Lid spot welding mechanism and method for cylindrical battery

A cylindrical battery, box cover point technology, applied in welding equipment, laser welding equipment, final product manufacturing, etc., can solve the problems of difficult cover plate, aluminum shell matching, etc., to achieve reasonable structure, ensure the pass rate, and ensure the success of closing the cover. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

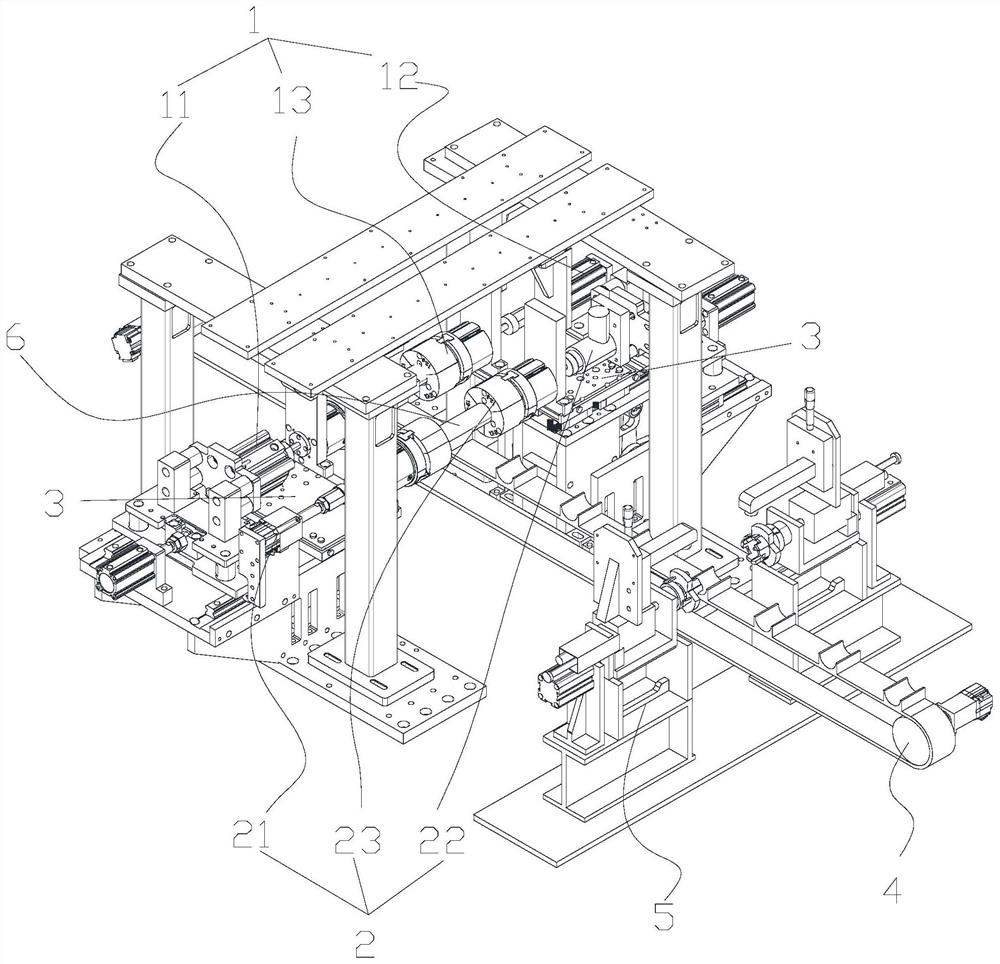

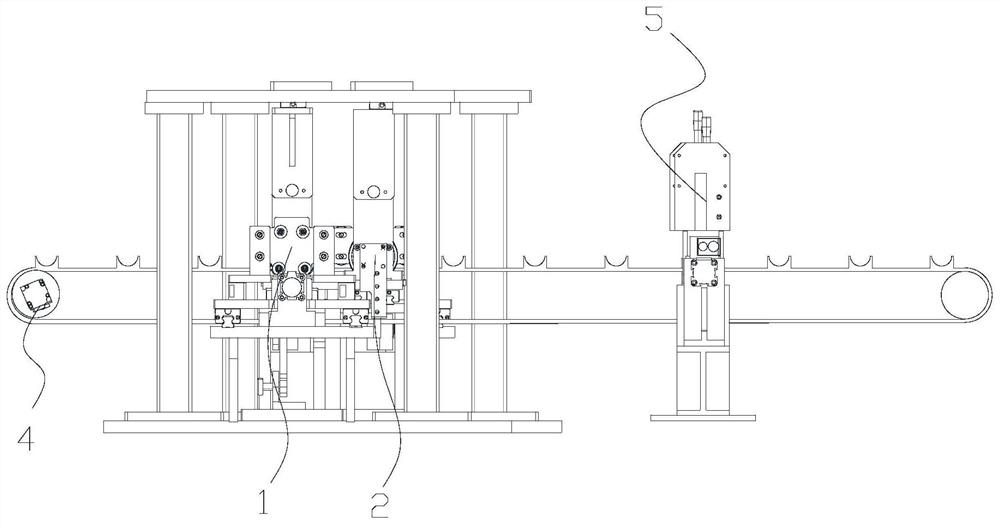

[0064] like figure 1 , figure 2 As shown, the lid spot welding mechanism of the cylindrical battery includes a pre-case lid assembly 1, a lid assembly 2, a coaxiality adjustment assembly 3, a battery transfer assembly 4, and a laser spot welding assembly 5. The battery The transfer assembly 4 passes through the pre-box cover assembly 1, the box cover assembly 2, and the laser spot welding assembly 5 in sequence, and the cylindrical battery 6 is moved to the pre-box cover station in turn, and the cylindrical battery is realized through the pre-box cover assembly 1. 6, the box cover is realized by the box cover assembly 2 at the box cover station, and the spot welding is realized by the laser spot welding assembly 5 at the spot welding station, and the coaxiality adjustment assembly 3 is located in the battery transfer assembly. into 4 sides;

