Integrated high-temperature high-pressure metal seal ball valve

A metal sealing, high temperature and high pressure technology, used in shaft seals, valve details, valve devices, etc., can solve the problems of easy leakage, erosion, cavitation, abrasion, and unreasonable structure of valve body and stem seals, so as to improve product quality. Accuracy, reduced friction, reduced effect of structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

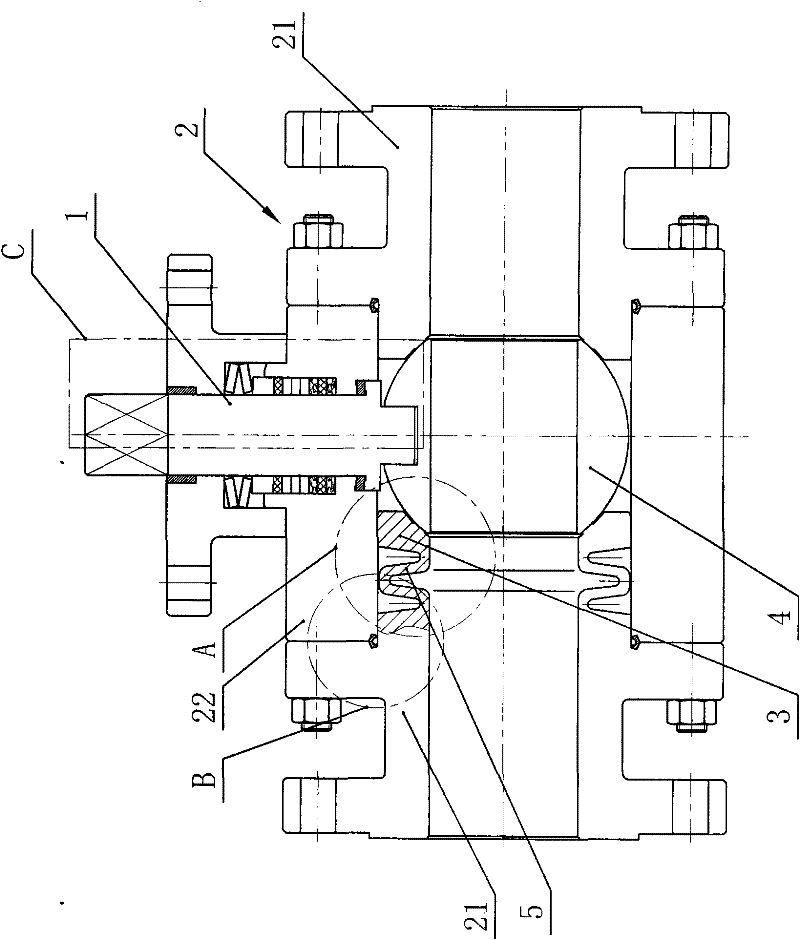

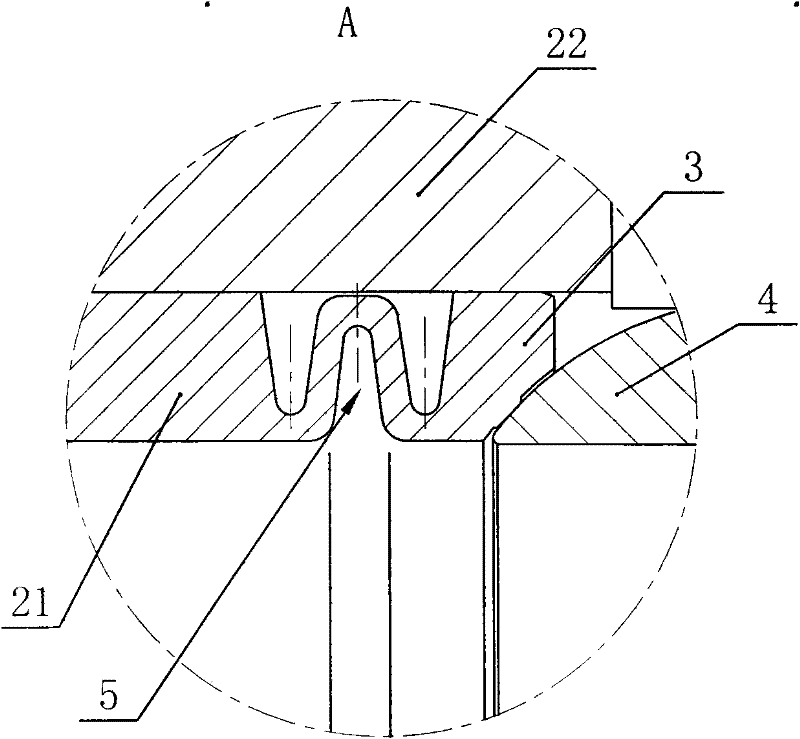

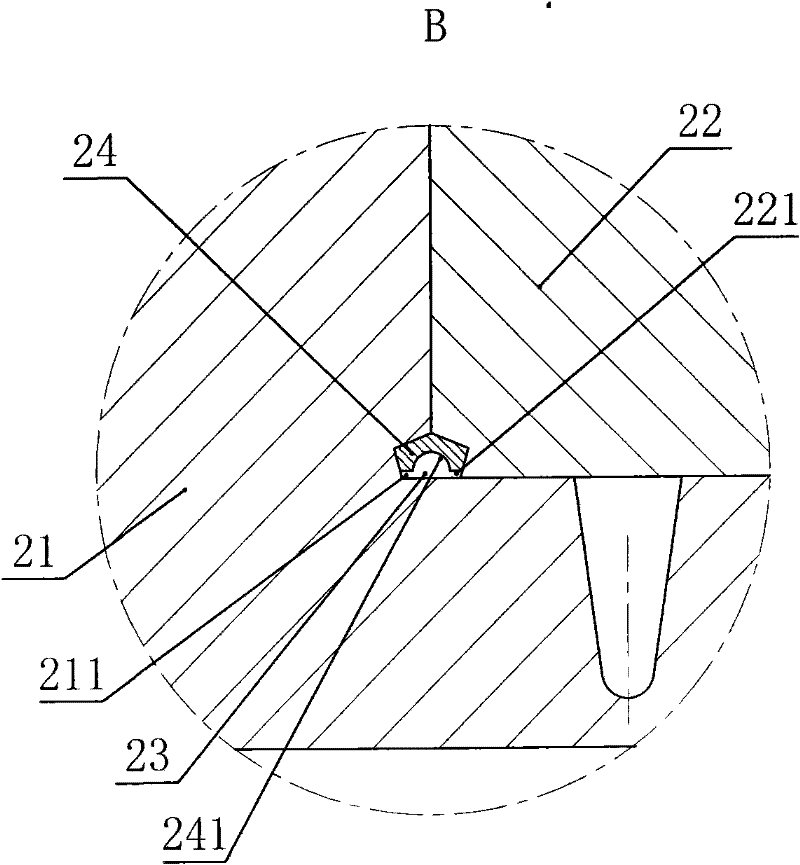

[0011] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the integrated high-temperature and high-pressure metal-sealed ball valve includes a valve stem 1, a valve body 2, a valve seat 3 and a valve core ball 4. In the embodiment of the present invention, the valve seat 3 is integrated with the valve body 2, and The integral connection between the valve seat 3 and the valve body 2 is horizontally arranged as a corrugated structure 5. By adopting the above scheme, a part of the valve seat on the valve is canceled, the structural design of the seal is reduced, the sealing reliability is ensured, and the product accuracy is improved. Effective Improve the sealing performance and service life of the product. In addition, this structure ensures the self-compensation of the valve after alternate deformation under thermal stress cycle, and solves the necessary specific pressure increase of the sealing surface at high temperature, so that the ball valve can be self-com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com