Assembling device for steel wire check ring for hole

A steel wire retaining ring and assembly device technology, which is applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of wear, large overall structure, space limitation, etc., and achieve simple operation process, high success rate, and not easy to eject Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

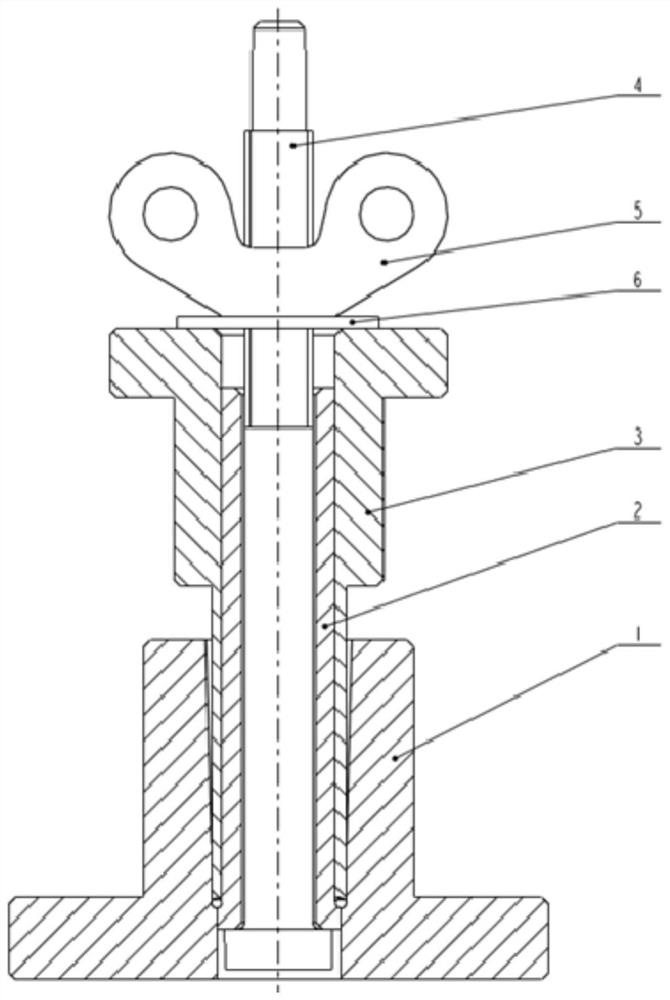

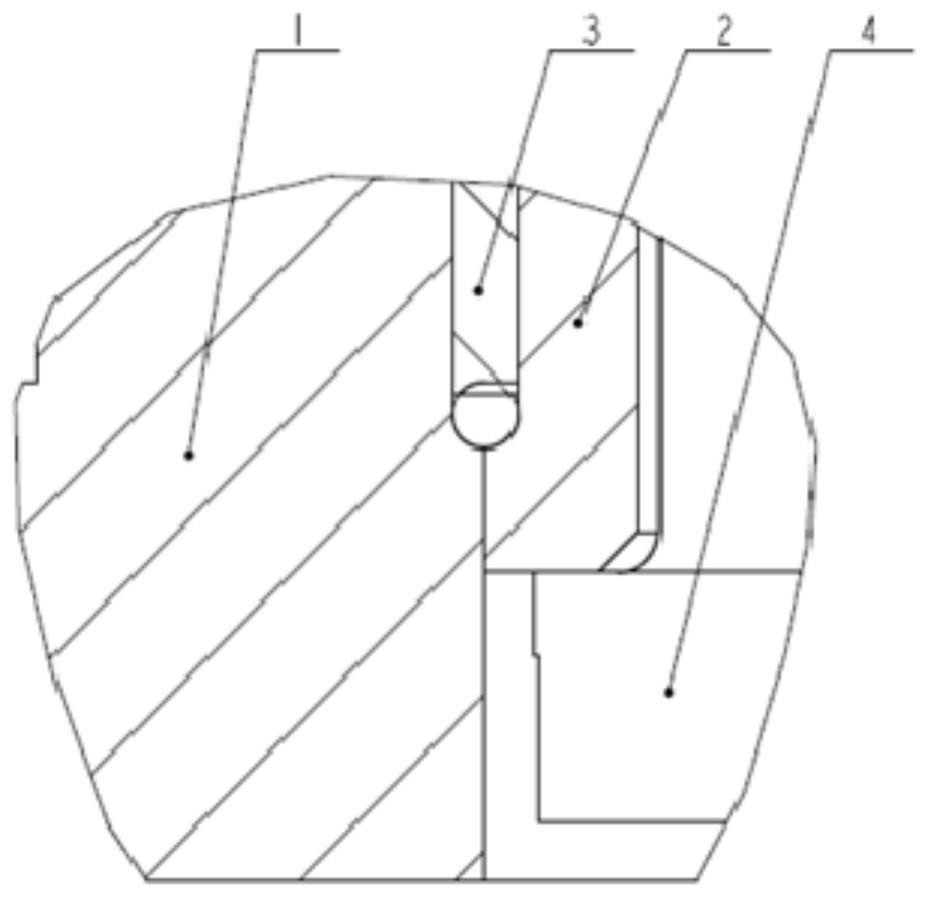

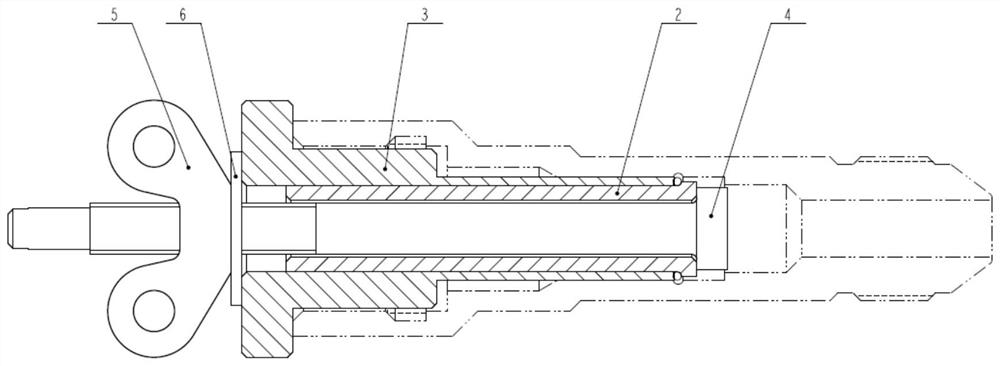

[0026] An assembly device for a steel wire retaining ring for holes, which adopts the design scheme of "fixing first and then assembling", and decomposes the assembly process into two parts: shrinking and fixing the retaining ring and assembling the retaining ring. The device includes a sleeve 1, a mandrel 2, and a push rod 3. Fasten bolts 4, wing nuts 5, washers 6. The sleeve 1 serves as the base of the whole device, and its inner hole is divided into three parts, namely, a tapered hole section, an arc-shaped groove, and a straight hole section. , and its arc groove part plays a limiting role on the retaining ring. The mandrel 2 passes through the inner hole of the sleeve 1. The outer shaft section is provided with an arc groove as a stop ring, and the inner part is a through hole. The fastening bolt 4 passes through this hole and cooperates with the washer 6 and the nut to press the top. The rod 3 thus fixes the retaining ring. The outside of the ejector rod 3 is a stepped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com