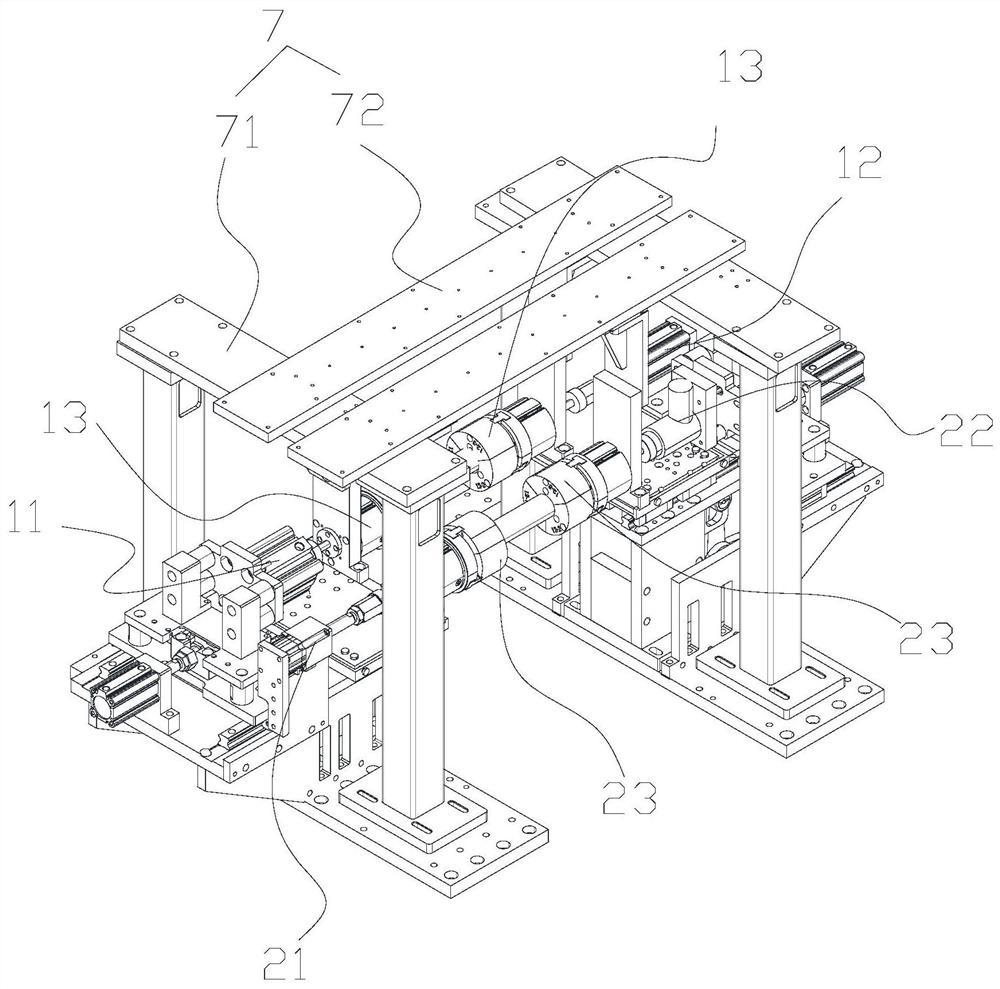

[0065] The pre-box cover assembly 1 includes a first positioning assembly 11 , a first knocking assembly 12 , two first three-jaw pos...

Embodiment 2

[0084] like Figure 12 As shown, on the basis of the above-mentioned first embodiment, the coaxiality adjustment assembly 3 includes a bottom plate 31 and a top plate 32, and both sides of the bottom plate 31 have upward bending edges. A rectangular boxed structure with an opening on one side of the cylindrical battery 6, the two sides of the top plate 32 are connected to the bent side by adjusting bolts 33, and the top plate 32 is connected to the bottom plate 31 by vertically arranged adjusting bolts 33, so The top plate 32 is located inside or above the bottom plate 31; the top plate 32 can be adjusted horizontally in reverse left and right through the adjustment bolts 33 on the side, and the height in the vertical direction can be adjusted through the adjustment bolts 33 in the vertical direction. The first three-claw positioning assembly 13 and the second three-claw positioning assembly 23 are connected to the top plate 32 of one side of the coaxiality adjusting assembly ...

Embodiment 3

[0088] like Figure 13 As shown, on the basis of the above-mentioned second embodiment, the battery transfer assembly 4 includes a transfer motor 41, a first roller 42, a second roller 43, a transfer belt 44, and a battery slot 45. The first roller 42 and all The second rollers 43 are respectively connected with the transfer motor 41, the first roller 42 and the second roller 43 are connected by the transfer belt 44, and the transfer belt 44 runs through the pre-box cover assembly 1, the box cover Assembly 2. Laser spot welding assembly 5. The battery slots 45 are connected to the outside of the transfer belt 44 at even intervals.

[0089] The transmission mode can be belt transmission or chain transmission. The top of the battery slot 45 is arc-shaped, which matches the shape of the cylindrical battery 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com