PPDM extraction method for agriculture waste straw fibre

A straw fiber, agricultural waste technology, applied in fiberboard, fiber raw material, fiber raw material processing and other directions, can solve the problems of increased power consumption, waste of heat source, small amount of cooking material, etc., to reduce the number of openings, save power, save artificial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

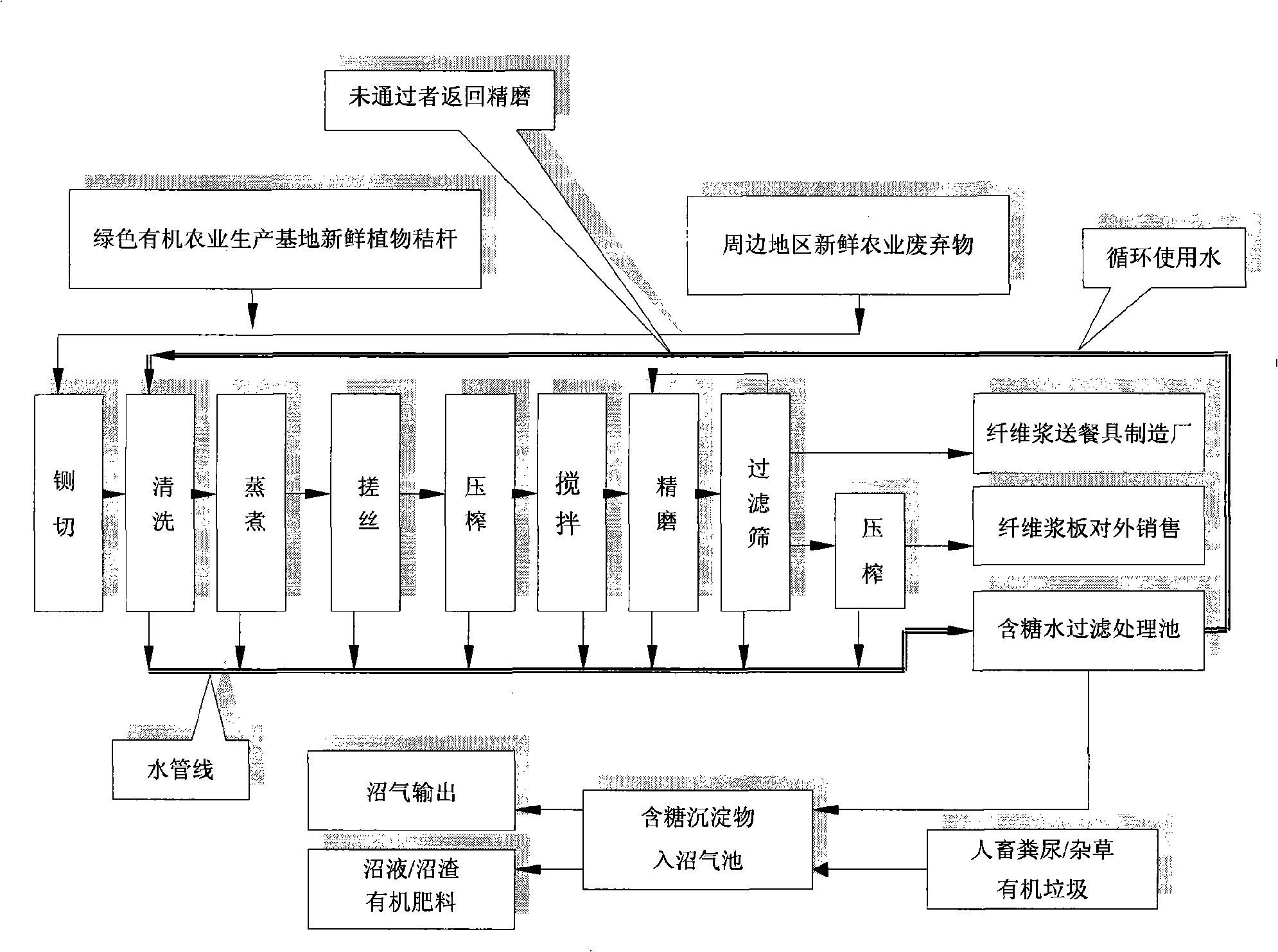

[0033] This embodiment PPDM extracts agricultural waste straw fiber method reference figure 1 , including the following processing steps

[0034] Raw material inspection-raw material storage-raw material cutting-soaking and cleaning-cooking-cooking-squeezing-squeezing-stirring-finishing-filtering sieve-sending to the tableware factory (excess parts are squeezed dry and sold externally)

