A high-pressure hole sealing and pressure maintaining and releasing device for coal and rock formations

A pressure relief device, a technology for coal and rock formations, used in wellbore/well valve device, sealing/isolation, wellbore/well components, etc. problems, to achieve the effect of facilitating the promotion and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

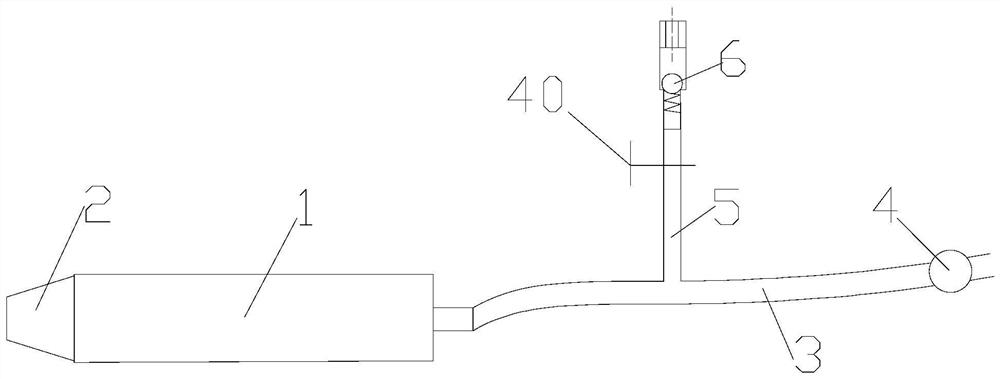

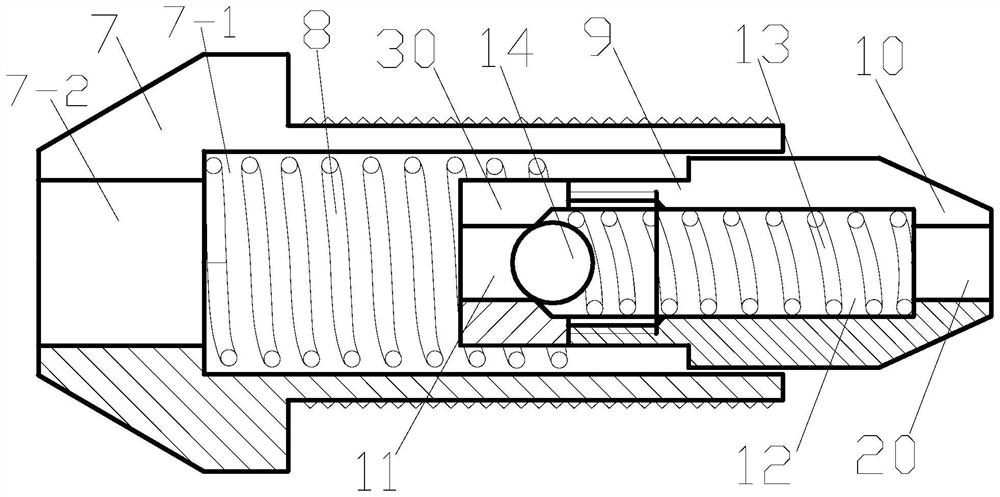

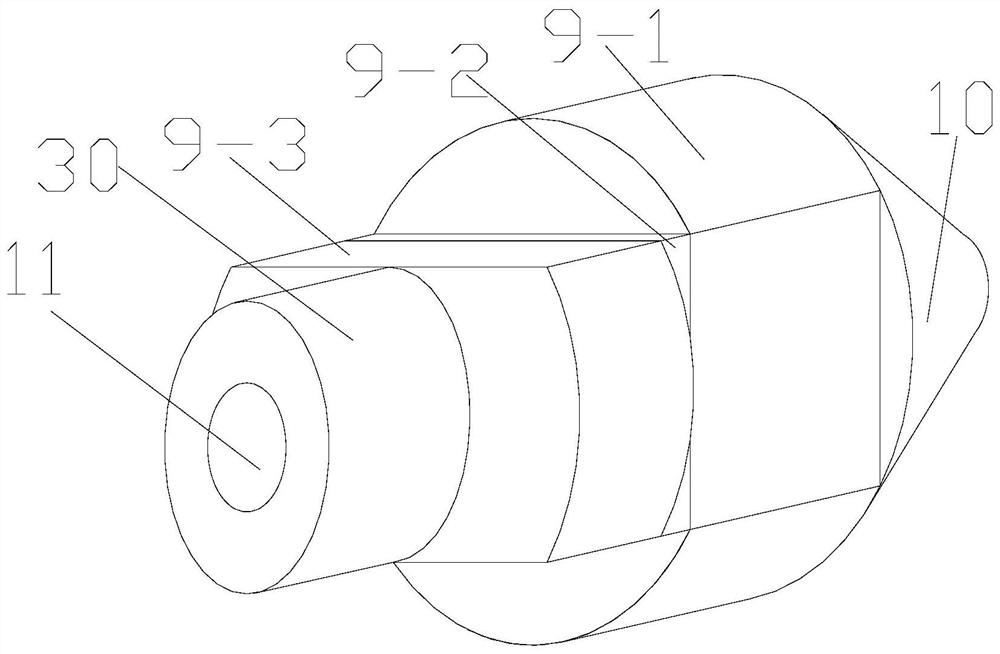

[0029] like Figure 1-Figure 4 As shown, the present invention includes a hole sealing device and a high-pressure water injection pipe 3 connected to the quick connector on the rear side of the hole sealing device. A check valve 4 is installed on the high-pressure water injection pipe 3. The hole sealing device includes a high-pressure rubber expansion The rubber hose 1 and the two-way safety valve 2 arranged at the front end of the high-pressure rubber expansion hose 1, the two-way safety valve 2 includes a hollow structure safety valve head 7 matched with the high-pressure rubber expansion hose 1, and a first spring 8 arranged in the safety valve head 7 And extend into the first spring 8 and is a two-way safety valve core with a hollow structure, the two-way safety valve core includes a safety valve core 9, a safety valve core of a hollow structure that is arranged at one end of the safety valve core 9 and cooperates with the first spring 8 The spool cover 30 and the hollow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com