A protection method for high-pressure hole sealing and pressure relief in coal and rock formations

A technology for coal and rock formation pressure protection, which is applied in the field of high-pressure sealing and pressure relief protection for coal and rock formations. It can solve problems such as poor sealing effect, hidden safety hazards, and damage to the sealing rubber due to impact force, and achieves the effect of being easy to popularize and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

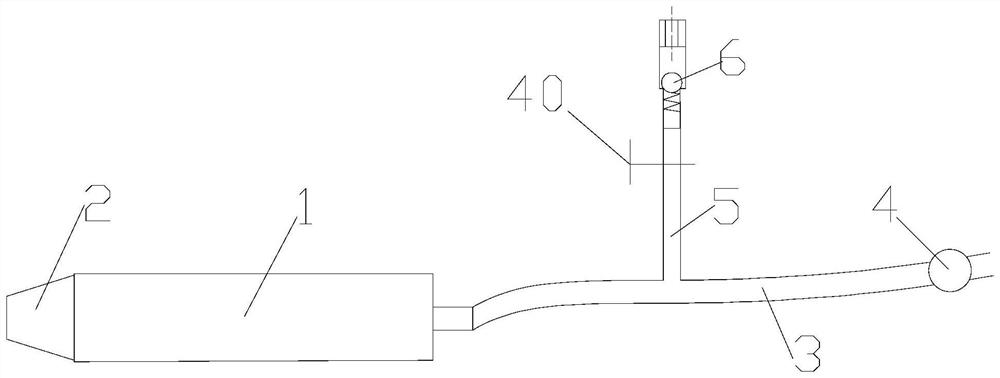

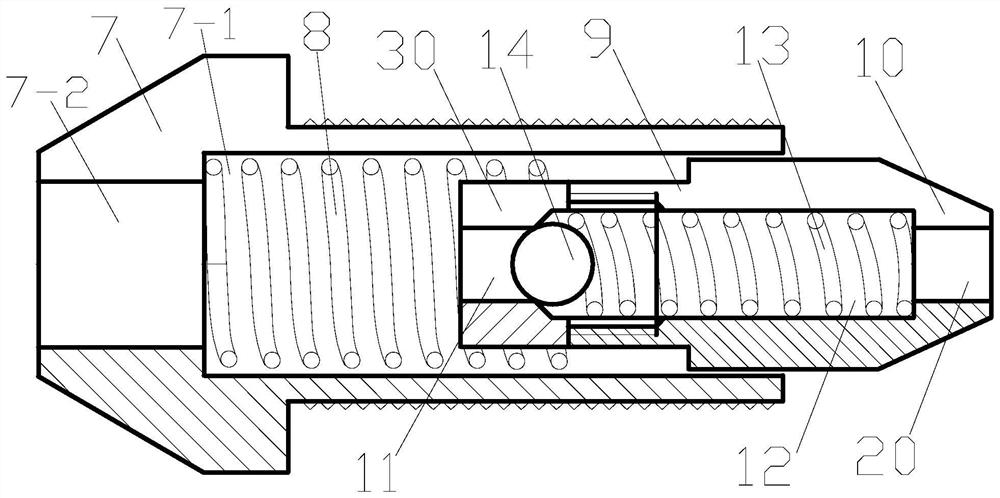

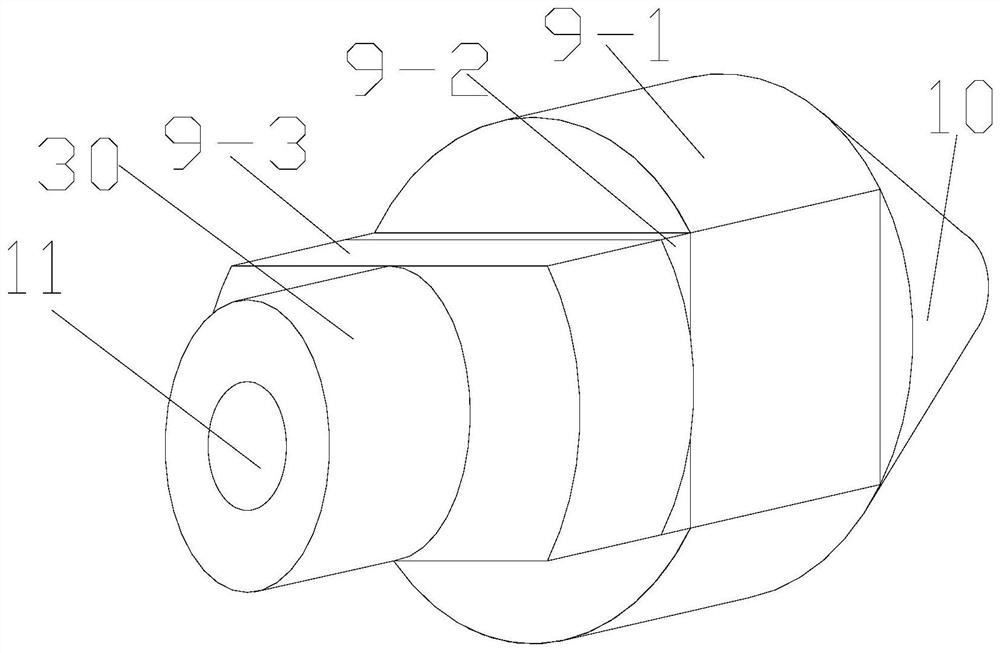

[0040] like Figure 1-Figure 5 As shown in the present invention, a method for high-pressure sealing and pressure-relief protection in a coal-rock seam includes the following steps:

[0041] Step 1. Drill a hole and extend the hole sealer into the hole: Drill holes at a designated position in the coal rock layer to be pre-split, and extend the hole sealer into the hole, and the high-pressure water injection pipe 3 is connected to the seal. Install the quick joint on the rear side of the orifice and lead out to the outside of the coal rock layer. Install a check valve 4 and a pressure gauge on the pipe section of the high pressure water injection pipe 3 located outside the coal rock layer. The high-pressure water return pipe 5 is set on the pipe section of the high-pressure water return pipe 5, the shut-off valve 40 and the pressure regulating valve 6 are installed on the high-pressure water return pipe 5, the pressure regulating valve 6 is installed at the end of the high-pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com