[0035] 1) inspection: preliminary inspection is carried out to the stalk to ensure that it is free of impurities and dirt;

[0036] 2) Guillotine cutting: cut the raw materials to cut off the fibrous tissue to meet the requirements of deep processing;

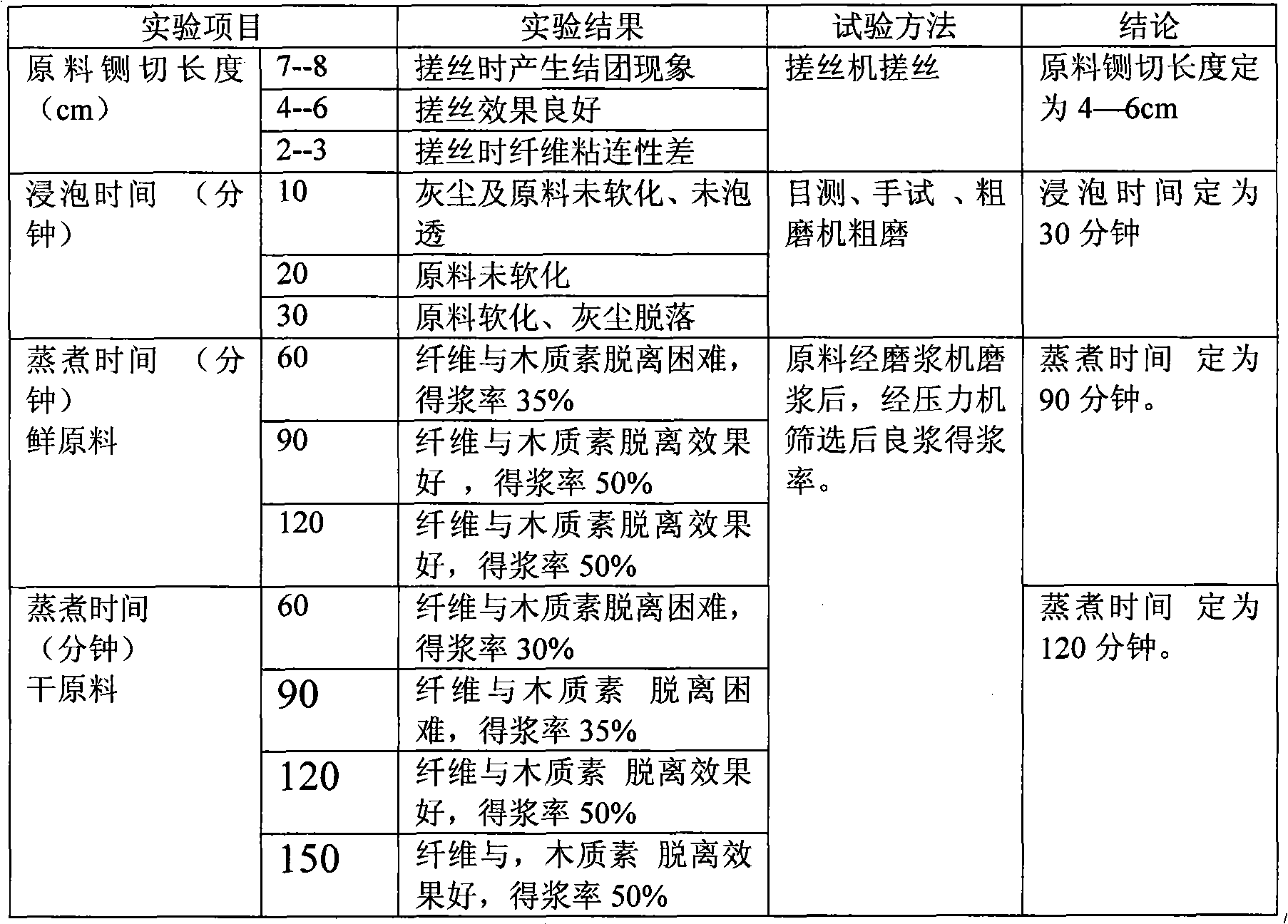

[0037] Cutting into 2-8cm sections, the best effect of rubbing when cutting into 4-6cm, that is to ensure the continuity of the rubbing, and the fibers will not agglomerate during the rubbing;

[0038] 3) Soaking and cleaning: Physical and mechanical cleaning of the cut raw materials to remove dust impurities, pesticide residues and other att...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com