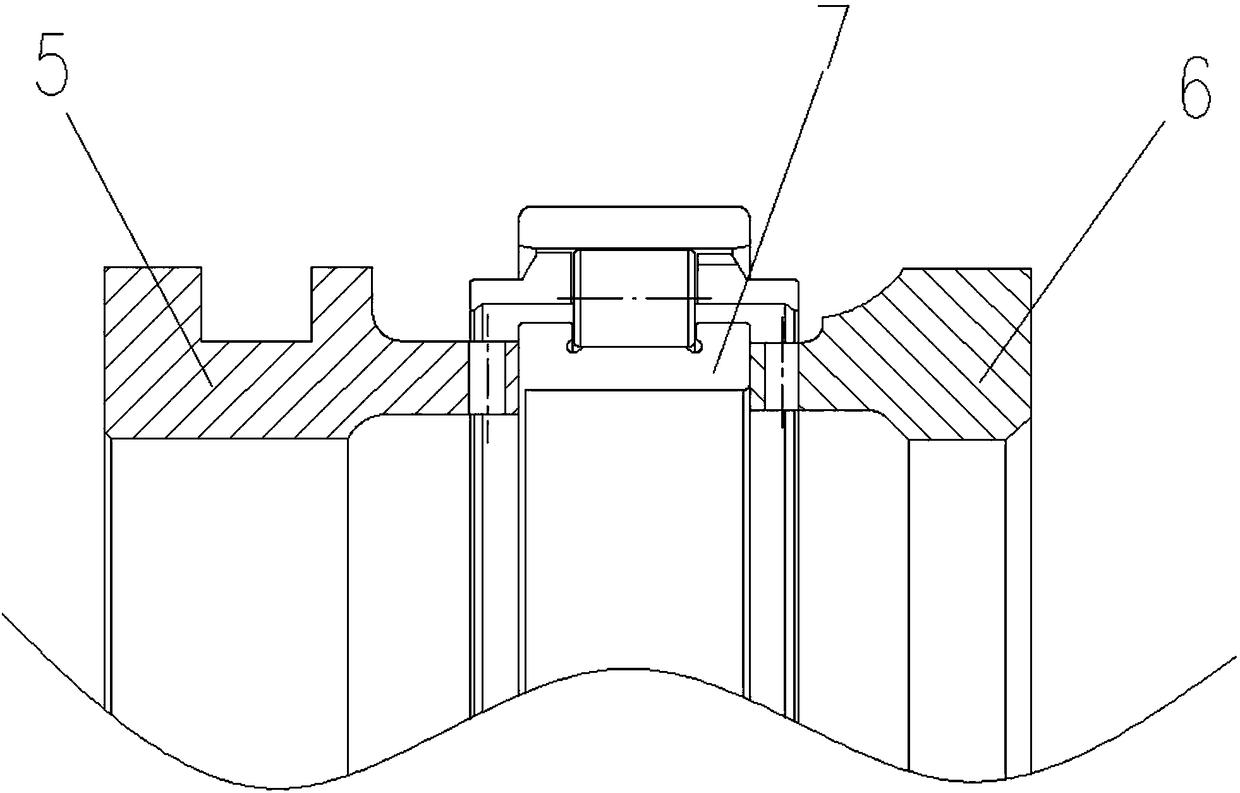

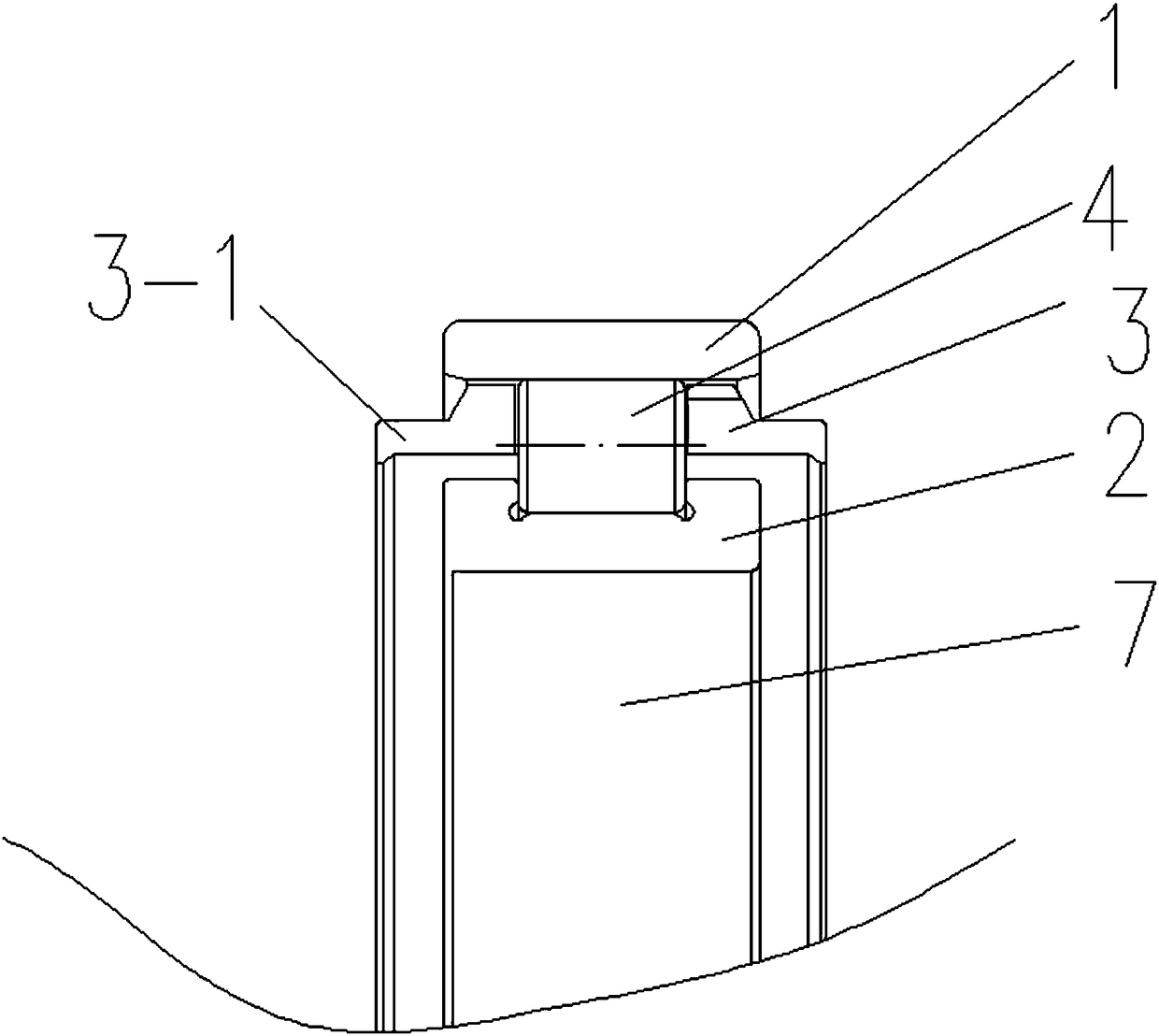

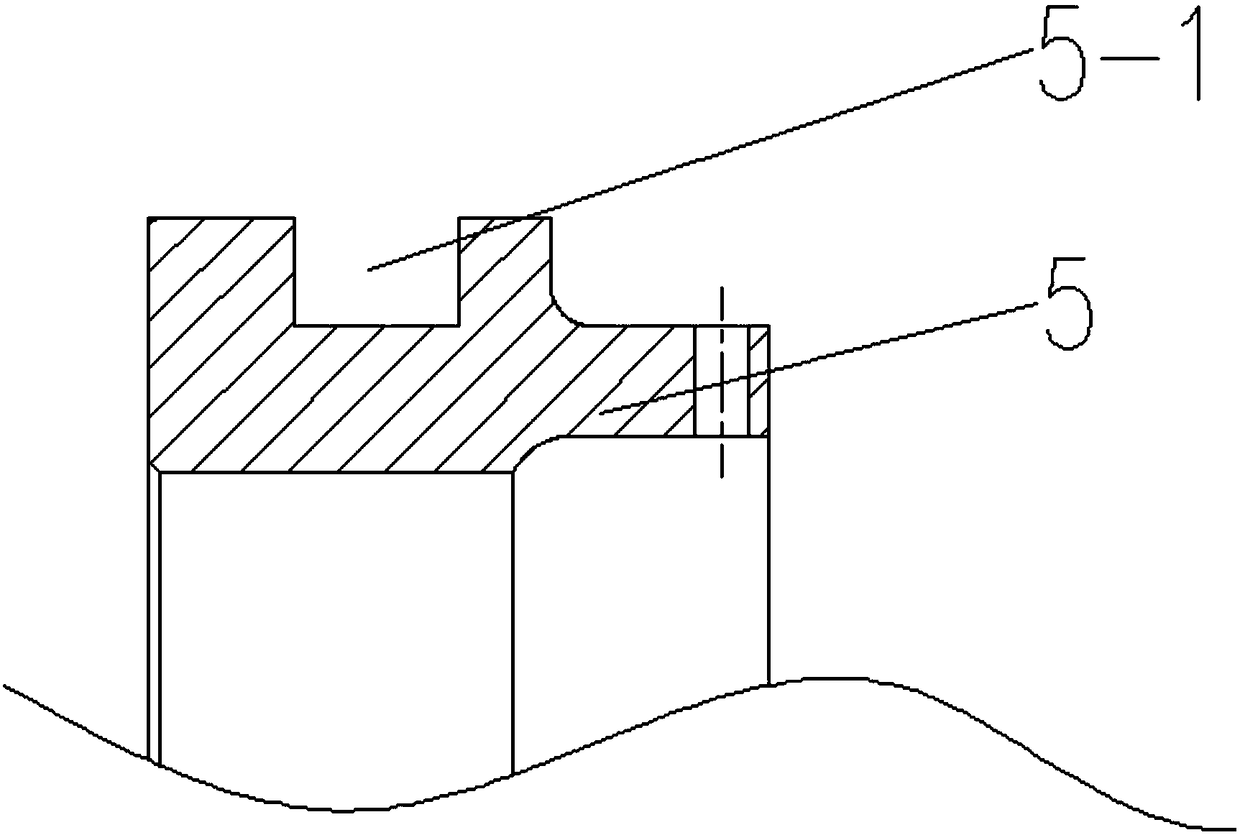

[0010] Specific implementation mode one: combine figure 1 , figure 2 , image 3 and Figure 4 Describe this embodiment, a connection structure for an aero-engine bearing and an oil skimmer described in this embodiment includes a bearing 7, a left oil skimmer 5 and a right oil skimmer 6, and a left oil skimmer 5 and a right oil skimmer 6 are concentrically arranged on both sides of the bearing 7, the bearing 7 includes an outer ring 1, an inner ring 2, a bearing cage 3 and a plurality of rollers 4, and two oil deflecting rings 3 are concentrically arranged on both sides of the bearing cage 3 -1, the outline of the left oil collecting ring 5 is in the shape of a ring, the outer surface of the left oil collecting ring 5 is provided with an annular groove 5-1, and the side of the left oil collecting ring 5 close to the bearing 7 is evenly arranged with a plurality of channels The contour of the right oil collecting ring 6 is in the shape of a ring, and the side of the right oi...

specific Embodiment approach 2

[0011] Specific implementation mode two: combination figure 1 and figure 2 This embodiment is described. This embodiment further limits the bearing described in Embodiment 1. In this embodiment, the outer sides of the two oil deflector rings 3 - 1 are provided with 45-degree chamfers. This design prevents lubricating oil from being thrown out of the bearing due to centrifugal force.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com