Coupling for stirring device

A stirring device and coupling technology, which is applied in the field of transmission component couplings, can solve problems such as loss, loose positioning of elastic parts, easy displacement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

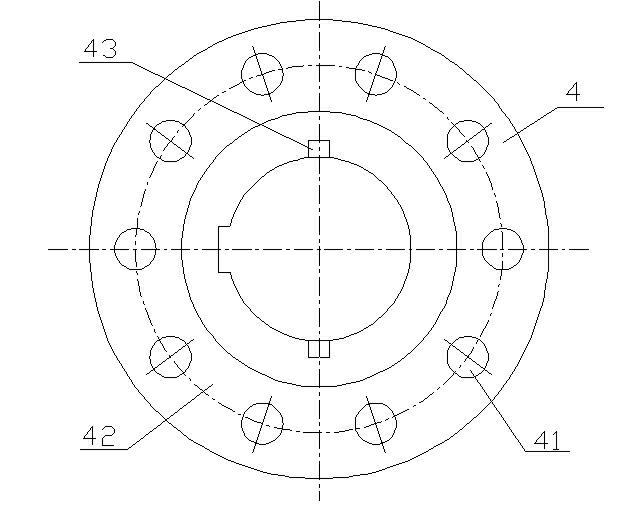

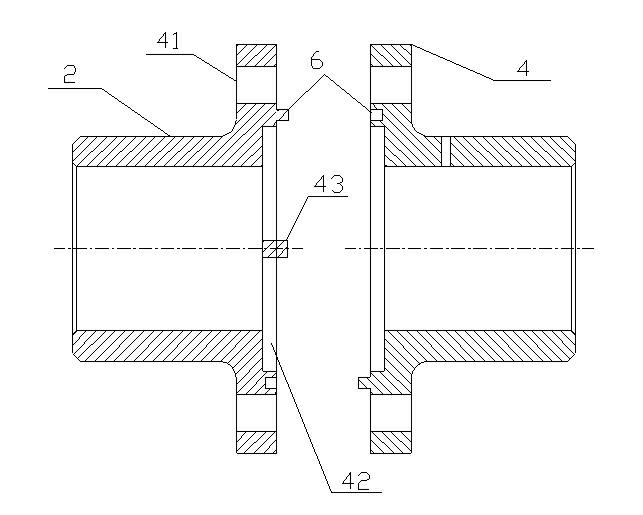

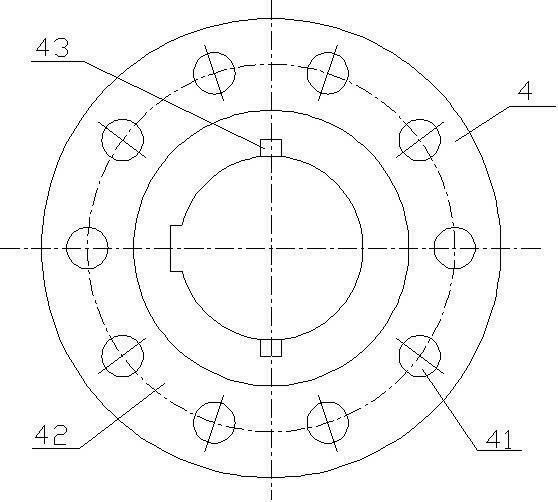

[0018] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

[0019] Such as Figure 1-2 As shown, a coupling of a stirring device of the present invention is used to connect the driving shaft and the driven shaft of the stirring device so that they rotate together to transmit torque, and the coupling includes two identical hollow half-couplings One end of each half-coupling cylinder 2 is provided with the same boss 4 extending outward from the side wall of the cylinder 2 . An annular elastic pad is arranged between the two half-couplings to reduce vibration. The cross section of the two bosses 4 is circular, and the two bosses 4 are provided with circular fixing holes 41 corresponding to each other, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com