Spiral spring fixture

A technology of coil springs and clamps, applied in the field of spring clamps, can solve the problems of hidden dangers to the personal safety of operators, easy ejection, and difficult fixation of coil springs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

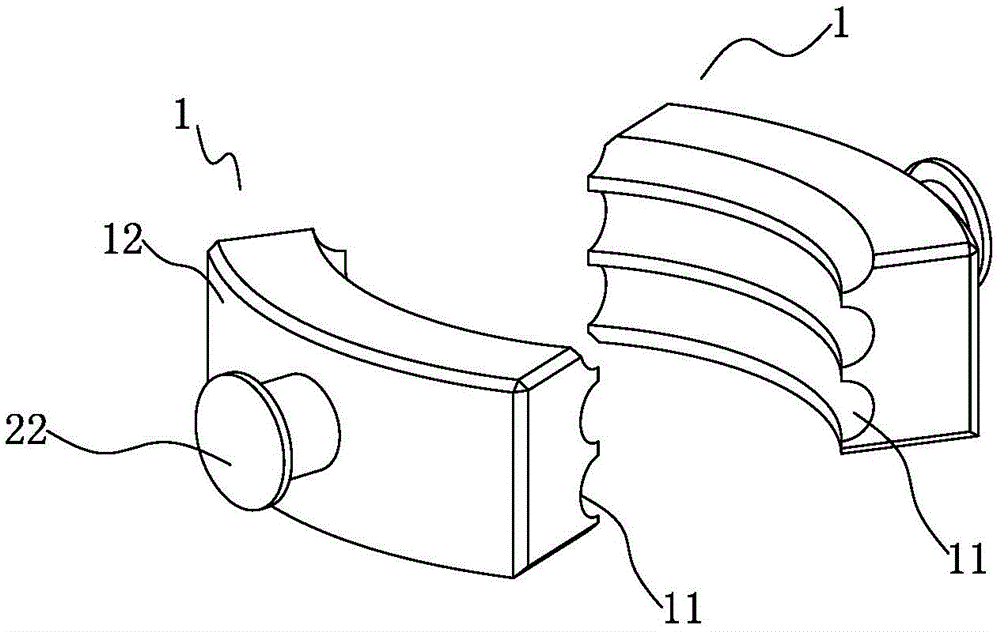

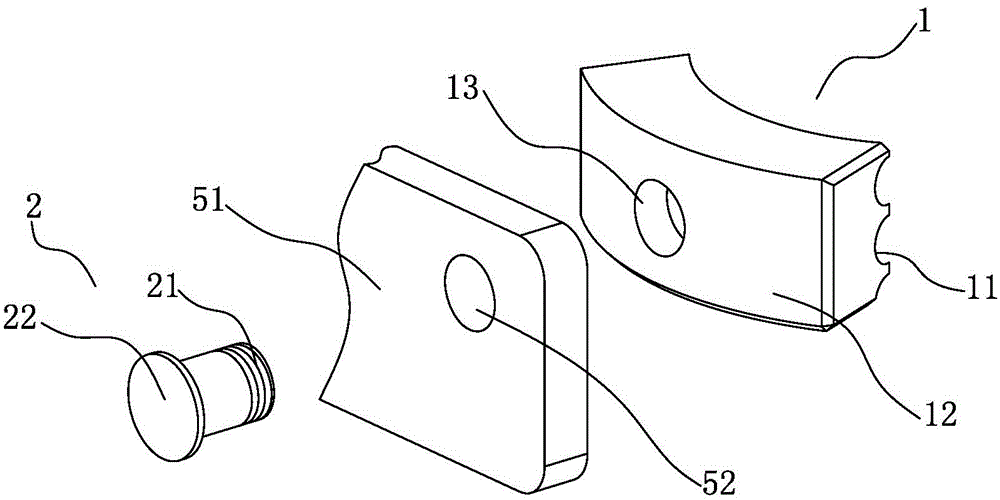

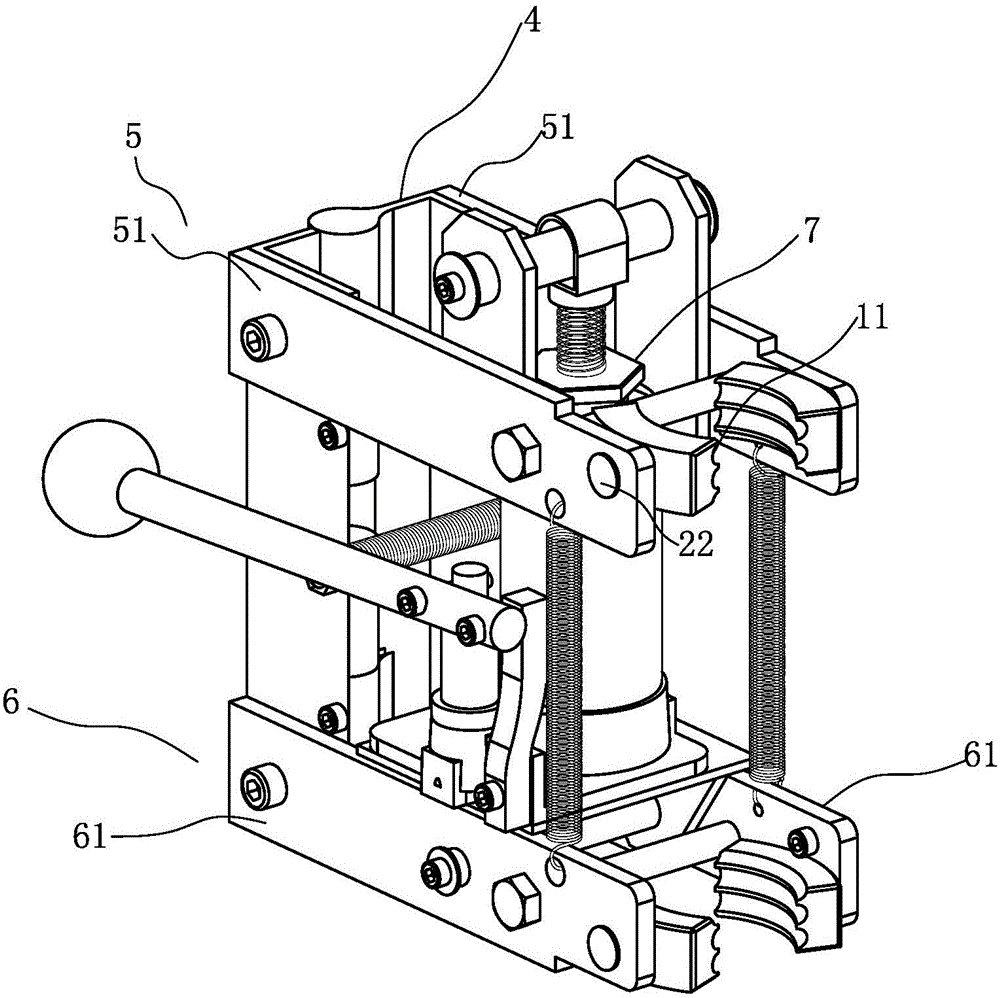

[0018] A coil spring clamp provided by the present invention is installed in a spring dismounting device, and is used for realizing disassembly and assembly of the coil spring. refer to figure 1 and figure 2 , a coil spring clamp, including two opposite clamping plates 51 arranged on the spring dismounting device, two clamping plates 51 are formed with oppositely disposed through holes, locking bolts 53 and setting locks pierced on the two through holes The nuts on the tightening bolts 53 also include two chucks 1 that are relatively separately arranged on the two clamping plates 51 and are rotatable.

[0019] A thread groove 11 is formed on the working surface of the chuck 1 . The thread groove 11 is adapted to the outer peripheral surface of the coil spring, so that the two collets 1 can better clamp the coil spring.

[0020] Threaded holes 13 matching the bolts 2 are formed on the fixing surface 12 of the chuck 1 , through holes 52 are formed on the two clamping plates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com