Press die for preparing agglomerate ultra-fine crystal material

An ultra-fine grain and upsetting technology, which is applied in the field of molds and upsetting dies, can solve the problems that it is difficult to prepare ultra-fine grained materials with uniform structure and the deformation cannot be too large, and achieves simple structure, wide practical range, and crystal grains. The effect of strong refinement ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

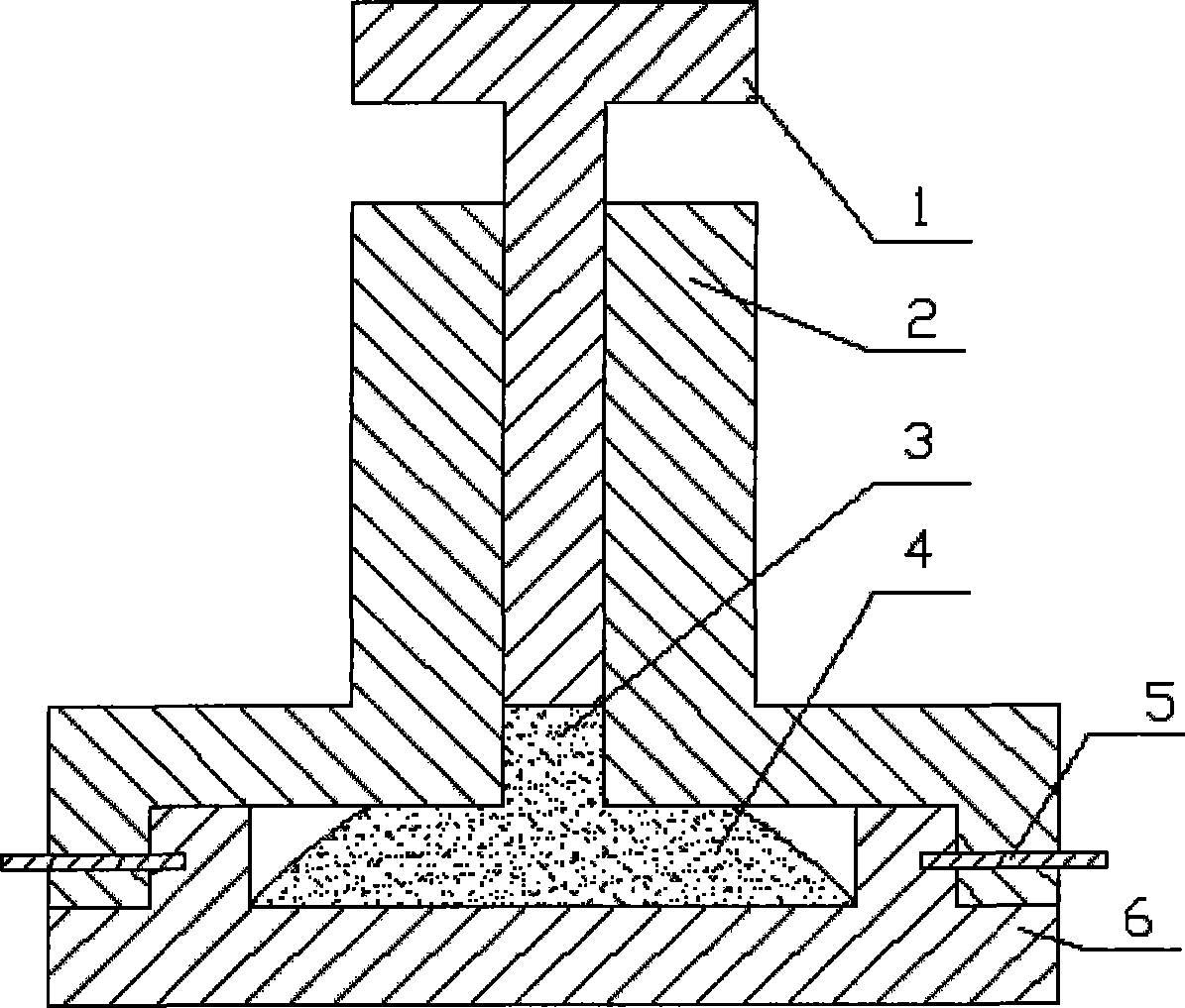

[0014] As shown in FIG. 1 , this embodiment includes: an extrusion punch 1 , an upper die 2 , a pin 5 , and a lower die 6 . The connection relationship is: there is a vertical square through hole in the upper die 2, and the extrusion punch 1 is inserted thereinto to form the upper cavity 3, so the upper cavity 3 is a vertical cuboid with large height and length and small width. There is a cuboid or cylinder groove in the lower die 6, and together with the upper mold 2, a cuboid or cylinder lower cavity 4 is formed.

[0015] When the lower cavity 4 is a cuboid, its he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com